Housing element for transmission-drives of convenience drives

A technology for driving equipment and driving devices, applied to transmission parts, components with teeth, transmission boxes, etc., can solve the problems of reduced strength characteristics, different cooling speeds and pressure ratios, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

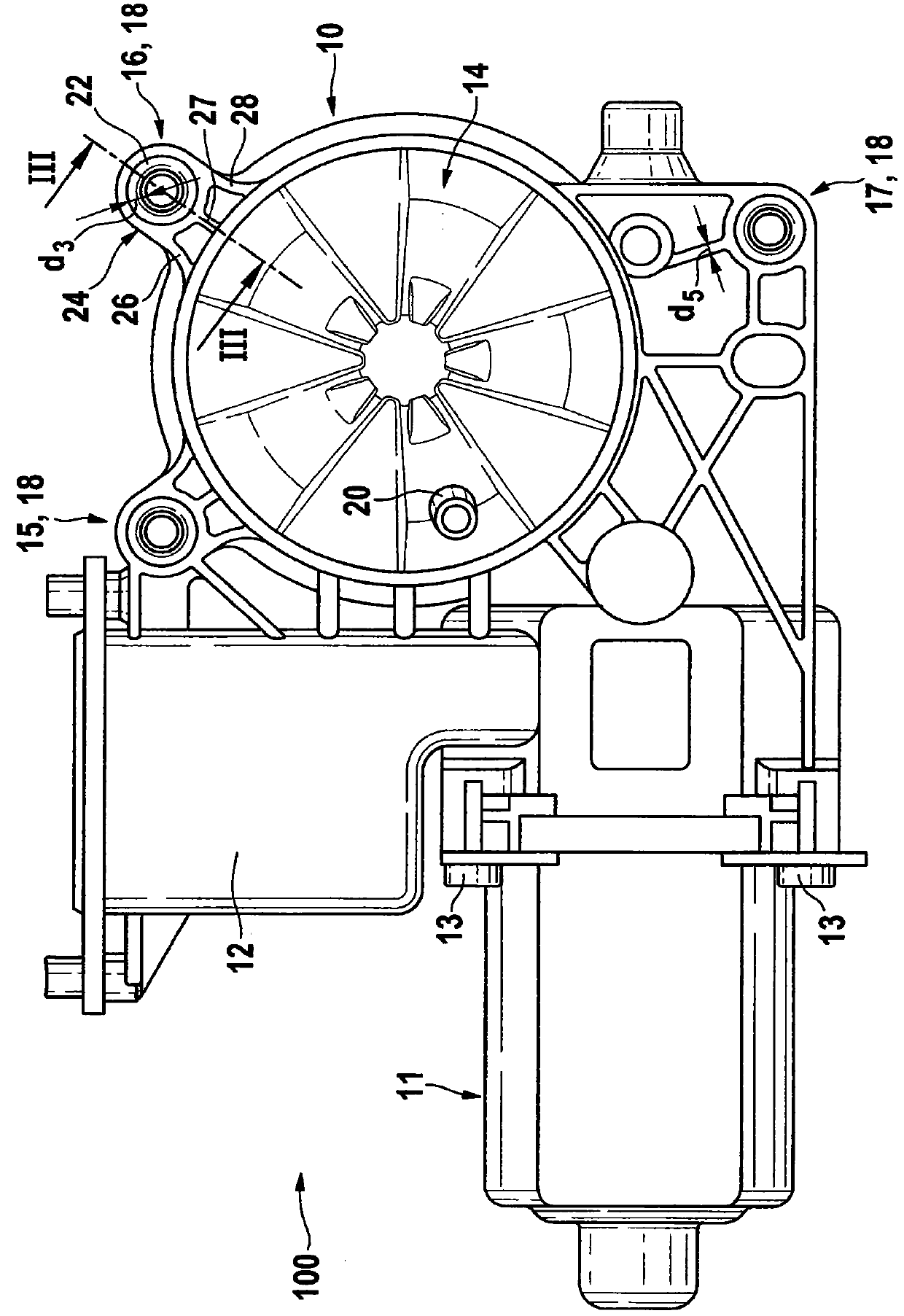

[0022] figure 1 shows a transmission drive 100 according to the invention, which is used in particular as a component of a convenience drive in a motor vehicle. Within the scope of the present invention, a "comfort drive" is to be understood as an example and not in a limiting sense a seat adjustment drive, a sliding roof drive, a window lift drive, etc.

[0023] The transmission drive 100 comprises a housing element in the form of a multi-part transmission housing 10 , to which a motor housing 11 of the electric motor is flanged. Furthermore, a connecting plug 12 integrally formed on the transmission housing 10 can be seen, which is used to electrically contact or actuate the transmission drive 100 . Usually, the motor housing 11 , which is made of sheet metal (alternative: plastic), is fastened to the transmission housing 10 by means of a plurality of fastening screws 13 . In the interior of the transmission housing 10 is arranged a one-stage or multi-stage transmission, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com