Patents

Literature

116results about How to "Avoid uneven coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

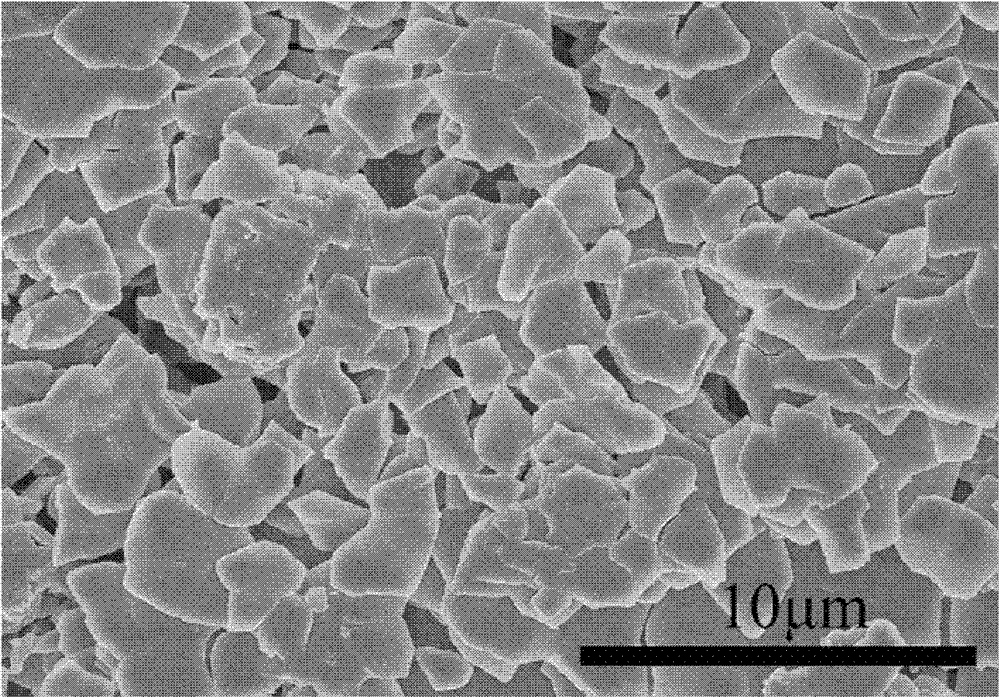

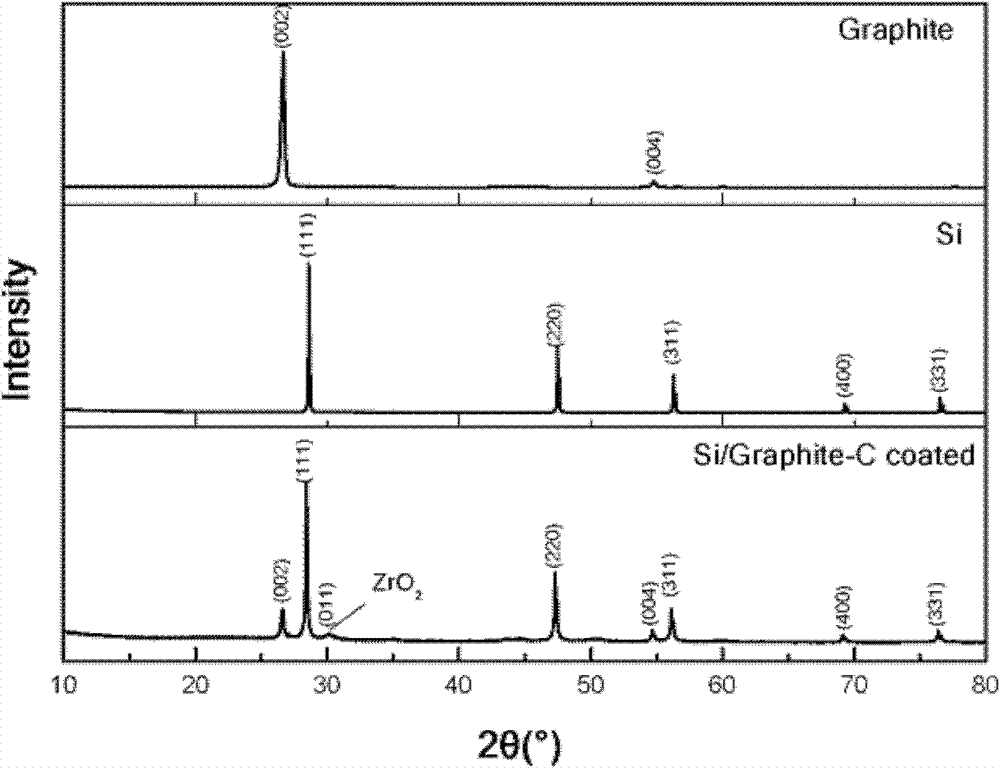

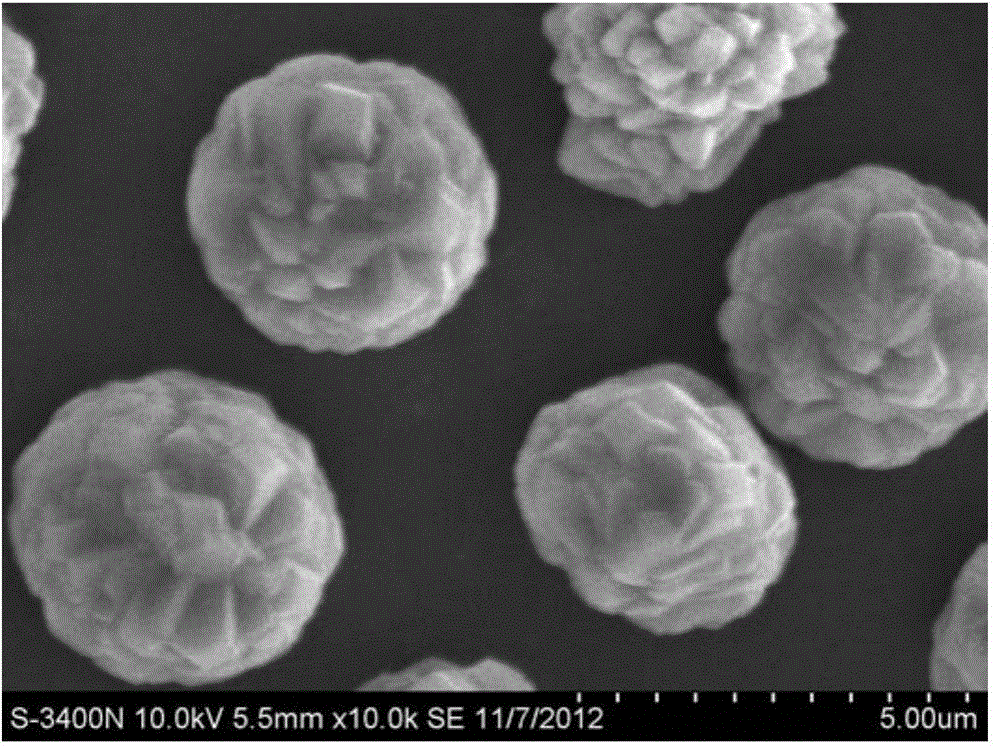

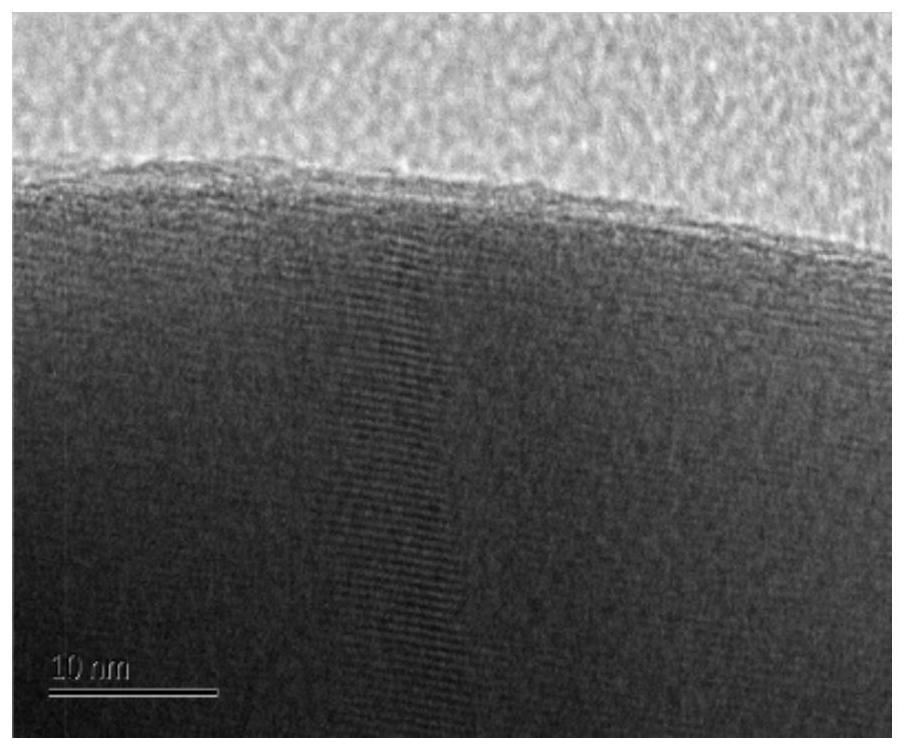

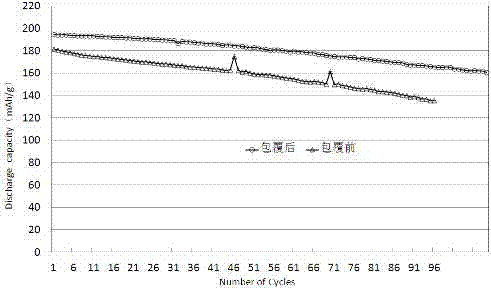

Preparation method of silicon carbon lithium ion battery cathode material

ActiveCN102790204AImprove cycle performanceIncrease capacityCell electrodesSurface oxidationFreeze-drying

The invention provides a preparation method of a silicon carbon lithium ion battery cathode material, which comprises the following steps: a) mixing a polymer solution, silicon powder and graphite to obtain a mixed solution; b) performing freeze drying of the mixed solution to obtain a solid mixture; c) sintering the solid mixture to obtain the silicon carbon lithium ion battery cathode material. The invention adopts freeze drying instead of a common drying method; the freeze drying means freezing the material, allowing the solvent component to rapidly become a solid state and to directly sublime under a vacuum condition so as to reach the drying purpose. With the process, the composite material and a carbon source can rapid coagulate within a short period, which avoids the problems of surface oxidation of the silicon material caused by normal temperature drying or high temperature drying, and non-uniform coating caused by settlement of the composite material powder. The obtained carbon-coated material has improved recycle performance and capacity when compared with materials obtained by common drying.

