A test device for simulating hydraulic splitting of concrete members under different stress conditions

A technology of hydraulic splitting and testing equipment, which is applied in the direction of applying stable tension/pressure to test the strength of materials and the preparation of test samples, which can solve the problems of inability to carry out hydraulic splitting tests and achieve the effect of wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

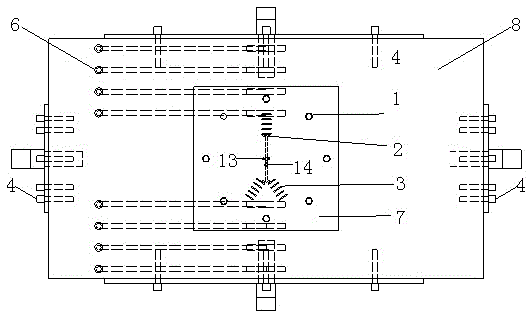

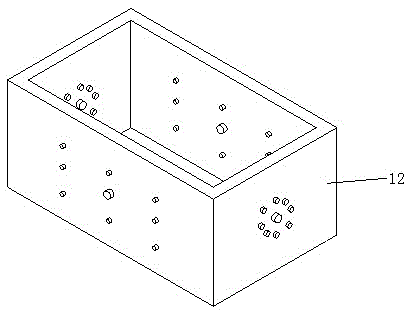

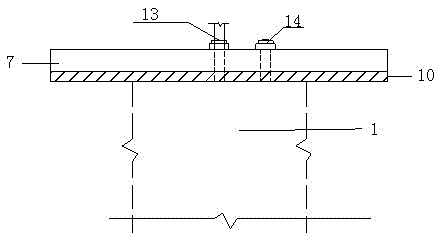

[0025] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0026] Such as Figure 1 to Figure 5 As shown, a hydraulic splitting test device for simulating concrete components under different stress conditions includes a cuboid mold 12 with an opening on one side. Concrete is poured into the mold 12 to obtain a concrete component 8. Eight high-pressure resistant water bends 5 are preset in the concrete component 8. , the end of each high-pressure resistant water bend 5 is provided with a water pressure sensor connector 6; a certain range of grooves are ground around the prefabricated initial crack 1, and the clip-type extensometer 2 and strain gauge 3 are arranged, and the grinding is filled with water-proof insulating glue 10 Flat; the water-sealed steel plate 7 is set on the concrete member 8, and the water-sealed steel plate 7 is arranged with a water inlet 13 and an exhaust port with a sealing cap 14.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com