Fabricated partition wall and construction method

A prefabricated and partitioned technology, applied to walls, building components, buildings, etc., can solve the problems of increased labor costs and parts costs, waste of material resources, cost-effectiveness, waste of resources, etc., to improve assembly efficiency and connection stability, reduce The cost of building structure and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

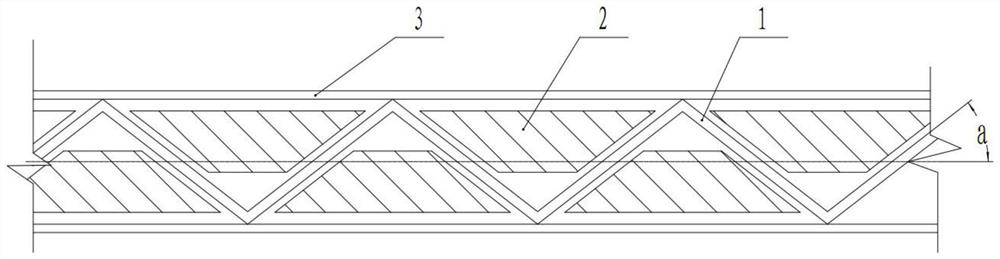

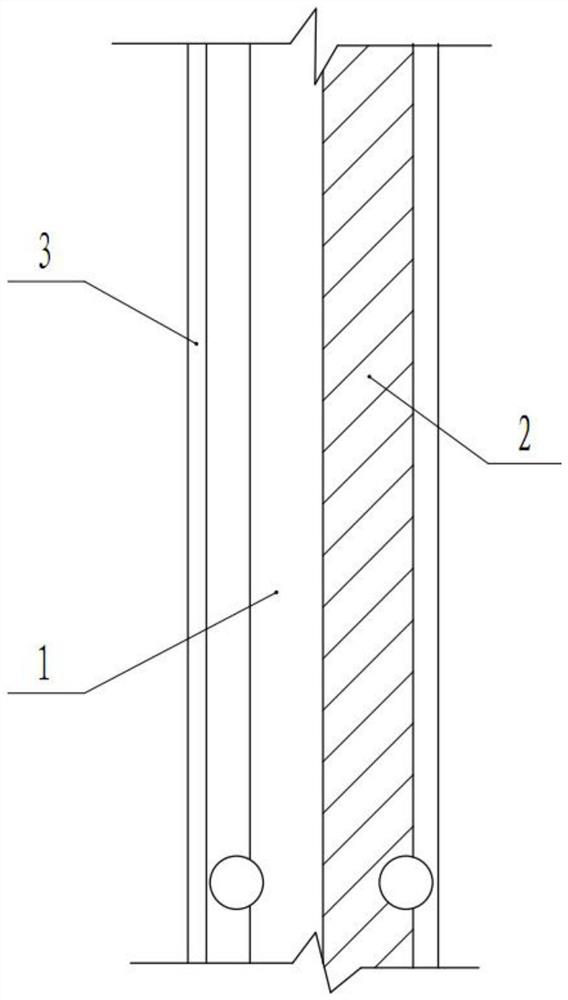

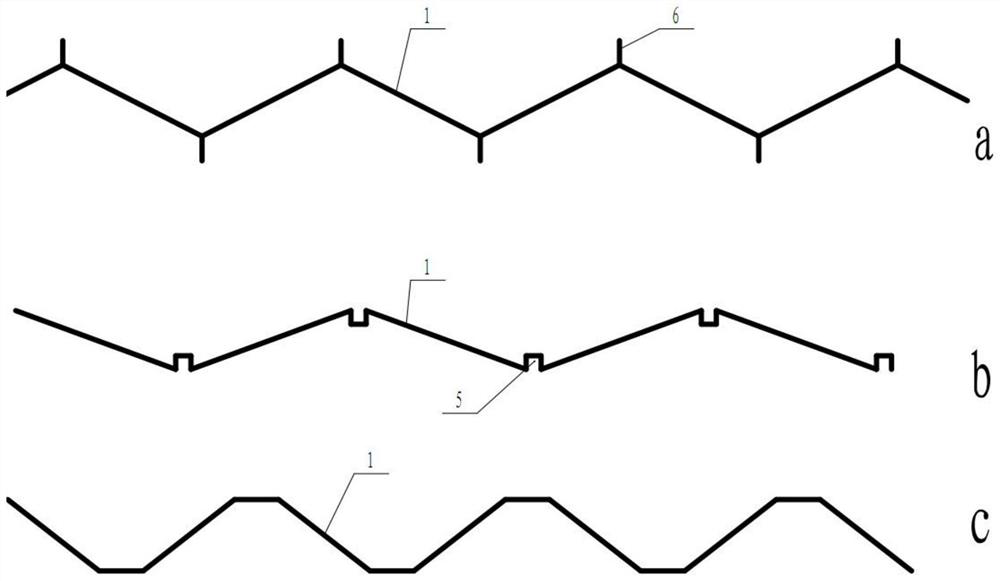

[0053] Embodiment 1: as Figure 1-5 As shown, a prefabricated partition wall includes a partition wall, a performance partition wall and a decorative partition wall. There are decorative partition walls on both sides of the partition wall, and the performance partition wall is filled between the partition partition wall and the decorative partition wall. Among them, the partition wall adopts a number of prefabricated partition core boards 1 to arrange according to certain rules along the longitudinal axis (or horizontal axis) of the partition wall (that is, according to non-planar rules, such as continuous w-shaped partition walls, etc.) , fixed upper and lower ends, the performance partition wall is assembled by additionally connecting the prefabricated filling strips 2 with the partition wall as the carrier, and the decorative partition wall is assembled with the partition wall as the carrier to additionally connect the prefabricated decorative strips 3 Or additionally conne...

Embodiment 2

[0063] Embodiment 2: A construction method of a prefabricated partition wall, the method is: dividing the state of the partition partition wall, performance partition wall and decorative partition wall during the construction and assembly process into from partition partition wall to decorative partition wall There are two states from performance partition wall to decorative partition wall, or three states from partition partition wall to performance partition wall and then to decorative partition wall. Partition walls in different states are constructed and assembled according to the requirements of different subjects at different times. And there is a standard connection method (detachable fixed connection of grooves and ribs) between the partition wall and the filling strips 2 and the facing strips 3 .

[0064] The specific construction process is as follows: partition core panels, filling strips and decorative strips are all prefabricated in the factory. First, transport t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com