Bearing platform construction process method within prefabricated vertical column range

A construction technology and column technology, which is applied to bridge parts, erection/assembly of bridges, bridges, etc., can solve problems such as increasing construction costs, unfavorable stress conditions of foundation piles, and complicated construction processes, and achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

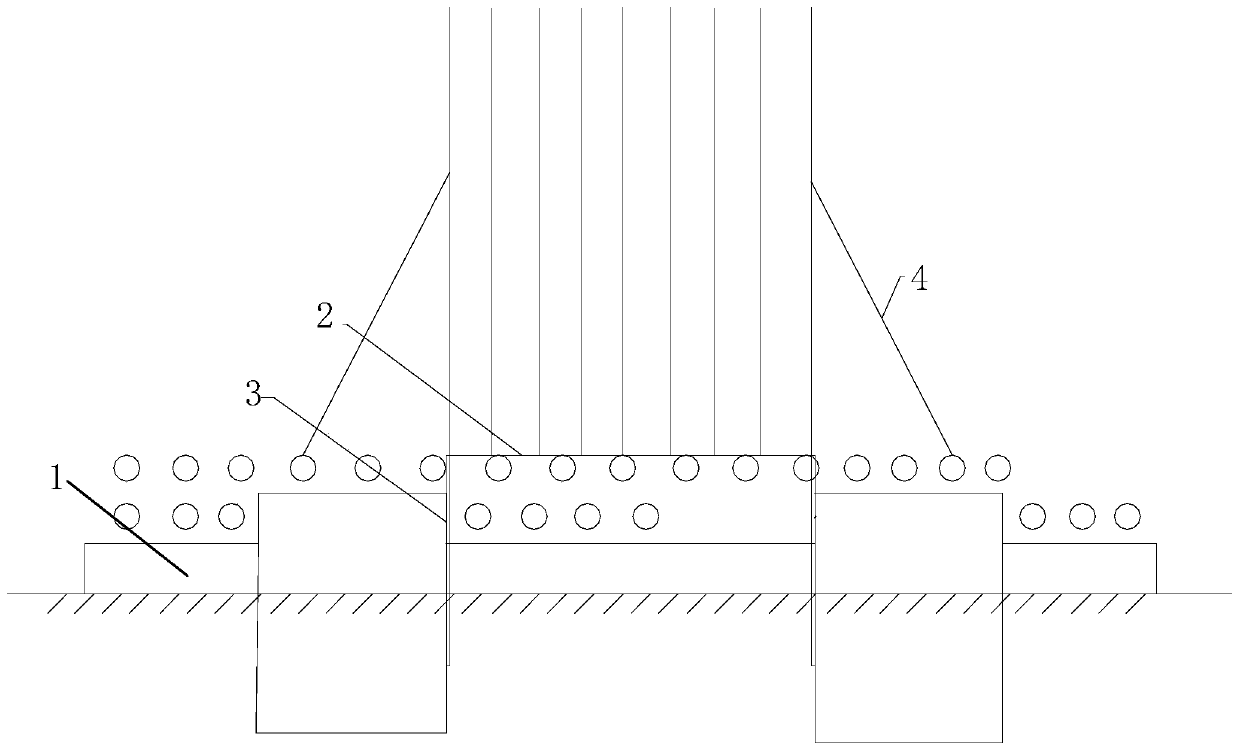

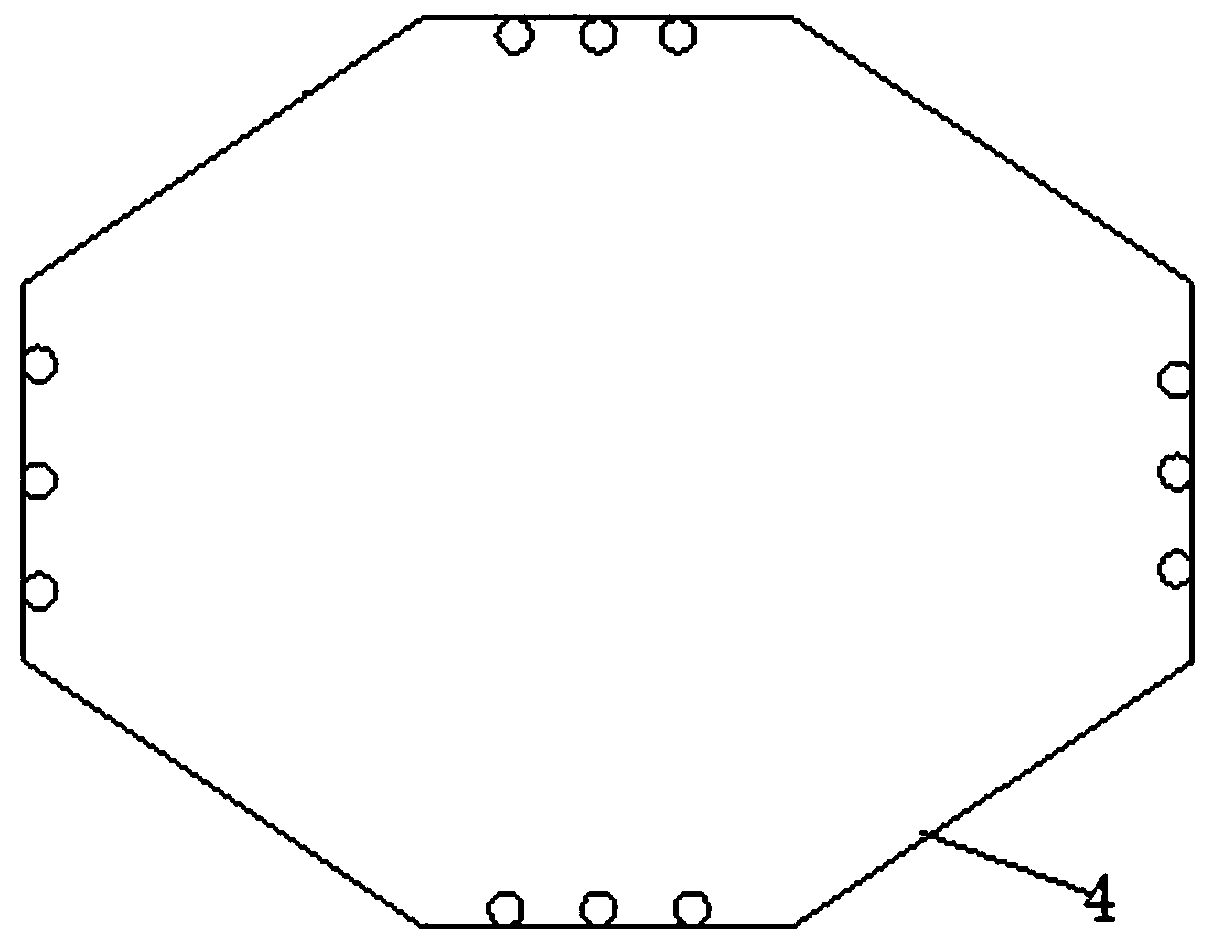

[0032] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

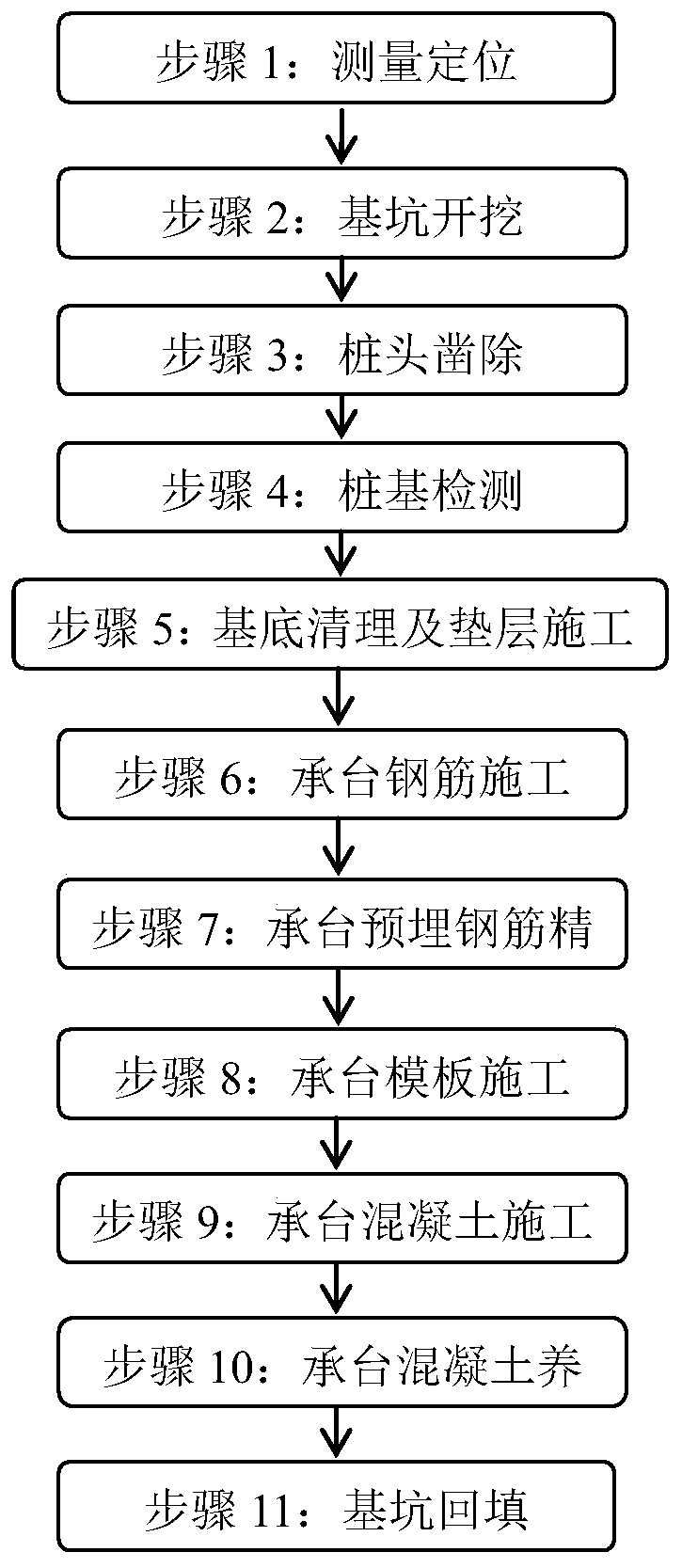

[0033] Such as figure 1 As shown in Figure 3, a construction method for caps within the scope of prefabricated prefabricated columns, the specific implementation process steps are:

[0034] S1: measurement positioning;

[0035] Measurement and positioning requires professional and technical personnel to be responsible for positioning, measuring and setting out work to ensure the accuracy of the location and elevation of the foundation pit. Use total stations and theodolites to measure and position and set the foundation pit elevation control points. After setting the control points, perform foundation pit positioning, and then Excavation of foundation pit earthwork.

[0036] S2: foundation pit excavation;

[0037] The foundation pit of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com