Prefabricated assembled hollow pier based on UHPC joints and construction method

A prefabricated assembly and hollow technology, which is applied in erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of high segment manufacturing accuracy, insufficient energy consumption, and low strength of connecting surfaces, so as to avoid the accumulation of construction errors and pouring And the effect of convenient maintenance and low manufacturing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

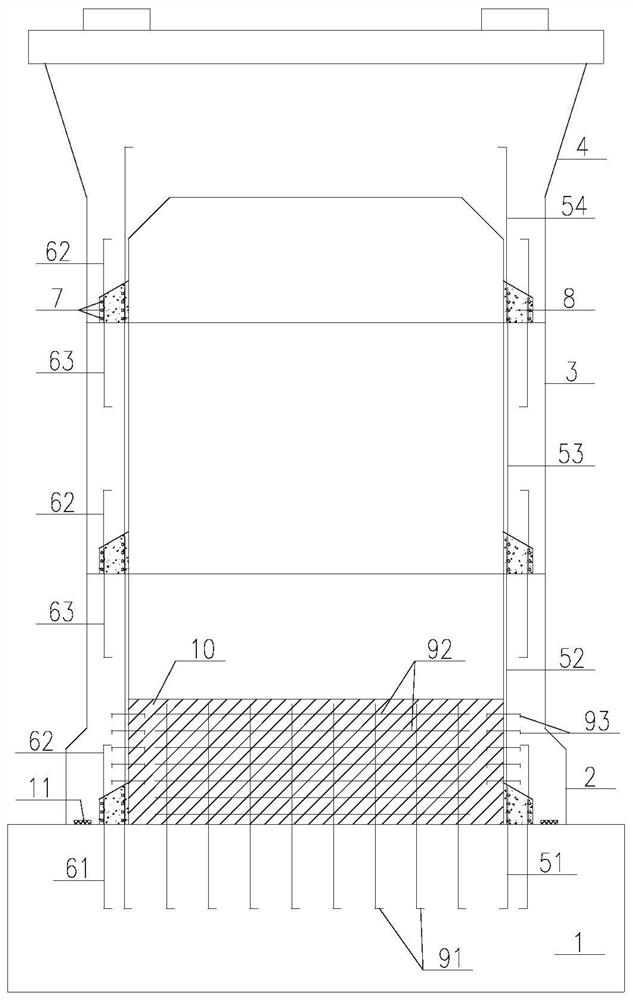

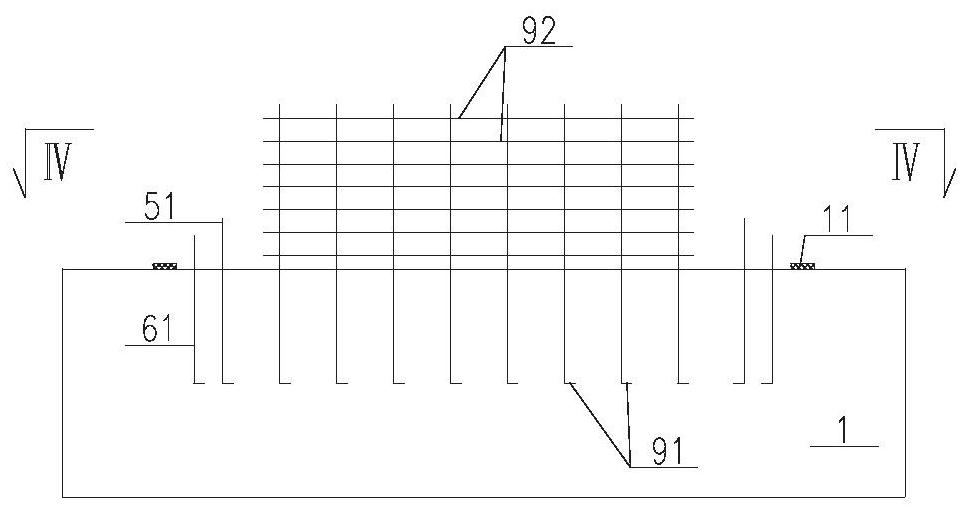

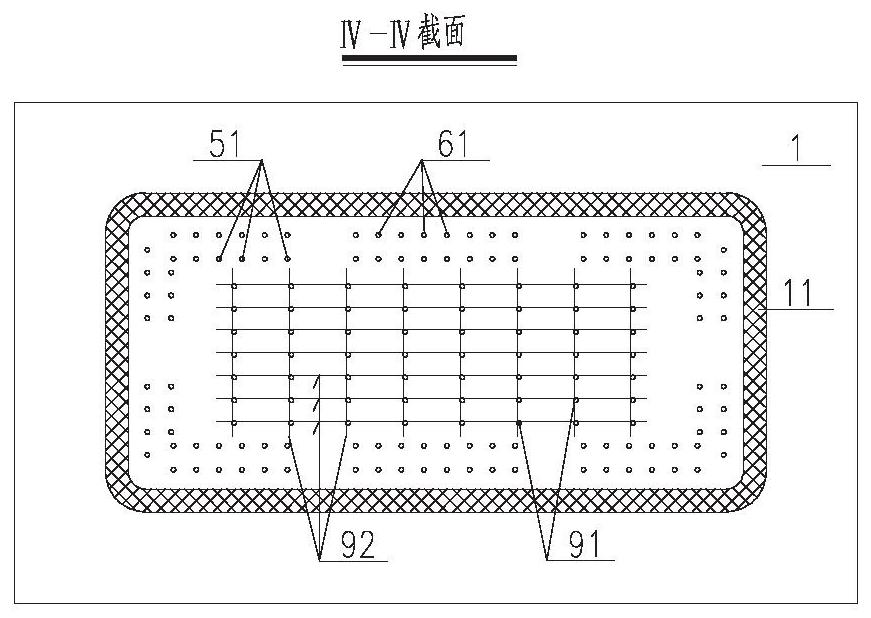

[0055] Such as Figure 1-11 A prefabricated hollow pier based on UHPC joints is shown, which has a pier column and a base 1, the pier column is a hollow pier column, and the pier column is composed of a pier bottom segment 2 and a middle segment 3 from bottom to top , top hat segment 4, the pier bottom segment 2 is located at the top of the base 1, between the pier bottom segment 2 and the base 1, between the pier bottom segment 2 and the middle segment 3, between the middle segment 3 and the top The steel bar joints are pre-embedded between the cap segments 4, and the reinforcement stirrups 7 are arranged outside the steel bar joints. Reinforcing bar, the bottom of the pier bottom section is a solid section 10, the top is a hollow section, the solid section 10 of the pier bottom section is connected with the base 1, the hollow section of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com