Owner:宁波富理电池材料科技有限公司

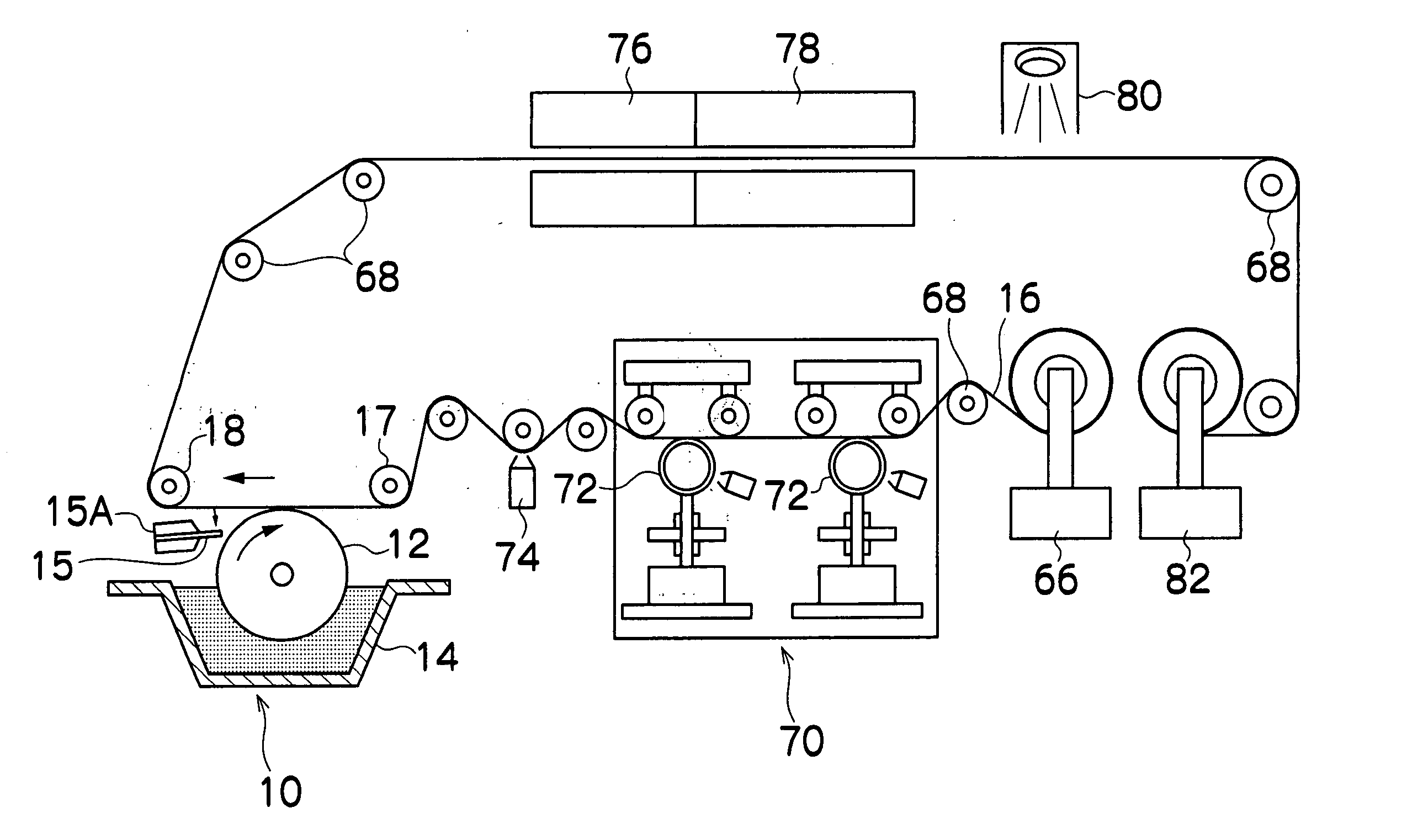

