Patents

Literature

67results about How to "Large bearing surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

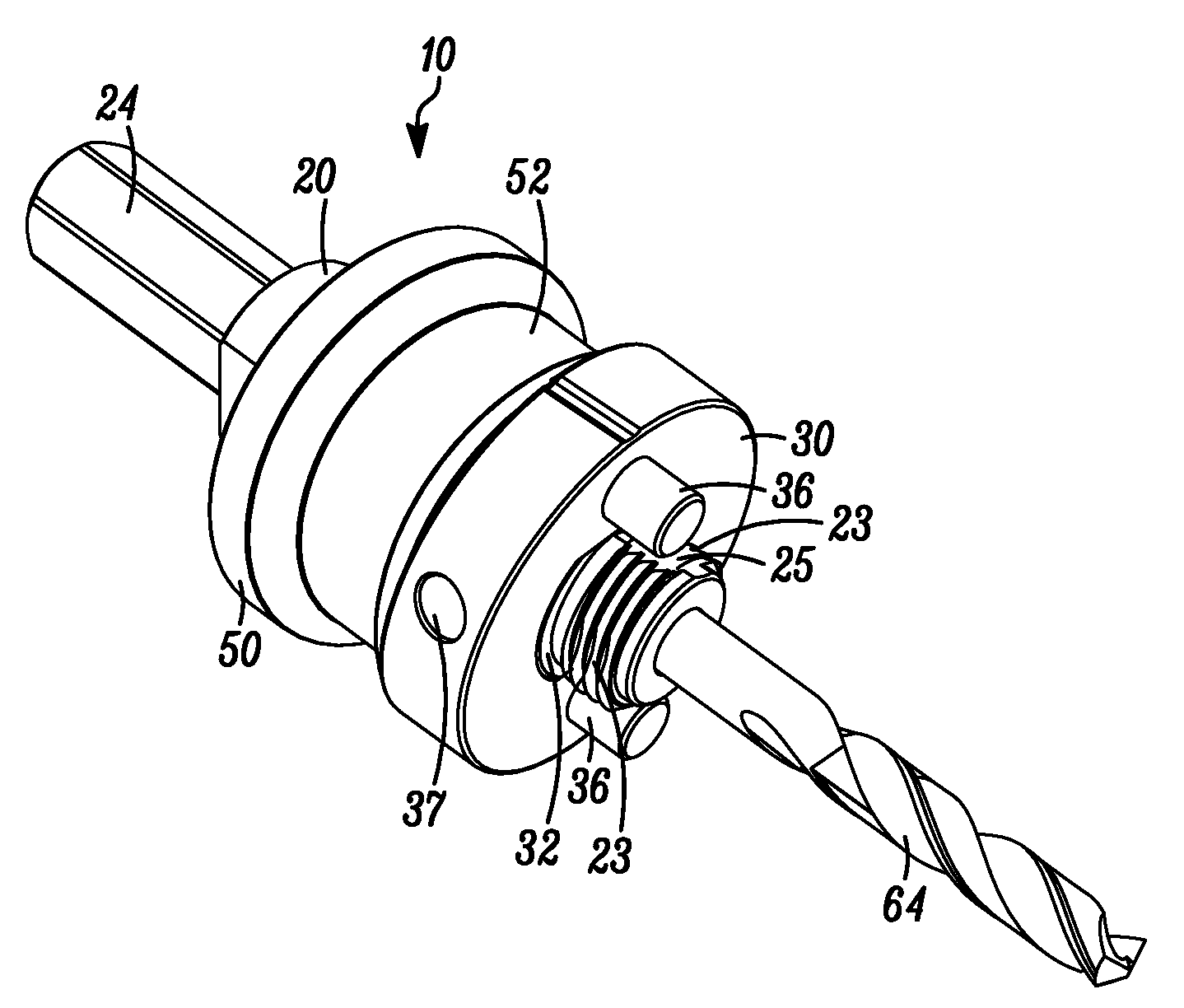

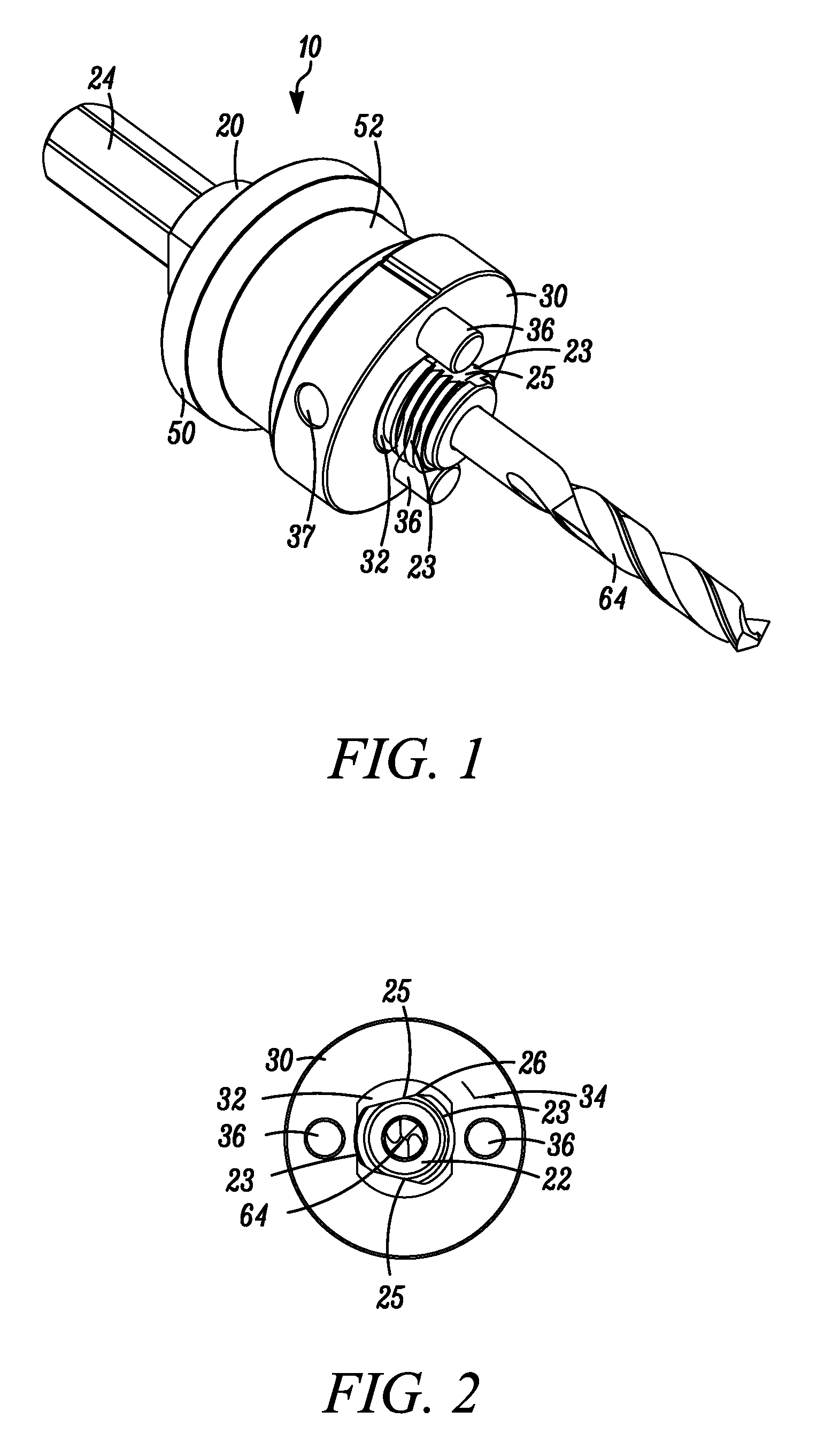

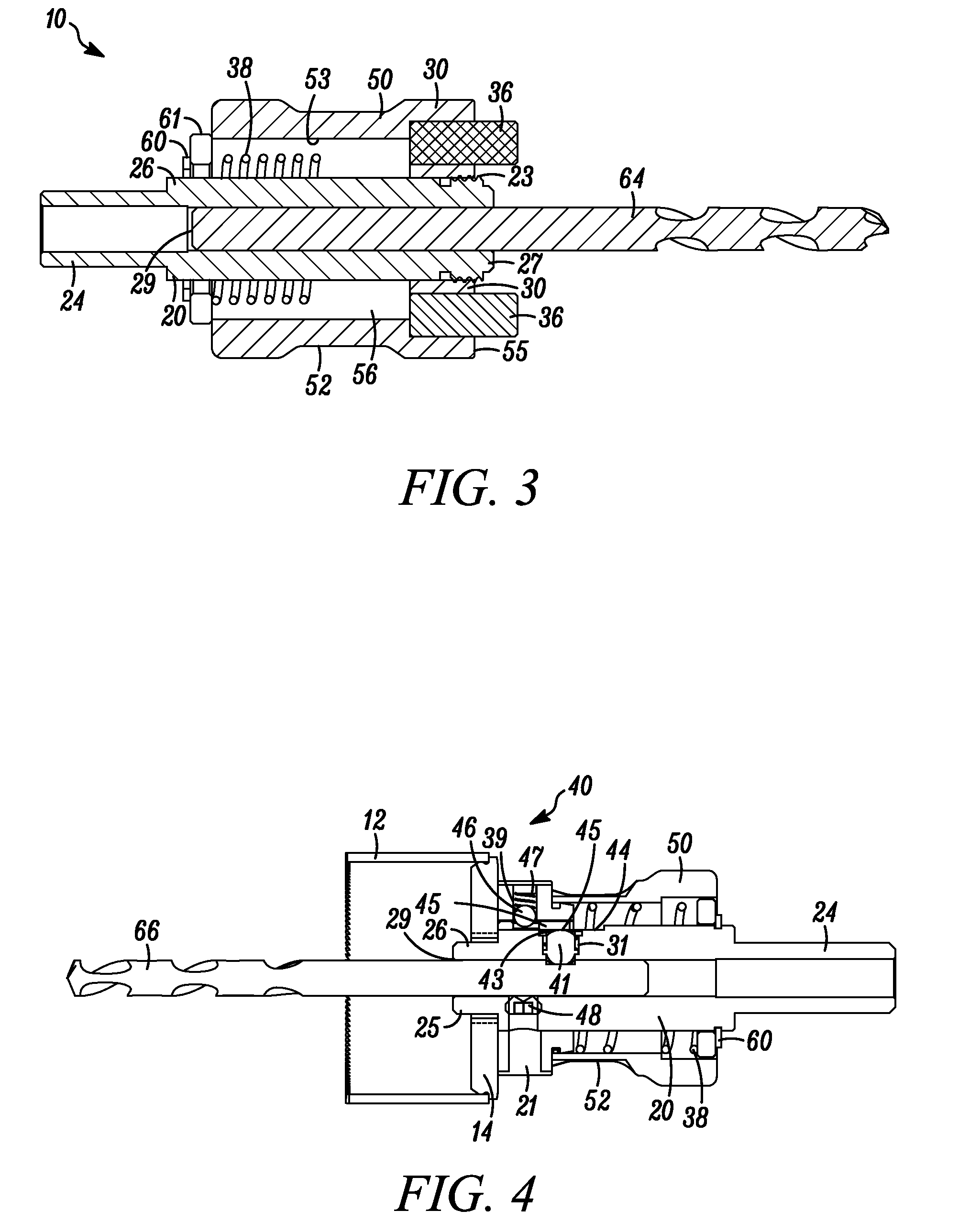

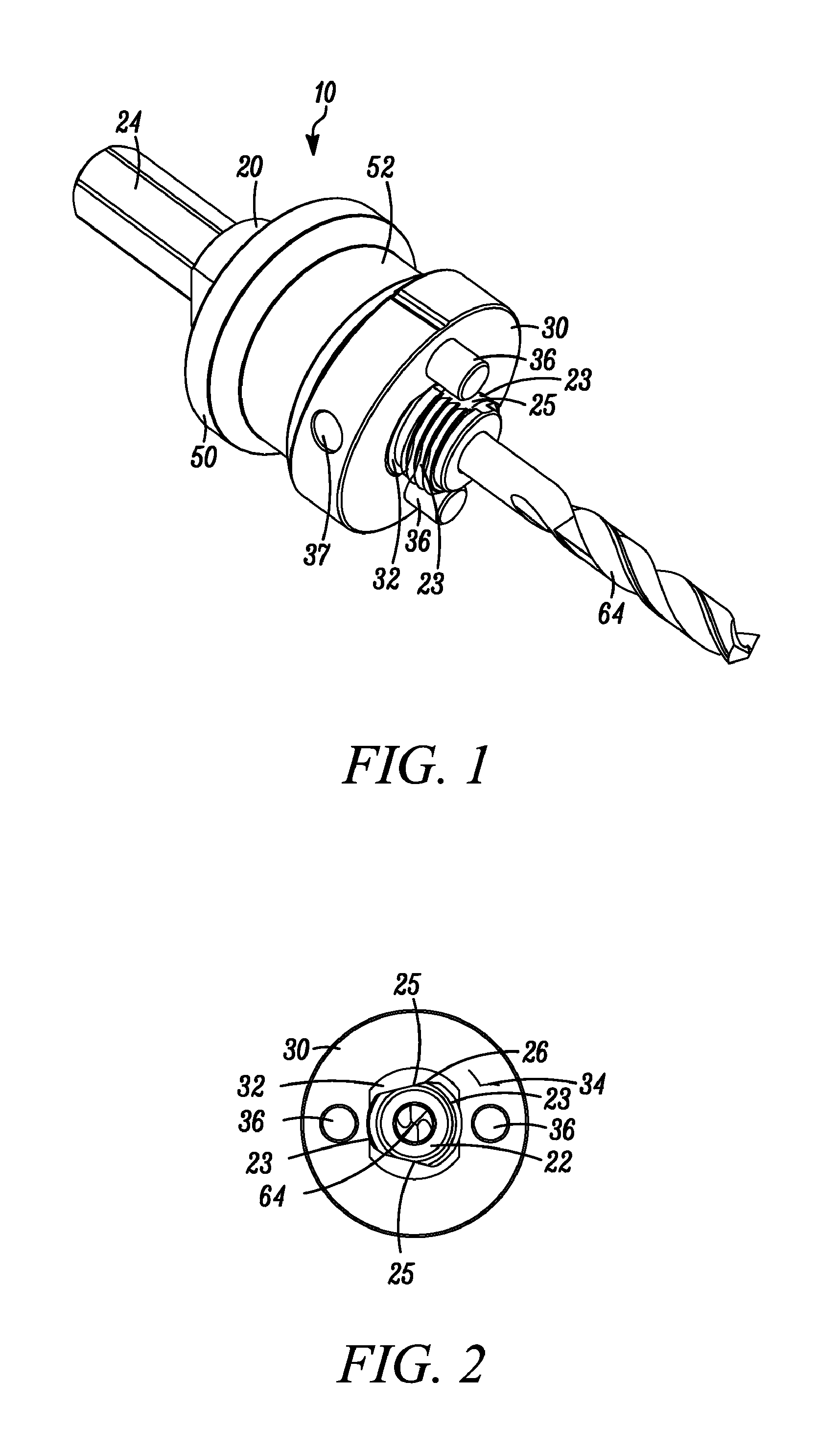

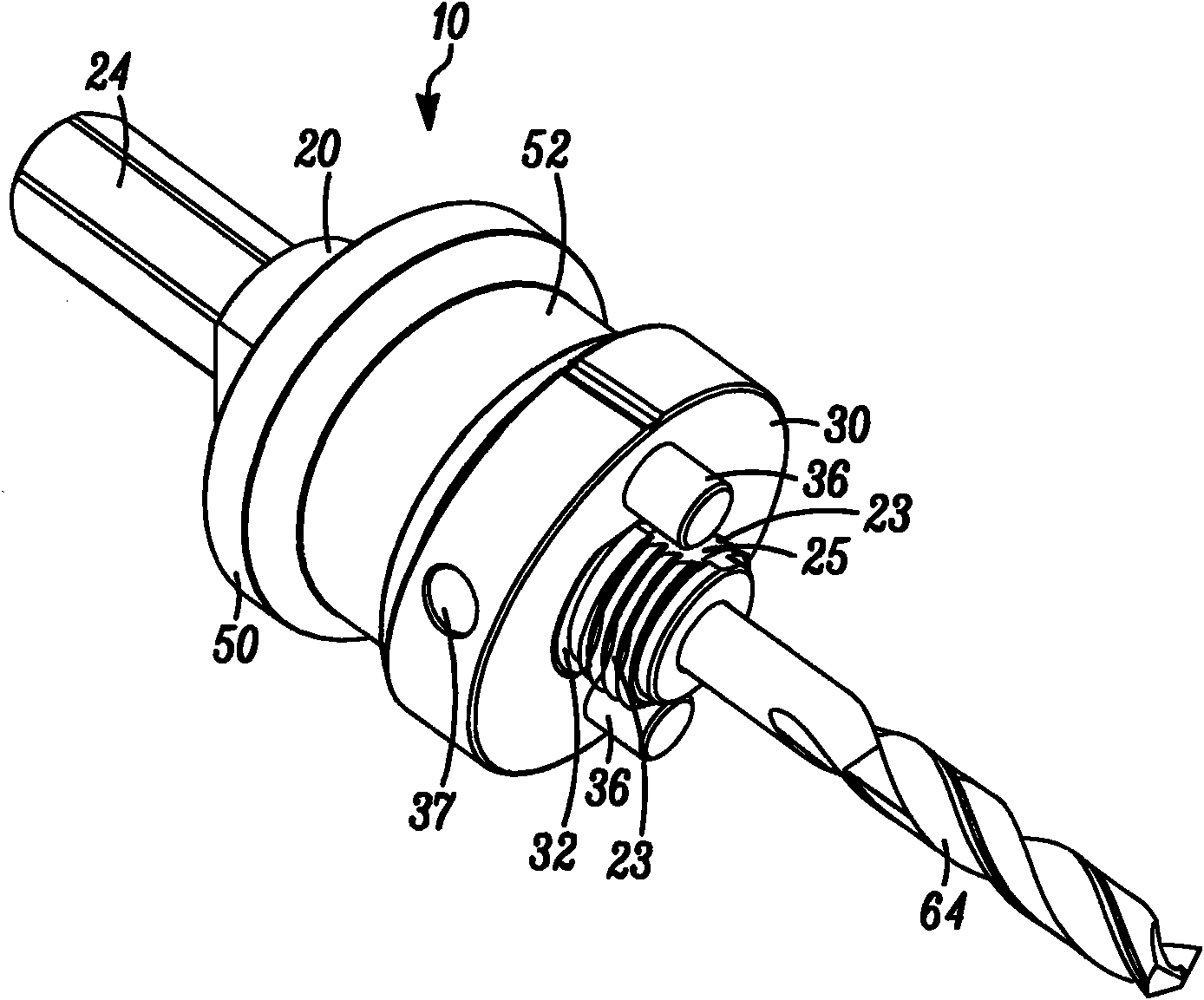

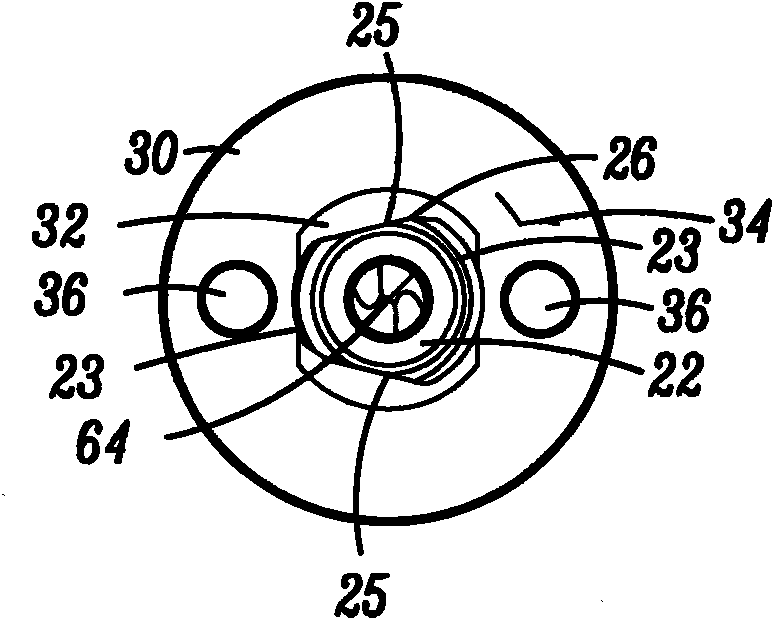

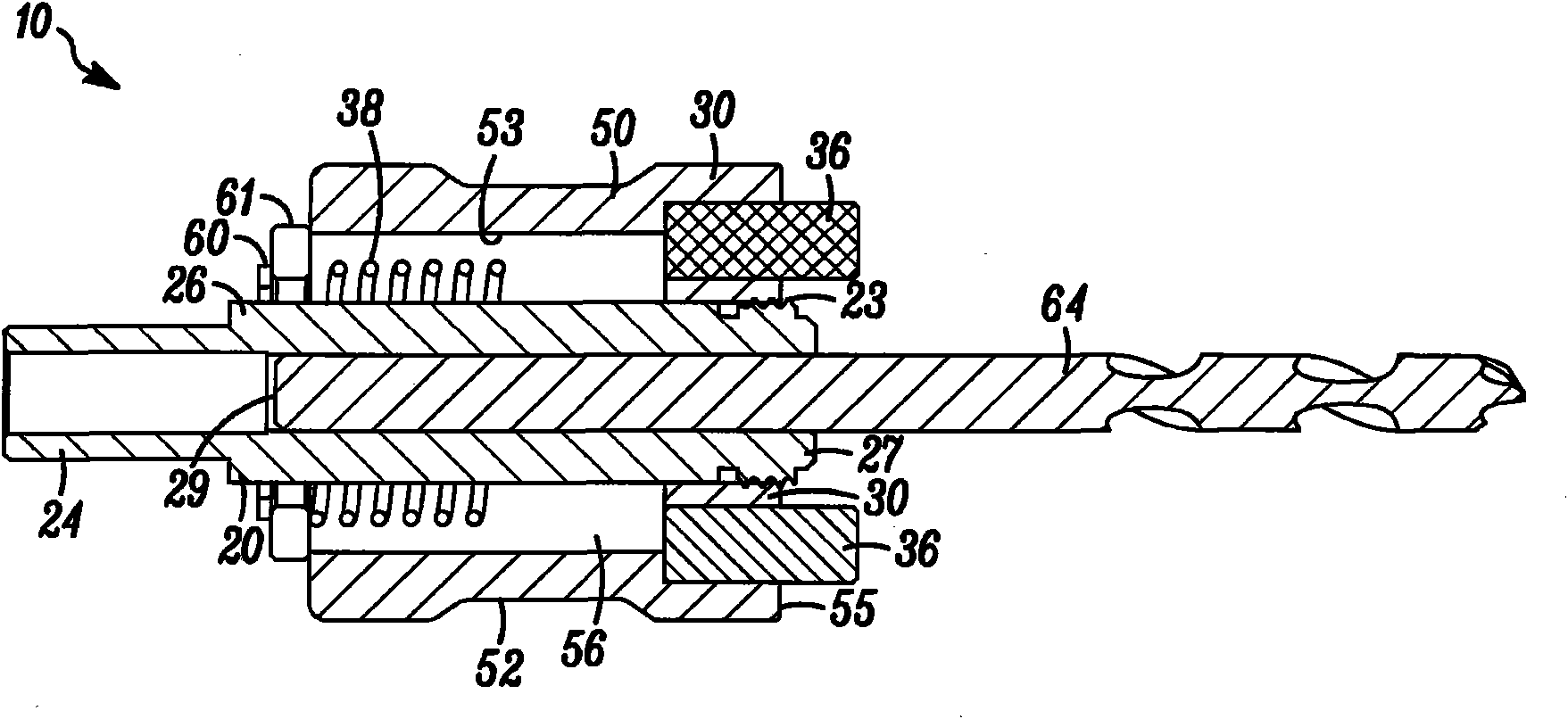

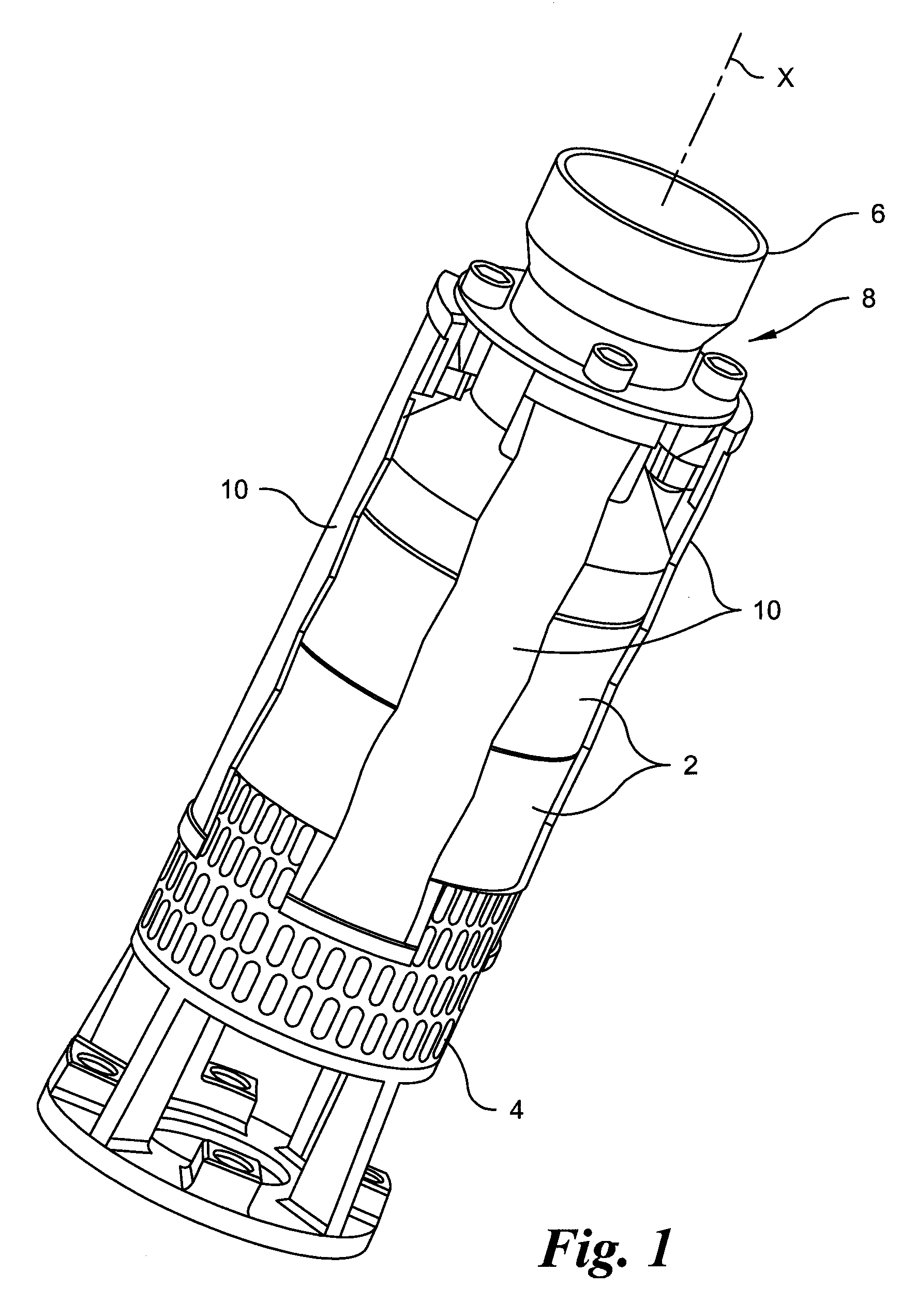

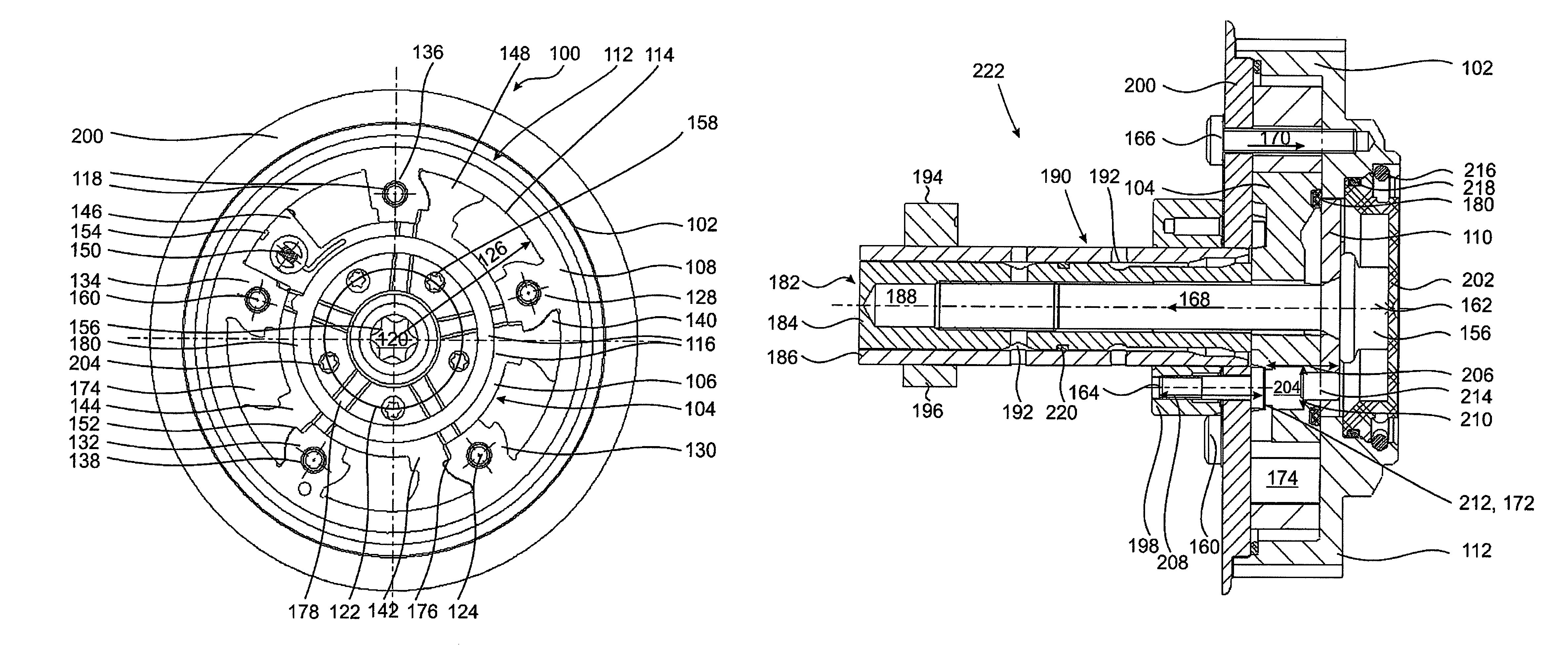

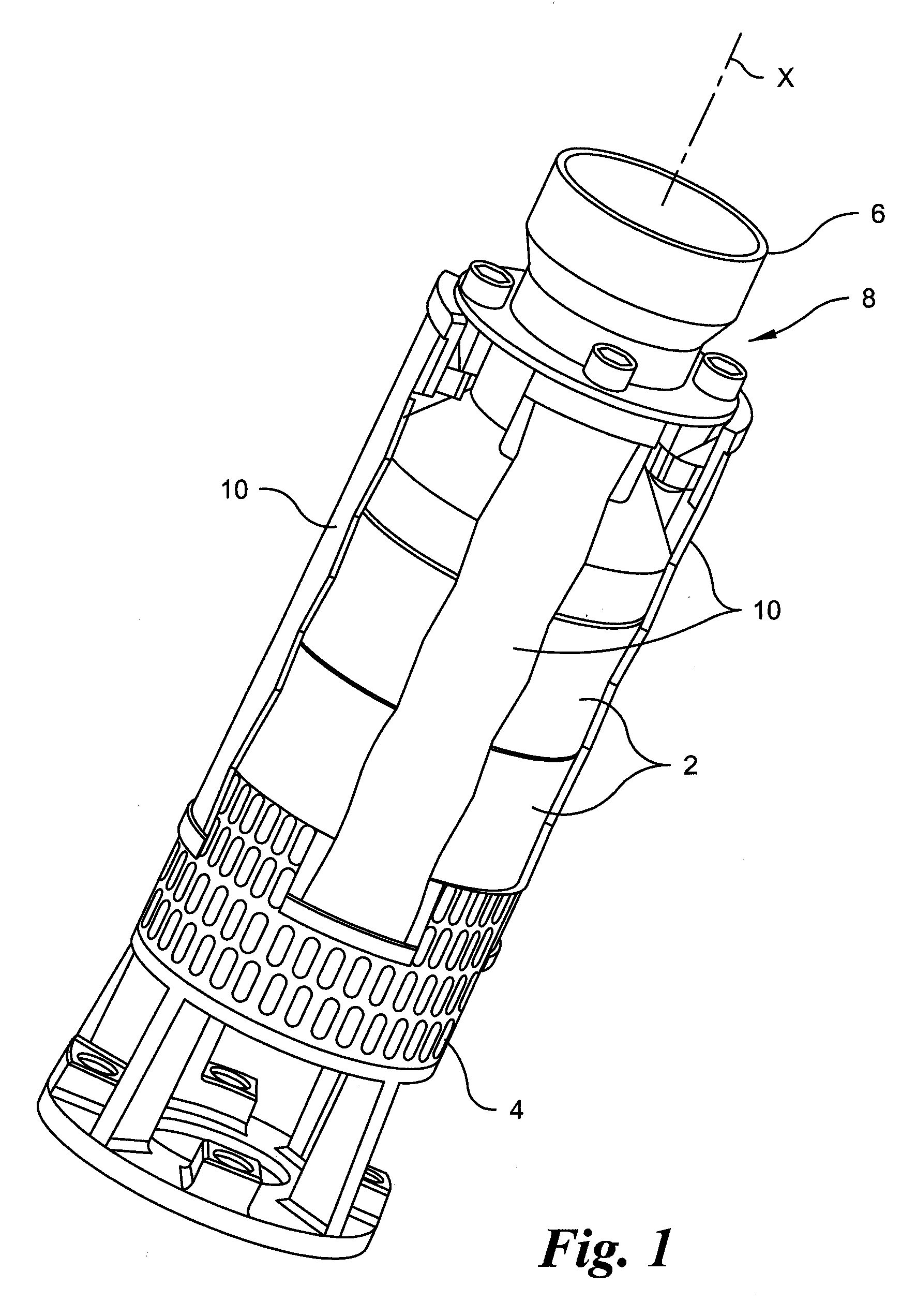

Quick change arbor, hole cutter, and method

ActiveUS20090279972A1Prevent rockingAvoid wobblingThread cutting machinesTransportation and packagingHole sawEngineering

An arbor for quick change and standard hole cutters, wherein each hole cutter includes a central aperture and at least one drive pin aperture. The arbor comprises an arbor body including an end portion engageable within the central aperture, a drive shank opposite the end portion for engaging a power tool, and an aperture for receiving a pilot bit. The arbor further comprises a drive pin plate and / or collar having at least one drive pin receivable in a corresponding drive pin aperture of the hole saw for drivingly engaging the hole saw. The arbor, in at least one embodiment, further comprises a pilot bit mechanism for engaging and releasing a quick change or standard pilot bit.

