Light wall board drying plate

A light-weight wallboard and core board technology, which is applied to walls, building components, buildings, etc., can solve problems such as increased construction costs, low strength, and wallboard damage, so as to reduce project costs, ensure product quality, and reduce The effect of building loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

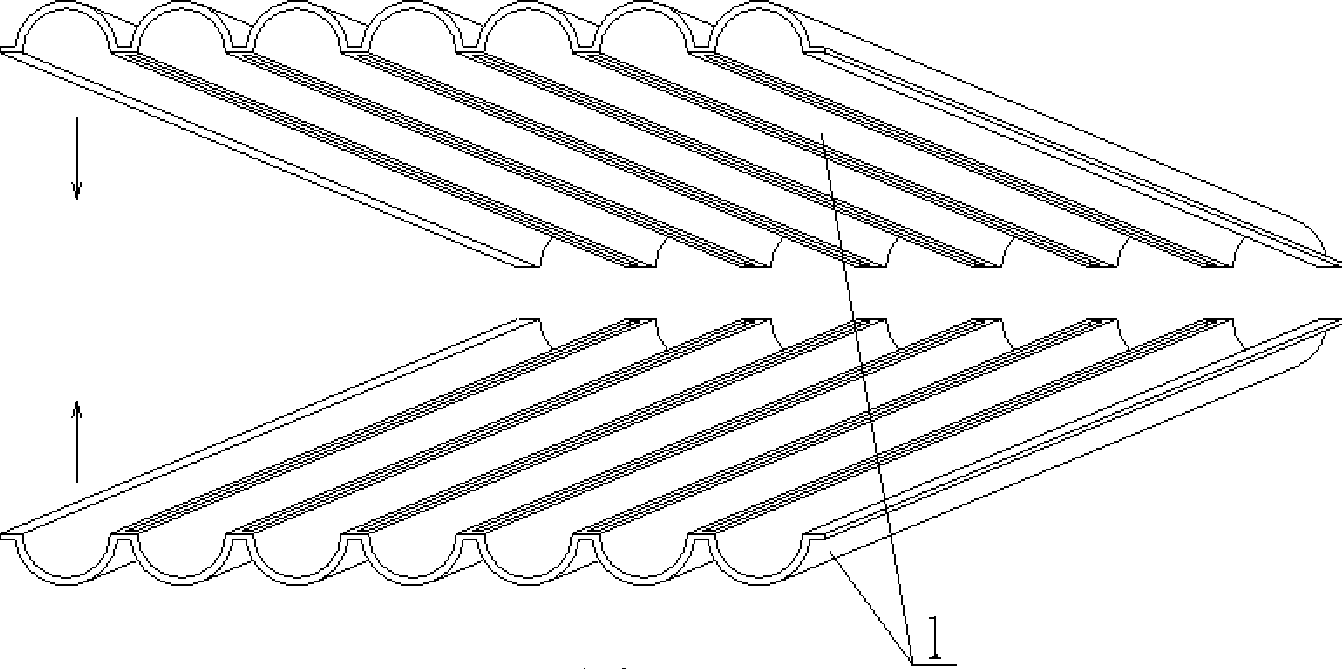

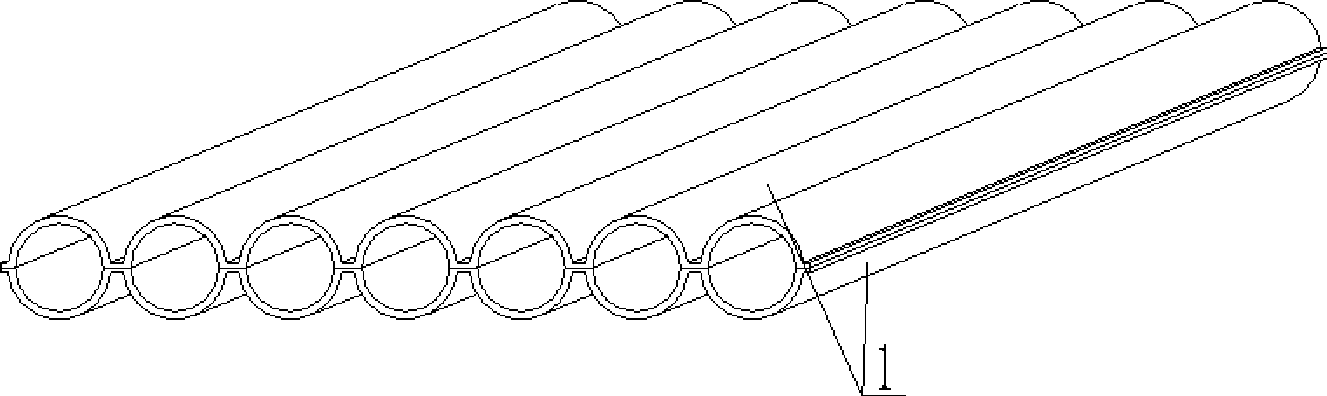

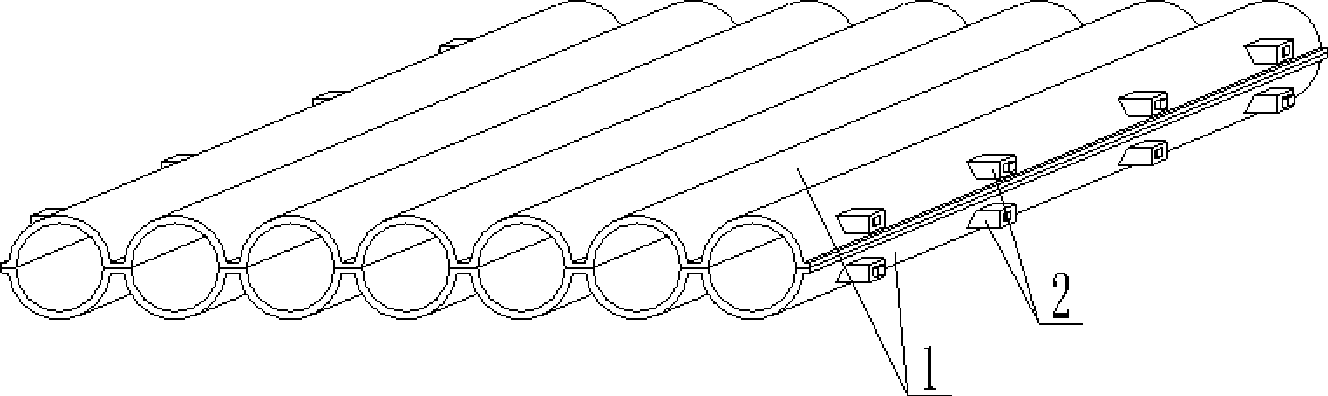

[0087] As shown in the accompanying drawings, the present invention includes a core plate component 1, which is characterized in that the core plate components 1 are relatively buckled. In each accompanying drawing, 1 is a core plate component. In each following accompanying drawing, those with the same number have the same description. like figure 1 As shown, a lightweight wallboard core board includes a core board part 1, which is characterized in that the board parts 1 are relatively fastened, and the core board part 1 is also provided with a raised edge, and the core board part 1 is provided with a through seam.

[0088] The present invention is characterized in that the two core board components 1 are joined together to form a whole. like figure 2 As shown, the two core plate parts 1 described above are joined together to form a whole, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com