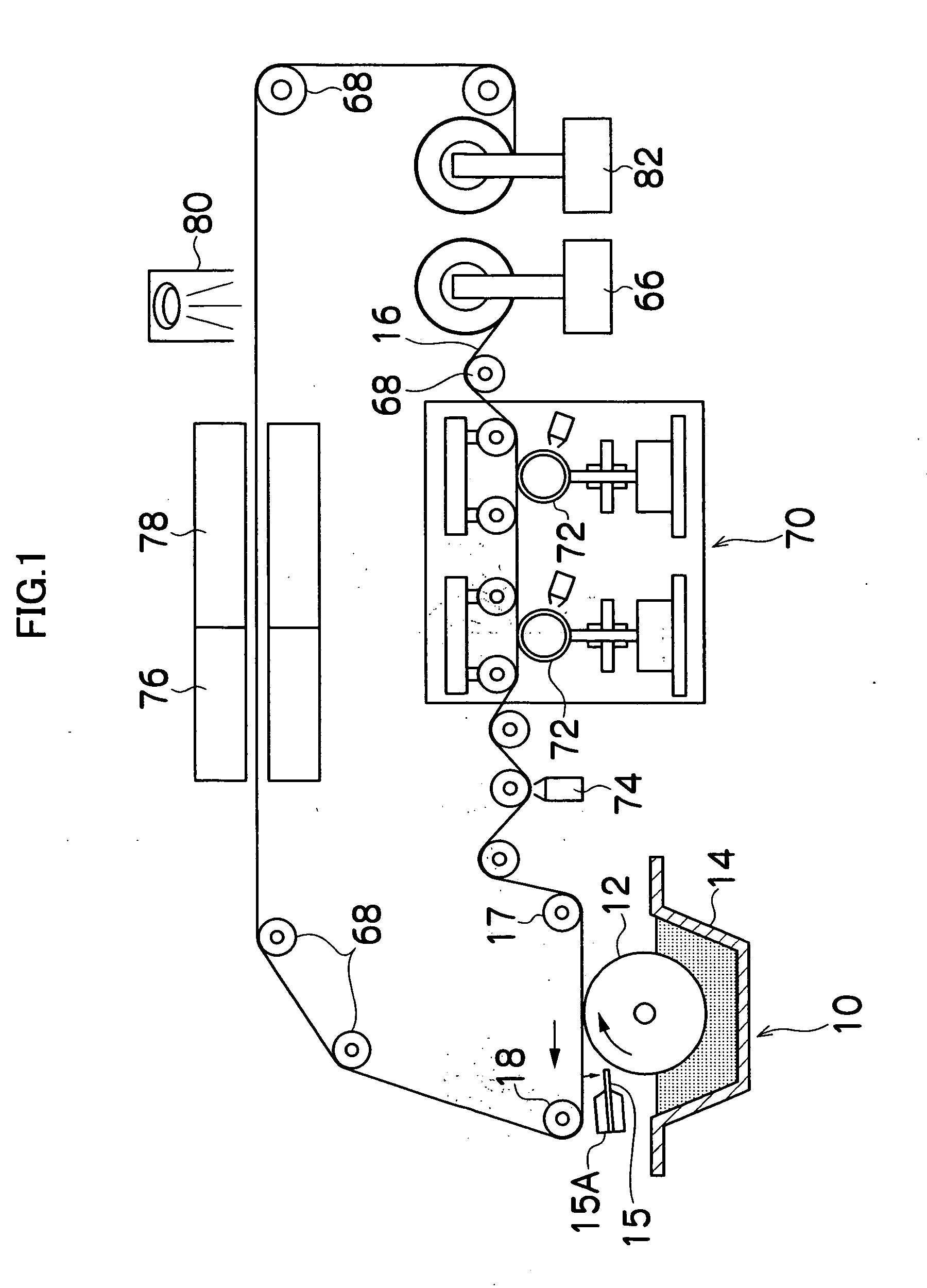