Owner:BLACK & DECKER INC

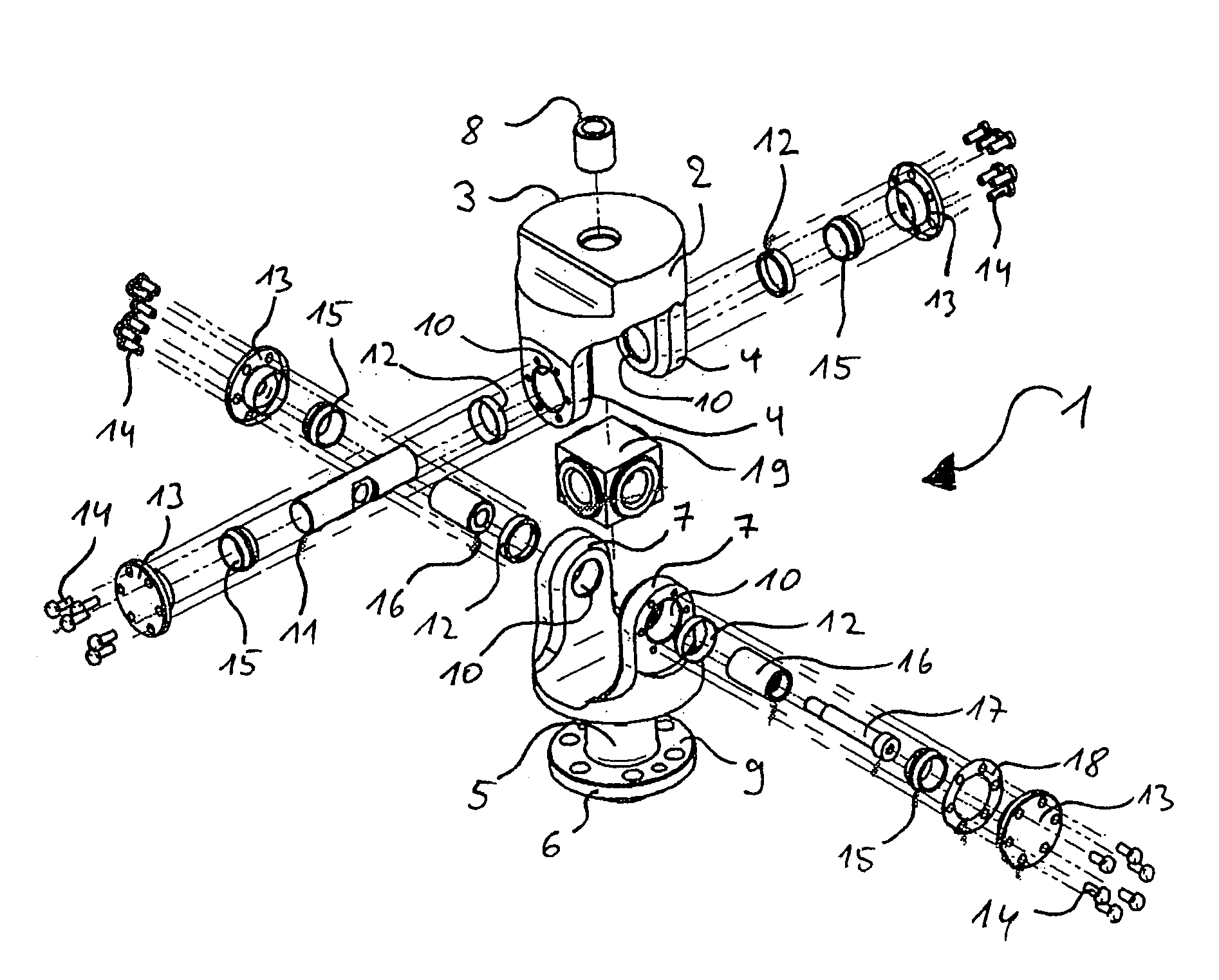

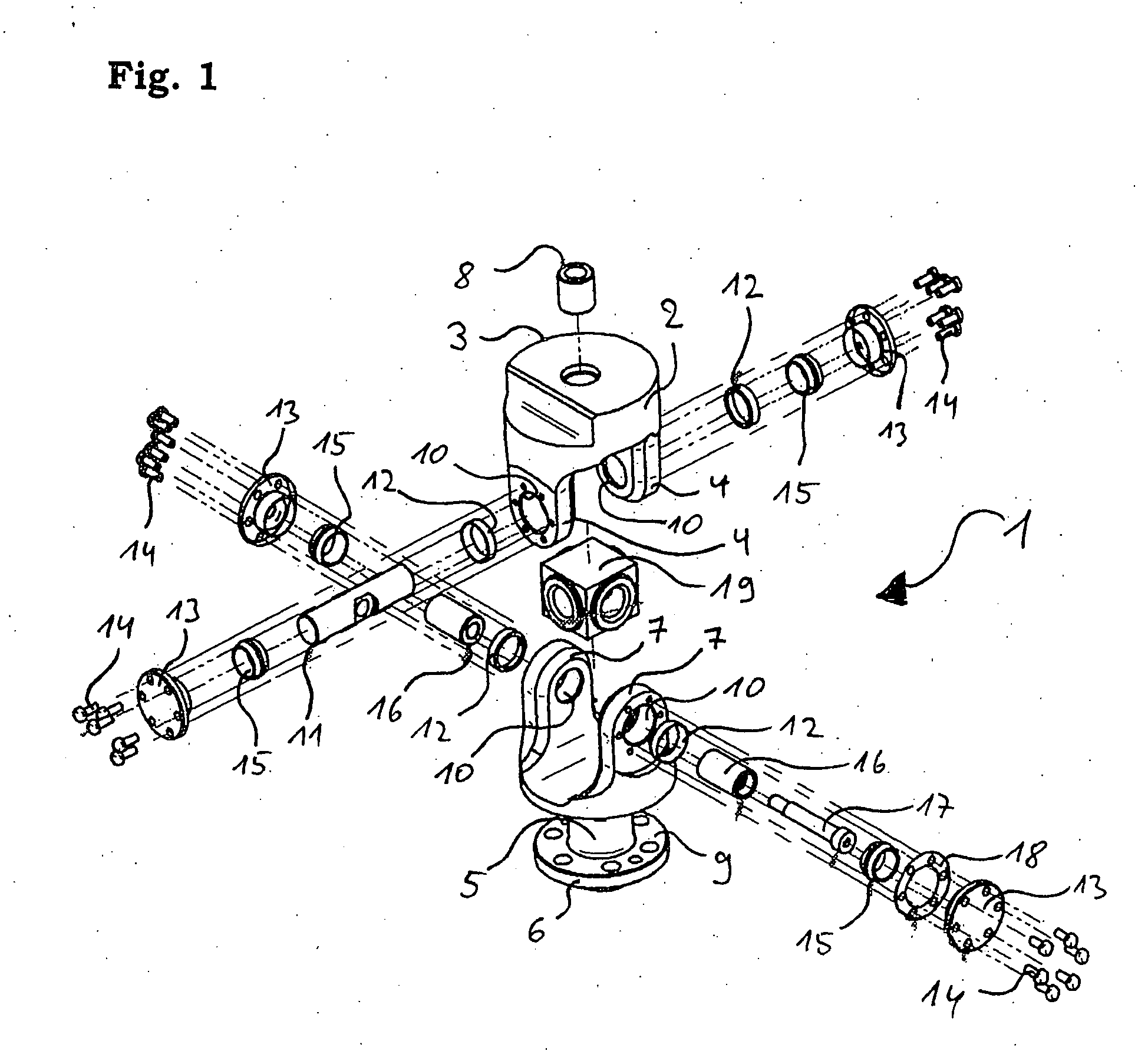

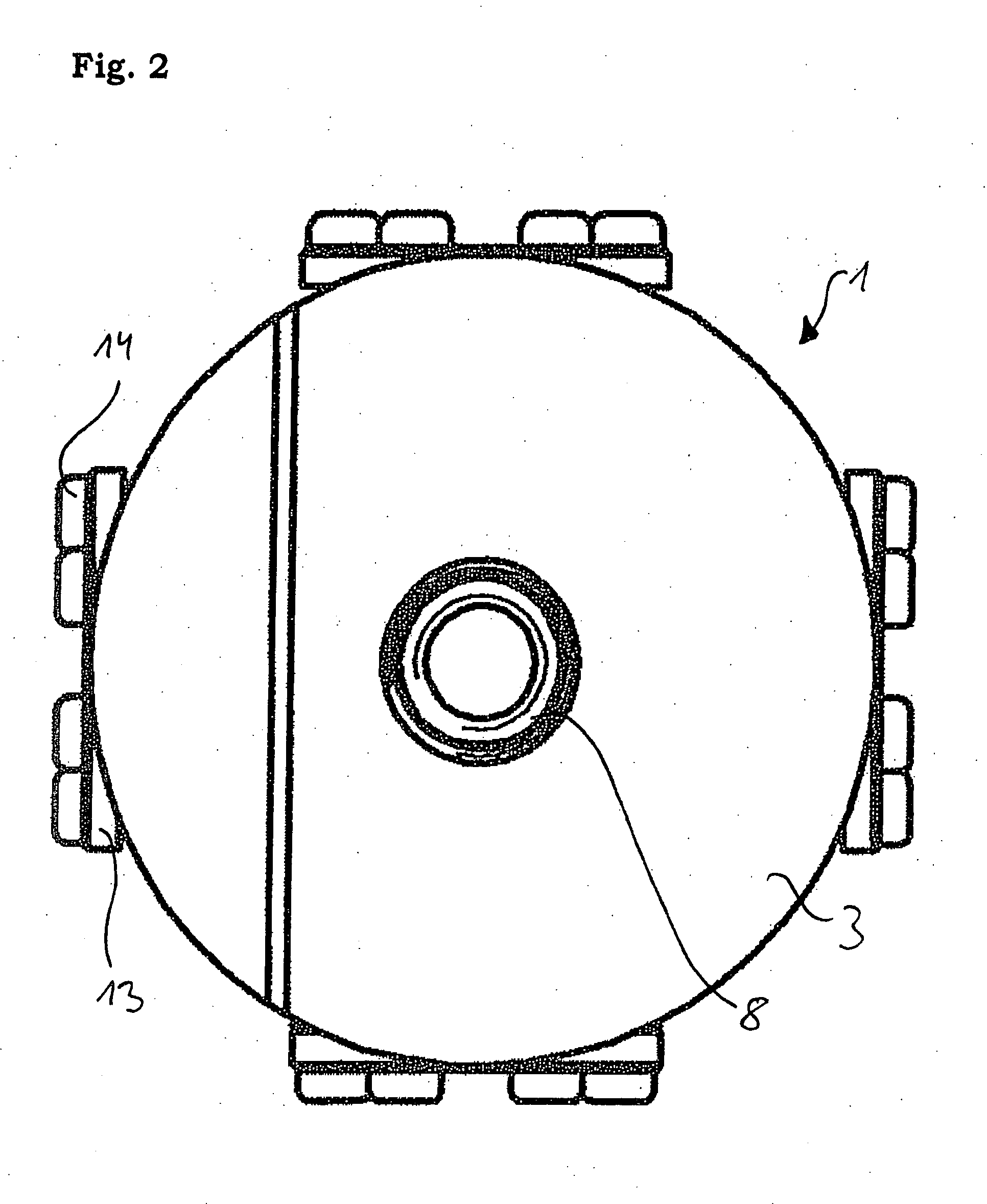

Universal Joint

InactiveUS20080108446A1Precise positioningReduce stip slick effectYielding couplingUniversal jointEngineering

A universal joint includes a first joint fork having a joint axis and a second joint fork having a joint axis, the joint axes being borne by plain bearings and the joint forks each being formed by a base part and two fork elements. Each fork element has a closable bore, and the joint axes intersect between the bores, whereby a bearing prestress unit allows the joint fork to function without play about the joint axis thereof so that the universal joint can be positioned precisely.

Owner:FAUDE DIETER

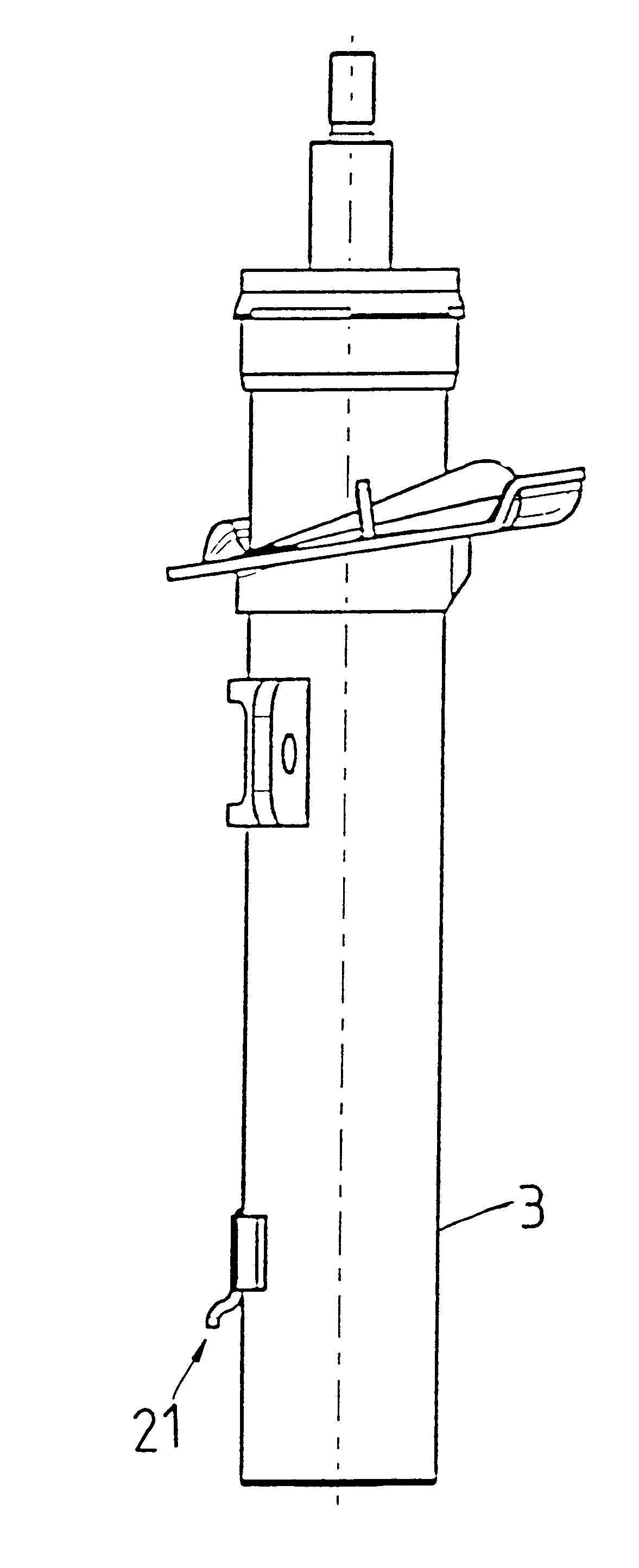

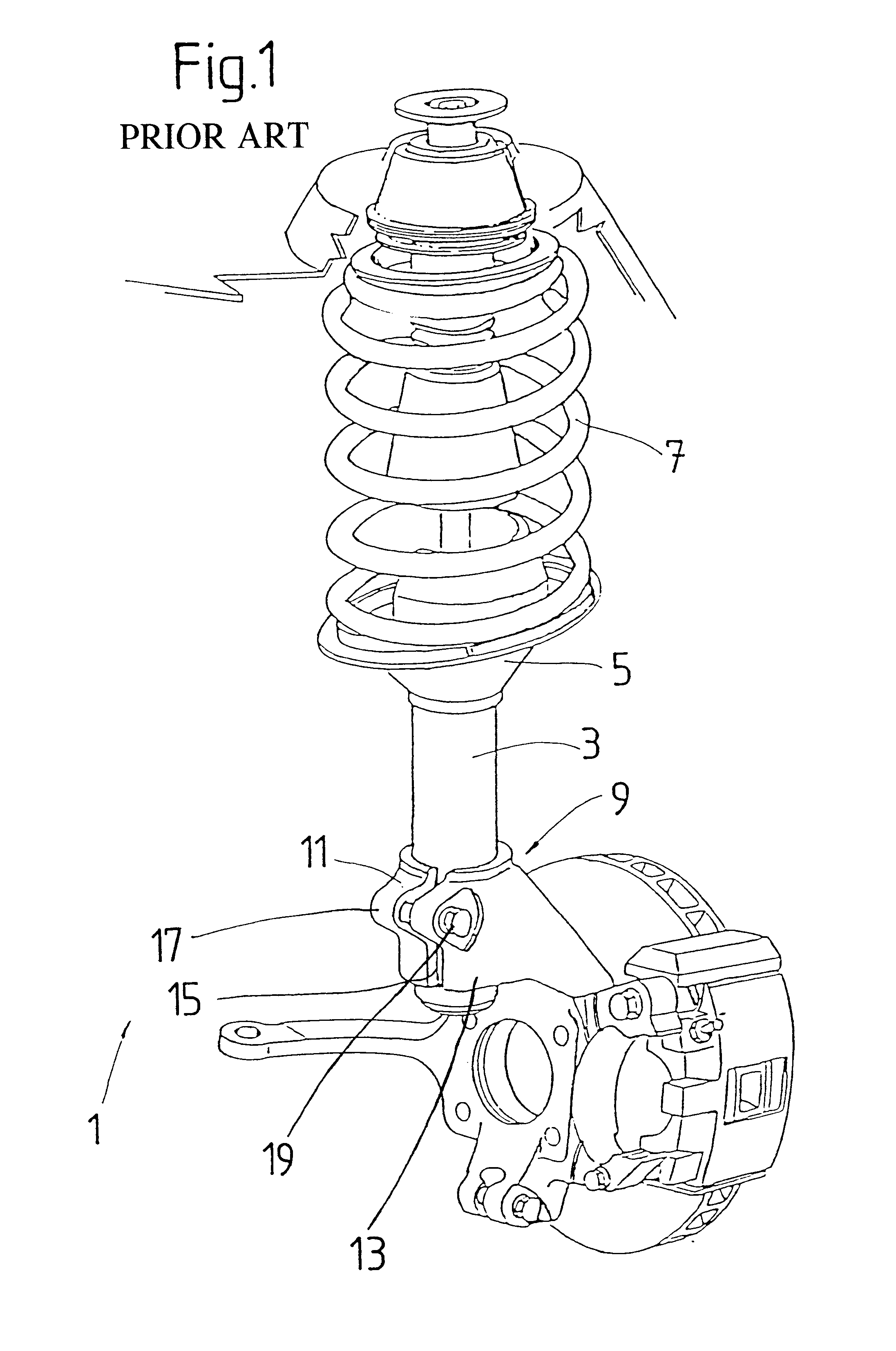

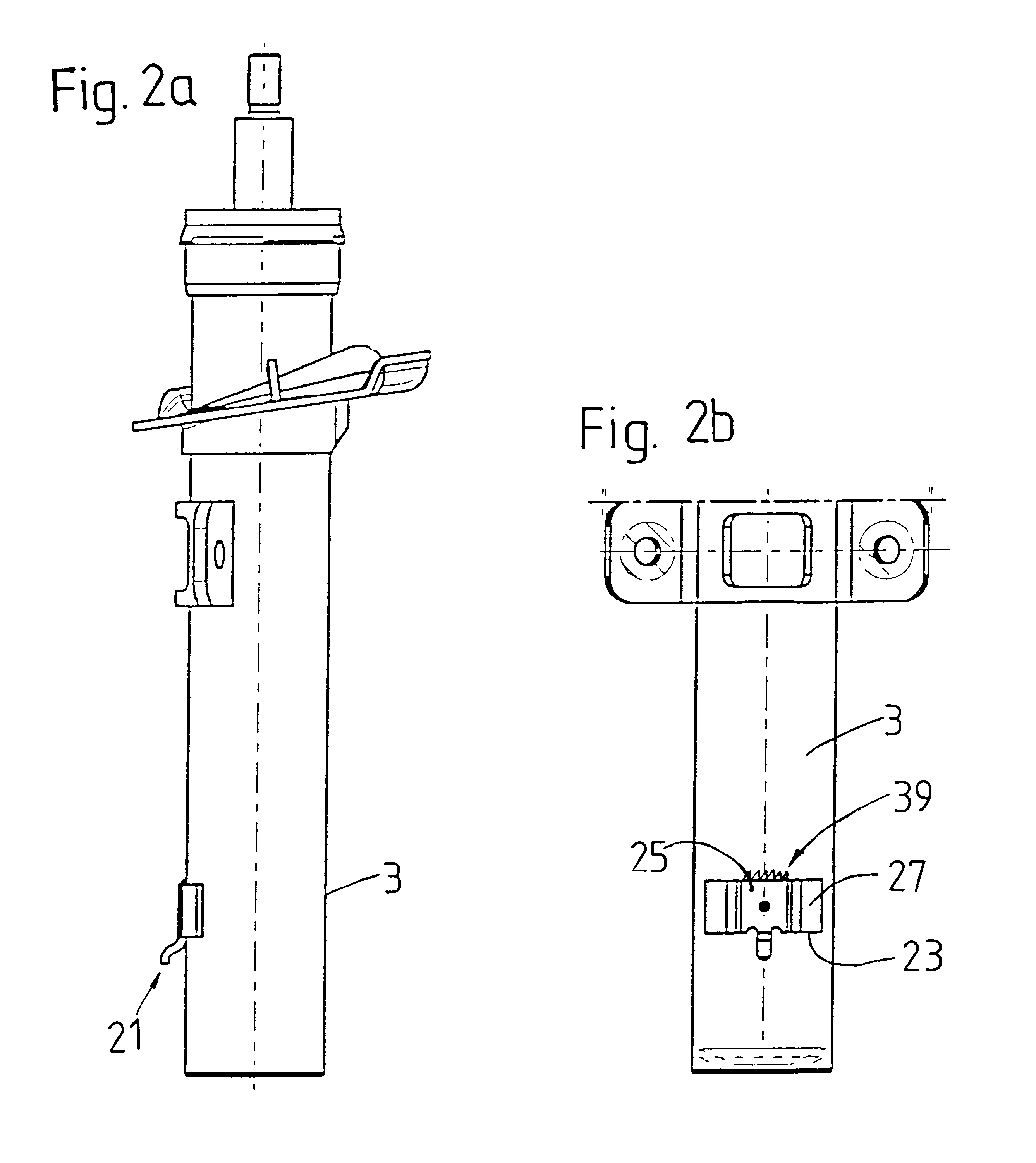

Shock absorber strut with steering knuckle

InactiveUS6343804B1Restraint torsionLarge bearing surfaceSteering linkagesResilient suspensionsEngineeringShock absorber

A shock absorber strut is provided including a tubular body, a clamping member, a steering knuckle, a fastening member and a positioning member. The tubular body is arranged at a lower region of the strut. The clamping member clamps the steering knuckle to the tubular body and includes a continuous slot along the steering knuckle and a fastening member which fastens the steering knuckle tubular body. The positioning member is a one piece component for positioning the clamping member with respect to the tubular body and includes a stop for positioning in the longitudinal direction and a projection for positioning in a circumferential direction. Optionally, a further positioning connection may be provided including a bead on the positioning member and a corresponding recess in the tubular body which engages the bead and allows the clamping member to be exactly aligned in the circumferential direction. Various welding processes performed on the positioning member and / or the positioning connection provide further strength and support to the strut.

Owner:ZF FRIEDRICHSHAFEN AG

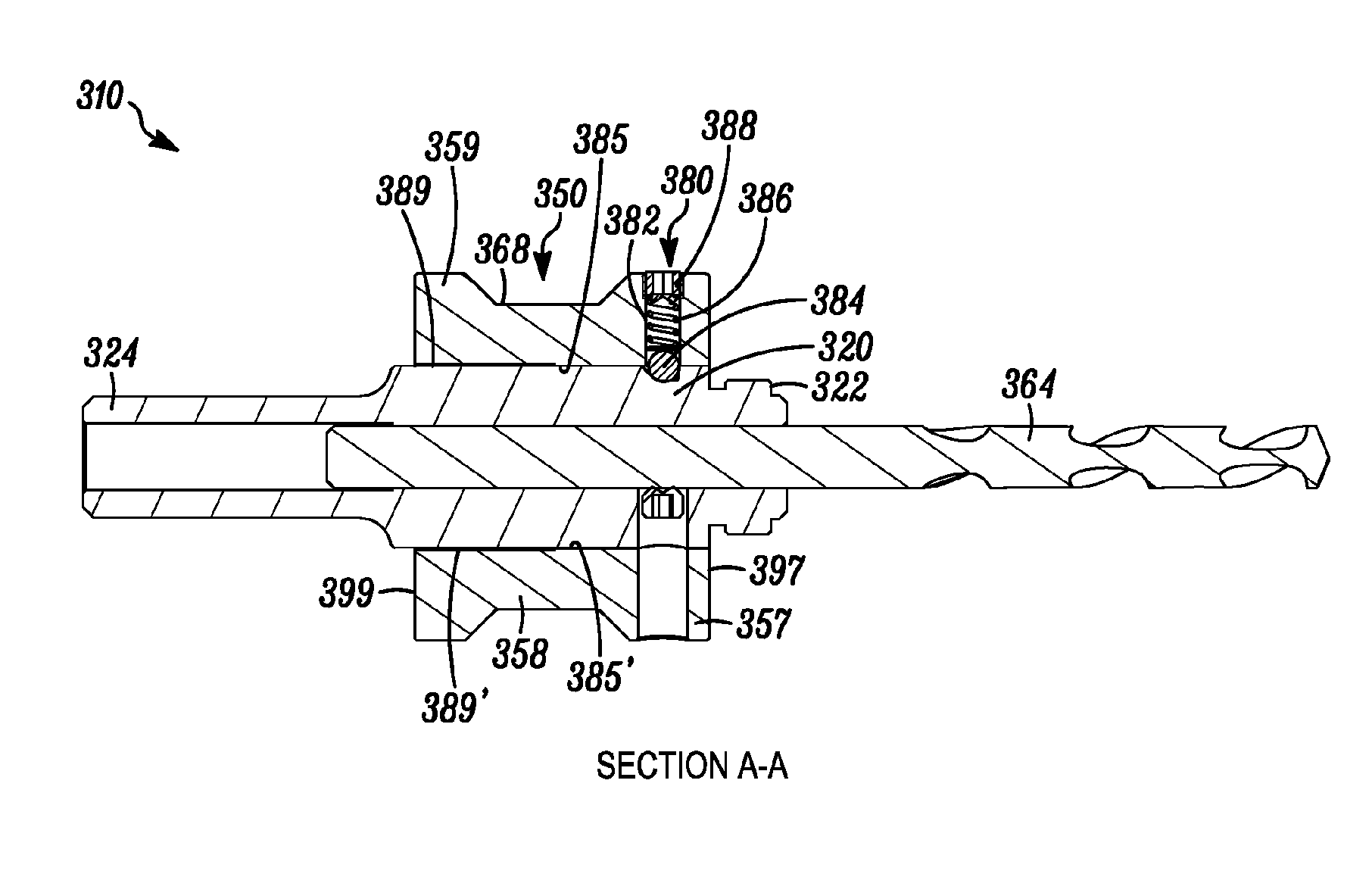

Quick change arbor, hole cutter, and method

ActiveUSRE46103E1Prevent rockingAvoid wobblingTransportation and packagingTrepanning drillsHole sawEngineering

An arbor for quick change and standard hole cutters, wherein each hole cutter includes a central aperture and at least one drive pin aperture. The arbor comprises an arbor body including an end portion engageable within the central aperture, a drive shank opposite the end portion for engaging a power tool, and an aperture for receiving a pilot bit. The arbor further comprises a drive pin plate and / or collar having at least one drive pin receivable in a corresponding drive pin aperture of the hole saw for drivingly engaging the hole saw. The arbor, in at least one embodiment, further comprises a pilot bit mechanism for engaging and releasing a quick change or standard pilot bit.

