Quick change arbor, hole cutter, and method

An arbor and hole cutter technology, used in drilling/drilling equipment, manufacturing tools, transportation and packaging, etc., can solve the inaccuracy that reduces the drilling life of the drill bit, the inability of the drill bit to be completely fixed in the arbor, and the inability to install Standard directional drills, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

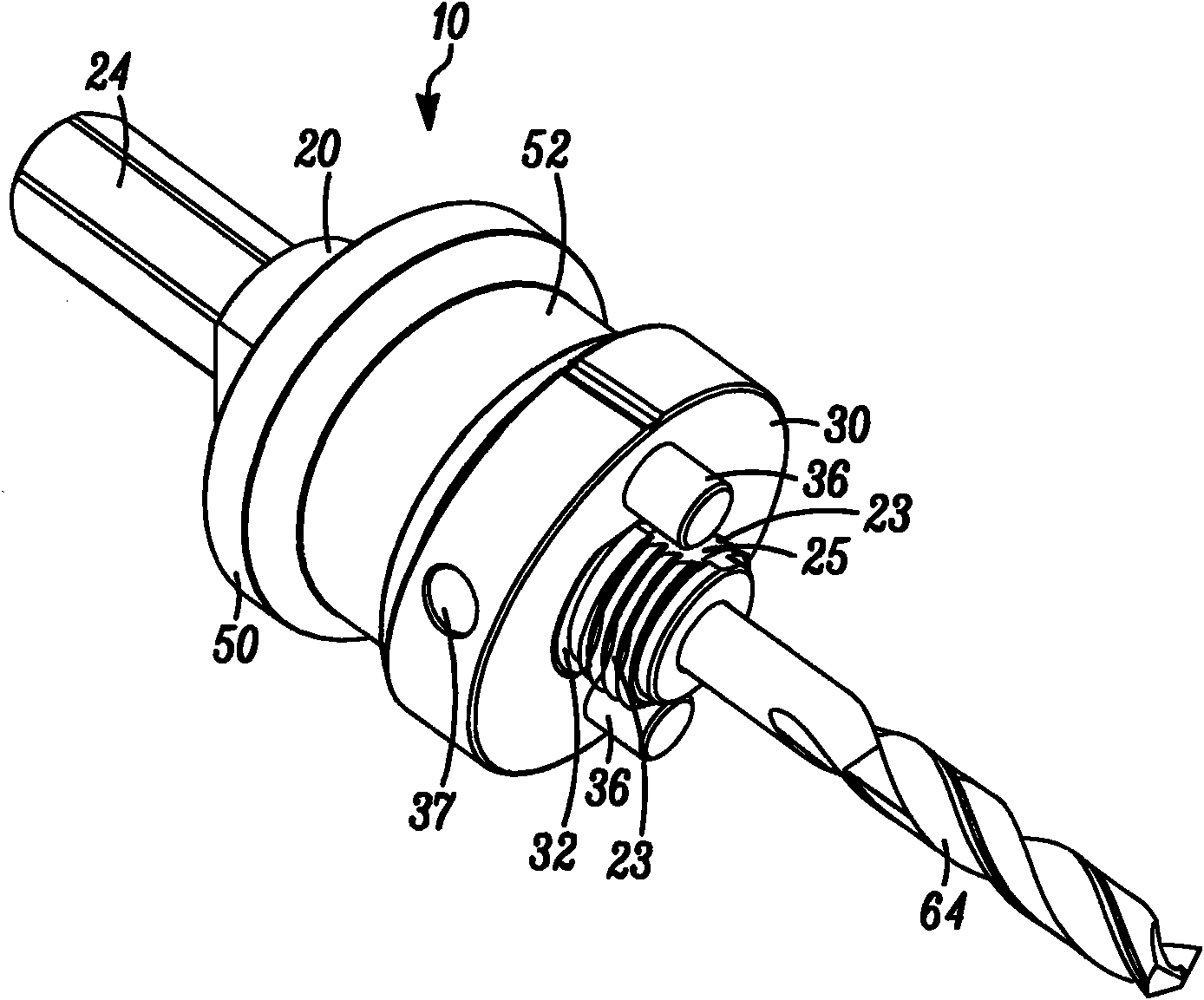

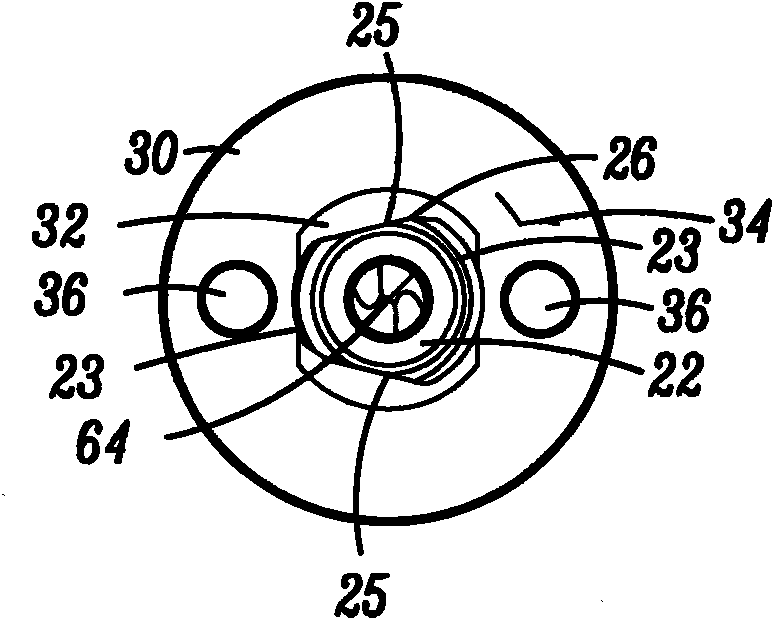

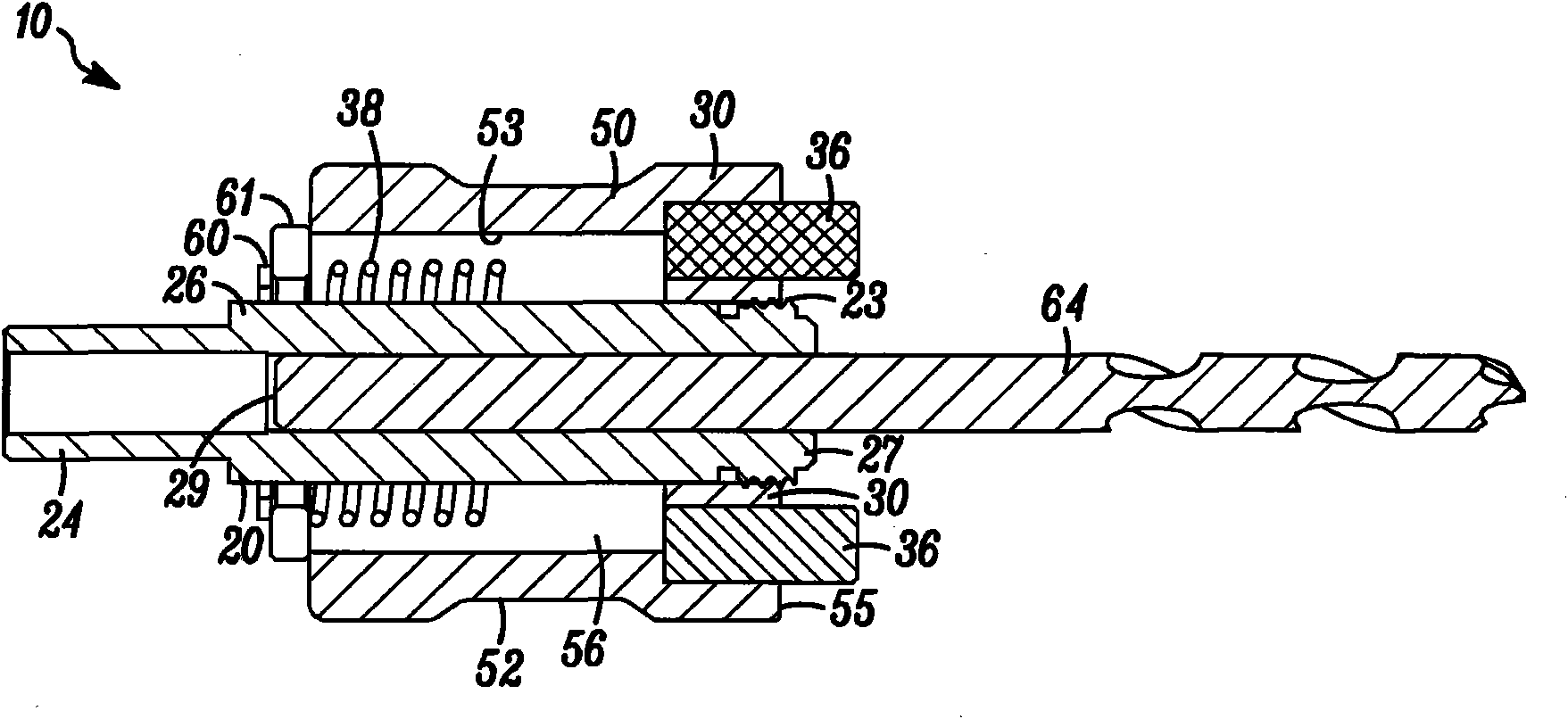

[0072] exist Figure 1-4 In , an arbor embodying the invention is generally indicated by reference numeral 10 . The arbor 10 is used with hole cutters, such as hole saws and sheet metal hole cutters. As used herein, the term "hole cutter" refers to any of various types of cutting tools used to create holes in workpieces, such as hole saws, sheet metal hole cutters, and the like. As used herein, the term "arbor" refers to any of various types of devices used to support a rotating tool, such as a hole cutter, on a power tool, such as a drill, the arbor further including but Not limited to mandrels. As shown, for example in Figure 4 and 10 A typical quick-change hole cutter 12 includes: an end plate 14 defining a hole cutter hole 16 extending through a central portion of the end plate; and at least one drive pin hole 18 radially spaced relative to the hole 16 . In the illustrated embodiment, there are two drive pin holes 18 radially spaced relative to the hole 16 and angula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com