Anti-slip multistage-drop box culvert

An anti-slip and box culvert technology, applied in the field of box culvert structure, can solve the problems of complex box culvert structure, aggravating the construction difficulty of box culvert, unfavorable top soil body of box culvert and the safety and stability of road facilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

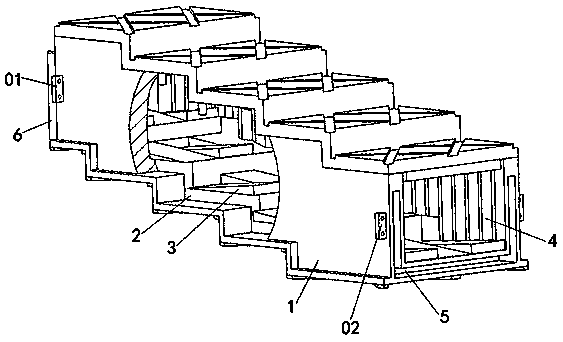

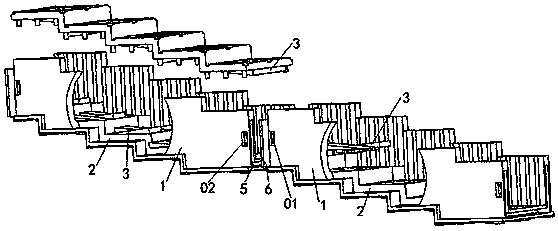

[0039] A kind of anti-slip multi-stage drop water box culvert of this embodiment, such as figure 1 with Figure 4As shown, it includes a hollow box culvert body 1, the outer top and outer bottom of the box culvert body 1 are stepped, and the inner bottom surface of the box culvert body 1 is provided with a number of falling water steps 2 along the direction of water flow. An inclined gentle and steep slope 3 is provided on the step surface of the falling water ladder 2 .

[0040] The outer bottom of the box culvert body 1 is set as a number of continuous steps, each step includes a horizontal step surface and a vertical vertical surface, and the bottom of the steps is provided with a 20cm thick C15 concrete cushion along the step surface and the vertical surface , the steps at the outer bottom of the box culvert body 1 are in contact with the soil through the concrete cushion. The box culvert body 1 is in contact with the soil through the stepped surface and the vertical sur...

Embodiment 2

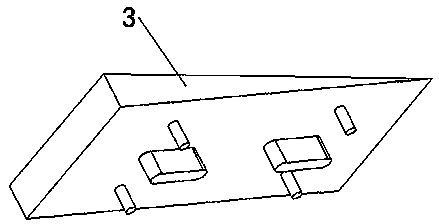

[0046] This embodiment is further optimized on the basis of embodiment 1, such as figure 1 As shown, the corresponding positions along the direction of water flow on the step surfaces of the adjacent falling water steps 2 are provided with gentle and steep slopes 3 with opposite inclination directions.

[0047] The corresponding positions on the step surfaces of the adjacent two falling water ladders 2 are all provided with slow energy steep slopes 3, and the inclination directions of the slow energy steep slopes 3 on the step surfaces of the adjacent two falling water ladders 2 are opposite, ensuring When the water flows through the slow energy steep slope 3 on the first water drop ladder 2, it falls and collides with the slow energy steep slope 3 on the second water drop ladder 2 to effectively dissipate the energy of the water flow.

[0048] The step surface of the water drop ladder 2 is linearly provided with at least two slow energy steep slopes 3 along the width directio...

Embodiment 3

[0052] This embodiment is further optimized on the basis of embodiment 1 or 2, such as figure 1 with Figure 4 As shown, a number of protruding energy-cutting protrusions 4 are arranged in an array along the direction of water flow on opposite sides of the box culvert body 1 .

[0053] The energy-cutting protrusions 4 protrude toward the inner side of the box culvert body 1, and the sides of the box culvert body 1 are continuously arranged or spaced apart. Further energy dissipation of the water flow.

[0054] The top of the energy-cutting protrusion 4 transitions smoothly with the inner top surface of the box culvert body 1 through a curved surface, and the bottom of the energy-cutting protrusion 4 transitions smoothly with the inner bottom surface of the box culvert body 1 through a curved surface. 4 is in the shape of a semicircle or a triangular prism.

[0055] In order to prevent the energy-cutting protrusions 4 from hindering the flow of water, the height of the energ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com