Owner:BLACK & DECKER INC

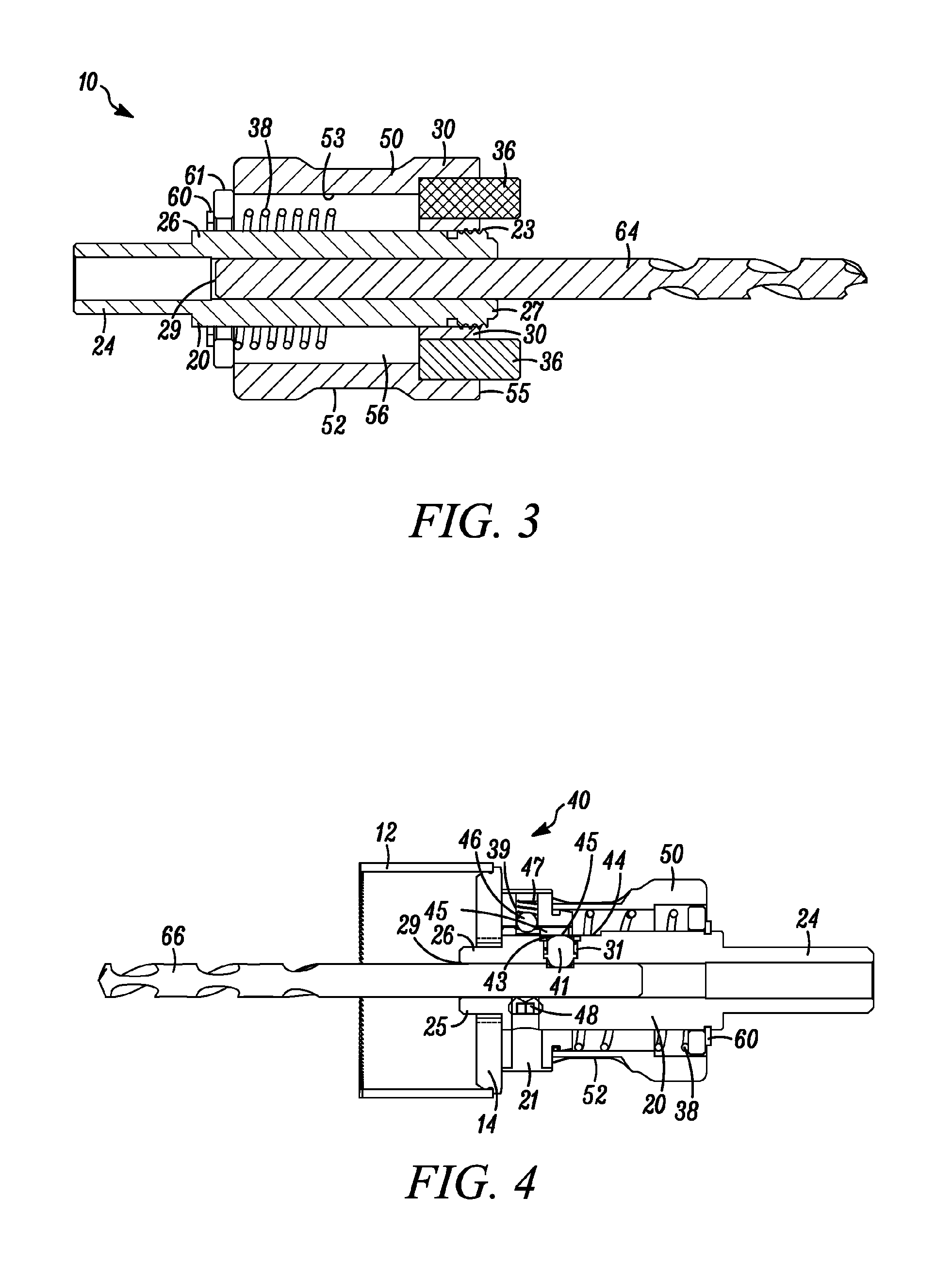

Quick change arbor, hole cutter, and method

InactiveCN101983114AEasy to moveAvoid vibrationTransportation and packagingTrepanning drillsHole sawMechanical engineering

An arbor for quick change and standard hole cutters, wherein each hole cutter includes a central aperture and at least one drive pin aperture. The arbor comprises an arbor body including an end portion engageable within the central aperture, a drive shank opposite the end portion for engaging a power tool, and an aperture for receiving a pilot bit. The arbor further comprises a drive pin plate and / or collar having at least one drive pin receivable in a corresponding drive pin aperture of the hole saw for drivingly engaging the hole saw. The arbor, in at least one embodiment, further comprises a pilot bit mechanism for engaging and releasing a quick change or standard pilot bit.

Owner:IR WIN IND TOOL

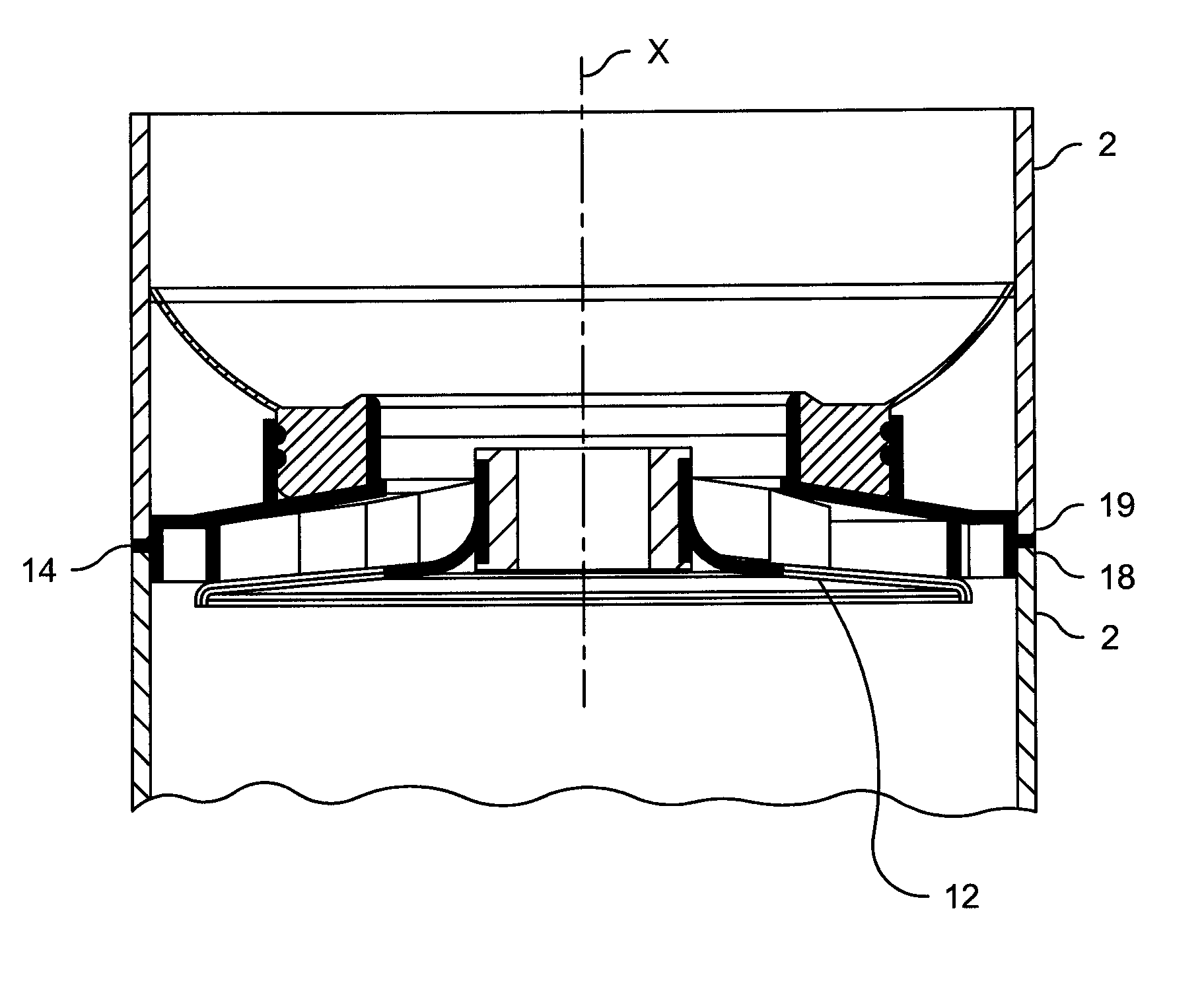

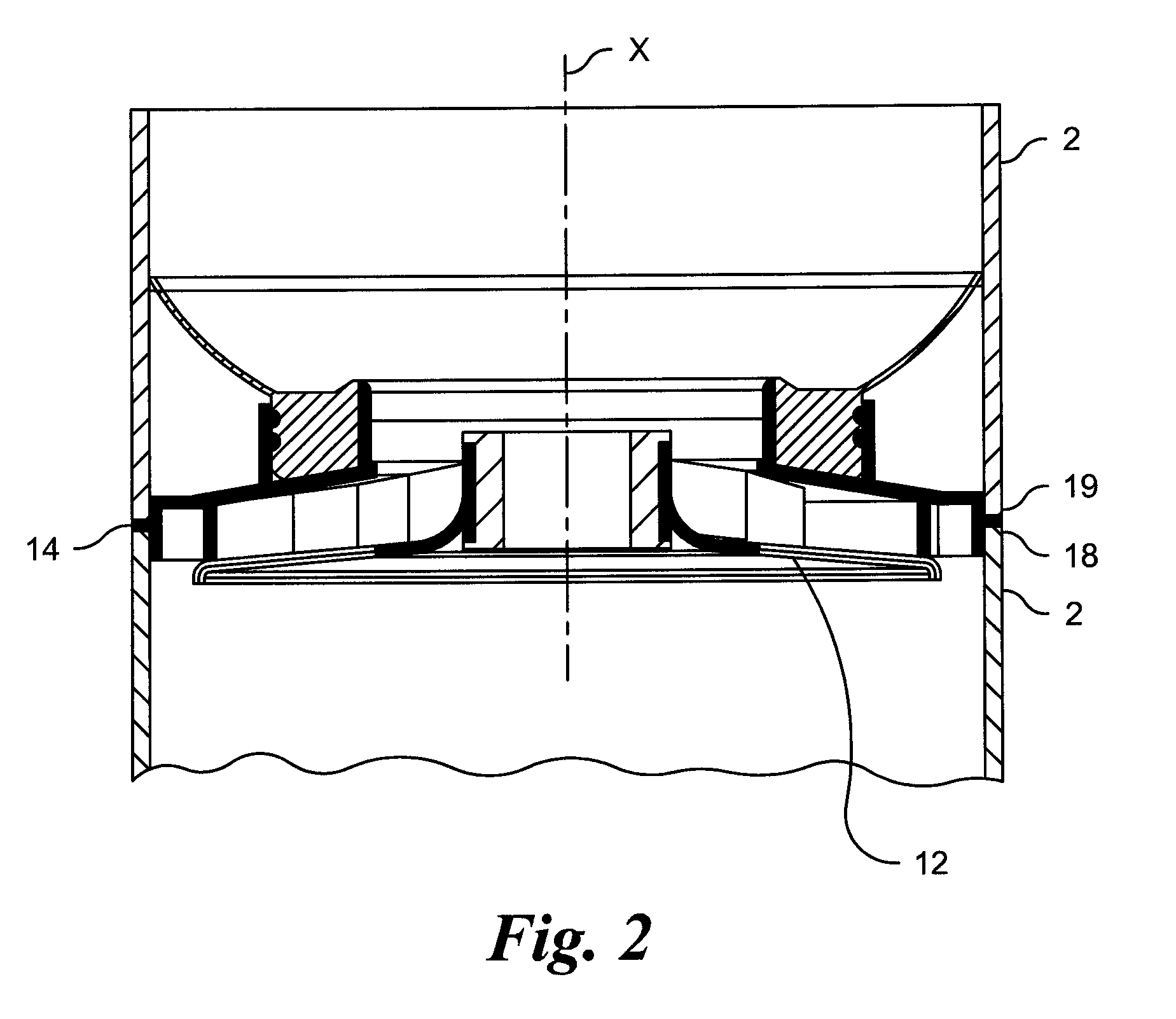

Pump unit

Owner:GRUNDFOS MANAGEMENT AS

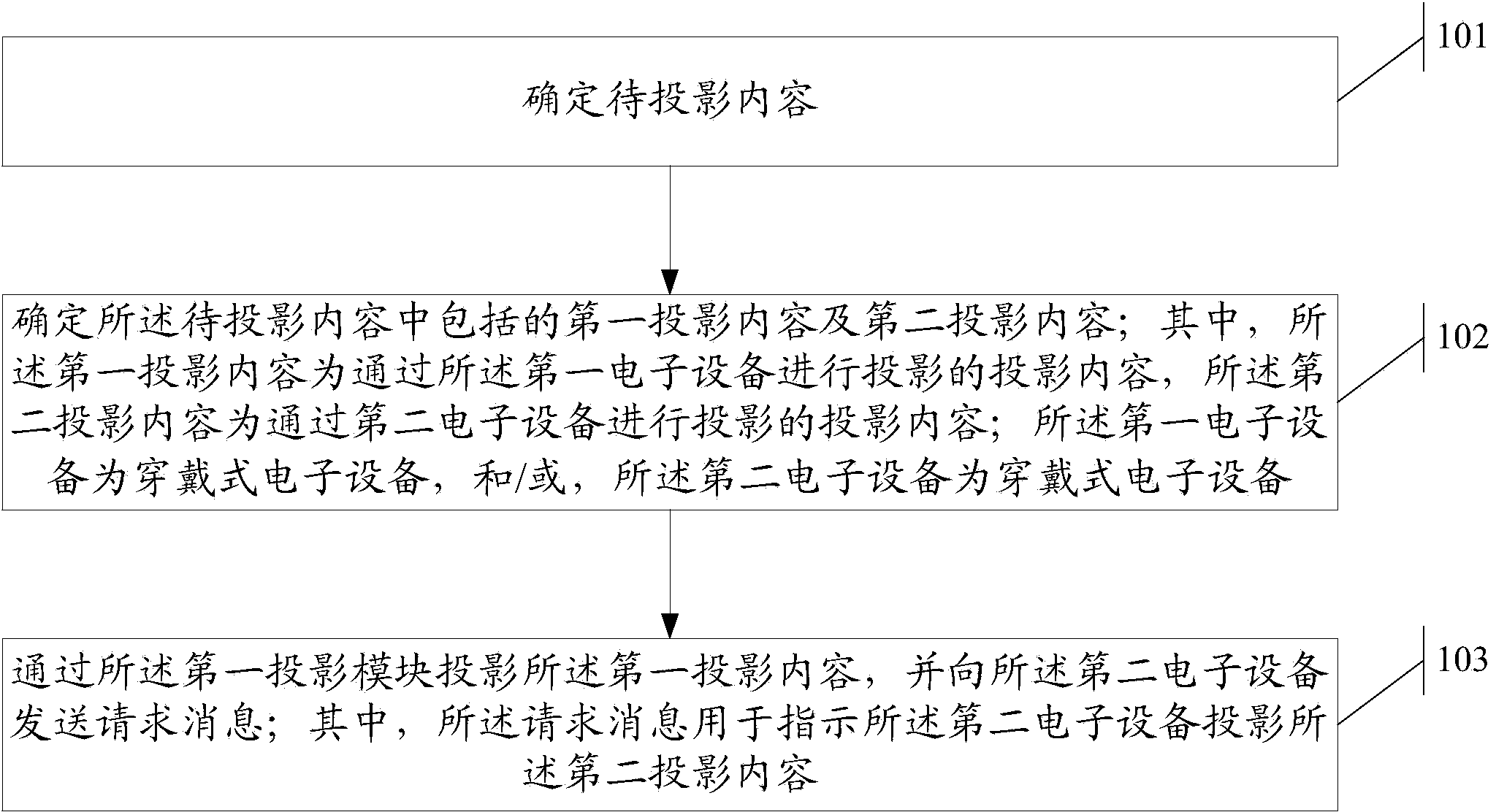

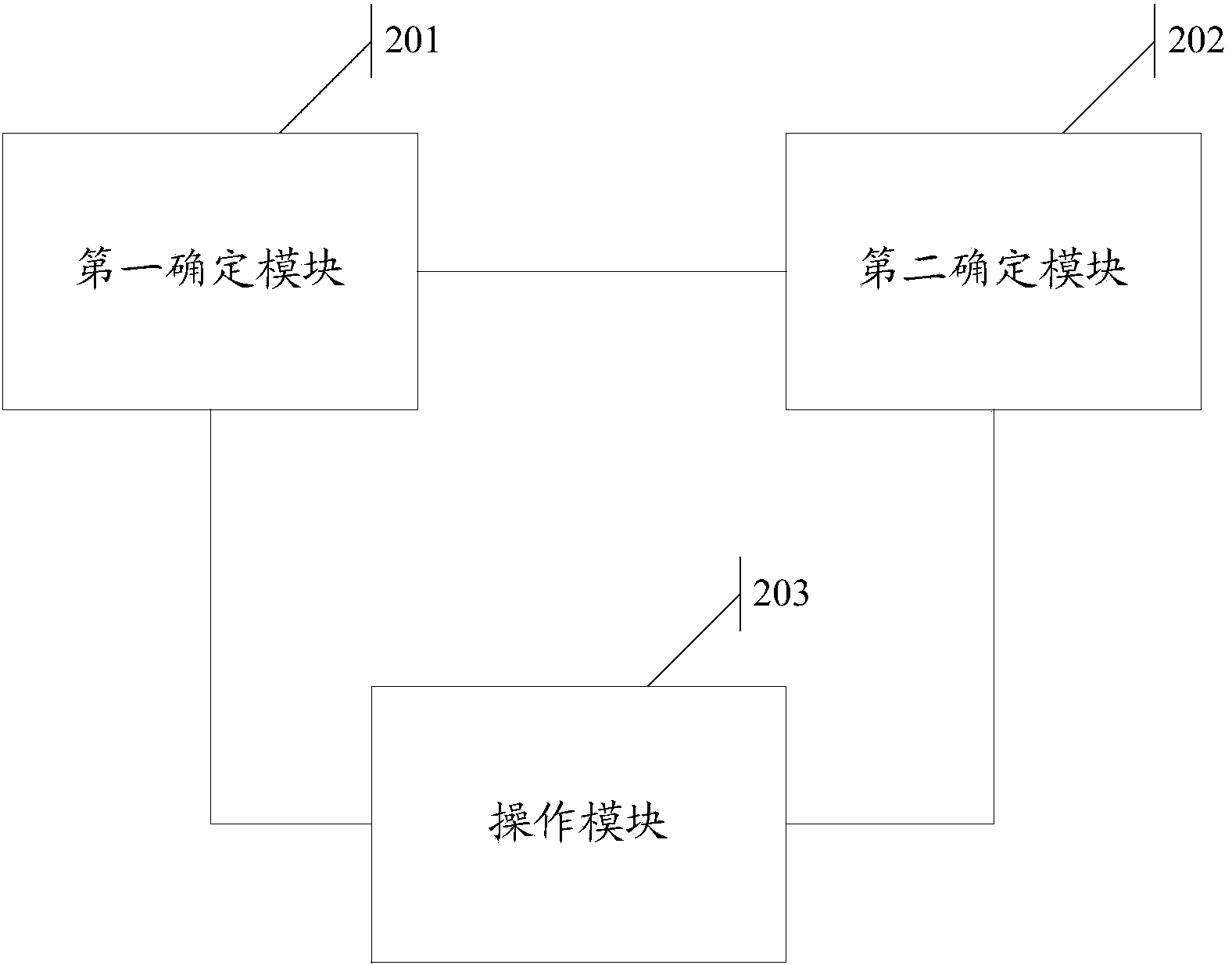

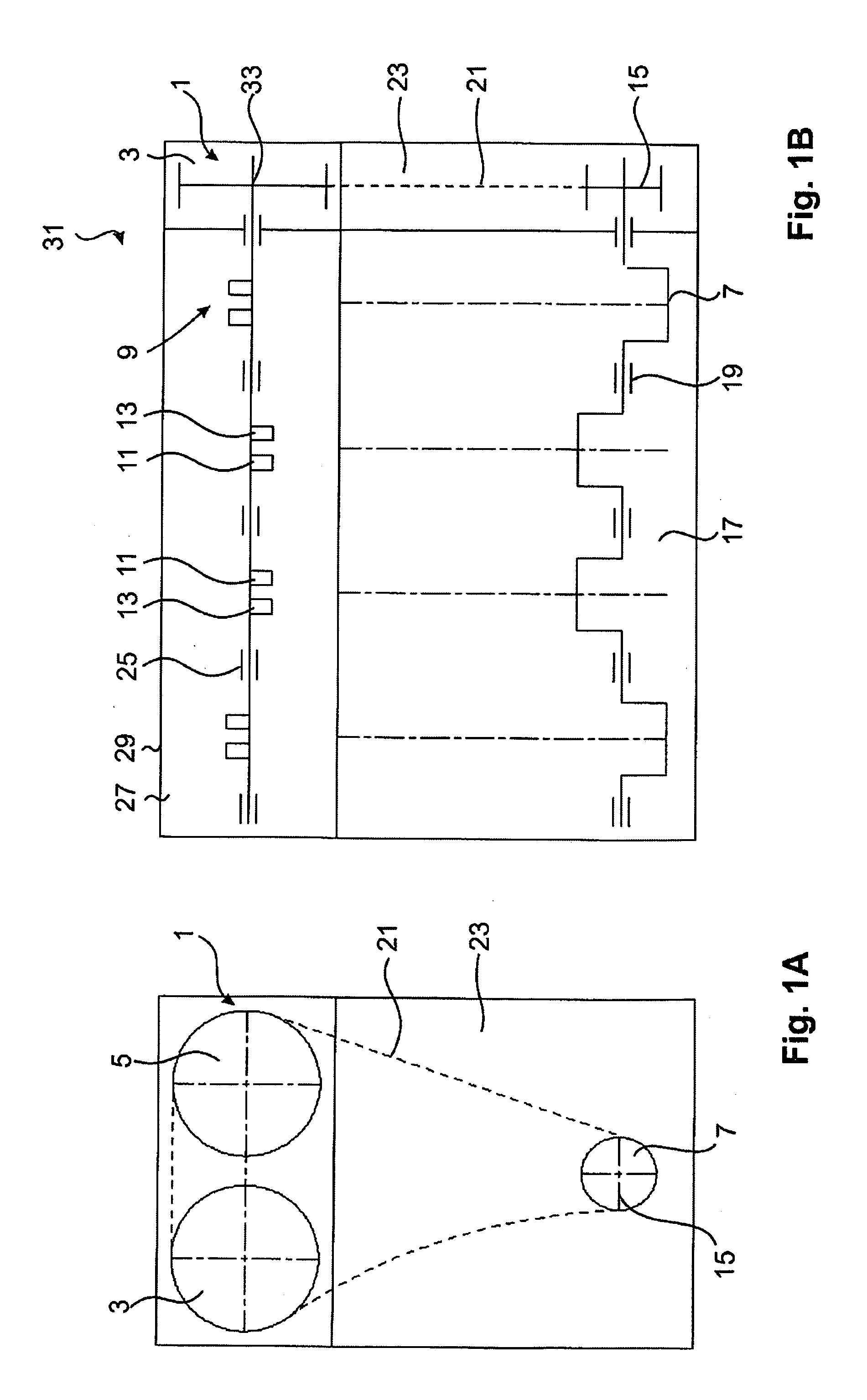

Projection method and electronic devices

ActiveCN104077101AEasy to useReduce the burden onTelevision system detailsColor television detailsWearable Electronic DeviceElectronic equipment

The invention discloses a projection method which is used for simplifying the projection operation process. The method comprises the steps of determining to-be-projected contents; determining first projection contents and second projection contents which are contained in the to-be-projected contents, wherein the first projection contents are projection contents projected through a first electronic device, the second projection contents are projection contents projected through a second electronic device, the first electronic device is a wearable electronic device, and / or the second electronic device is a wearable electronic device; projecting the first projection contents through a first projection module, and sending a request message to the second electronic device, wherein the request message is used for indicating the second electronic device to project the second projection contents. The invention further discloses the corresponding electronic devices.