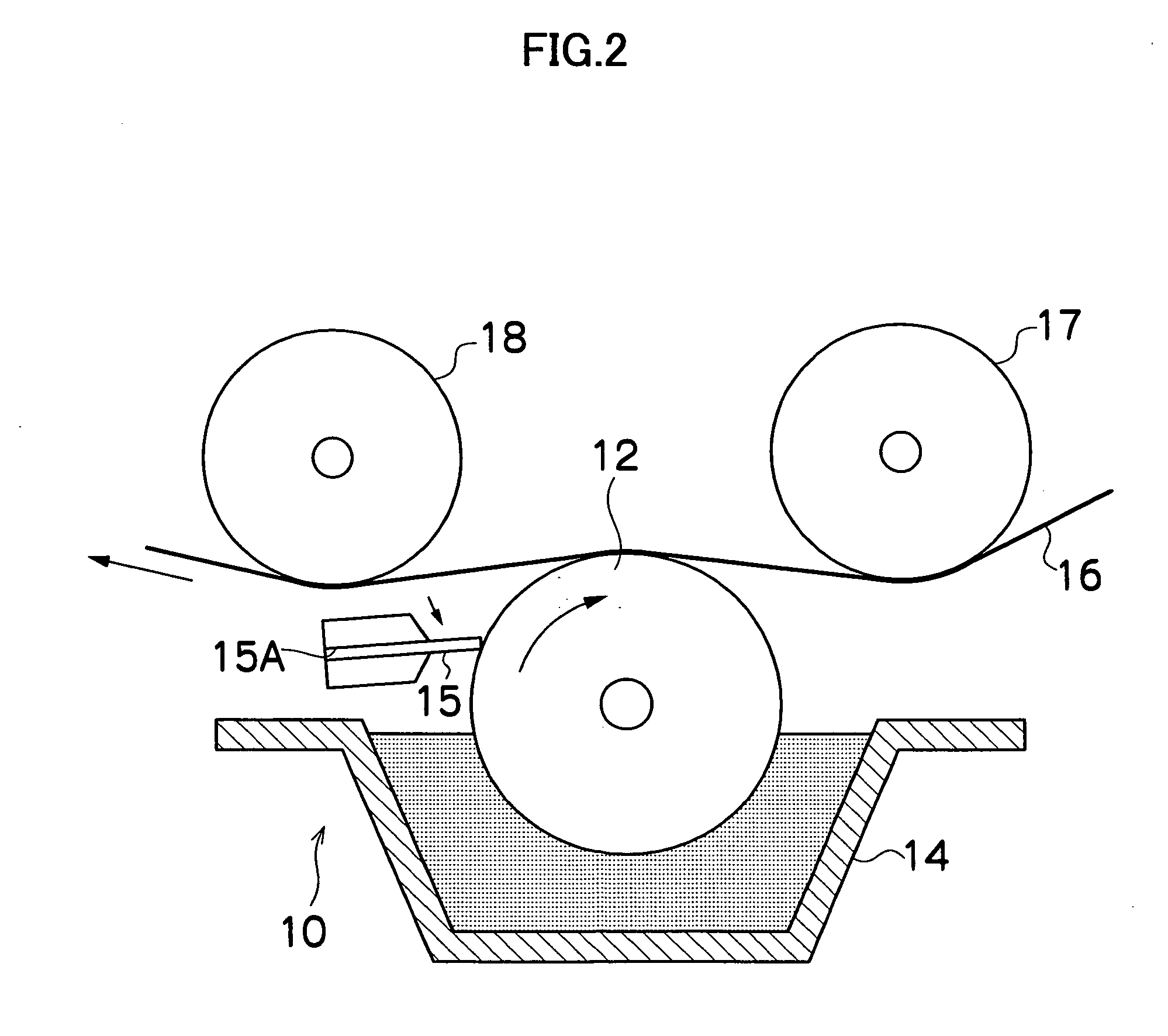

