Foam concrete demoulding equipment

A foamed concrete and demoulding technology, applied in the directions of mold auxiliary parts, unloading devices, ceramic molding machines, etc., can solve the problems of slow production speed and low efficiency of the demoulding process, and achieve improved quality, good appearance quality, and reduced placement. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

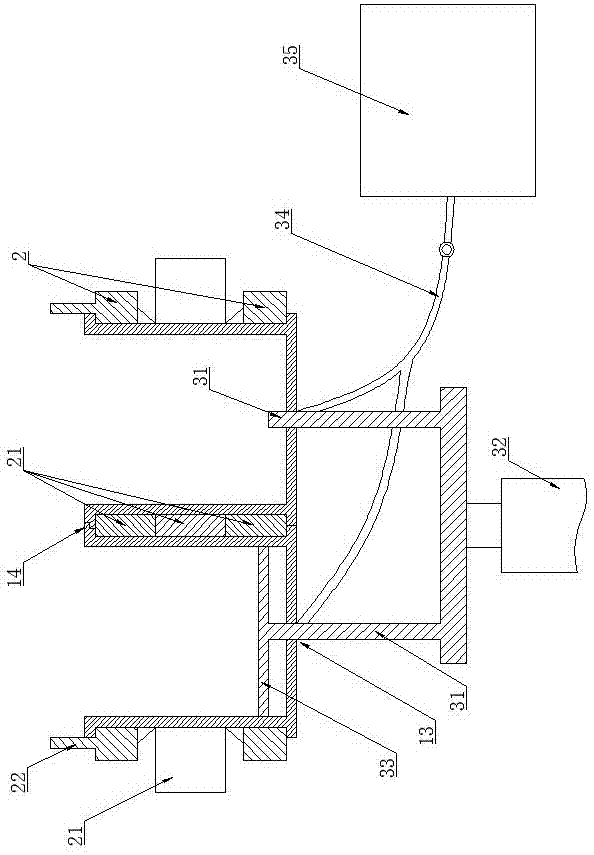

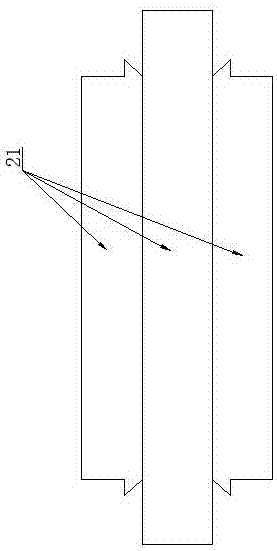

[0033] Further, see figure 2 , as a specific embodiment of the foamed concrete demoulding equipment provided by the present invention, the pressure mechanism includes a support rod 31 for pushing out the molded foamed concrete through the through hole 13 and a support rod for driving the support Cylinder or cylinder 32 for rod 31 . When this structure is in use, it is necessary to fix the frame body 2 and the mold 1, start the oil cylinder or the air cylinder 32, and make the support rod 31 eject the formed foam concrete. Because the mold 1 has a draft taper, the support bar 31 only needs to loosen the top of the foam concrete to take out the foam concrete smoothly. The foam concrete will not be damaged or ejected due to excessive local force, it is safe and convenient to use, can save a lot of labor for demoulding, and improve the demoulding efficiency.

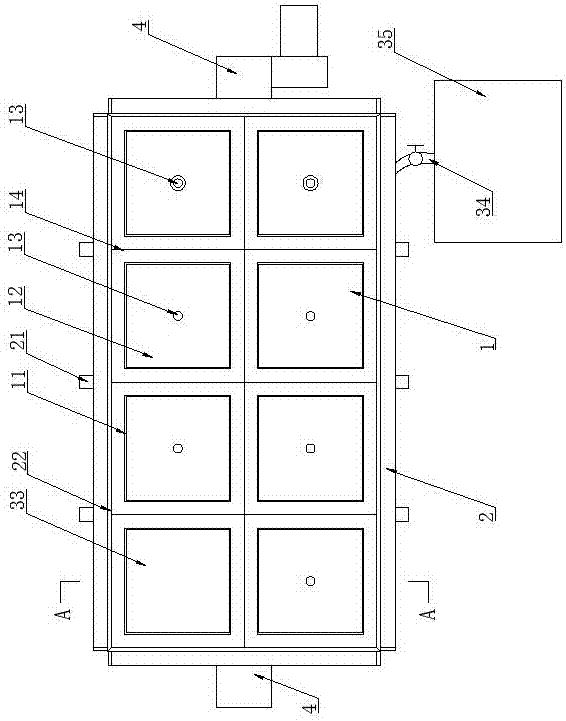

[0034] Furthermore, please also refer to figure 1 with figure 2 , as a specific embodiment of the demoulding equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com