Owner:LENOVO (BEIJING) CO LTD

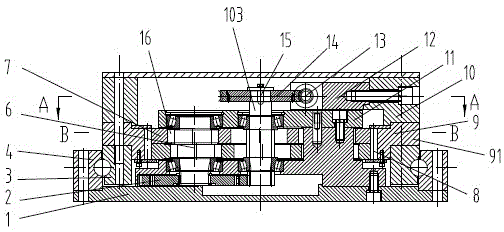

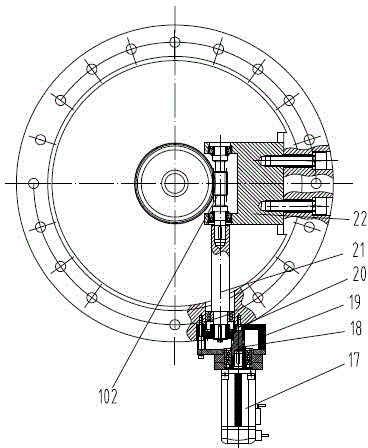

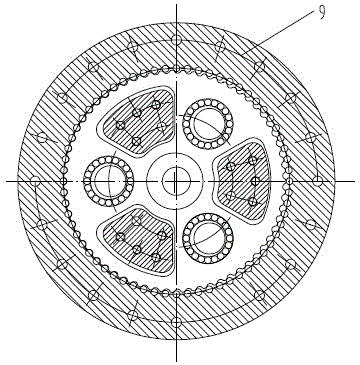

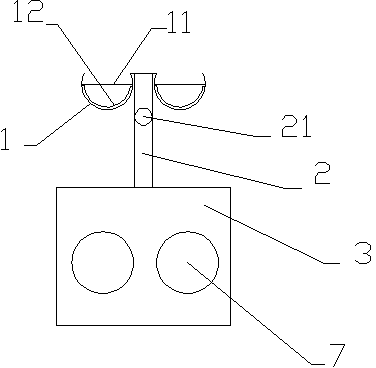

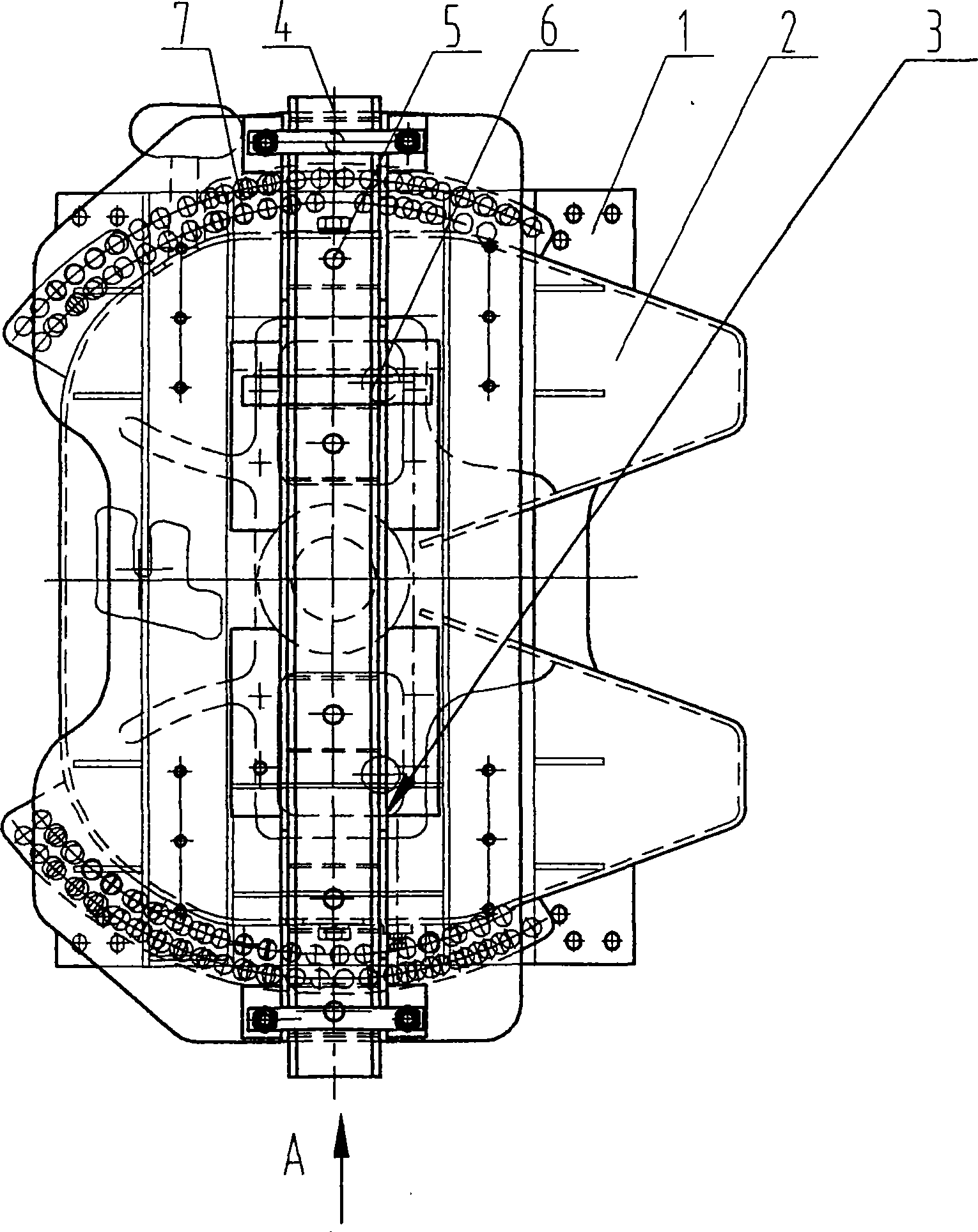

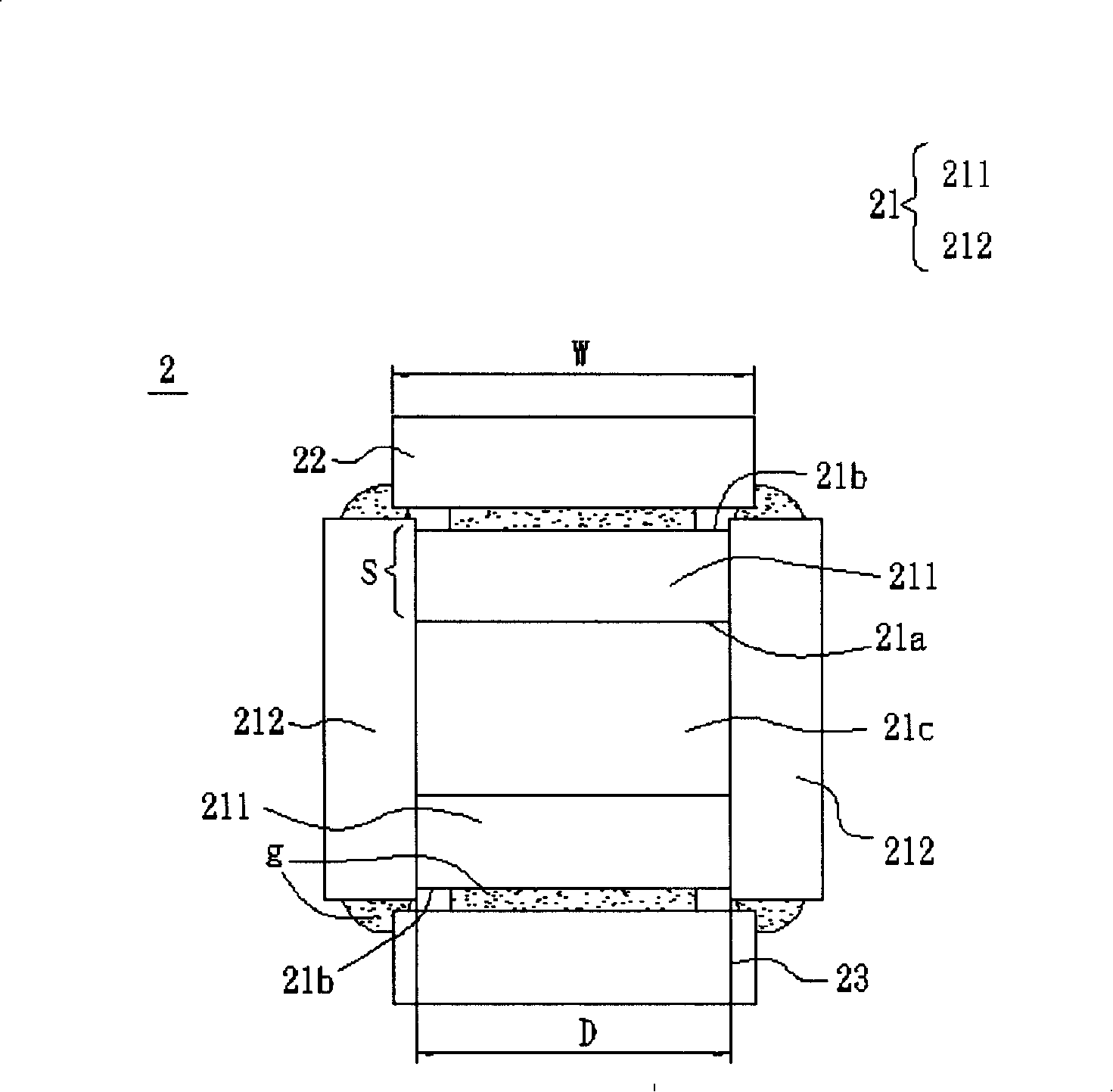

Precision rotational transmission mechanism

The invention discloses a precision rotational transmission mechanism, and aims to mainly solve the problems of complex structure, low transmission efficiency, small output shaft, insufficient rigidity, weak bearing capacity and impact resistance, short service life, inconvenience in mounting due to an overlong worm, high machining difficulty and high production cost of the existing positioning transmission mechanism. The precision rotational transmission mechanism comprises a rotation box which is arranged on a fixed rack, wherein a first transmission mechanism (namely a worm wheel and worm mechanism) is driven by a motor on the rotation box to drive a second transmission mechanism to work; the rotation box is driven by the second transmission mechanism to rotate by driving an output member and is provided with an output face which is connected with a load. The precision rotational transmission mechanism has the characteristics of compact and practical structure, simple structure, large bearing surface of the output shaft, light overall weight, suitability for industrial production, high anti-impact capacity and long service life; besides since a worm connecting shaft is additionally arranged in the first transmission mechanism, the overall length of the worm is shortened, the mounting and the machining are facilitated, and the production cost is reduced.

Owner:ZHEJIANG HENGFENGTAI REDUCER MFG

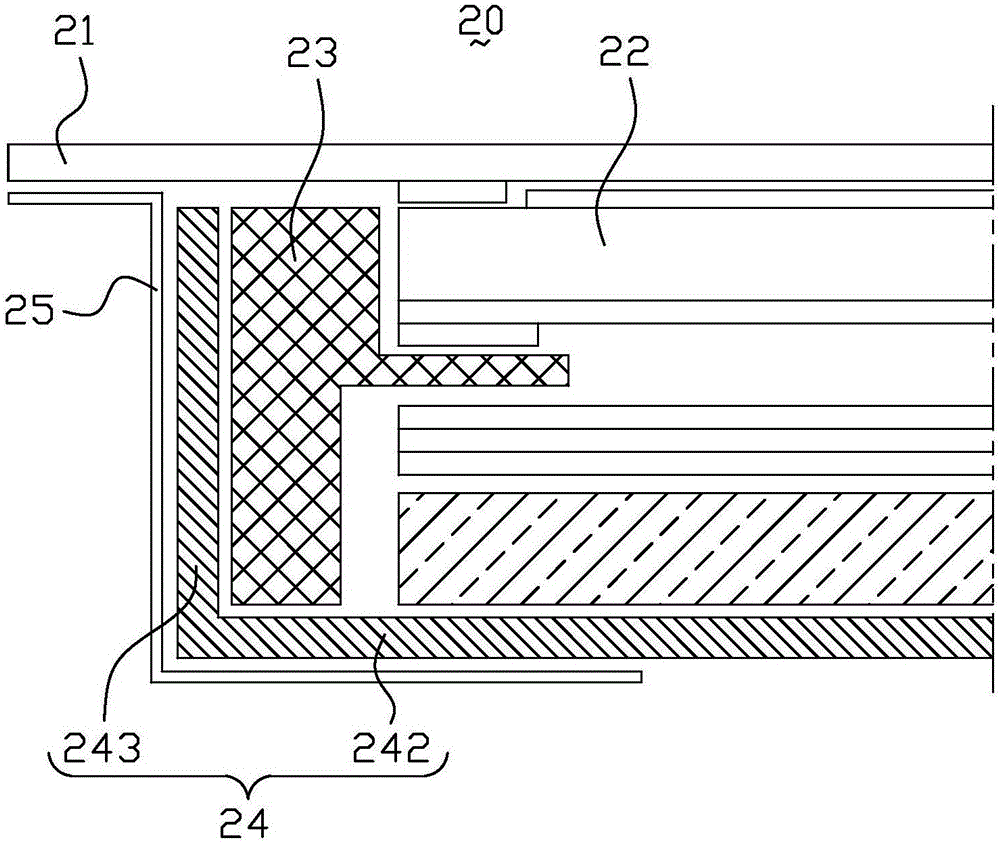

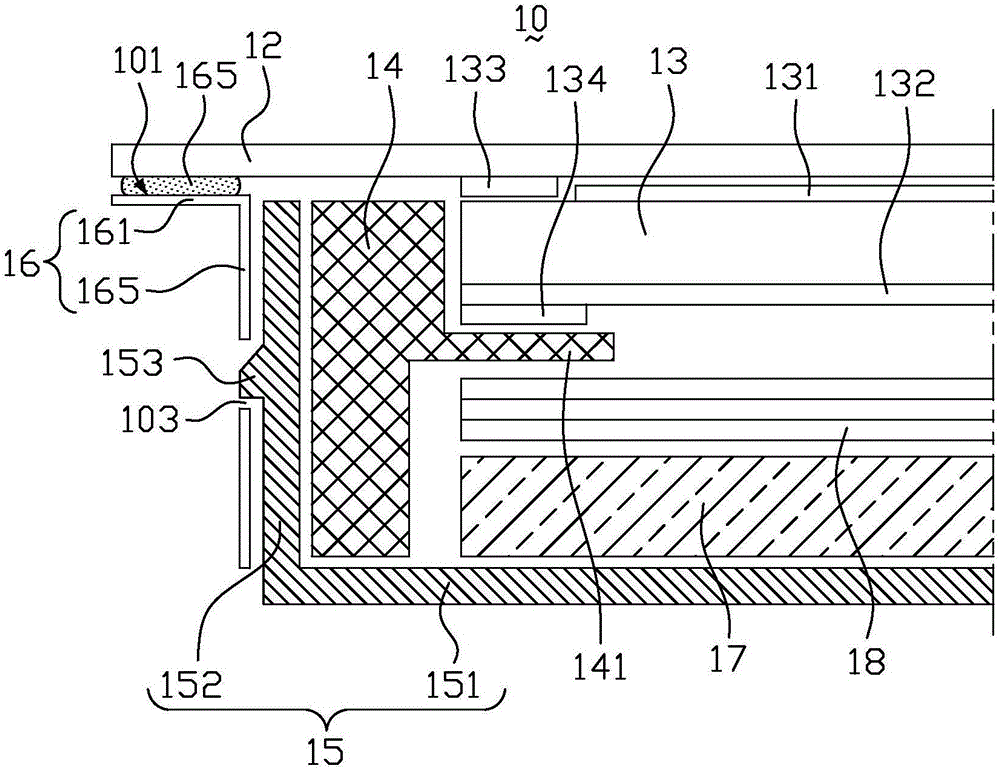

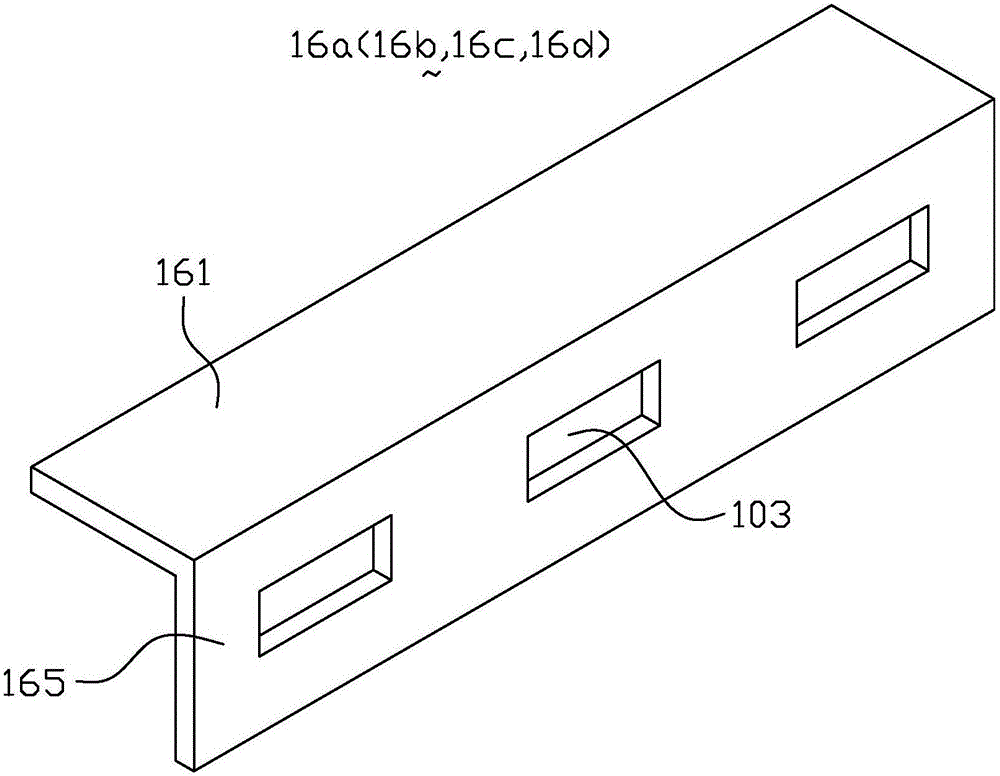

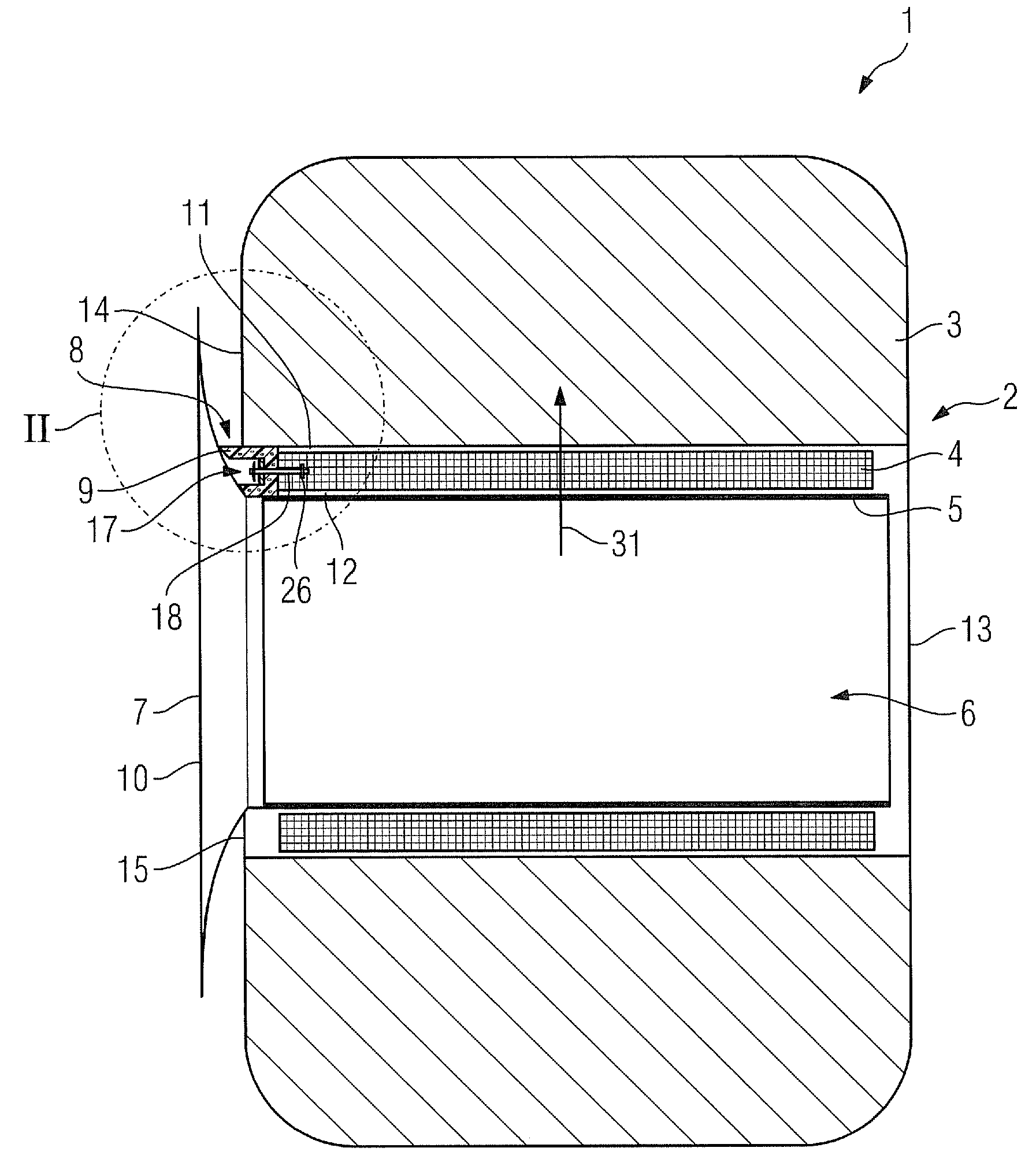

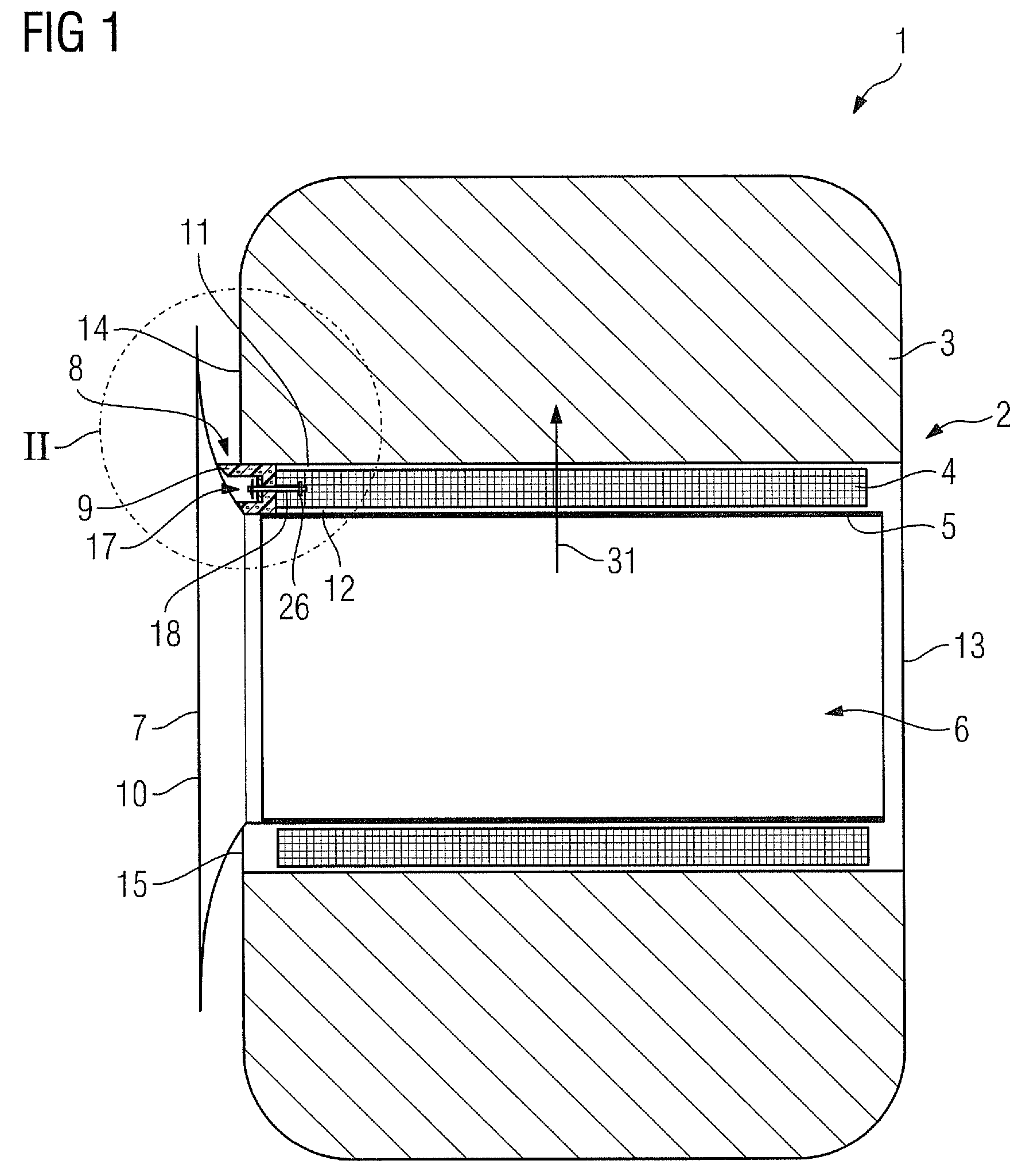

Liquid crystal displayer and display device

InactiveCN106168718AAvoid peelingDoes not affect appearanceNon-linear opticsLiquid-crystal displayAgricultural engineering

The invention relates to the technical field of liquid crystal display and discloses a liquid crystal displayer and a display device with the liquid crystal displayer in the embodiment. The liquid crystal displayer comprises a cover plate, a display panel, a glue frame, a back plate and a bearing frame. The cover plate is connected to the display panel. The display panel is adjustably arranged on the glue frame. The glue frame is arranged on the back plate. The bearing frame is connected to the back plate and provided with a bearing face. The area, away from the display panel, of the cover plate is connected to the bearing face of the bearing frame through glue. According to the liquid crystal displayer and the display device, the display panel can be adjusted within small displacement, the assembling efficiency of the display panel is improved, the cover plate of the liquid crystal displayer is prevented from being disengaged due to the fact that the bearing frame is provided with the large bearing face, meanwhile, the bearing frame is not deformed in the installation process, and the appearance of the liquid crystal displayer is not affected.

Owner:KUSN INFOVISION OPTOELECTRONICS

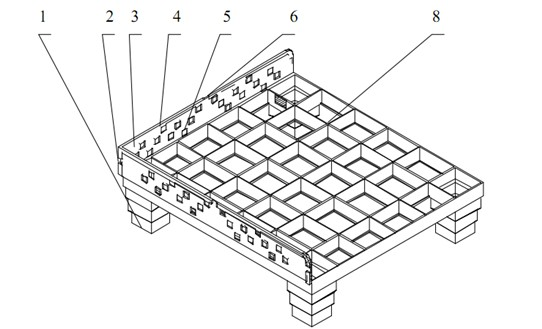

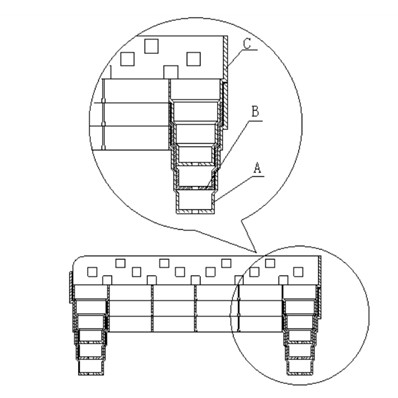

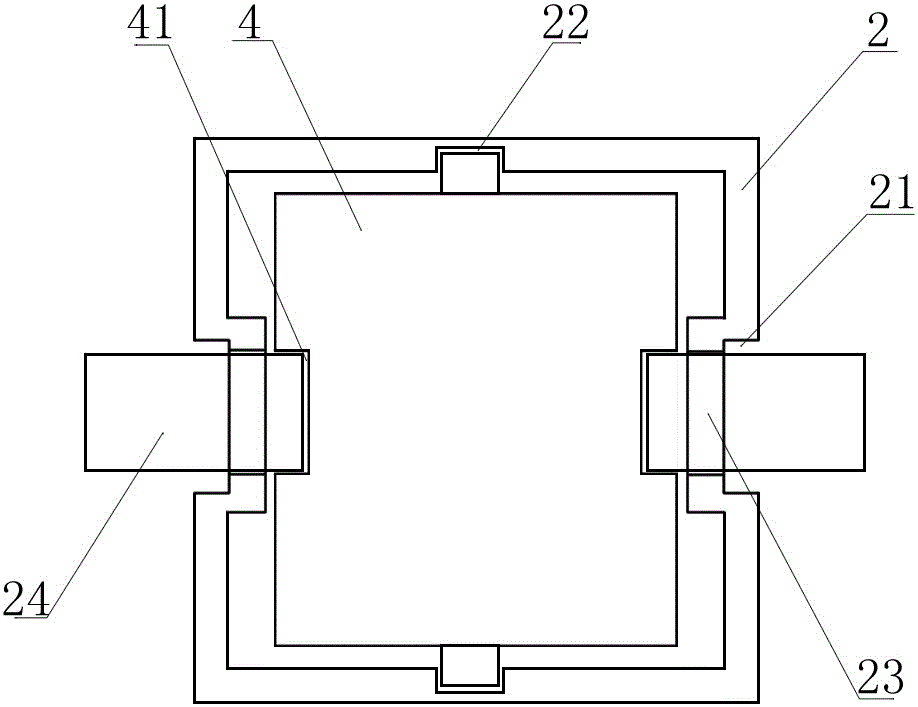

Bearing corner bracket, bearing seat frame, combined bearing corner bracket and combined bearing corner seat frame

The invention discloses a bearing corner bracket, which comprises a square corner bracket grid platform, wherein shell-type corner bracket piers are respectively arranged at four corners on the bottom part of the square corner bracket grid platform; shell-type corner bracket piers are tapered; a corner bracket bead is arranged on any one of the corners on the upper part of the square corner bracket grid platform; and the minimal distance from the inner wall of the shell-type corner bracket pier adjacent to the corner bracket bead to the inner side of the corner bracket bead is no smaller than the minimal distance from the outer wall of the shell-type corner bracket pier to the outer side of the square corner bracket grid platform. A bearing seat frame comprises a corner bracket base and a bearing corner bracket. A combined bearing corner bracket comprises four bearing corner brackets arranged two by two, and the corner bracket beads on the four bearing corner brackets are positioned on the periphery of a bearing base formed by combining four bearing corner brackets. A combined bearing seat frame consists of a corner bracket base and four bearing corner brackets, wherein the four bearing corner brackets are arranged two by two; and the corner bracket beads on the four bearing corner brackets are positioned on the periphery of the bearing seat formed by combining the four bearing corner brackets.

Owner:NANJING HANQING BAMBOO PALLETAB

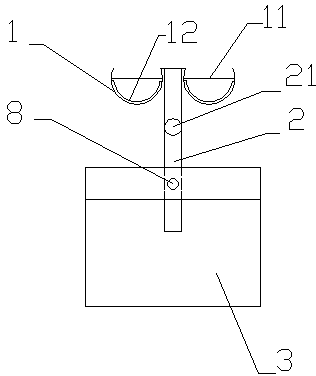

Respirator tube fixing frame used for sickbed

InactiveCN103800153ALarge bearing surfaceAvoid displacementRespiratorsNursing bedsRespiratorJackscrew

A respirator tube fixing frame used for a sickbed comprises a base and a cambered surface bracket with a supporting column. The base is composed of a first component and a second component, the first component and the second component are connected through a spring clamping lock to form a clamping part with the width adjustable, and the clamping part is clamped and fixed to the sickbed through a first jackscrew. The cambered surface bracket used for bearing a respirator tube is inserted in a hole formed in the base through the supporting column and fixed through a second jackscrew. The supporting column is divided into an upper part and a lower part which are connected through a rotary connecting device. Compared with a cantilever fixing mode of a respirator, the respirator tube can be effectively supported and fixed, the respirator tube fixing frame has good stability and can effectively avoid the phenomenon of shift of the respirator tube caused by vibration of the respirator and action of external force, the position of the respirator tube can be adjusted easily and conveniently, time and labor are saved, moreover, the respirator tube fixing frame is small in size and occupied space and favorable for operation of medical workers, and the working efficiency of the medical workers is improved.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

Nozzle clamping nut for injection valves and method for producing said nozzle clamping nut

InactiveUS7475829B2Large bearing surfaceLow stress levelWatering devicesSpray nozzlesStress concentrationEngineering