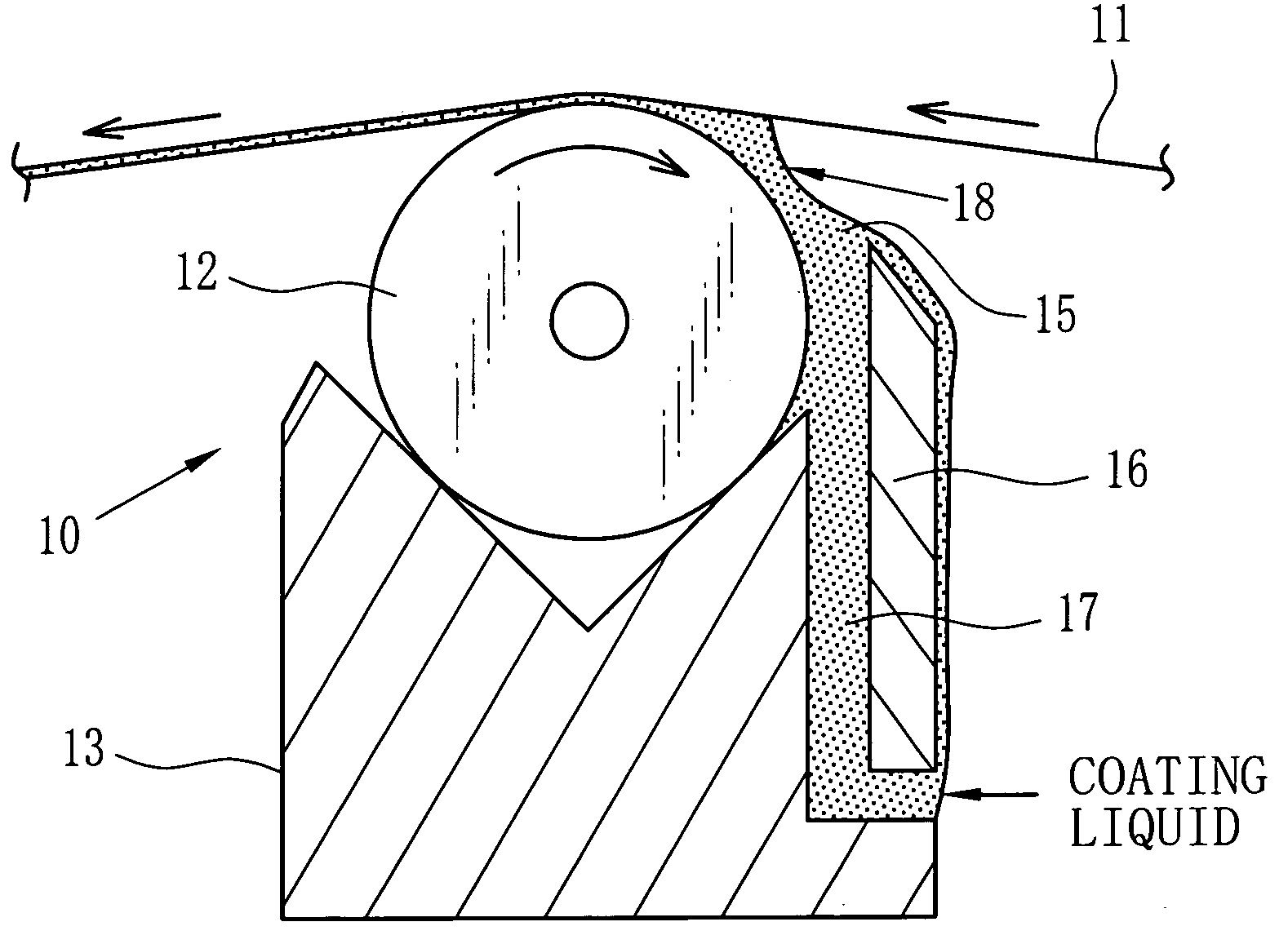

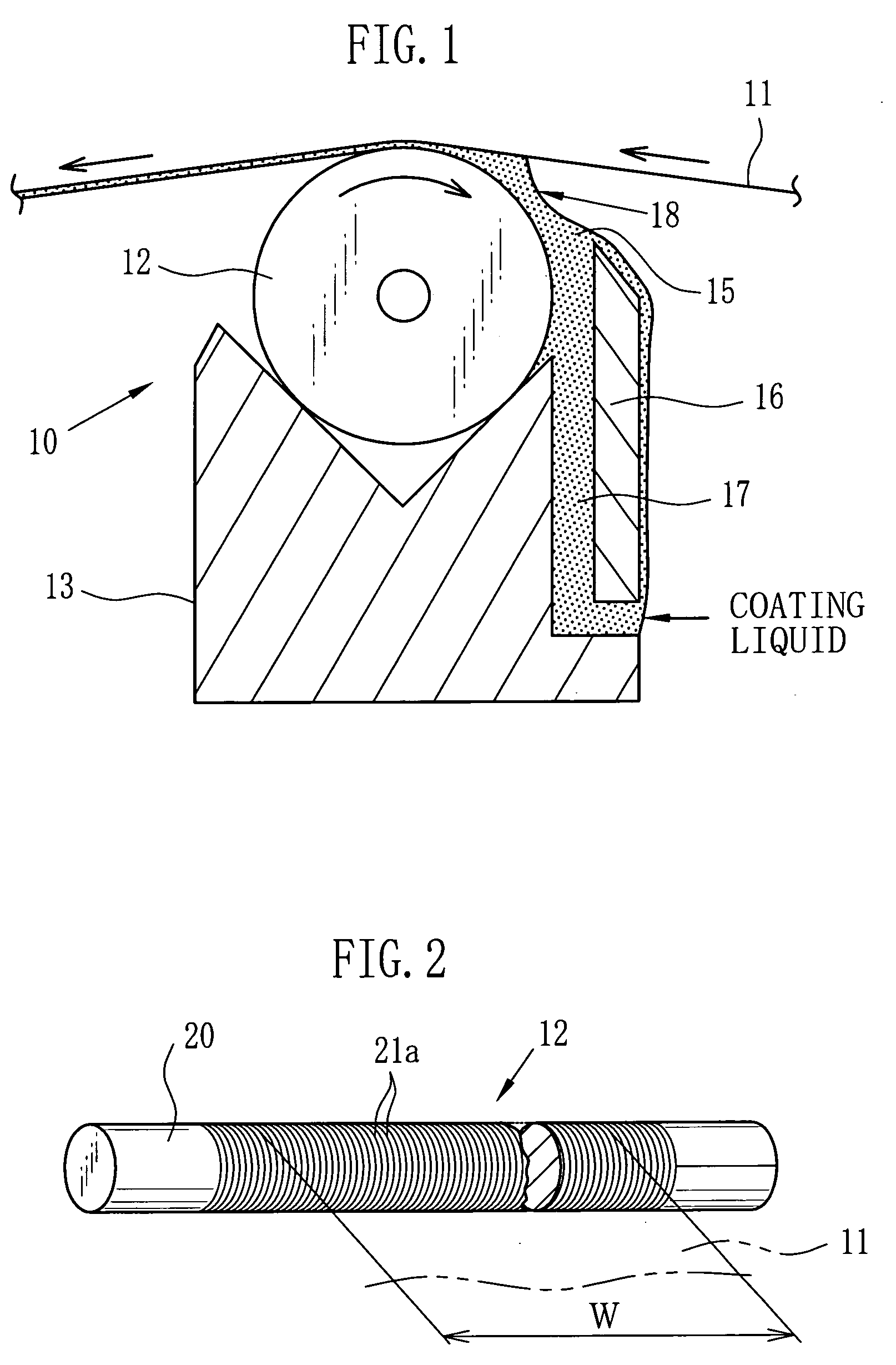

