Prefabricated bottom plate preparation method, prefabricated bottom plate structure and construction method of prefabricated bottom plate structure

A base plate and structure technology, which is applied in the field of prefabricated buildings, can solve the problems that the mold design cannot be standardized, affects the installation efficiency, and affects the quality of components, so as to reduce the difficulty of pipe penetration, save material consumption, and improve construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

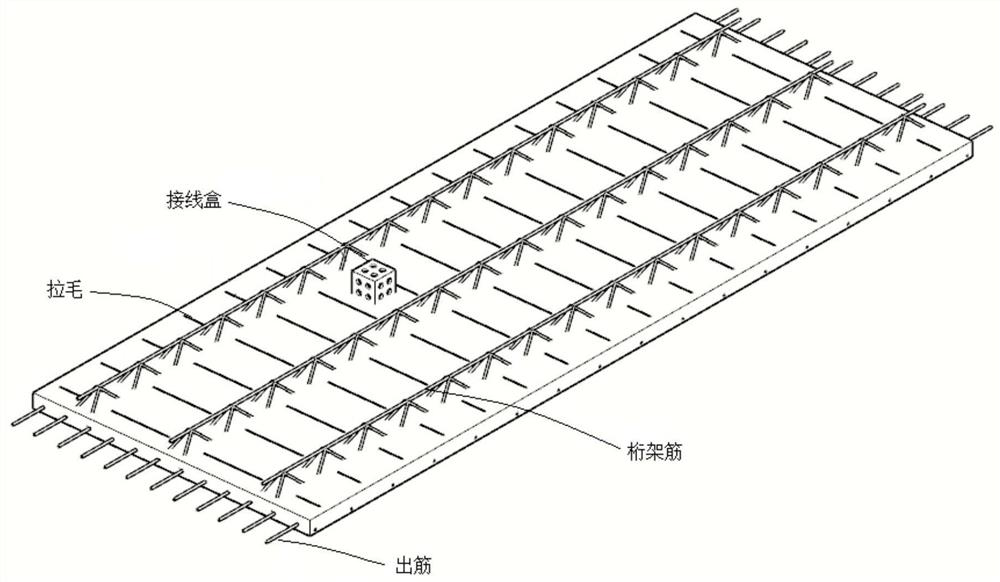

[0048] A method for preparing a prefabricated floor, characterized in that it comprises the following steps:

[0049] S1: Assemble the mold according to the size of the prefabricated bottom plate, and there is no need to open rib holes on the side mold of the mold;

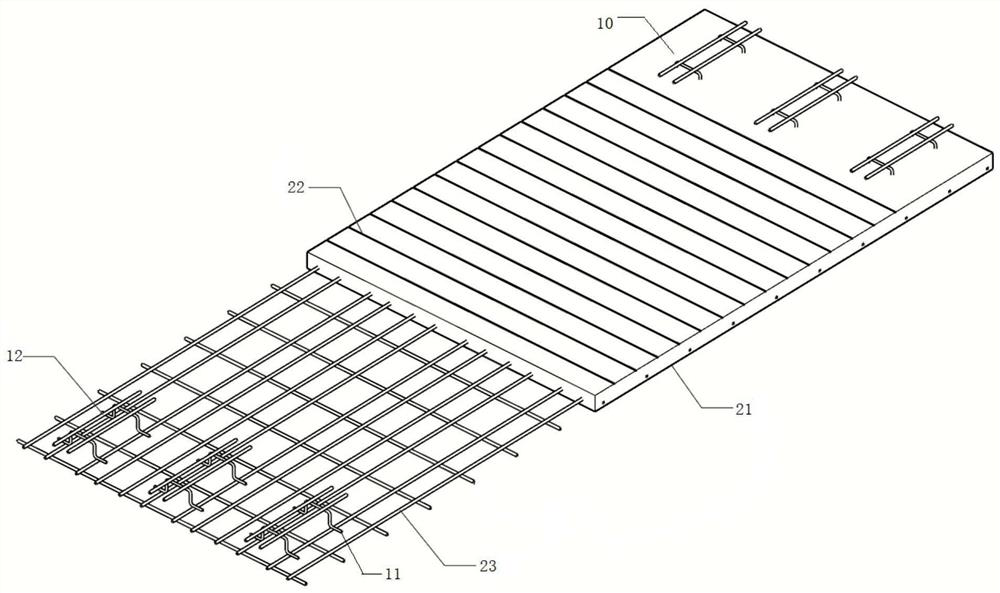

[0050] S2: according to the size of the mould, cut the longitudinal stress reinforcement 28 and the transverse distribution reinforcement 27, and weld them into reinforcement mesh 23 and place them in the mould assembled in step S1;

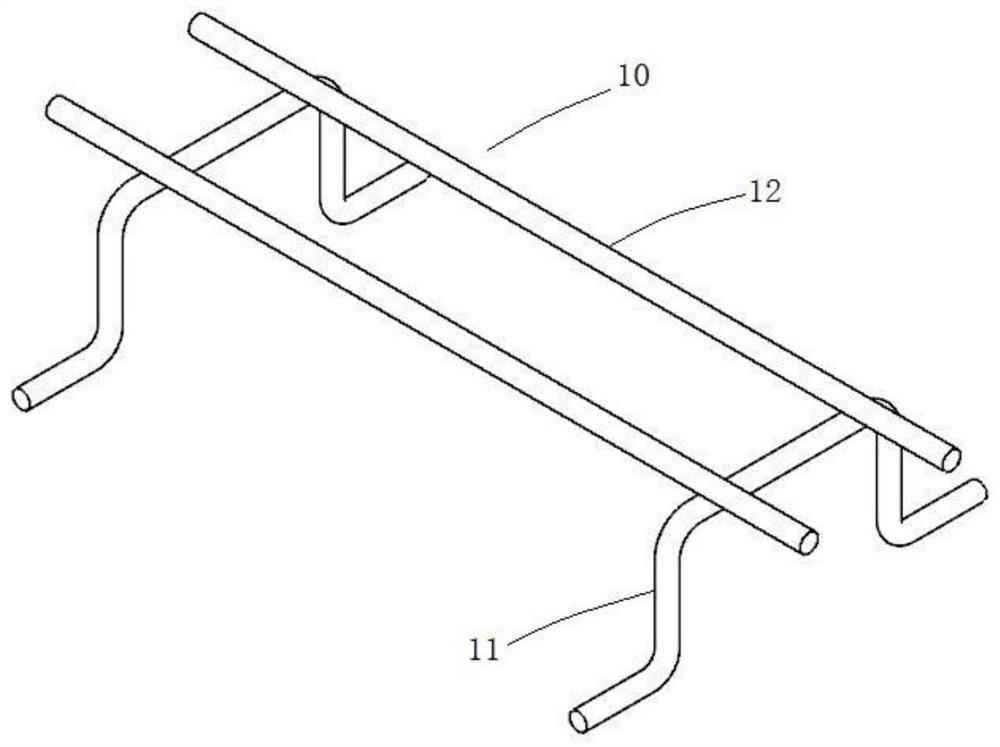

[0051] S3: arranging the reinforcement trusses 10 in sections along the direction of the longitudinal stressed reinforcement of the reinforcement mesh 23, the bottom of the reinforcement truss 10 is tied and fixed to the reinforcement mesh 23;

[0052] S4: Pouring concrete;

[0053] S5: when the concrete is close to the initial setting, the surface of the concrete is roughened 22;

[0054] S6: Carry out natural curing or steam curing on the soleplate;

[0055] S7: Remove the formw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com