Owner:CONTINENTAL AUTOMOTIVE GMBH

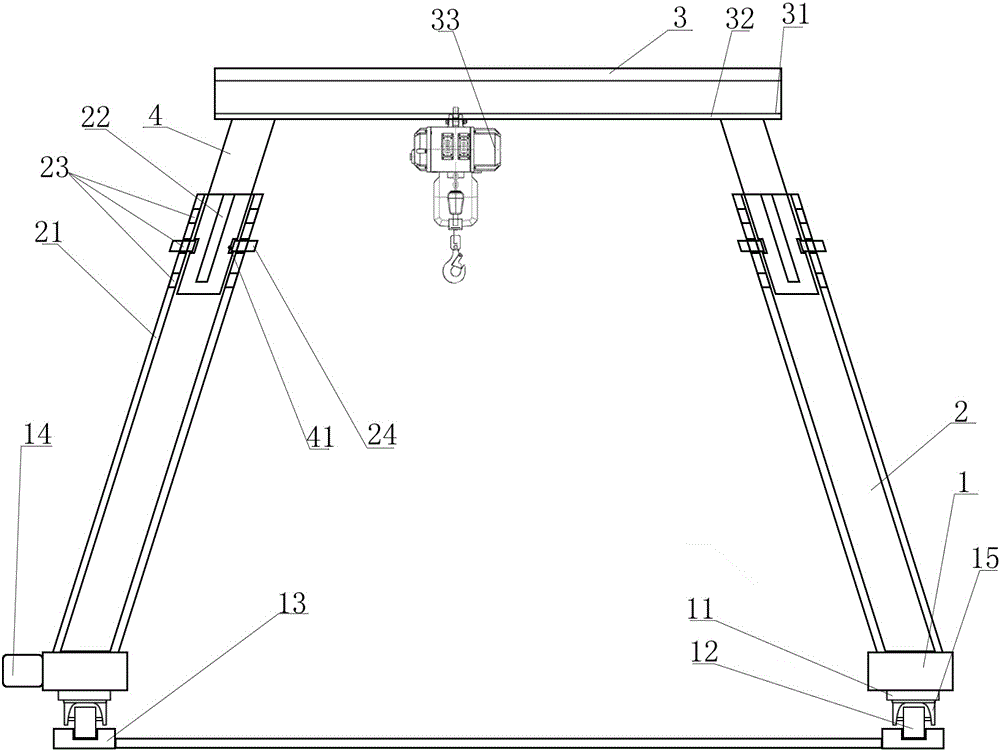

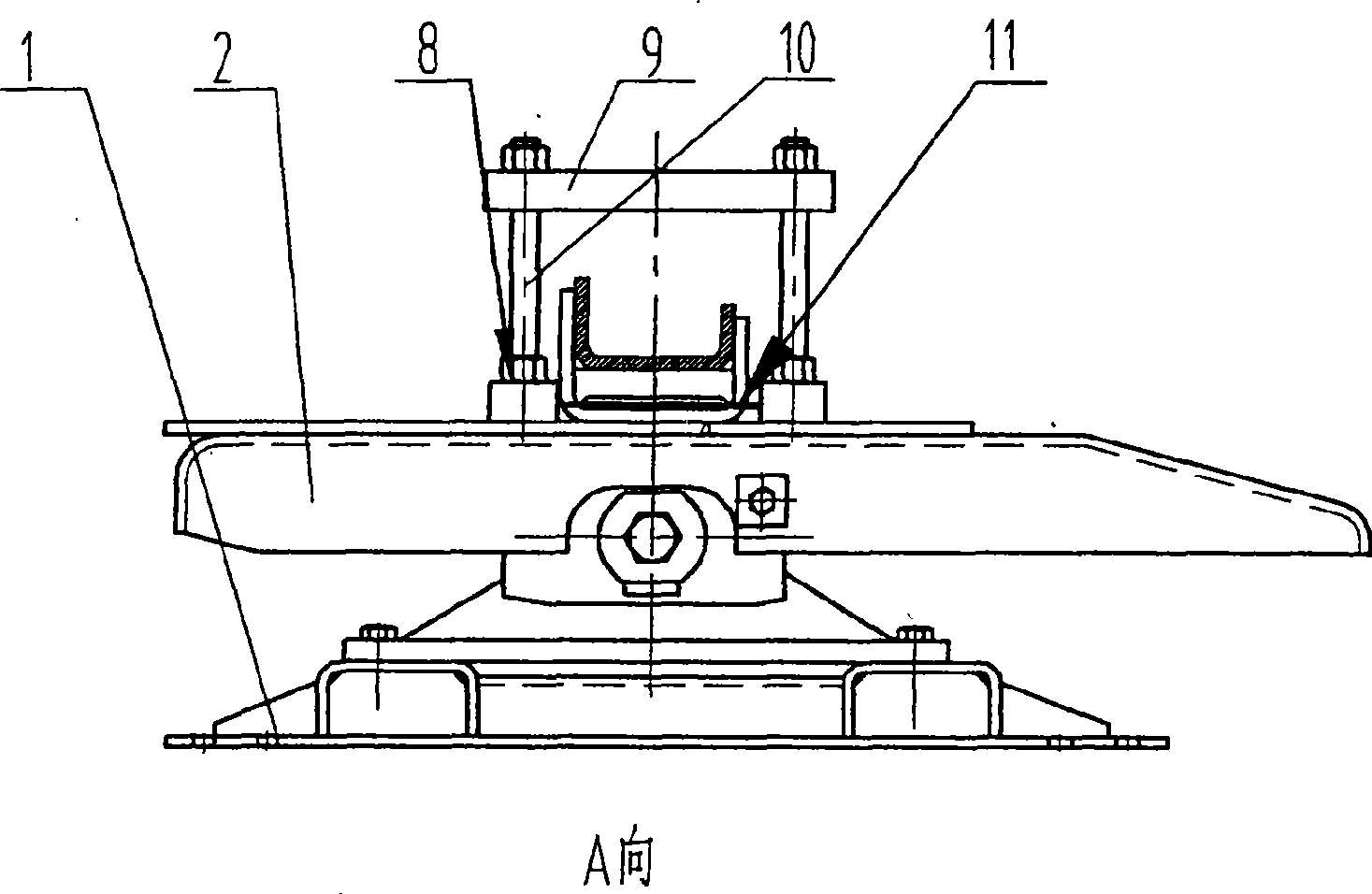

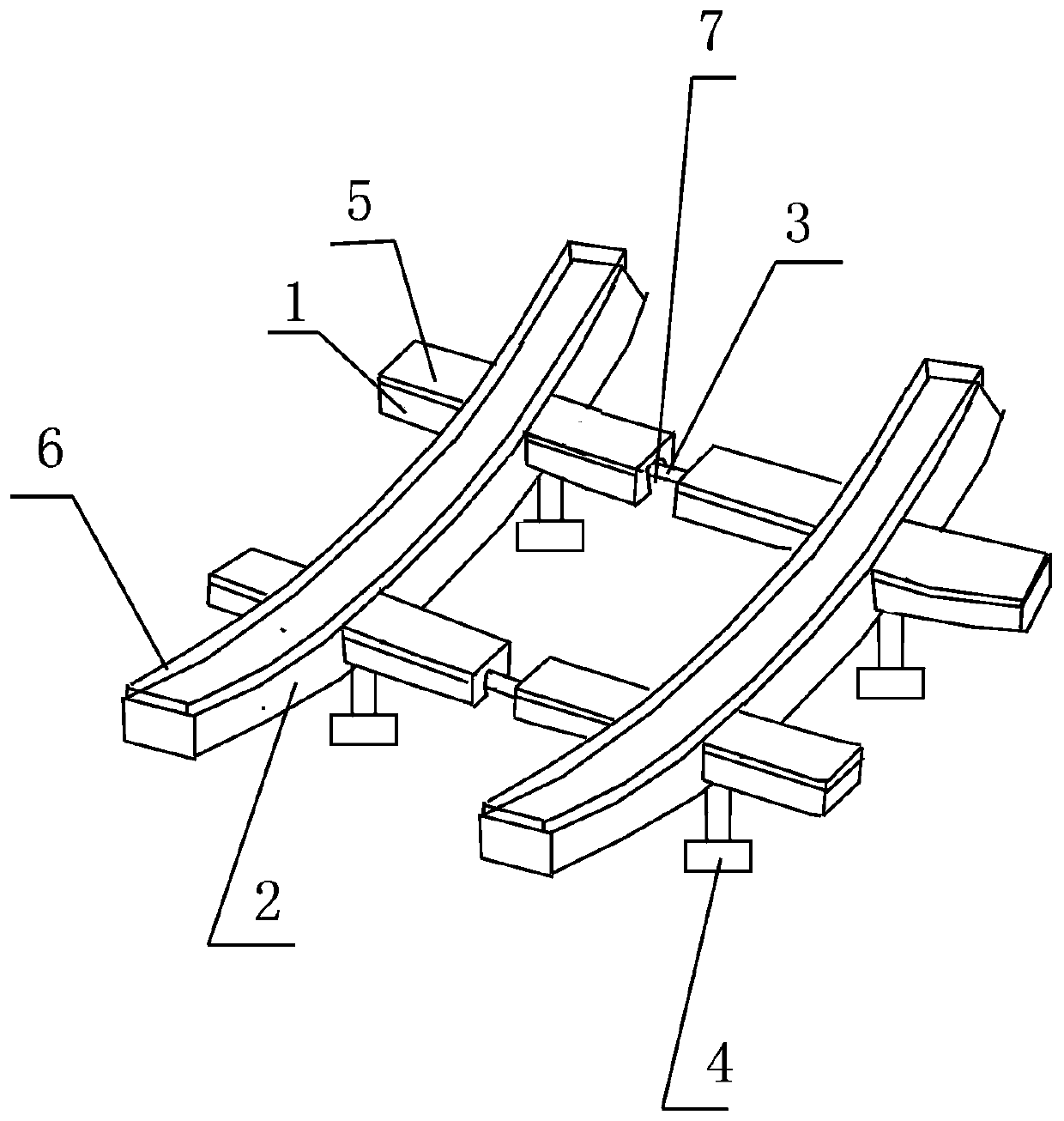

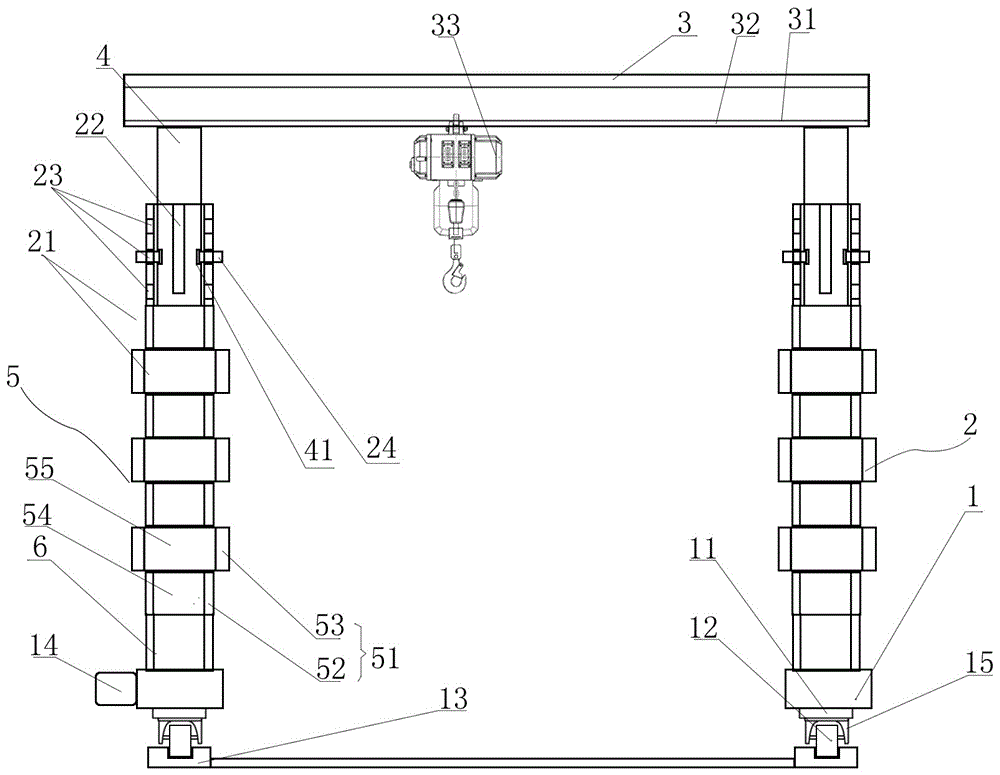

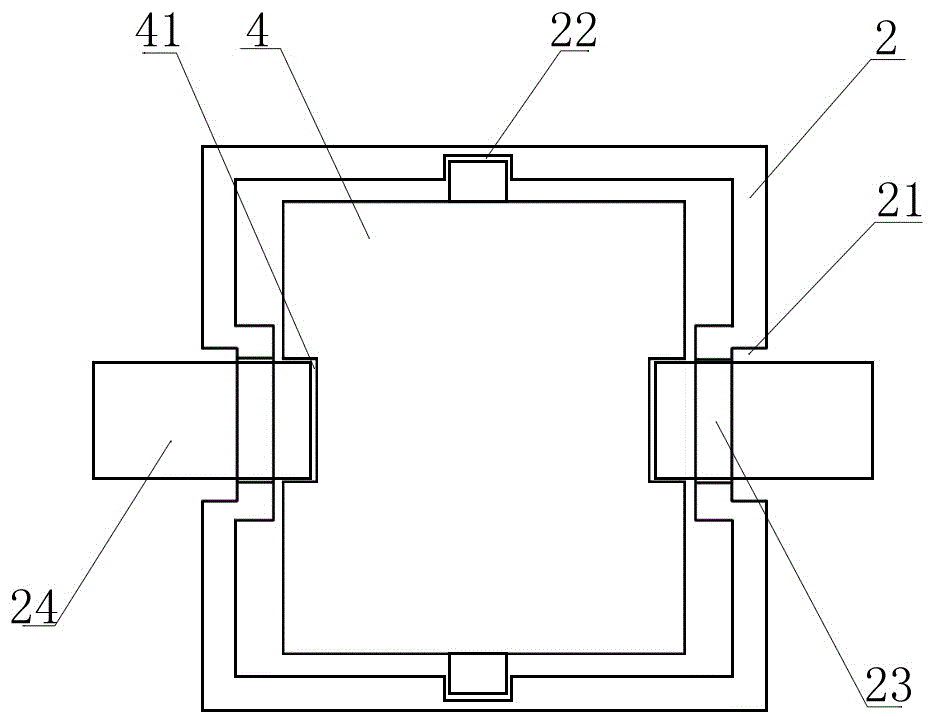

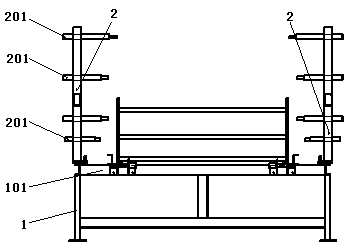

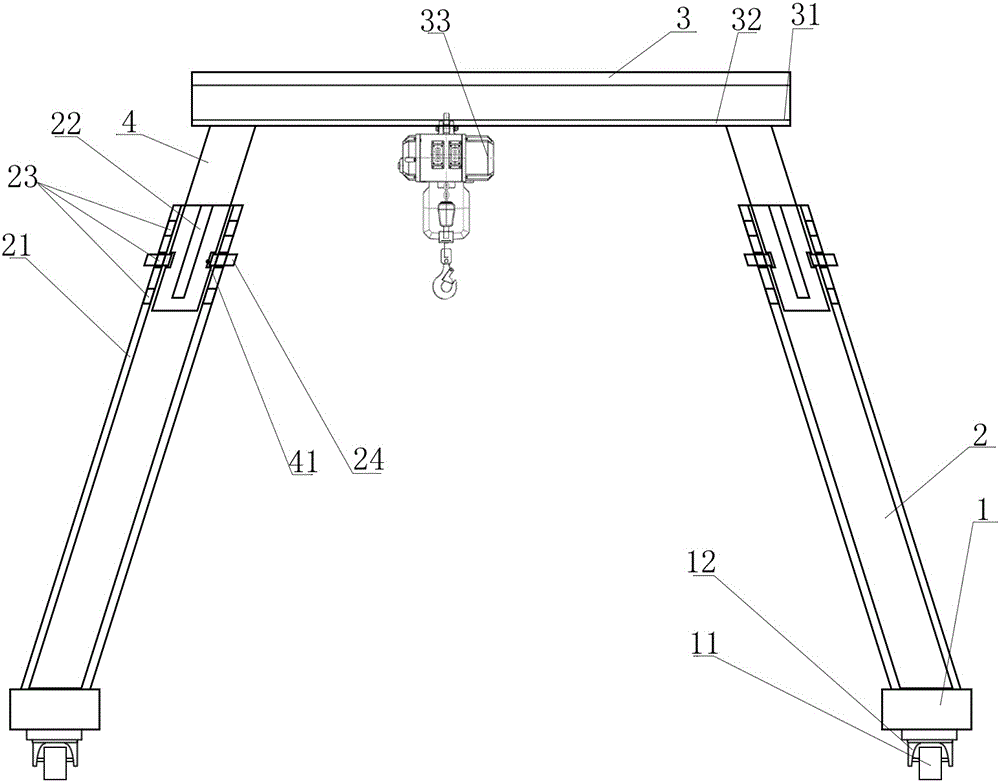

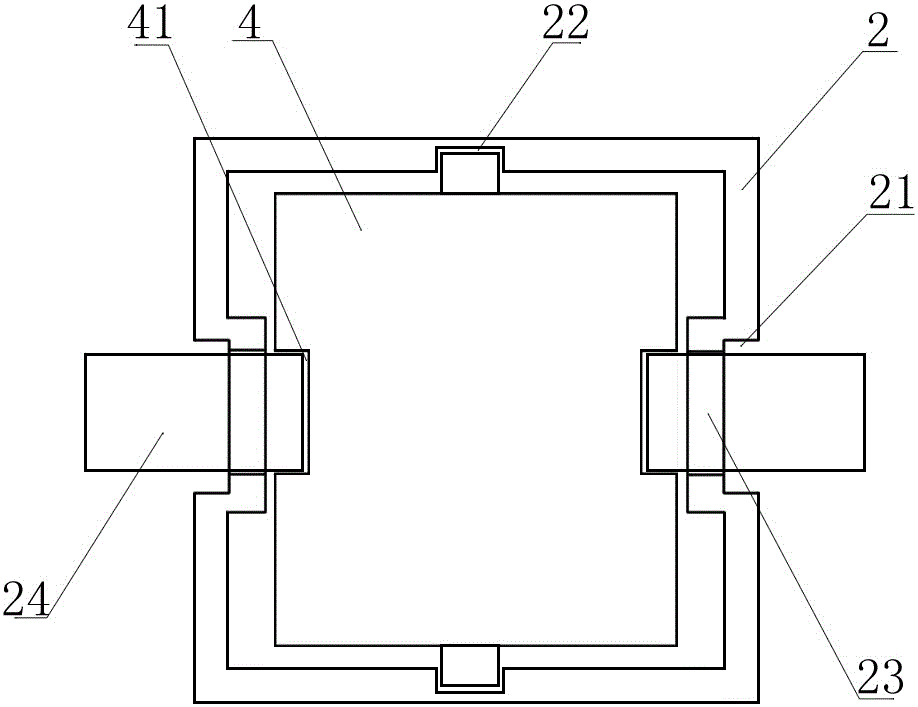

Oblique-post type rail-mounted gallows frame

InactiveCN105035967ASave materialReduce weightBase supporting structuresBraking devices for hoisting equipmentsGallowsEngineering

The invention discloses an oblique-post type rail-mounted gallows frame. The oblique-post type rail-mounted gallows frame comprises two bases arranged in parallel and supporting posts arranged on the bases. A hanging beam is horizontally arranged above the supporting posts. The oblique-post type rail-mounted gallows frame is characterized in that the supporting posts are hollow, the two sides of each supporting post are each provided with a first groove inwards, and each supporting post is arranged in a vertically through mide; two corresponding side faces in each supporting post are each vertically provided with a sliding groove, each sliding groove and the corresponding first groove are located in two adjacent sides, and square pipes capable of moving along with the sliding grooves are connected to the sliding grooves; the upper side faces of every two first grooves are each horizontally provided with a plurality of limiting holes located at equal intervals, the two sides of each square pipe are each provided with a limiting groove, a limiting rod is arranged in one limiting hole in the upper side face of each first groove, and the square pipes are welded to the hanging beam; the two supporting posts are obliquely arranged on the bases, the lower portion of each base extends to form a pair of fixing parts, a directional wheel is arranged between every two fixing parts, and a matched rail is arranged under each directional wheel. The oblique-post type rail-mounted gallows frame has the advantages of being simple in structure, long in service life, capable of being used for transporting large articles conveniently and efficiently and the like.

