Folded-plate truss concrete assembly

A concrete and slab truss technology, which is applied in building components, building structures, buildings, etc., can solve the needs of construction projects that cannot achieve large spans, the increase in the amount of steel bars for cast-in-place components, and the inconvenience of pre-embedding and installation of wire boxes. Convenience and other issues, to achieve the effect of easy pre-embedding and installation of the wire box, high overall bearing capacity, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described with reference to the accompanying drawings.

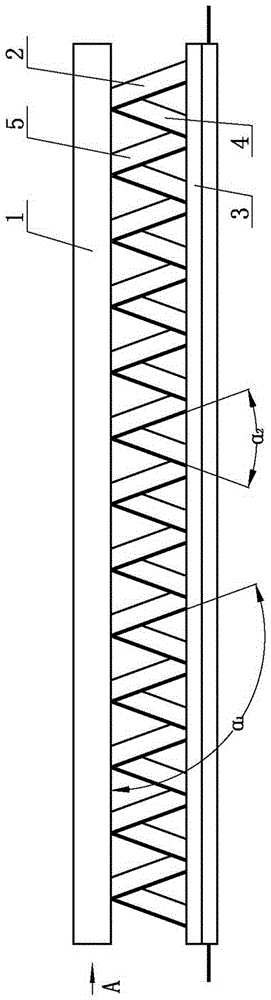

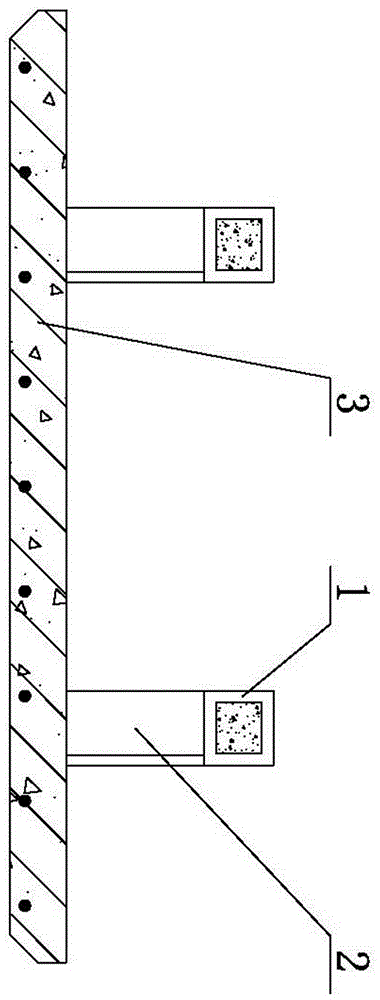

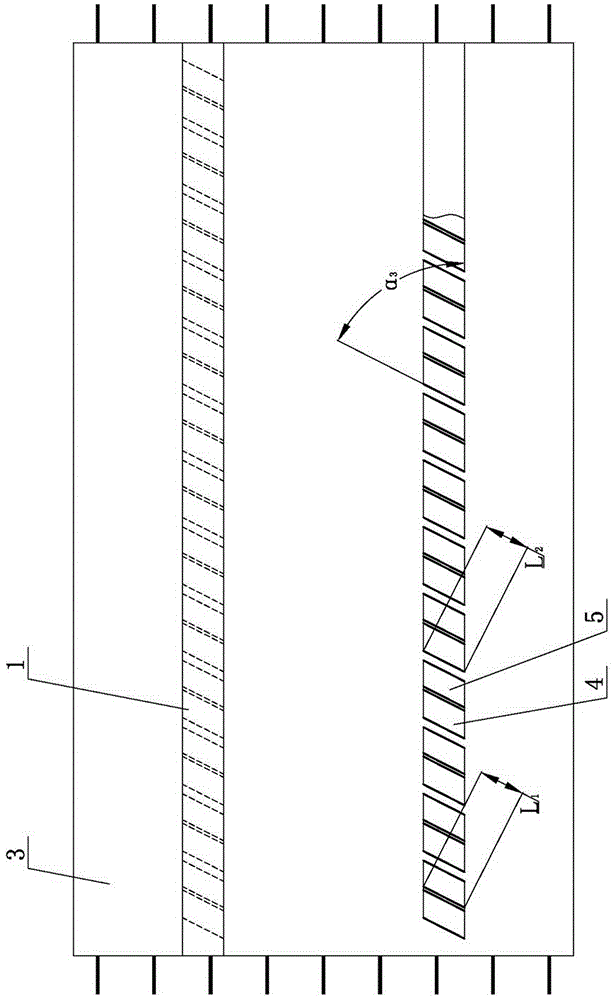

[0008] The concrete member of the folded plate truss of the present invention comprises a base plate 3, protruding steel bars are arranged on both sides of the base plate 3, and a folded plate type truss is arranged on the surface of the base plate 3, and the folded plate type truss is composed of a connecting rod 1 and several folded plates, the folded plates One end is connected to the surface of the bottom plate 3, and the other end of the folded plate is connected to the connecting rod 1. The folded plate is composed of several first inclined plates 2 and several second inclined plates 4, and the several first inclined plates 2 are distributed parallel to each other. The second slant plates 4 are distributed parallel to each other, and a second angle α is set between each first slant plate 2 and each second slant plate 4 2 .

[0009] According to the present invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com