Respirator tube fixing frame used for sickbed

A pipeline fixing and ventilator technology, which is applied in the field of medical equipment, can solve the problems of unfavorable patient rescue, pulling, violent shaking of the breathing pipeline, etc., and achieve good vibration reduction effect, effective and fast adjustment, and enhanced stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

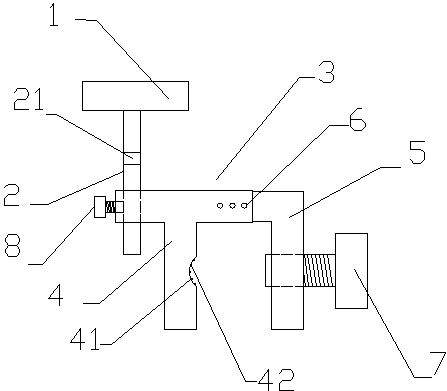

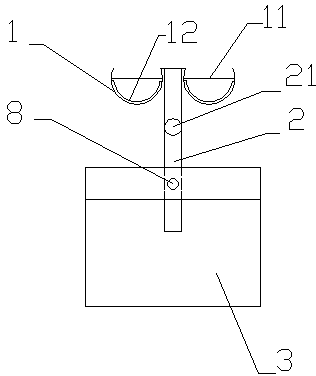

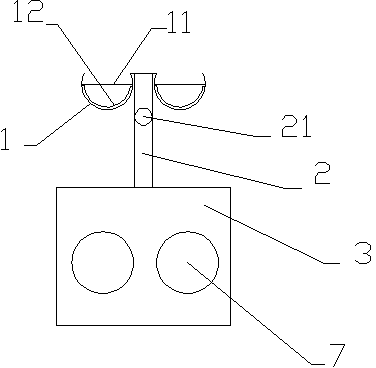

[0027] As shown in the figure, a ventilator pipe fixing frame for a hospital bed includes an arc-shaped bracket 1 with a pillar 2 and a base 3. The base 3 is composed of a part I4 and a part II5, and the part I4 and part II5 are connected by a spring. The clips are clamped in different small holes 6 to form a clamping part with adjustable width, which is clamped and fixed on the hospital bed by the top wire I7. The clamping part is provided with an arc-shaped groove 41 for clamping on the guardrail of the hospital bed. In addition, a plurality of ribs 42 made of flexible materials are provided in the arc-shaped groove 41, and the arc-shaped bracket 1 for carrying the ventilator pipeline is inserted into the opening of the base 3 through the pillar 2, and is connected by the top wire II 8 fixed, the pillar 2 is divided into upper and lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com