Owner:SUZHOU SUTENG ELECTRONICS TECH

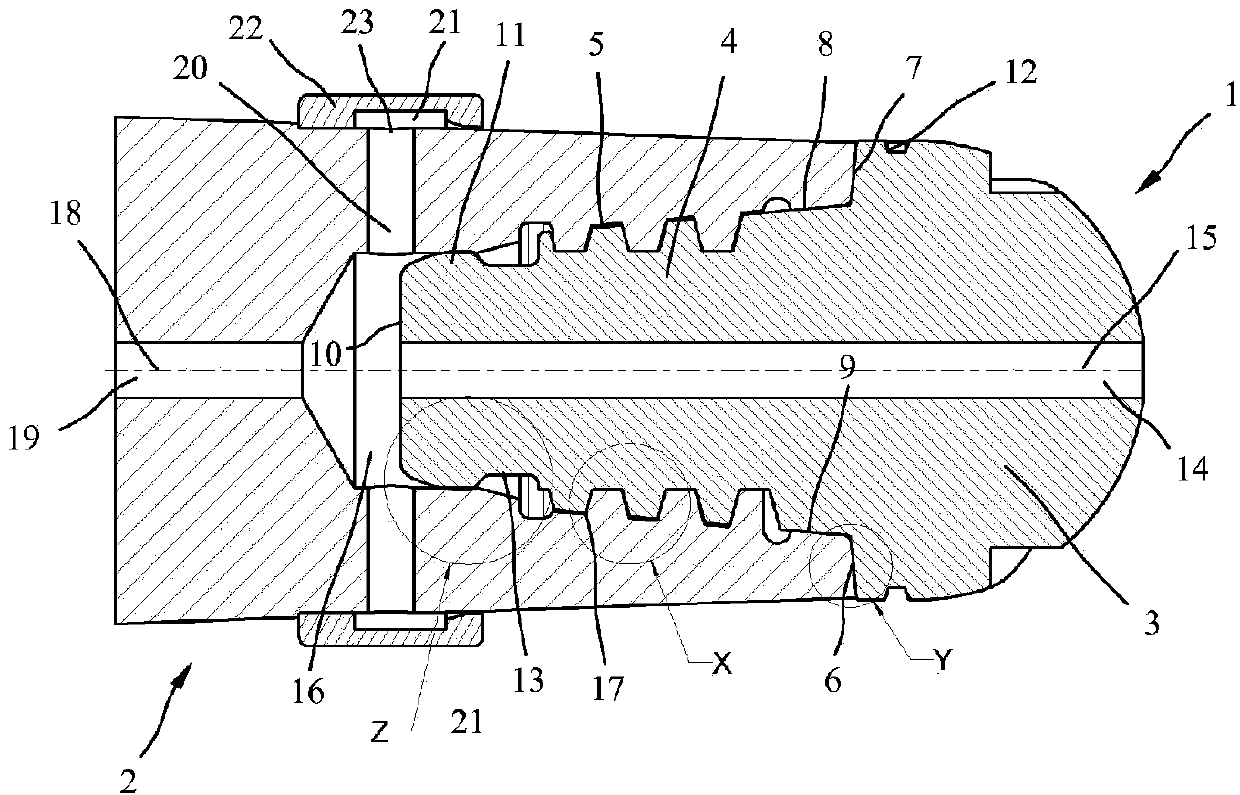

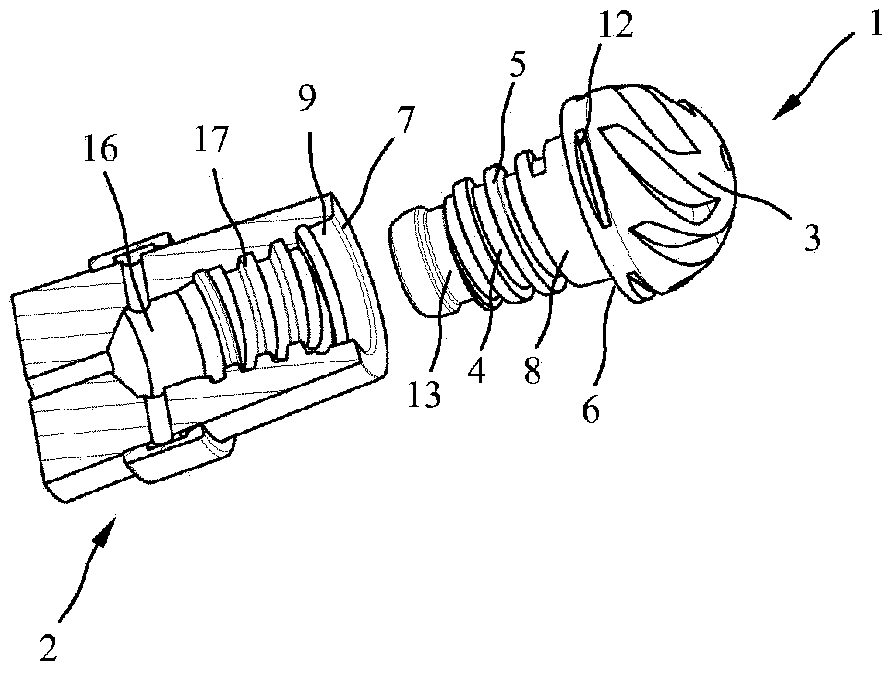

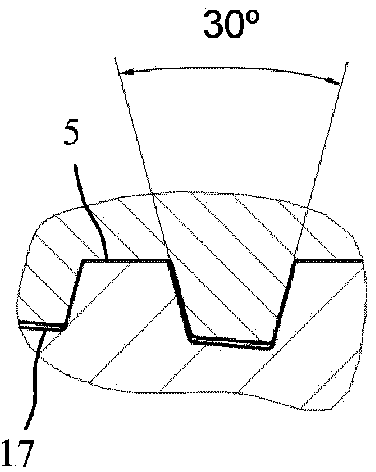

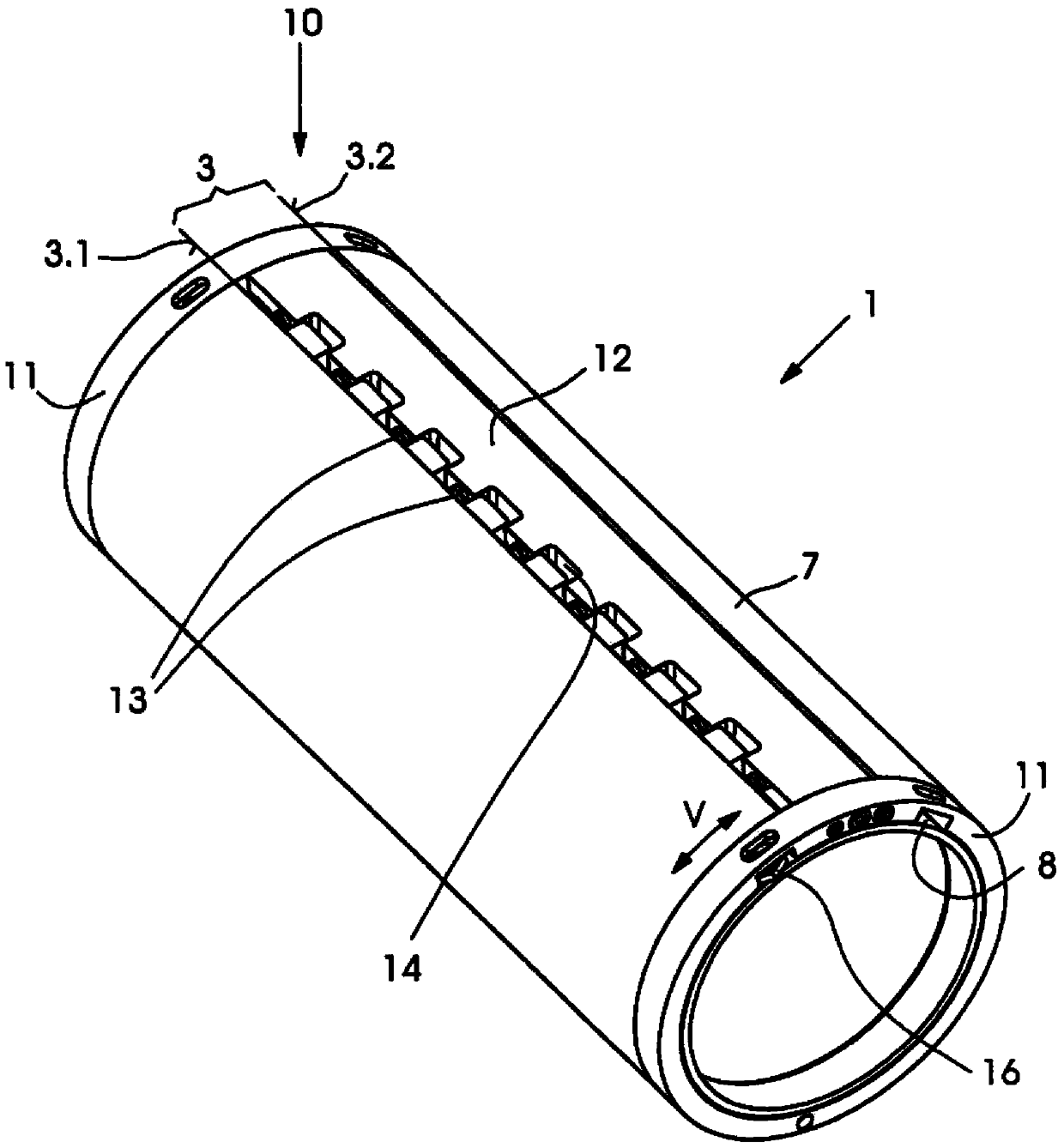

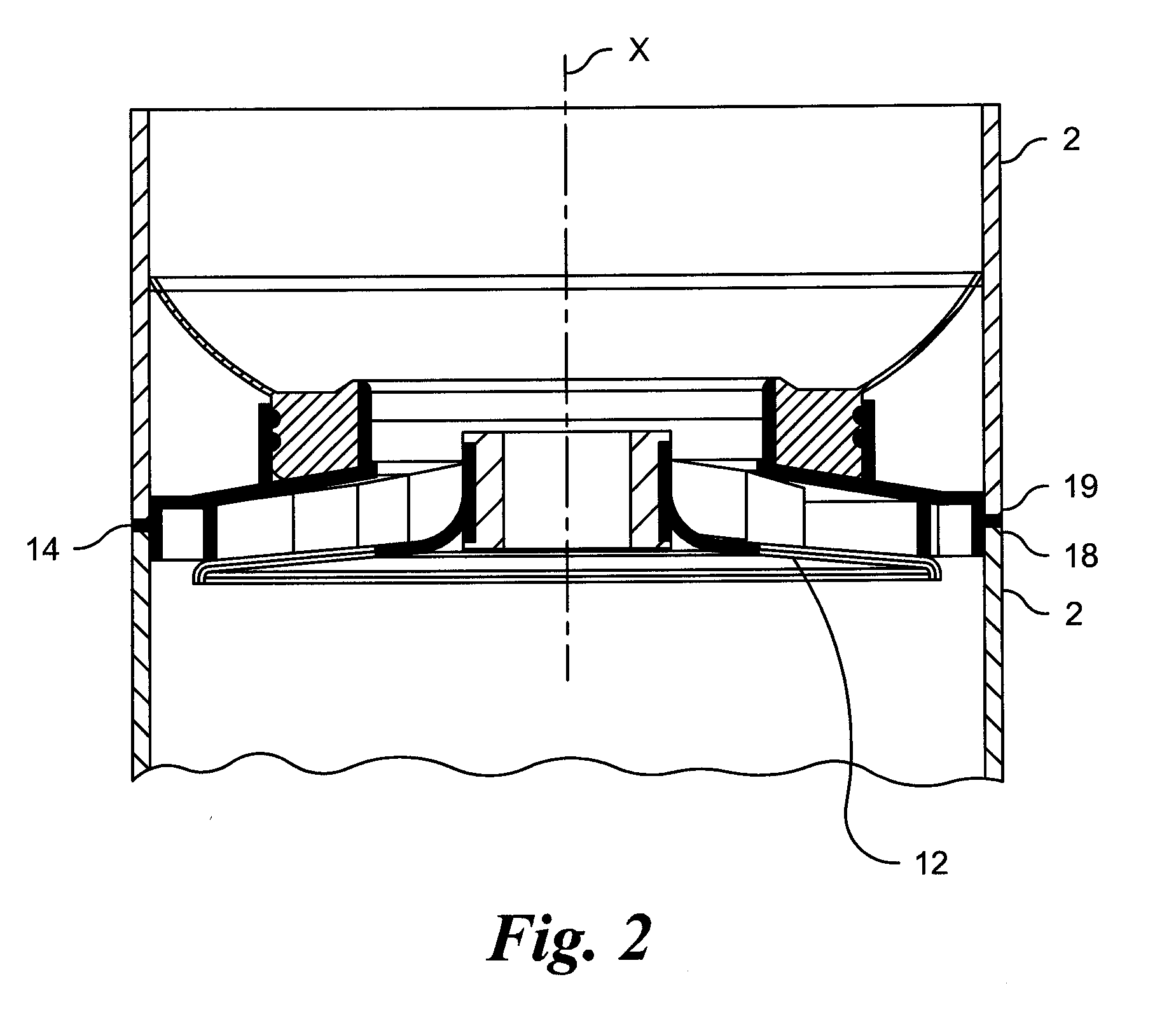

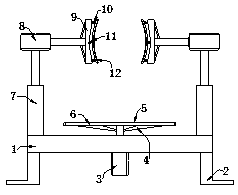

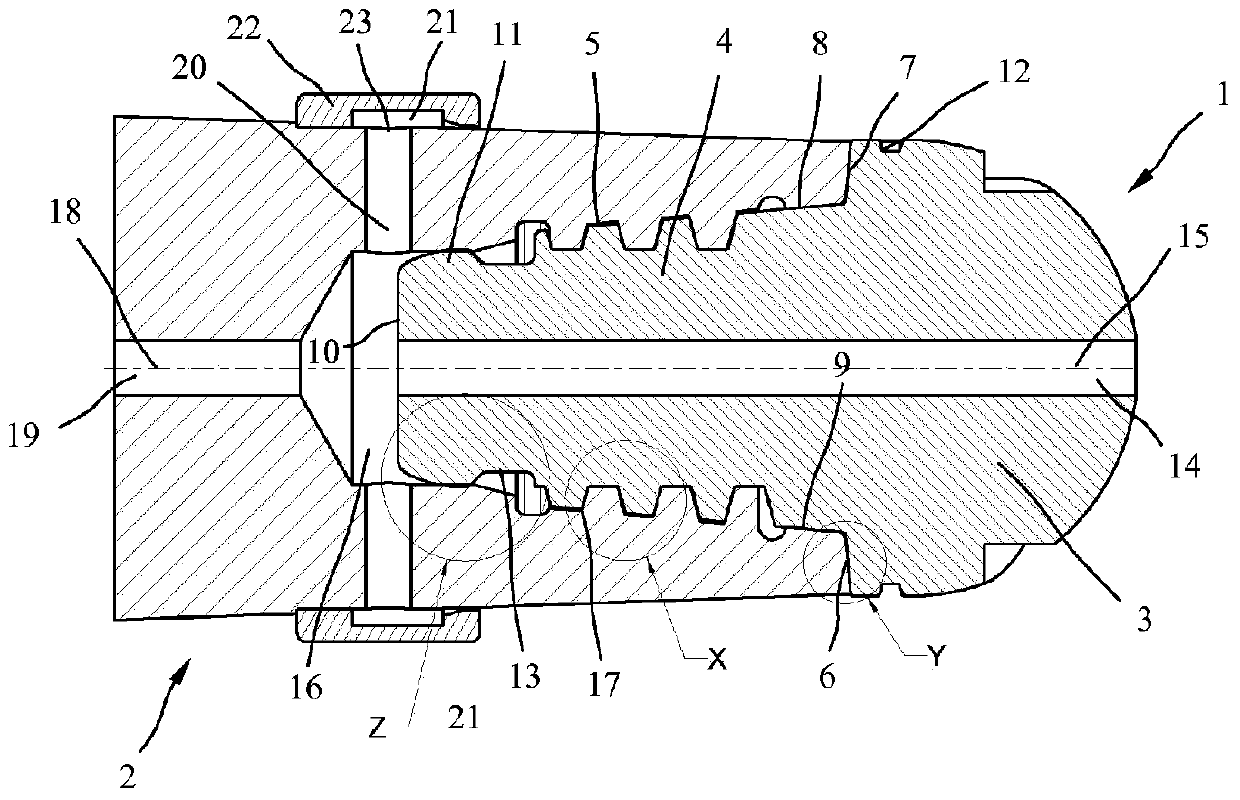

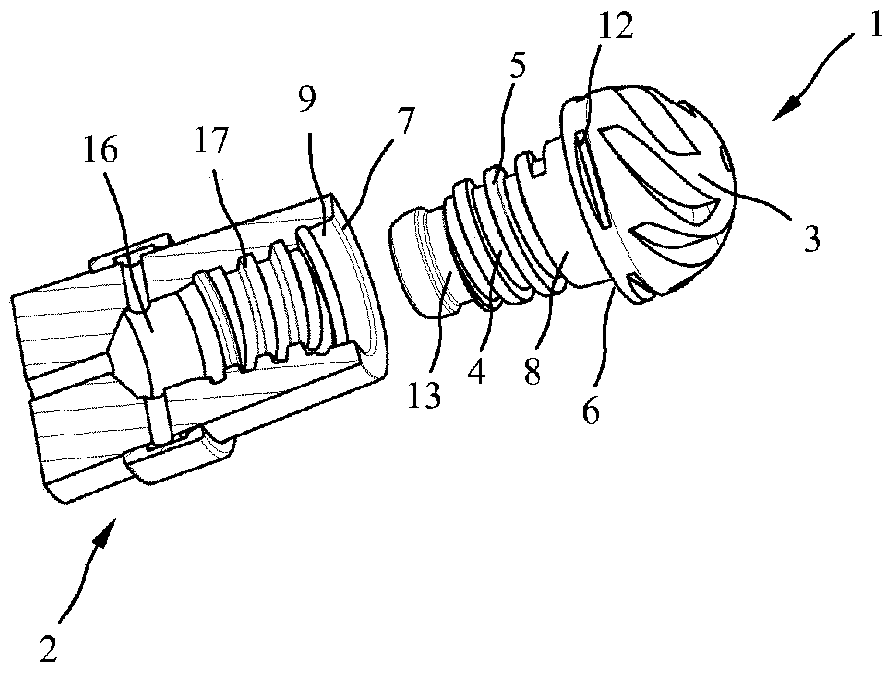

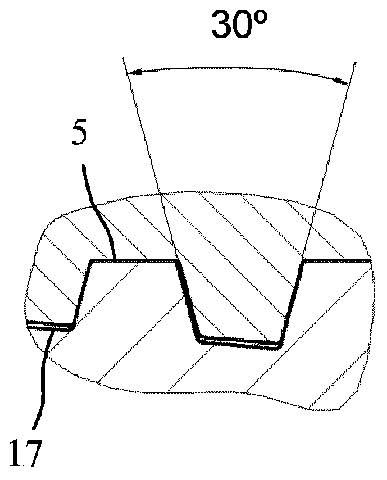

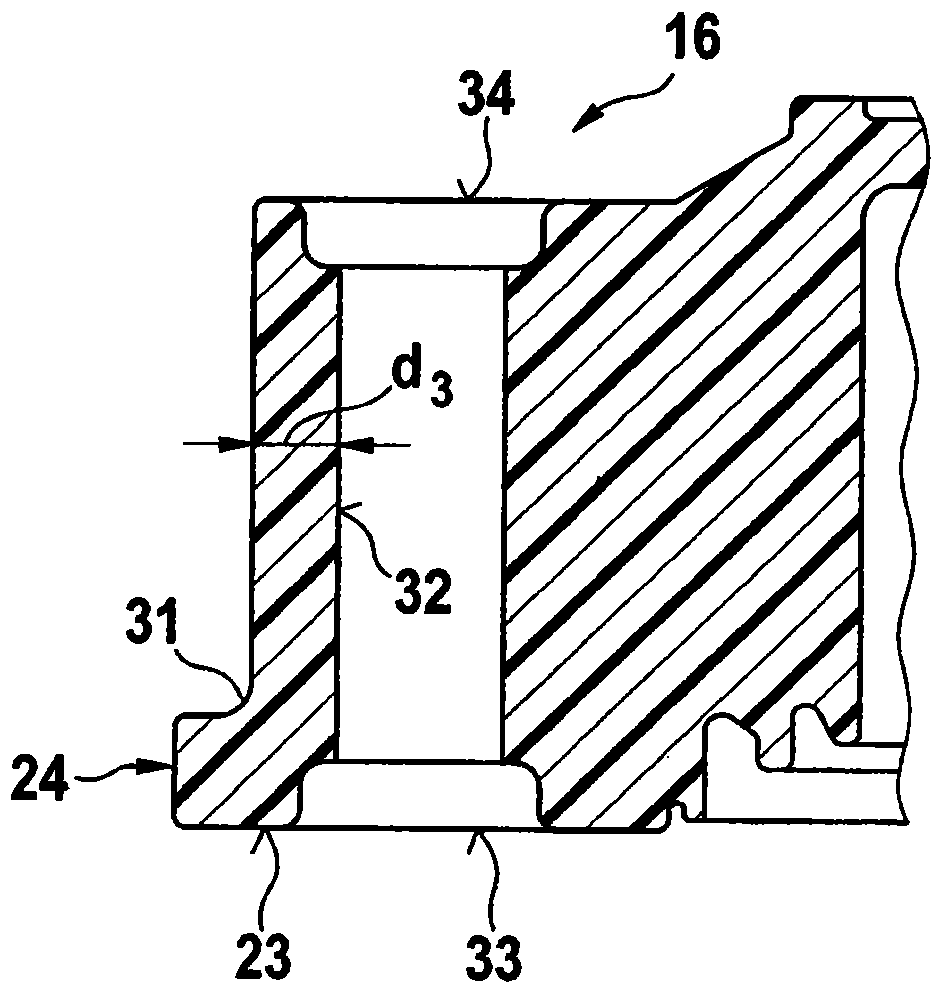

Screwdriving tool and tool holder for such a screwdriving tool

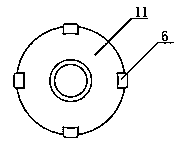

ActiveCN104093513ALarge bearing surfaceGood reassuring effectSleeve/socket jointsTool workpiece connectionEngineeringTool holder

The invention relates to a screwdriving tool (1) and to a tool holder (2) for such a screwdriving tool. the screwdriving tool (1) contains a tool head (3) and a tool shank (4) having an outer thread (5) and a supporting region arranged between the tool head (3) and the outer thread (5). according to the invention, the supporting region is formed by two conical bearing faces (6, 8) having different cone angles.

Owner:FRANZ HAIMER MASCHINENBAU KG

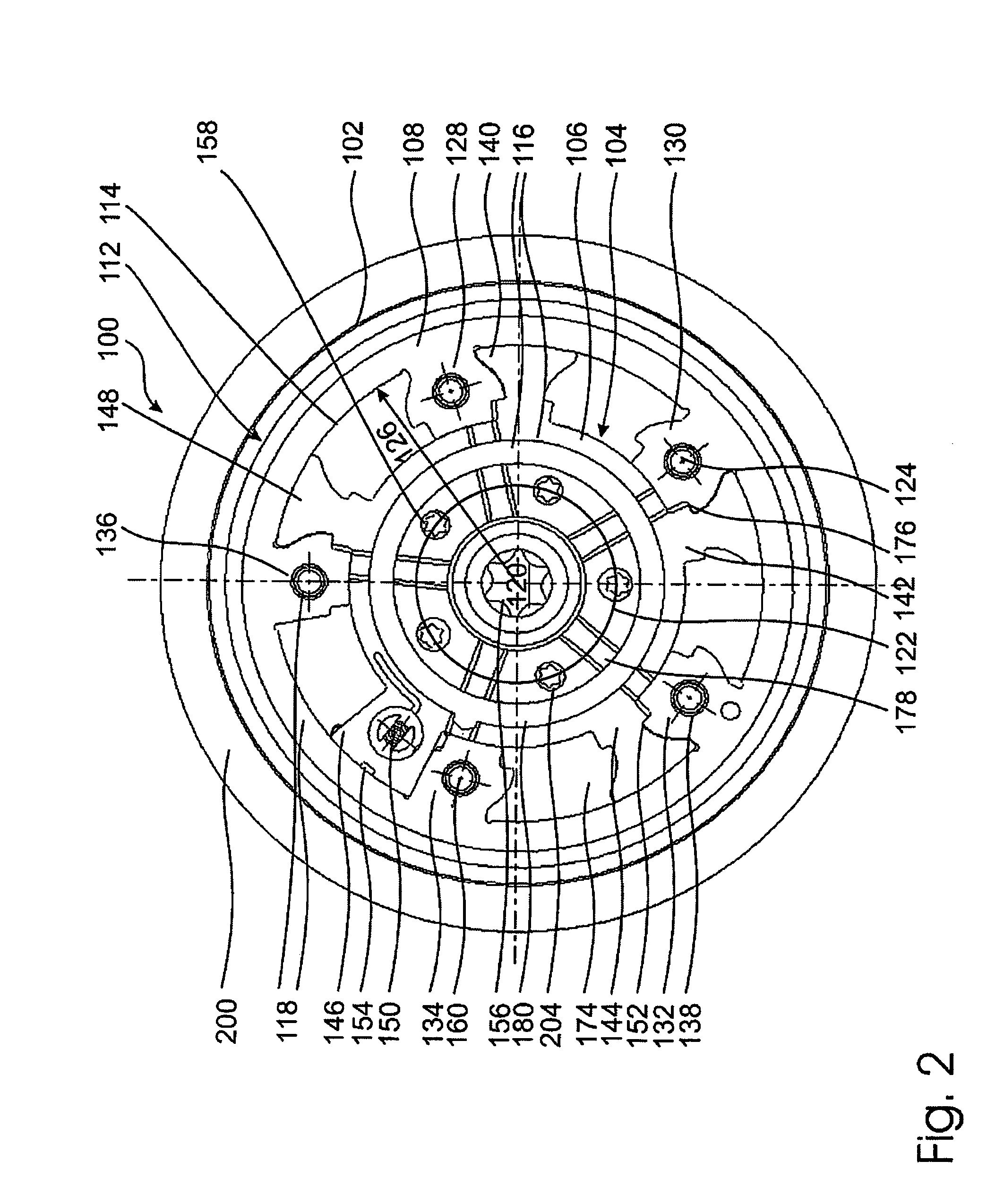

Camshaft adjuster, in particular with camshaft

InactiveUS8677960B2Avoid excessive massLarge bearing surfaceValve arrangementsYielding couplingCamValvetrain

A valve train comprises a double camshaft with an inner camshaft and an outer camshaft. The two camshafts are preferably designed coaxially. By means of a rotatory change in position of the inner camshaft to the outer camshaft, the angular position of at least one cam of the inner camshaft is adjusted or set relative to a cam of the outer camshaft. The cams are divided into sets that can occupy variable cam positions relative to one another. Various configurations of a camshaft adjuster are provided for this purpose.

Owner:HILITE GERMANY

Rear towing device

InactiveCN101497348AReduce wearReliable couplingTractor-trailer combinationsOperation modeProcessing cost

The invention relates to a rear traction device for a second tractor to draw a third tractor of a tractor with a one-traction-two mode. The rear traction device comprises a welded base plate, a modified traction seat assembly and a connecting device; the welded base plate is arranged below the modified traction seat assembly; and the connecting device is arranged above the modified traction seat assembly. As the connecting device adopts a groove type composite structure and is reliably coupled with a traction seat of a molded product, the bearing surface is large; the surface of the traction seat is provided with a lube groove; the addition of lube reduces the abrasion between the surface of a seat plate and the surface of a connecting body; and the rear traction device has the advantages of simple structure, good safety, wide range of application, low processing cost, and the like, realizes the one-traction-two operation mode of the tractor and fills up one blank of the state.

Owner:SIPING SPECIAL AUTOMOBILE FACTORY CHINA NO 1 AUTOMOBILE GRP

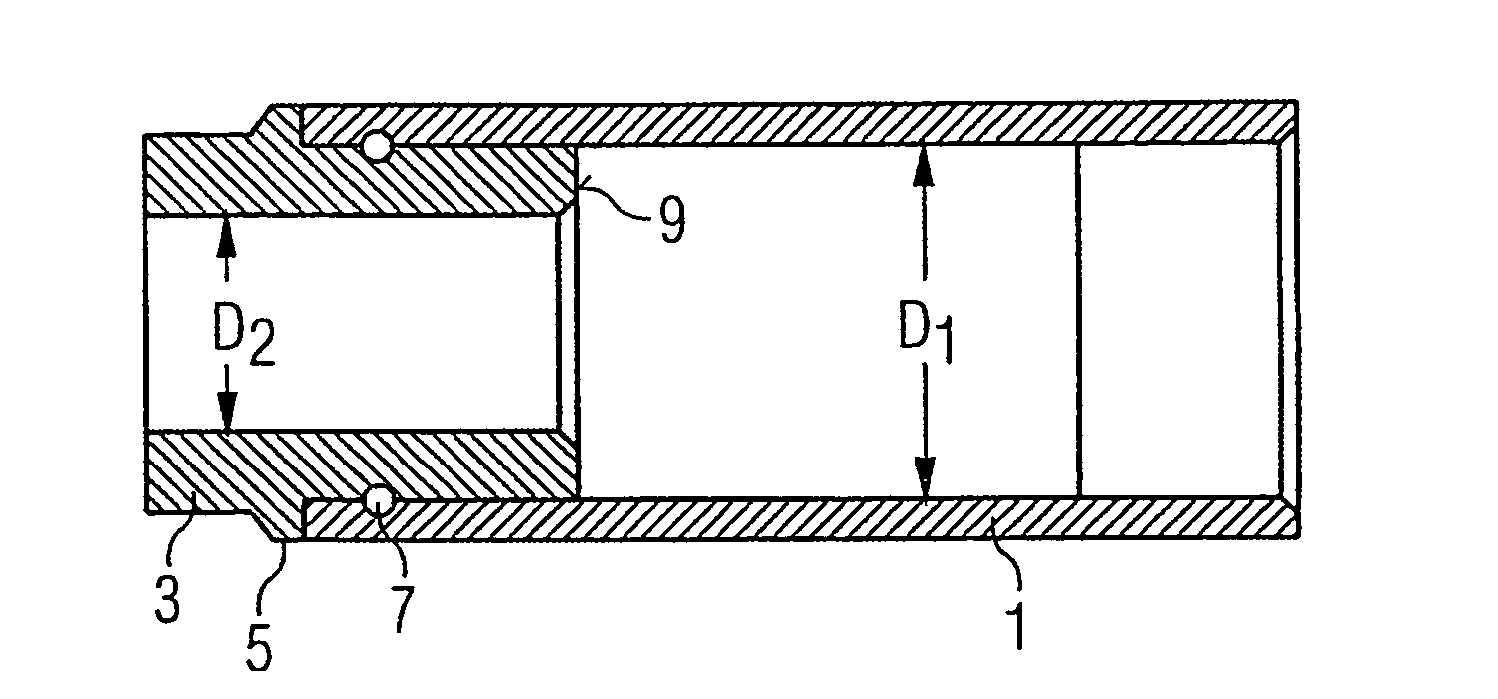

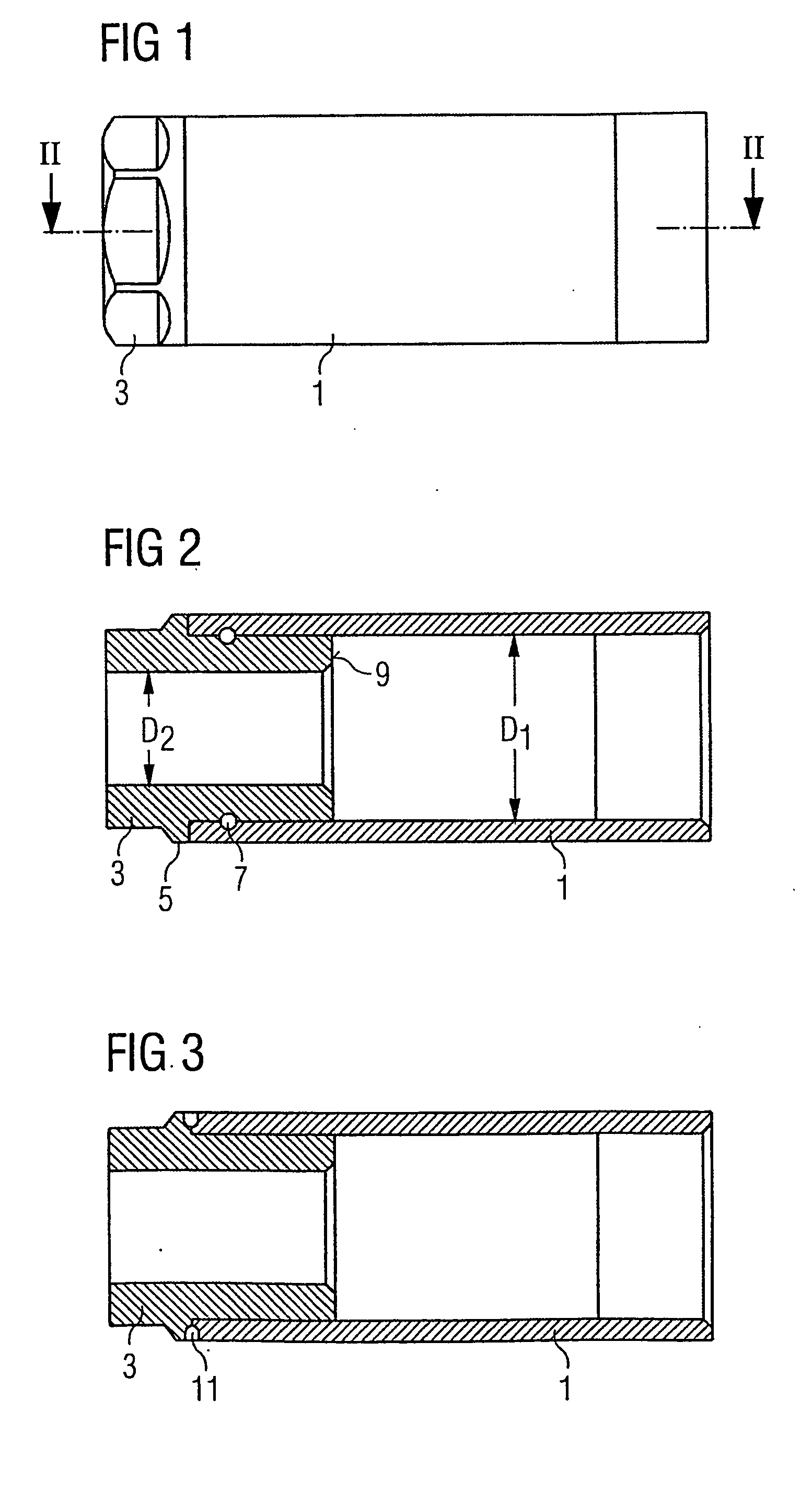

Nozzle clamping nut for injection valves and method for producing said nozzle clamping nut

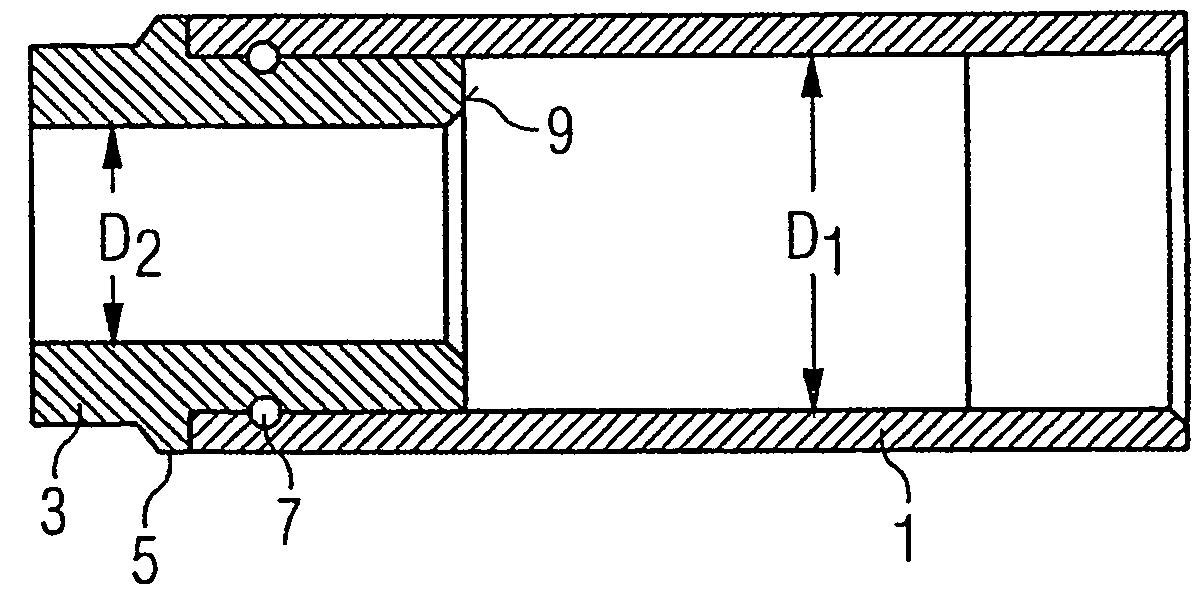

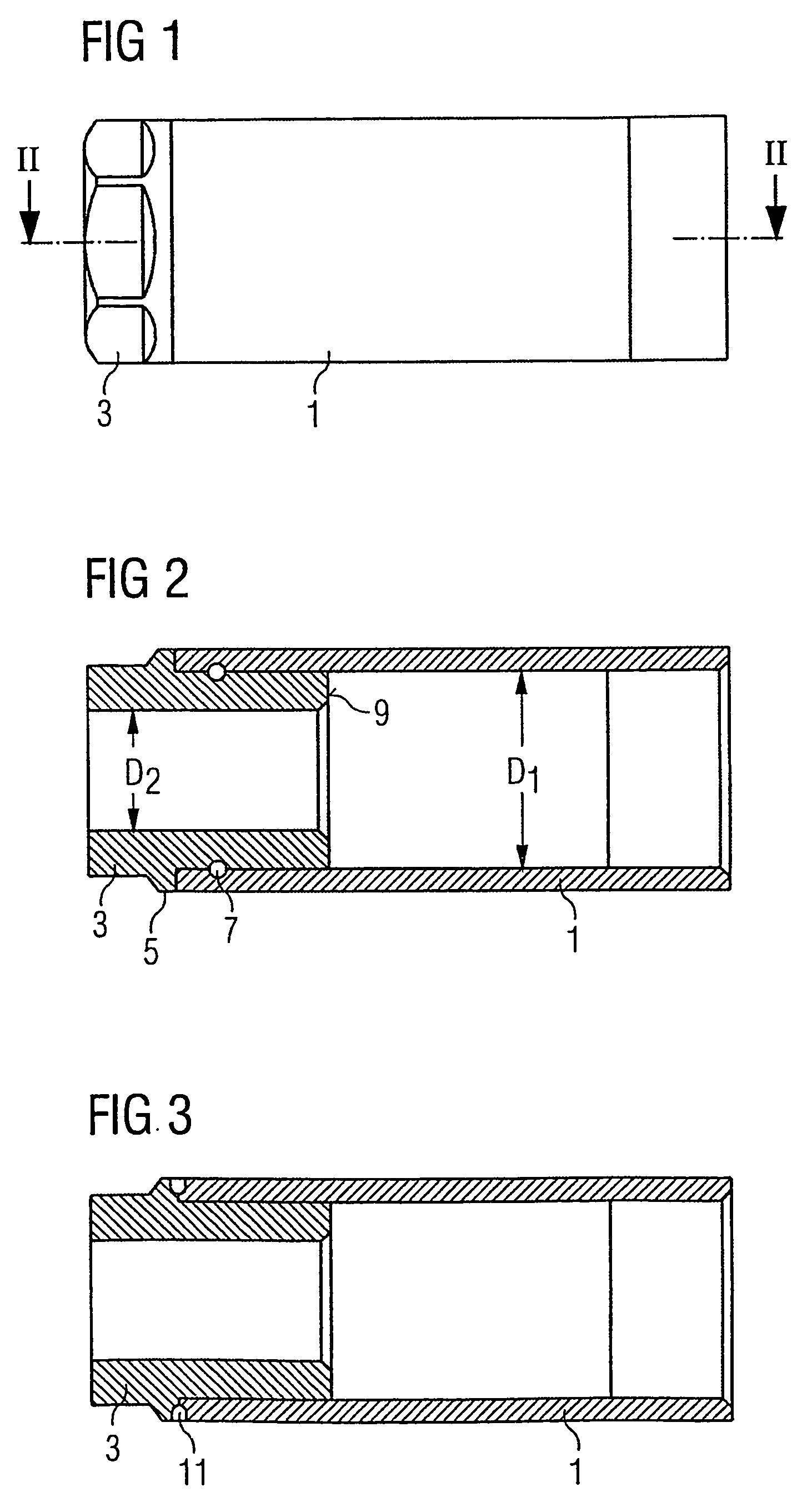

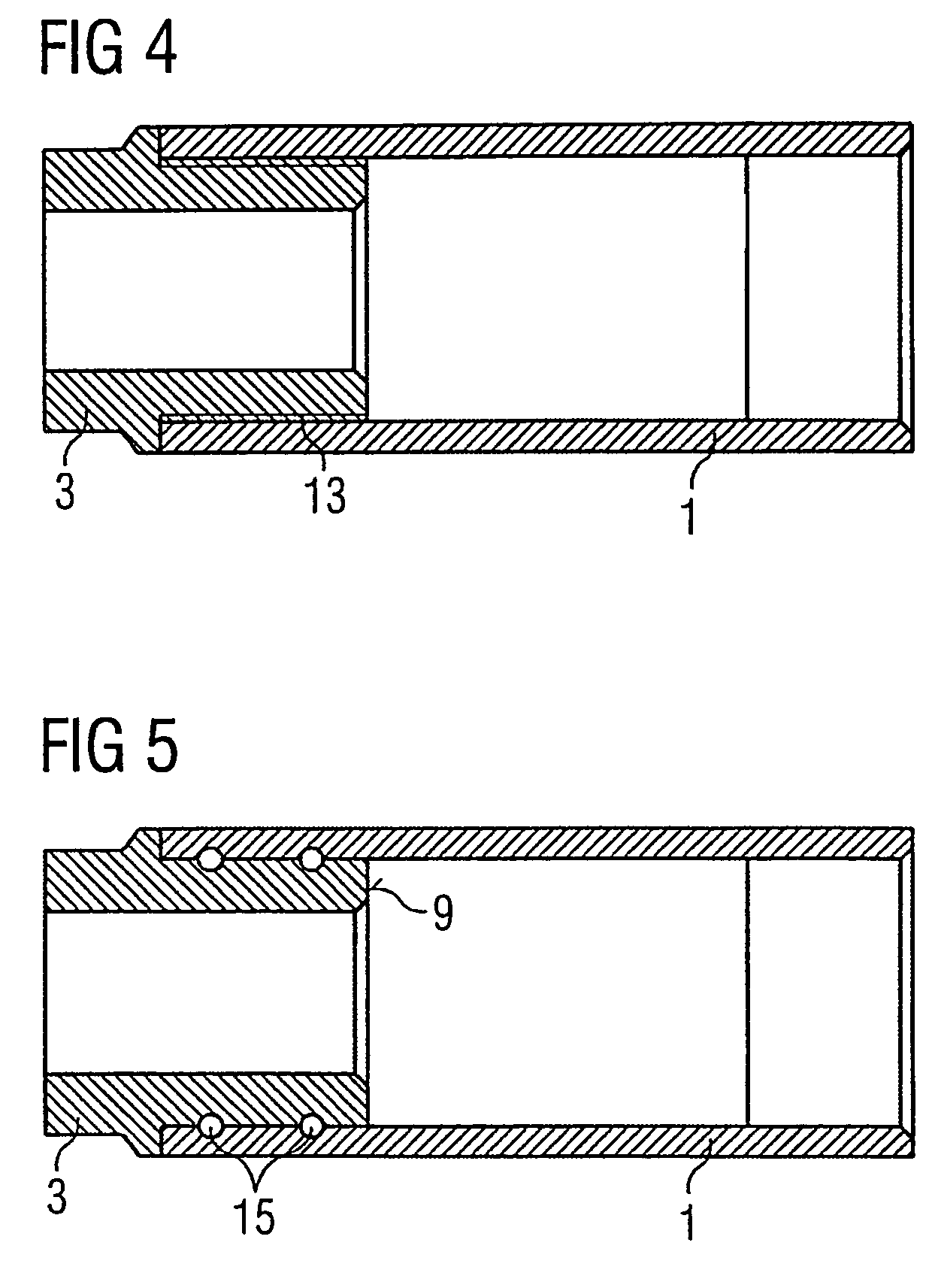

InactiveUS20050006898A1Reduce stress concentrationIncrease bearing surfaceWatering devicesSpray nozzlesBearing surfaceEngineering

A nozzle clamping nut for an injection valve comprises two sections in the longitudinal direction, having different-sized free inner diameters (D1, D2). A shoulder forms a bearing surface (9) in a transition region between the first and second sections, extending in a circular manner perpendicularly to the longitudinal direction. The nozzle clamping nut has a large bearing surface with low stress concentration. The nozzle clamping nut consists of an inner tube (3) and an outer tube (1) which have different-sized inner diameters (D1, D2), which fit inside each other and which are connected to each other in a fixed manner, and the bearing surface (9) is formed by the annular front surface of the inner tube (3).

