Asphalt pavement structure for expressway precast beam field pavement permanent and temporary structure conversion

A technology for asphalt pavement and expressway, which is applied to the condensed pavement, roads, roads and other directions paved on site, can solve the problems of delay in construction period, waste of resources, a lot of manpower, material resources, etc., and achieves extended service life, convenient construction and convenient Modulus transition and the effect of drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

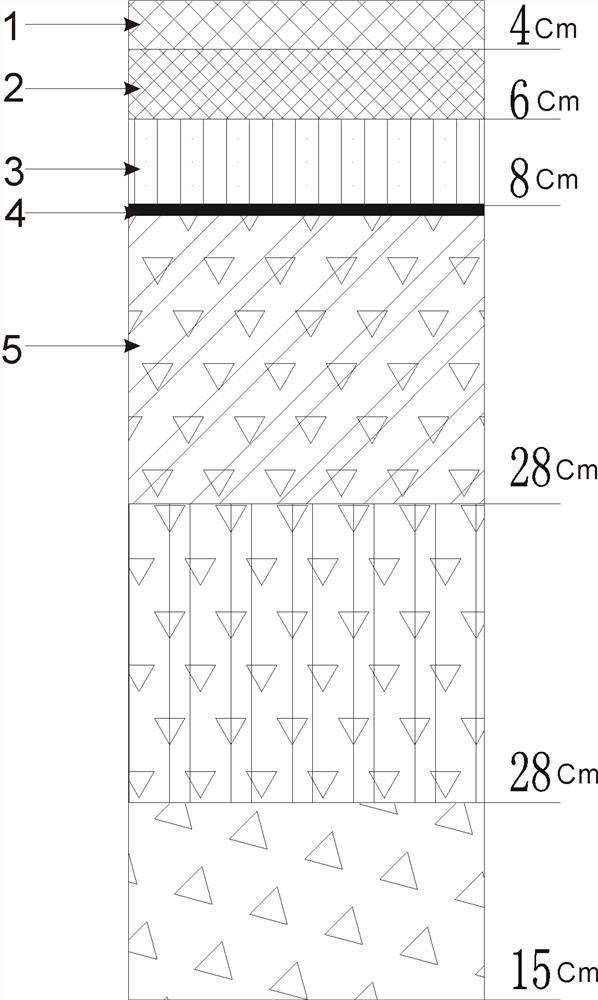

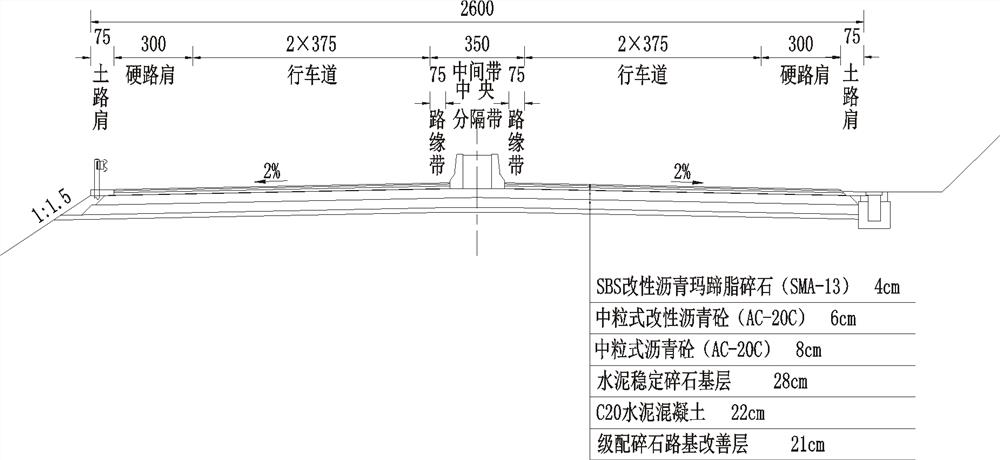

[0062] Example 1: see figure 1 , figure 2 , a kind of asphalt pavement structure used for the prefabricated beam field pavement of the main road base section, the thickness of the pavement structure is 89cm. The asphalt pavement surface layer is 18cm (the upper, middle and lower layers are 4cm, 6cm, and 8cm respectively), the cement stabilized macadam base is 28cm, the beam field cement concrete pavement is 22cm, and the graded macadam base is 21cm.

Embodiment 2

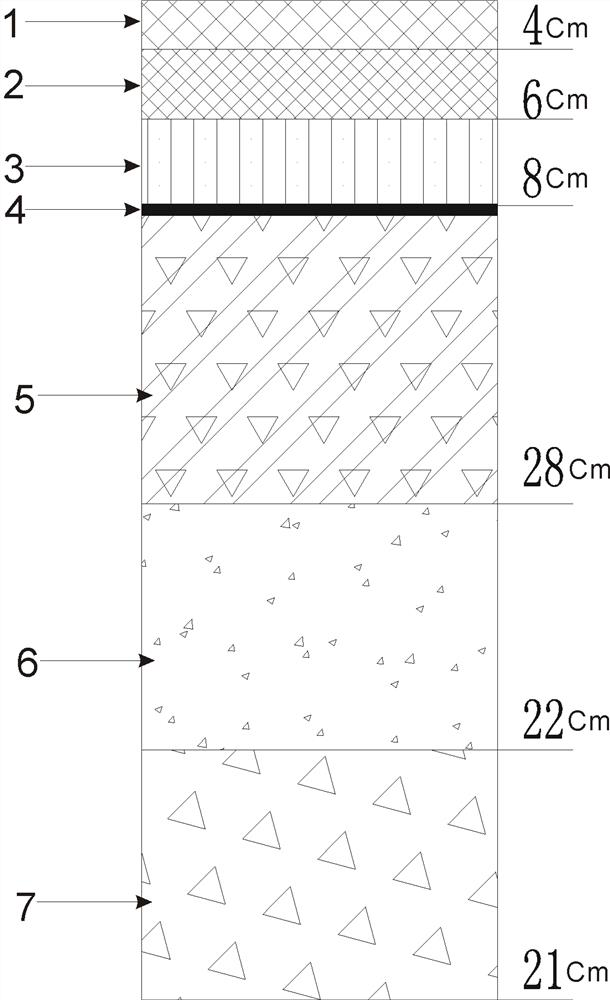

[0063] Example 2: see figure 1 , figure 2 , a kind of asphalt pavement structure used for the prefabricated beam field pavement of the subgrade section of the service area, the construction method is the same as that of Example 1, and the thickness of the pavement structure is 81cm. The asphalt pavement surface layer is 10cm (the upper and lower layers are 4cm and 6cm respectively), the cement stabilized macadam base is 28cm, the beam field cement concrete pavement is 22cm, and the graded macadam base is 21cm.

Embodiment 3

[0064] Embodiment 3: see figure 1 , figure 2 , a kind of asphalt pavement structure used for the prefabricated beam field pavement of the main road base section, the construction method is the same as that of Example 1, and the thickness of the pavement structure is 81cm. The surface layer of the asphalt pavement is 16cm (the upper, middle and lower layers are 4cm, 6cm, 6cm respectively), the cement stabilized macadam base is 25cm, the beam field cement concrete pavement is 22cm, and the graded macadam base is 18cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com