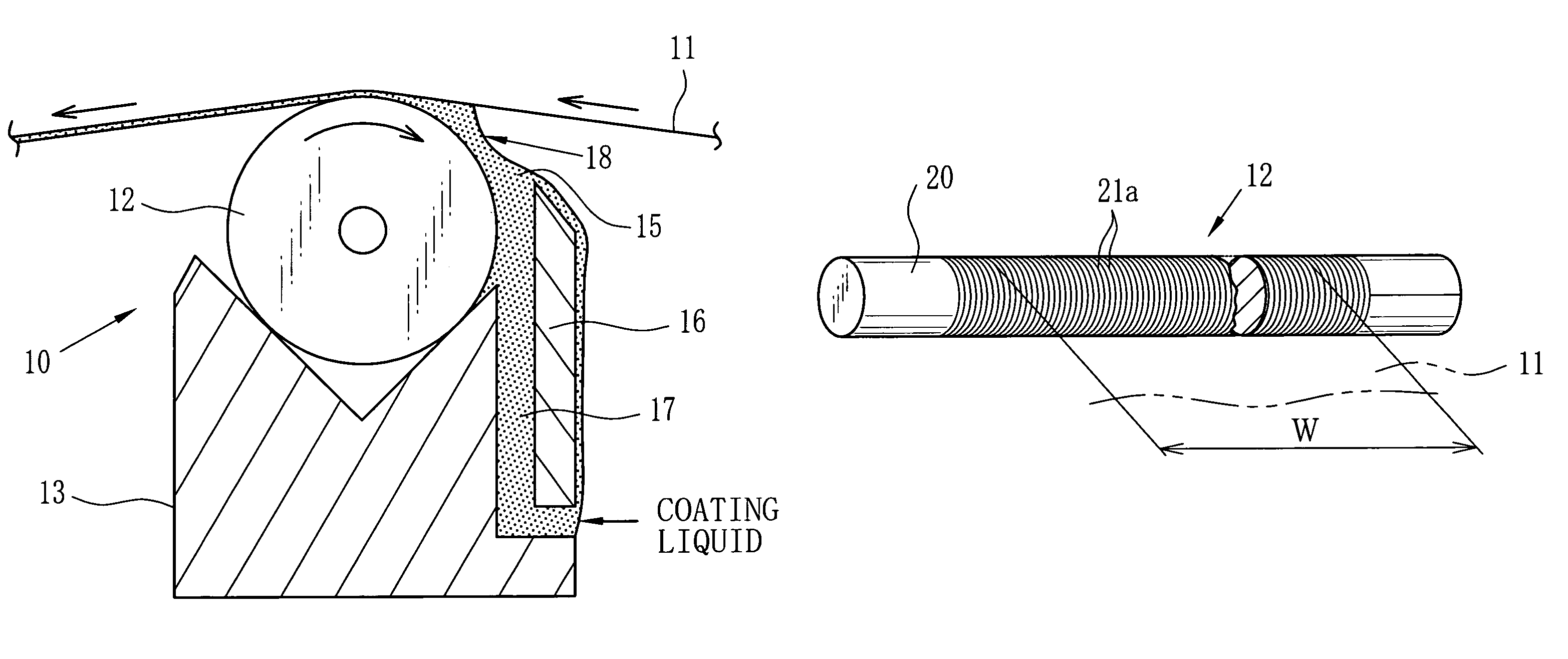