Owner:CONTINENTAL AUTOMOTIVE GMBH

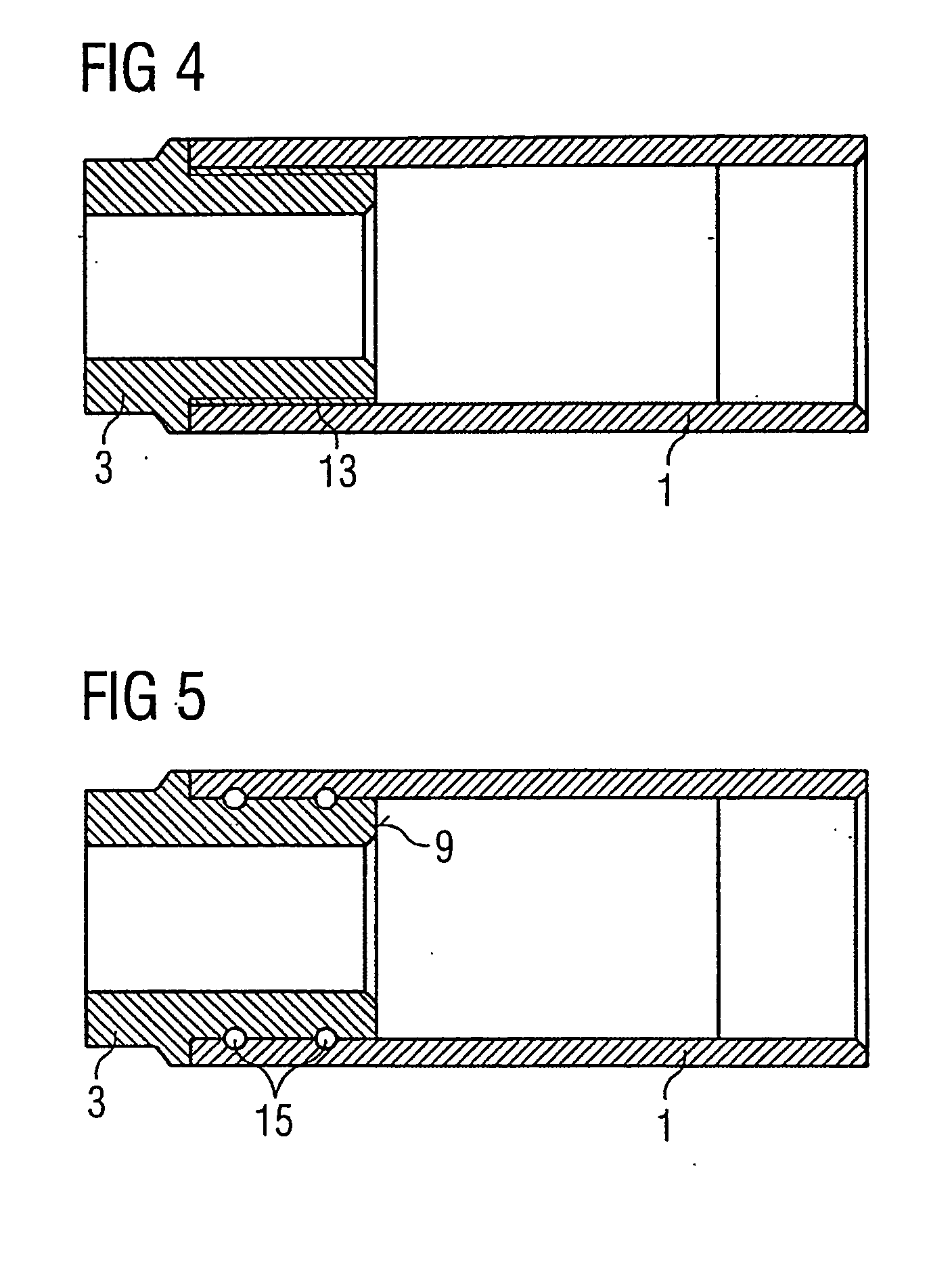

Embossing cylinder and embossing system having such an embossing cylinder

ActiveCN103722867ASimple but sure supportLarge bearing surfaceRotary pressesEmbossing decorationsSpring forceThermal expansion

An embossing cylinder for receiving a sleeve-shaped embossing mold has a hollow cylindrical body having two separating edges oriented in longitudinal direction of the body, such that a lateral surface broken by a gap is formed. The embossing cylinder is provided with a clamping system for expanding the hollow cylindrical body. The clamping system has two rotatable rings respectively supported on the axial end side of the body. The rings are connected by a carrier present in the gap. The spring elements are employed at the carrier and at the first separating edge. The spring force of the spring elements mainly act in the circumferential direction of the body. The advantage of the embossing cylinder of the invention is that a sleeve-shaped embossing mold can be mounted easily and rapidly, and the length difference can be compensated in the condition that different materials are applied to the sleeve-shaped embossing mold and the body, wherein the compensation is realized by different coefficients of thermal expansion. The invention also relates to an embossing system for processing belt-shaped or page-shaped elements, which comprises an embossing cylinder, a clamping shaft, a sleeve-shaped embossing mold, and a pressing roller pair.

Owner:GALLUS FERD RUESCH

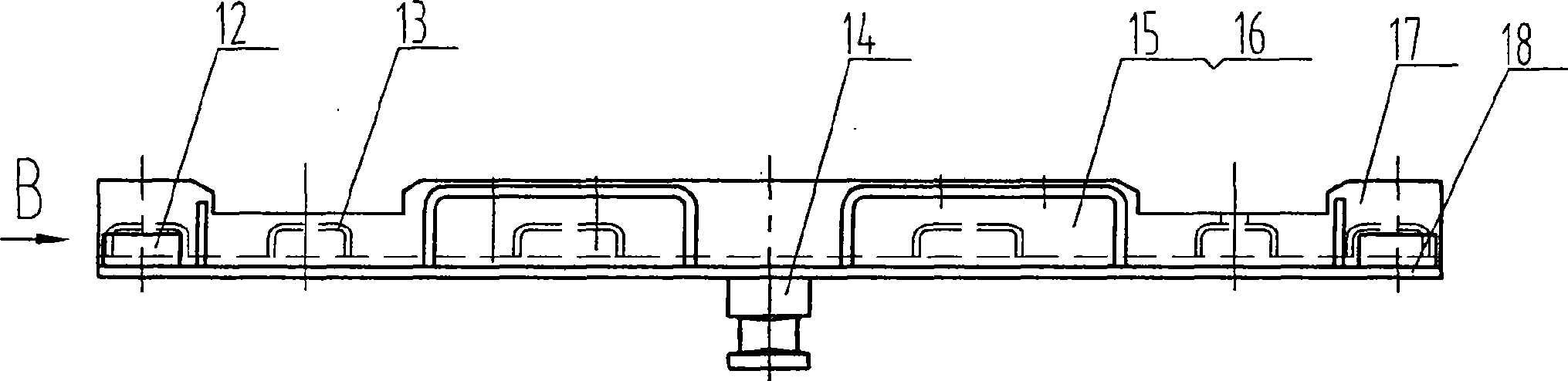

Saddle for placing coiled steel

The invention discloses a saddle for placing coiled steel. The saddle is provided with a saddle body, wherein the saddle body comprises two transverse pads (1) and two longitudinal pads (2), the two transverse pads (1) are crossed with the two longitudinal pads (2) in a # shape arrangement, screw rods (3) are arranged in the middle of the two transverse pads (1), the screw rods (3) divide the twotransverse pads (1) respectively into two parts, a part of each transverse pad (1) is fixed; each screw rod (3) passes through a corresponding sliding rail (7) arranged at the other part of the corresponding transverse pad (1) to form a transmission pair with the sliding rail (7), the screw rods (3) push the other parts of the transverse pads (1) respectively to move, and lifters (4) are arrangedat the bottoms of the transverse pads (1).

Owner:TAIZHOU YUXIN HOISTING EQUIP

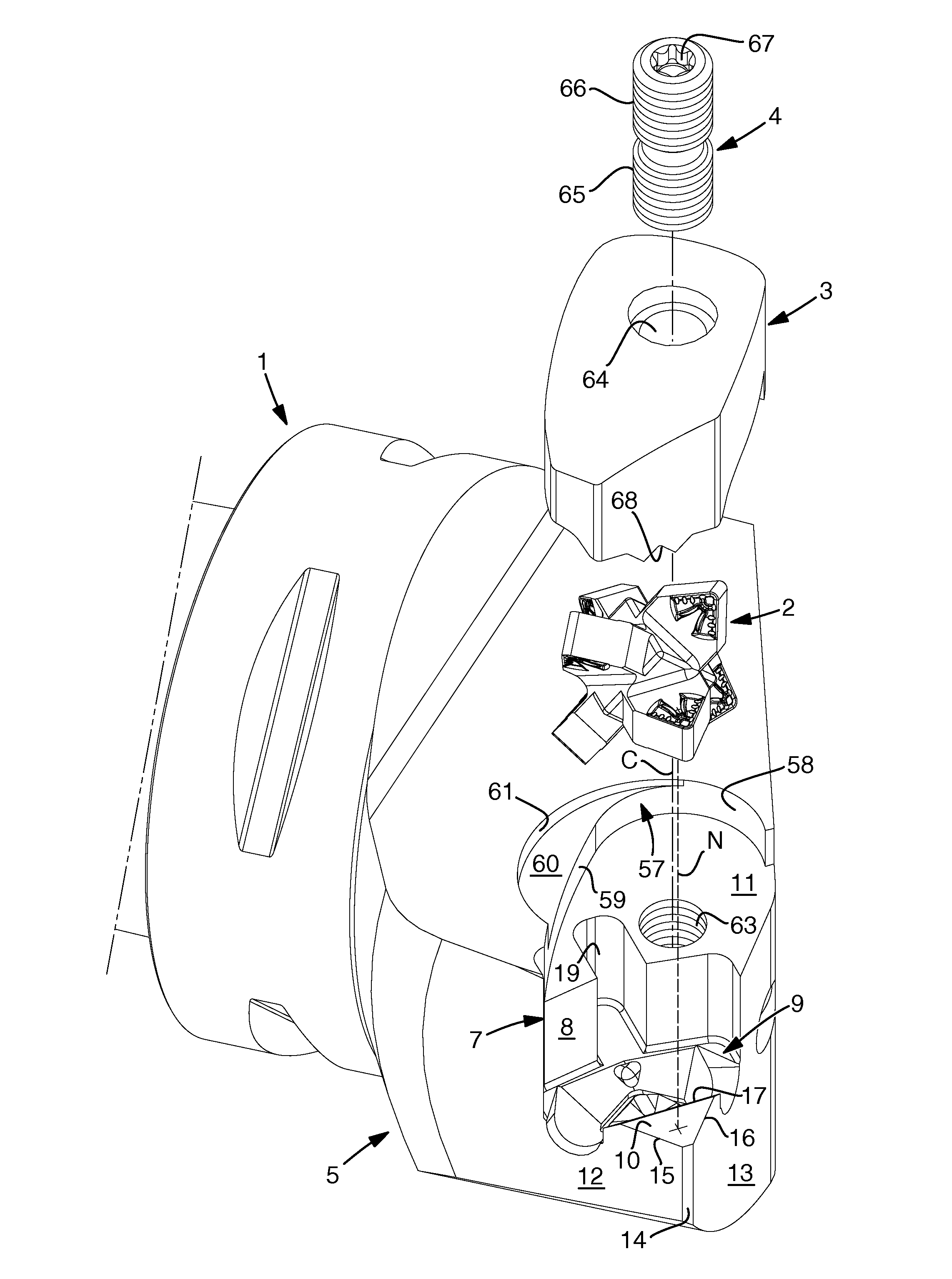

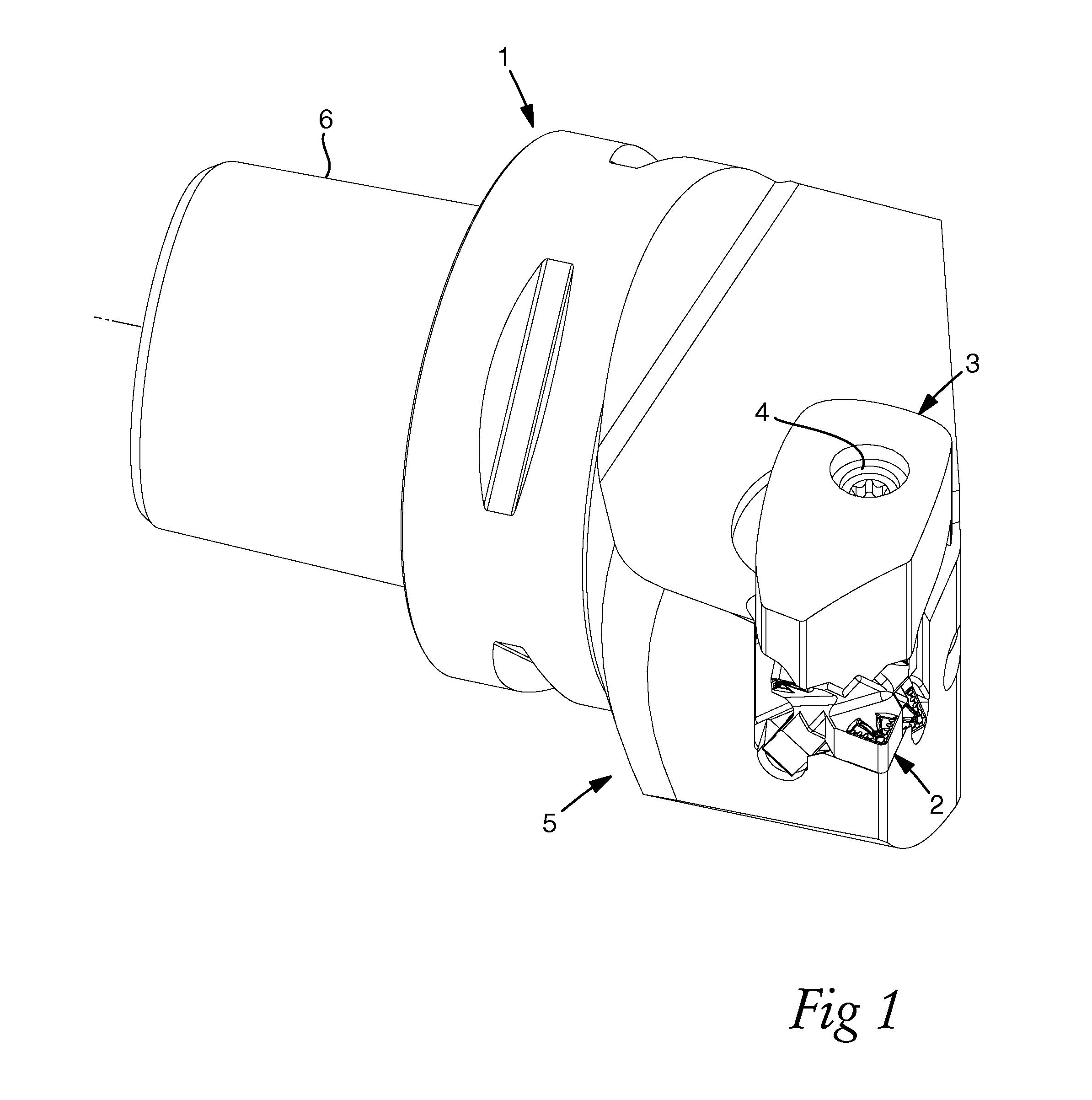

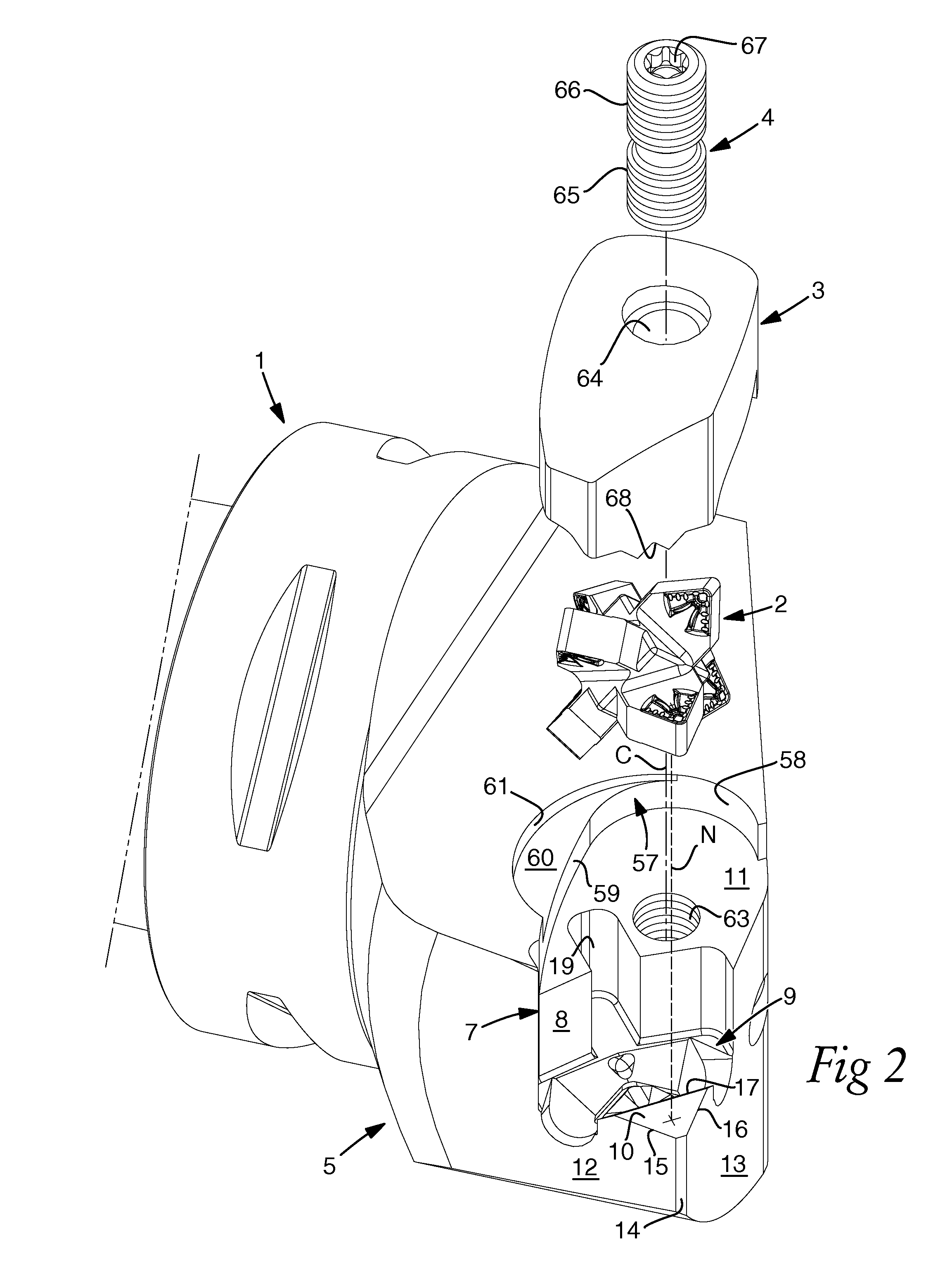

Indexable cutting insert and a tool for chip removing machining, as well as a basic body for the tool

ActiveUS20130279996A1Easy to understandImproved cutting insertMilling cuttersCutting insertsOrthogonal coordinatesEngineering

An indexable cutting insert for chip removing machining includes a plurality of cutting tips that protrude from a central core. Each of the individual tips include a cutting edge, which is formed in a transition between an upper side serving as chip surface and a clearance surface, which extends between the upper side and an under side. The cutting insert has six equally long cutting tips that are located in pairs along the co-ordinate axes of a three-dimensional, orthogonal system of co-ordinates, the origin of which is situated in the core. By arranging the cutting tips in this way, the inactive cutting tips, which are situated behind an active cutting tip, can be contained within a limited volume and therefore be installed in tool basic bodies having tapering parts. A tool equipped with the cutting insert according to the invention, as well as, a tool basic body is disclosed.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

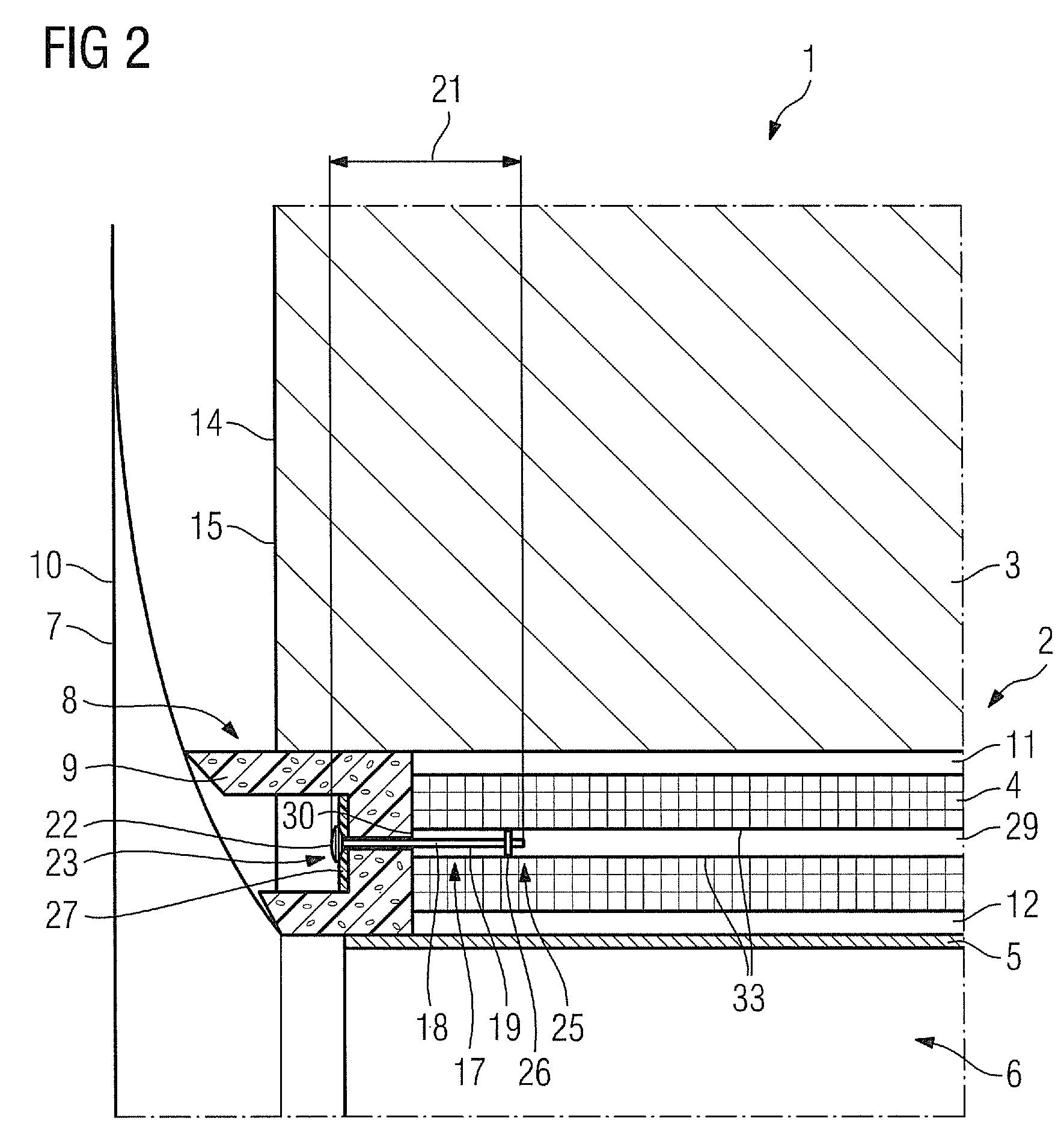

Magnetic resonance apparatus comprising a fastening element for attaching a noise-insulating element and a method for attaching a noise-insulating element

ActiveUS8624598B2Great inherent rigidityPrevent its falling out unintentionallyMagnetic measurementsElectric/magnetic detectionResonanceEngineering

A magnetic resonance apparatus is provided. The magnetic resonance apparatus comprises a gradient coil unit, a housing cover and a noise protection unit which has at least one noise-insulating element which is arranged between the gradient coil unit and the housing cover for deadening an operating noise of the gradient coil unit. The magnetic resonance apparatus also comprises at least one fastening element for attaching the at least one noise-insulating element. The fastening element engages in a connection with the gradient coil unit for attaching the at least one noise-insulating element.

Owner:SIEMENS HEALTHCARE GMBH

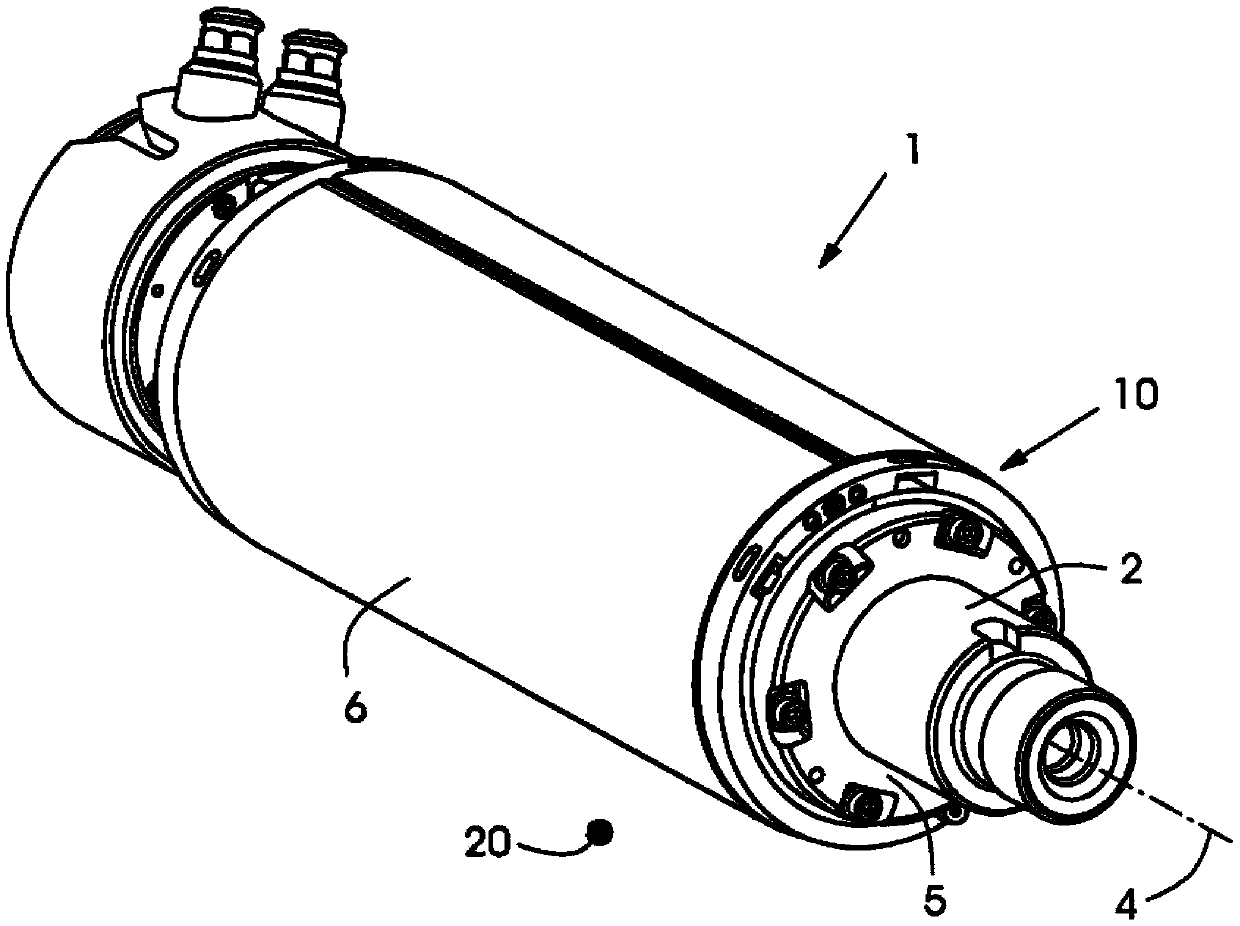

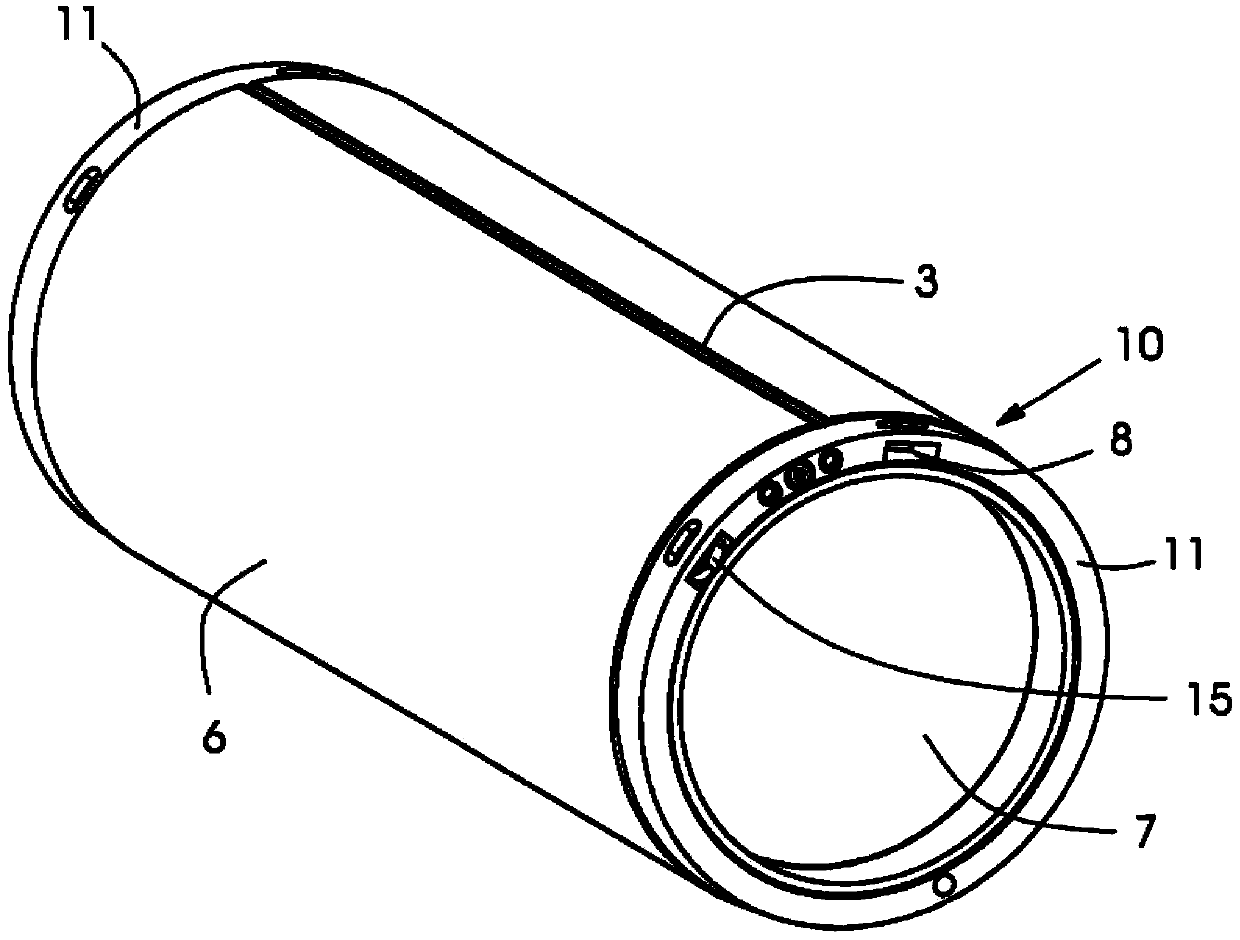

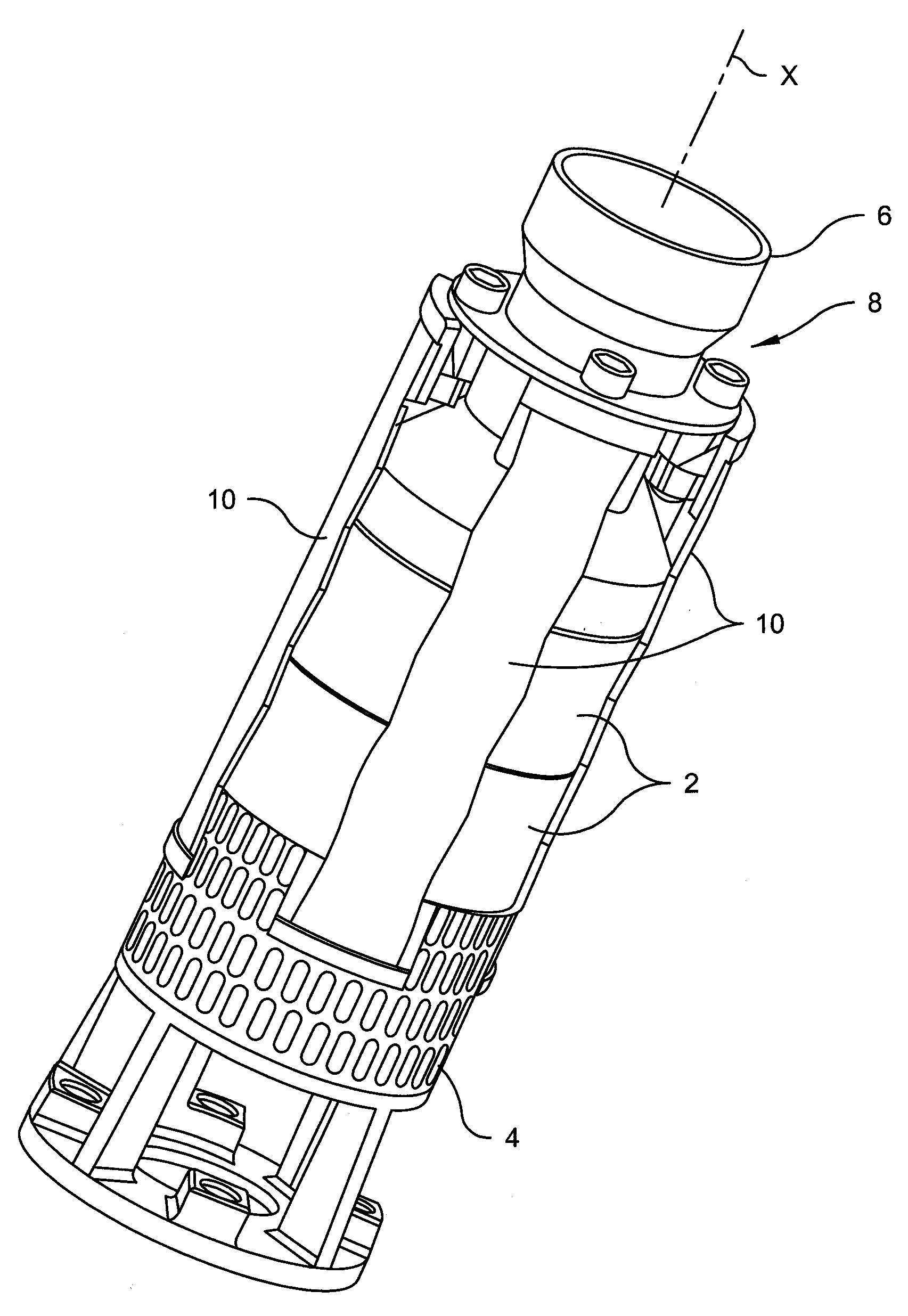

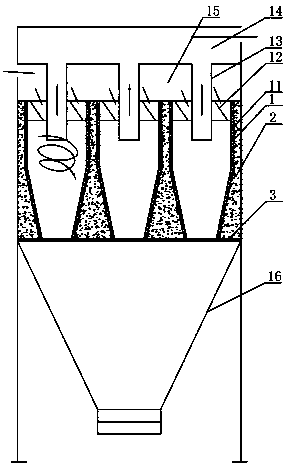

Pump unit

A pump assembly has a housing formed of at least two metallic housing parts (2) and at least one diffuser (12) arranged in the housing, wherein the diffuser (12) is fixed between the two housing parts in the axial direction, and the two housing parts (2) are directly or indirectly in metallic contact with one another, in a manner such that a force transmission in the axial direction between the housing parts (2) is effected via elements of metal.

Owner:GRUNDFOS MANAGEMENT AS

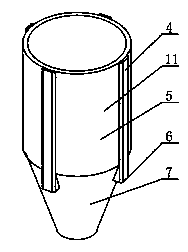

High-temperature-resisting cyclone barrel and cyclone separator

ActiveCN103785551AEasy and fast weightExtended service lifeReversed direction vortexCyclonePositive pressure

The invention discloses a high-temperature-resisting cyclone barrel. A barrel body comprises an upper-portion straight barrel portion and a lower-portion conical barrel portion, the peripheral wall of the barrel body is provided with a stepped face which serves as a supporting face and is borne on a bearing plate of a cyclone separator. The stepped face is formed by a structure extending from the end face of the top of the barrel body downward. The bearing plate of the cyclone separator is not located at the bottom of the cyclone barrel body, but is lifted to the peripheral wall of the middle of the barrel body and comprises a peripheral wall of the straight barrel portion or the conical barrel portion, the local portion of the periphery of the barrel body or the whole stepped face is directly in contact with the bearing plate to bear the weight of the whole cyclone barrel, positive pressure is even and stable, damage is not easily caused, and installation is convenient and quick. After the bearing plate is lifted, the using amount of heat preservation concrete can be greatly decreased, and the weight of the whole cyclone separator can be decreased by at least more than 5%. In addition, the cracked and leaked barrel body can be conveniently replaced, and the service life of the cyclone separator is remarkably prolonged.

Owner:YIXING CHENHAO TECH

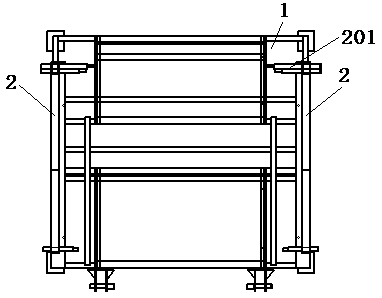

Tower type rail-mounted portal hanging frame

InactiveCN105035952ASave materialReduce weightBase supporting structuresBraking devices for hoisting equipmentsTower

The invention discloses a tower type rail-mounted portal hanging frame. The tower type rail-mounted portal hanging frame comprises two bases which are arranged in parallel and supporting columns which are arranged on the bases. A hanging beam is horizontally arranged on the supporting columns. First grooves are formed inwards in the two sides of each supporting column respectively. The supporting columns are arranged in a vertically through mode. Two corresponding side faces of the interior of each supporting column are each vertically provided with a sliding groove. Each sliding groove and the corresponding first groove are located in two adjacent sides. Square pipes which can move along with the sliding grooves are connected to the sliding grooves. A plurality of limiting holes are horizontally formed in the upper side faces of the two first grooves of each supporting column at equal intervals. Limiting grooves are formed in the two sides of each square pipe respectively. A limiting rod is arranged in one limiting hole of each first groove. The square pipes are welded to the hanging beam. The two supporting columns each comprise a reinforcing part located in the middle and connecting parts located on the upper side and the lower side of the reinforcing part. The sliding grooves and the square pipes are arranged in the connecting parts on the upper portions. Each reinforcing part comprises a plurality of tower-shaped connecting blocks which are vertically connected. A pair of fixing pieces extends out from the lower portion of each base. A directional wheel is arranged between the fixing pieces extending out from the lower portion of each base. A rail matched with the directional wheels is arranged below the directional wheels.

Owner:SUZHOU SUTENG ELECTRONICS TECH

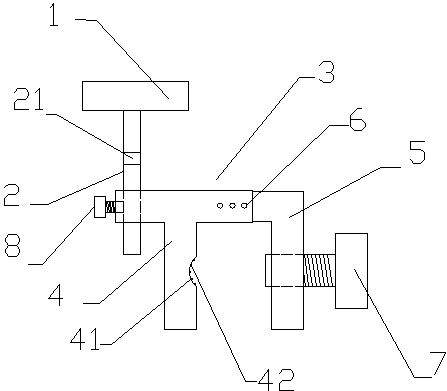

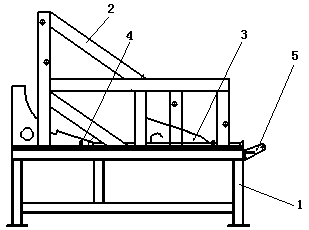

Waste compression box welding tool and manufacturing method of waste compression box welding tool

PendingCN111408898AGuaranteed assembly relationshipHigh precisionProcess engineeringManufacturing engineering

The invention relates to the technical field of welding tools, in particular to a waste compression box welding tool and a manufacturing method of the waste compression box welding tool. The tool andthe method can solve the problem of low precision of a waste compression box welding tool in the prior art. The waste compression box welding tool comprises a base, wherein the base is provided with positioning welding devices for positioning corresponding parts of a waste compression box, the base is provided with assembly seats for mounting the positioning welding devices, the bottoms of the positioning welding devices are provided with connecting seats for being connected with the assembly seats, the sides, close to each other, of the assembly seats and the connecting seats are separately provided with milled positioning planes, and the positioning planes on the assembly seats are in fit matching with the positioning planes on the connecting seats to realize the positioning between thepositioning welding devices and the base in the corresponding directions.

Owner:HENAN BENMA +1

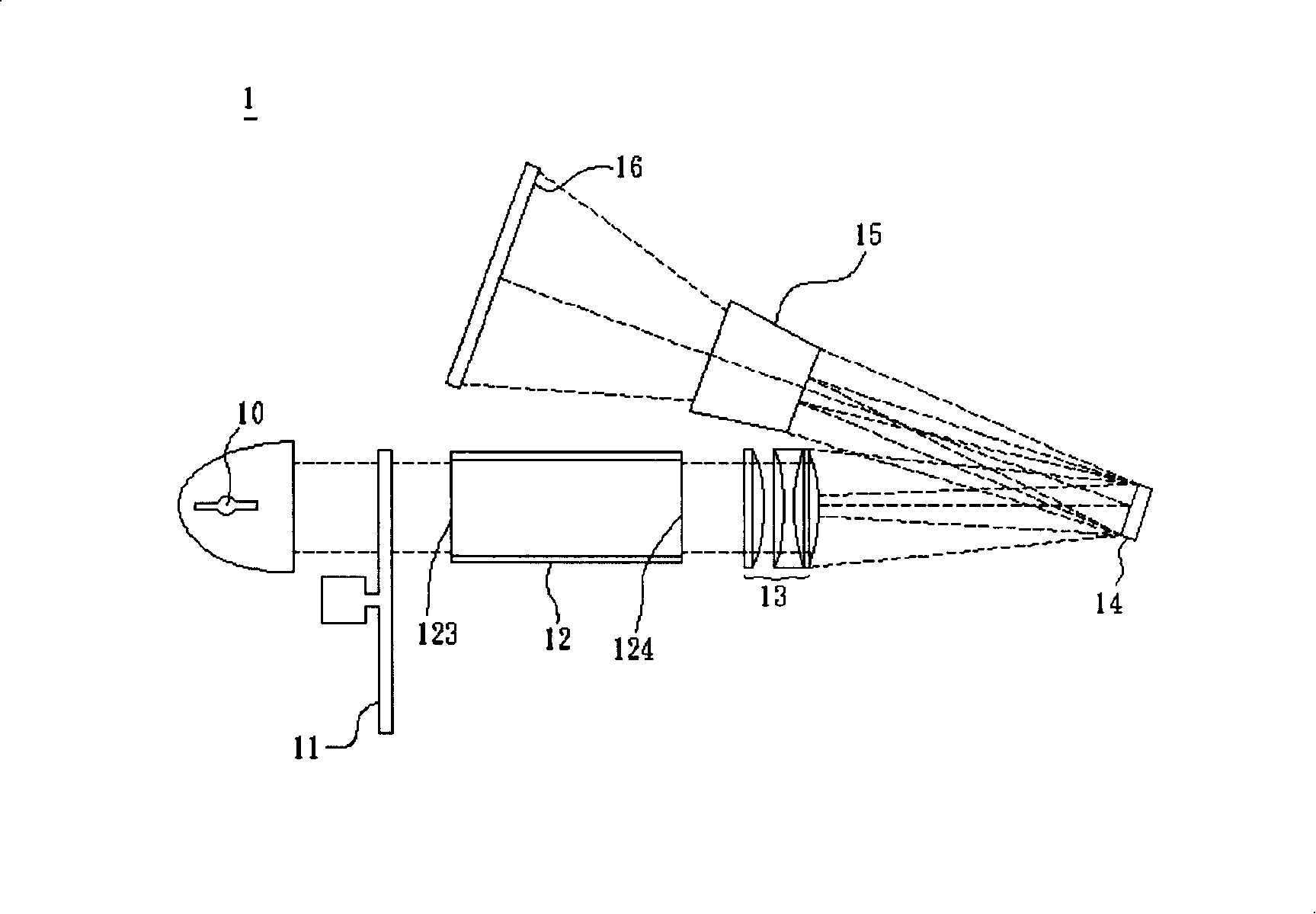

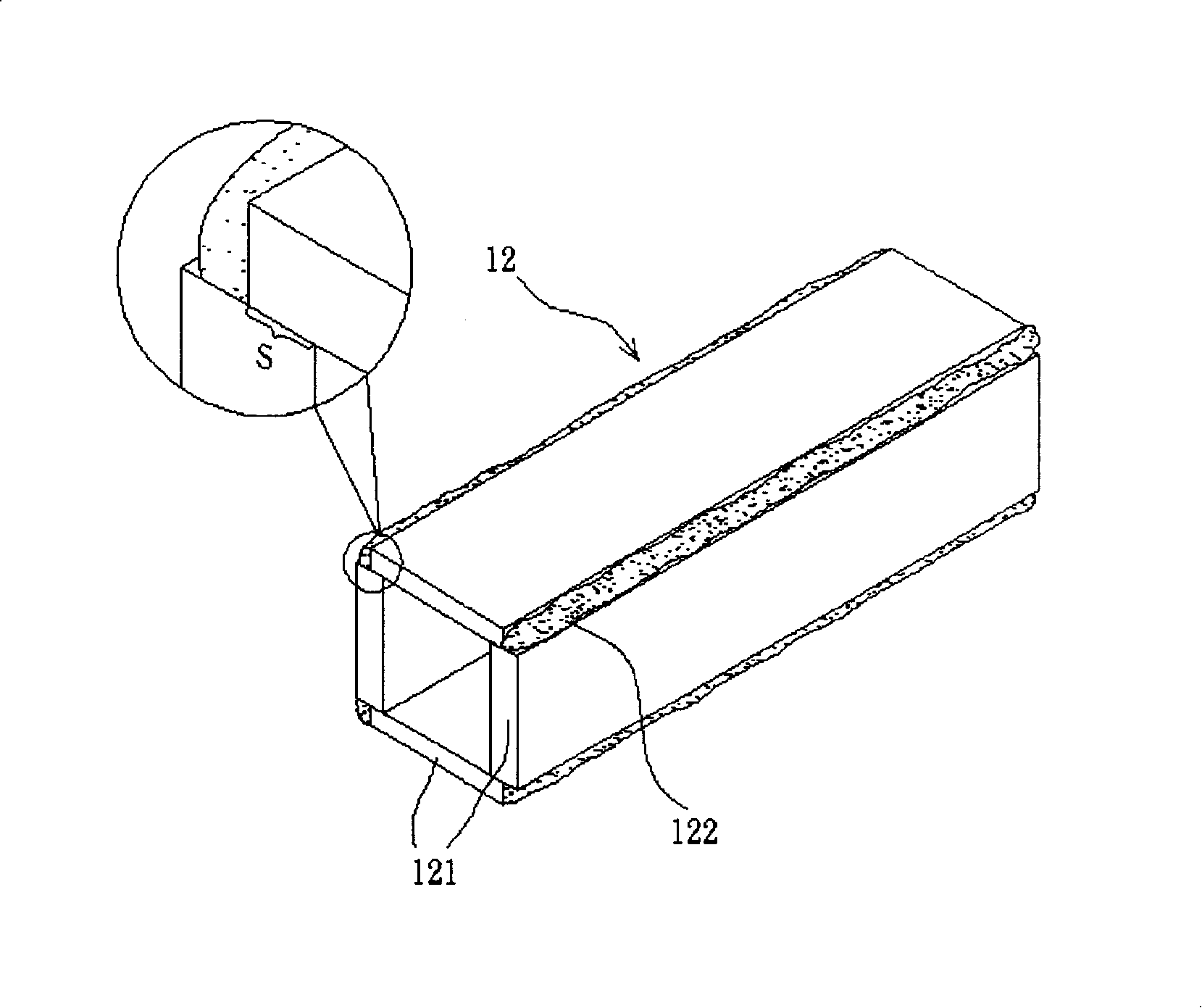

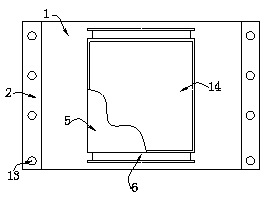

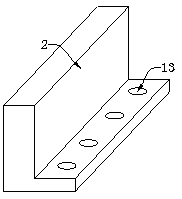

Projection system and light pipe thereof

InactiveCN101206279AImprove structural strengthNot easy to affect uniform light brightnessProjectorsOptical light guidesLight pipeProjection system

The invention relates to a projection system and an optical pipe of the system, wherein, the optical pipe comprises an optical pipe body and a first strengthened element; the optical pipe body has an internal surface and an external surface with the internal surface formed into an optical channel; the first strengthened element is arranged on the external surface of the optical pipe body. The invention also discloses a projection system which comprises a light source, a color wheel component and an optical pipe. The invention has better structural strength.

Owner:PRODISC TECH INC

Production clamping device for mechanical accessories

The invention belongs to the technical field of mechanical accessory production, and particularly relates to a production clamping device for mechanical accessories. The production clamping device comprises a bottom plate, bases are symmetrically and fixedly arranged on the bottom face of the bottom plate, a first air cylinder is installed in the middle of the bottom face of the bottom plate, an output shaft of the first air cylinder penetrates through the bottom plate and extends to the top of the bottom plate, connecting rods are symmetrically installed on the outer side wall of a telescopicshaft of the first air cylinder, two abutting plates clamp a mechanical accessory, each abutting plate has good deformation force due to the elastic effect generated by multiple compression springs inside the corresponding containing cavity so that the abutting plates can change along with the outline of the accessory, and the abutting plates can be attached to the accessory easily; meanwhile, the friction force between the abutting plates and the accessory is increased through connecting plates and multiple grooves, the stability and firmness are enhanced, and the accessory is not prone to slide and falling; and under the action of first springs and second springs, the abutting plates have certain rebound resilience, so that clamping is prevented from being too tight, damage to the accessory is reduced, and protection is enhanced.

Owner:JIAXING UNIV

Batter post type portal hanging frame

InactiveCN105035955ASave materialReduce weightBase supporting structuresBraking devices for hoisting equipmentsStructural engineering

The invention discloses a batter post type portal hanging frame. The batter type portal hanging frame comprises two bases which are arranged in parallel and supporting columns which are arranged on the bases. A hanging beam is horizontally arranged on the supporting columns. The batter post type portal hanging frame is characterized in that the supporting columns are hollow, first grooves are formed inwards in the two sides of each supporting column respectively, and the supporting columns are arranged in a vertically through mode; two corresponding side faces of the interior of each supporting column are each vertically provided with a sliding groove, each sliding groove and the corresponding first groove are located in two adjacent sides, and square pipes which can move along with the sliding grooves are connected to the sliding grooves; a plurality of limiting holes are horizontally formed in the upper side faces of the two first grooves of each supporting column at equal intervals, limiting grooves are formed in the two sides of each square pipe respectively, and a limiting rod is arranged in one limiting hole of each first groove; the square pipes are welded to the hanging beam, and the two supporting columns are obliquely arranged on the bases. The batter post type portal hanging frame has the advantages of being simple in structure, long in service life and the like.

Owner:SUZHOU SUTENG ELECTRONICS TECH

Screw-in tool and tool receiving device for such a screw-in tool

ActiveCN104093513BLarge bearing surfaceGood reassuring effectSleeve/socket jointsTool workpiece connectionScrew thread

The invention relates to a screw-in tool (1) and a tool holder (2) for such a screw-in tool. A screw-in tool (1) comprising a tool head (3) and a tool shank (4) with an external thread (5) and a support area arranged between the tool head (3) and the external thread (5) . According to the invention, the support region is formed by two conical contact surfaces (6, 8) with different cone angles.

Owner:FRANZ HAIMER MASCHINENBAU KG

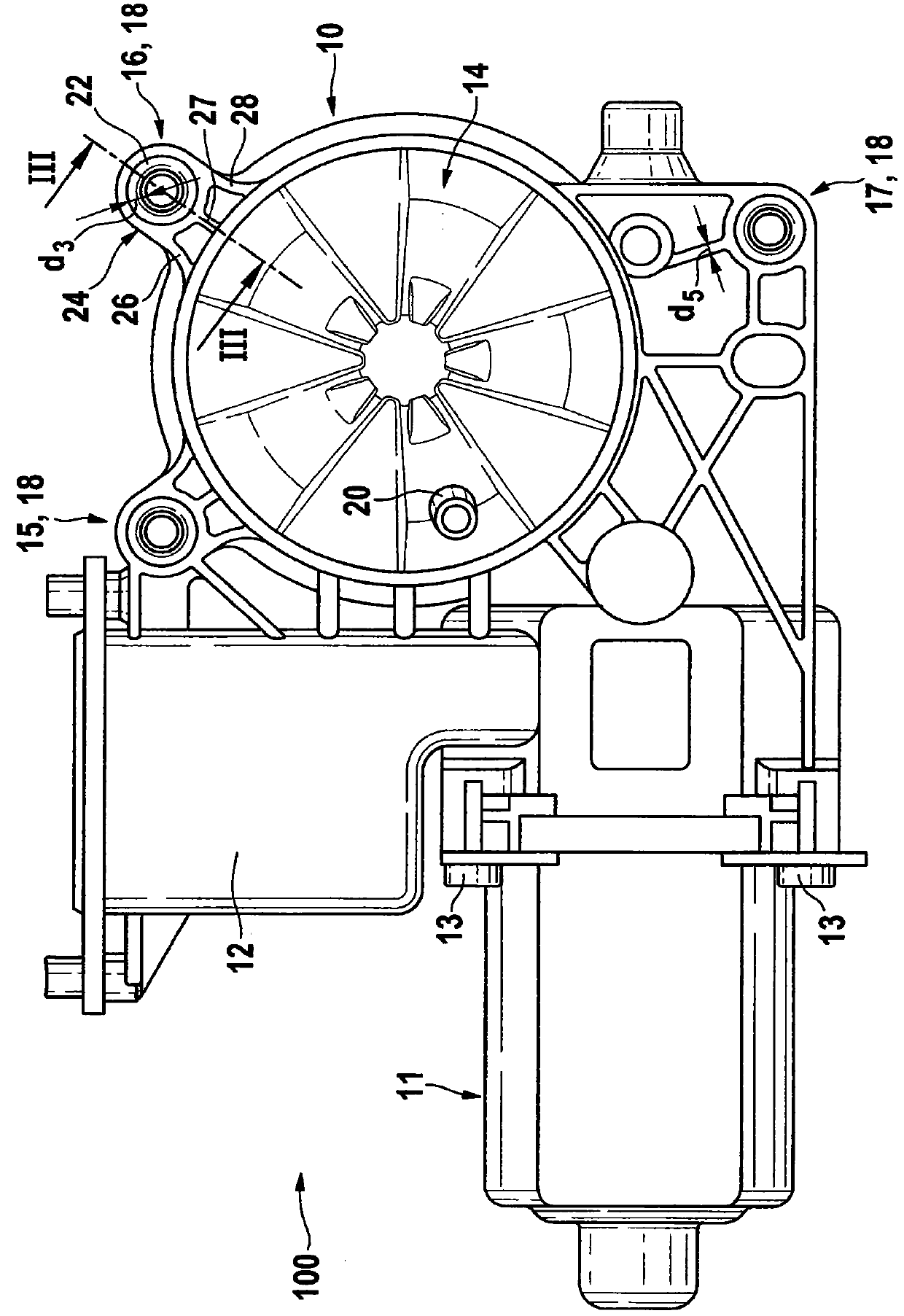

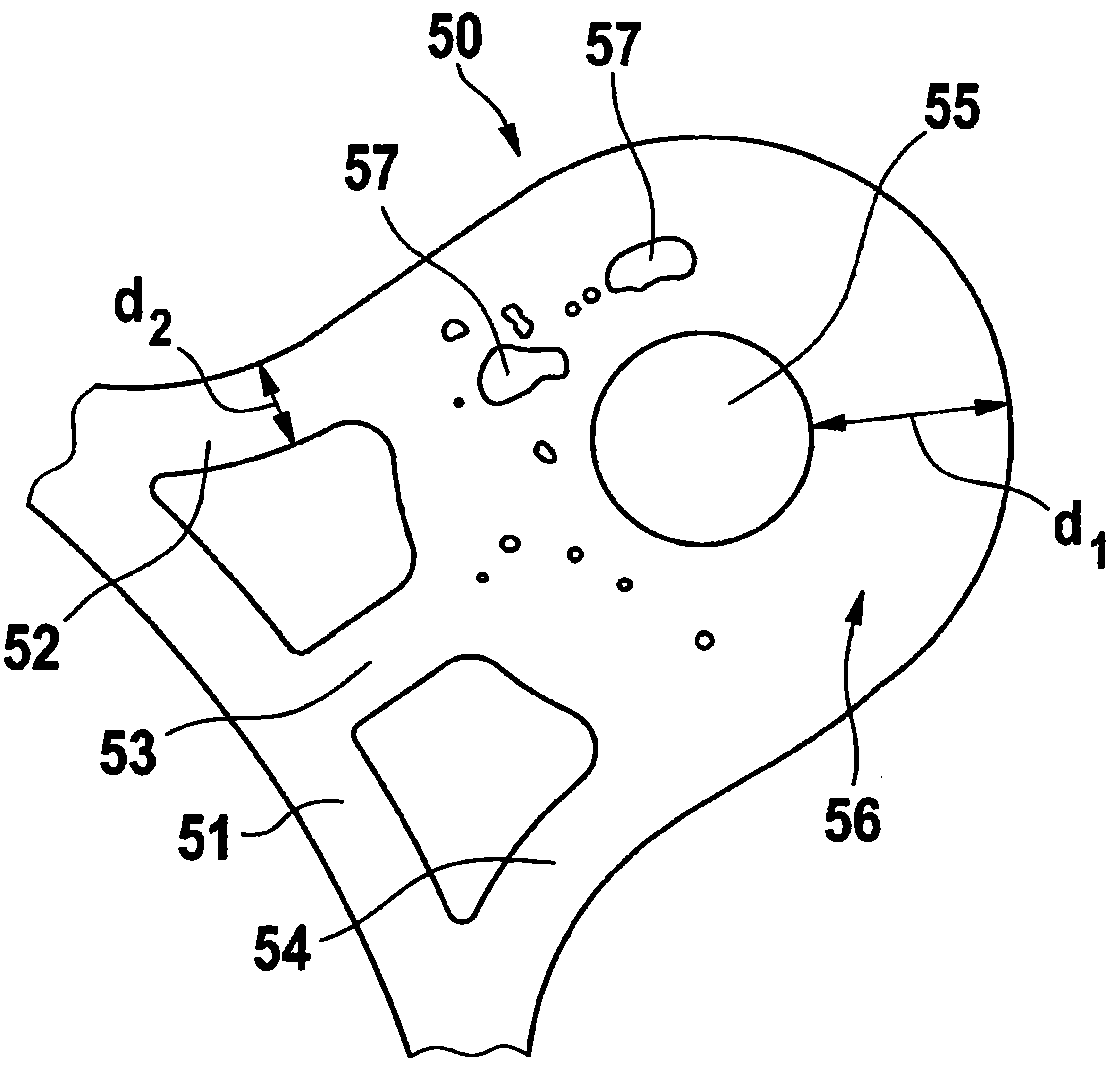

Housing element for transmission-drives of convenience drives

ActiveCN104696488BUniform solidificationReduce defect locationGearboxesPower-operated mechanismStructural engineeringMechanical engineering

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com