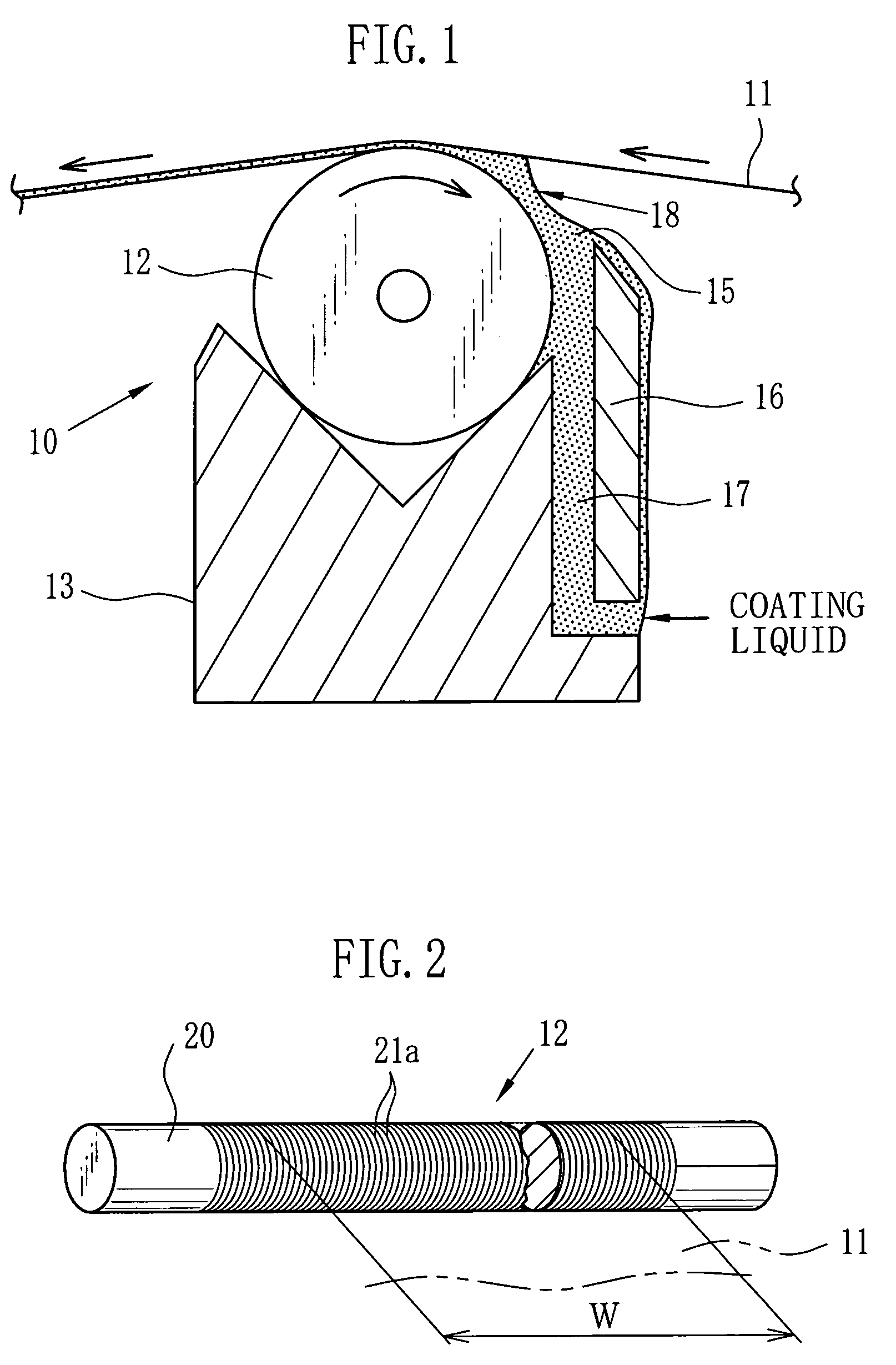

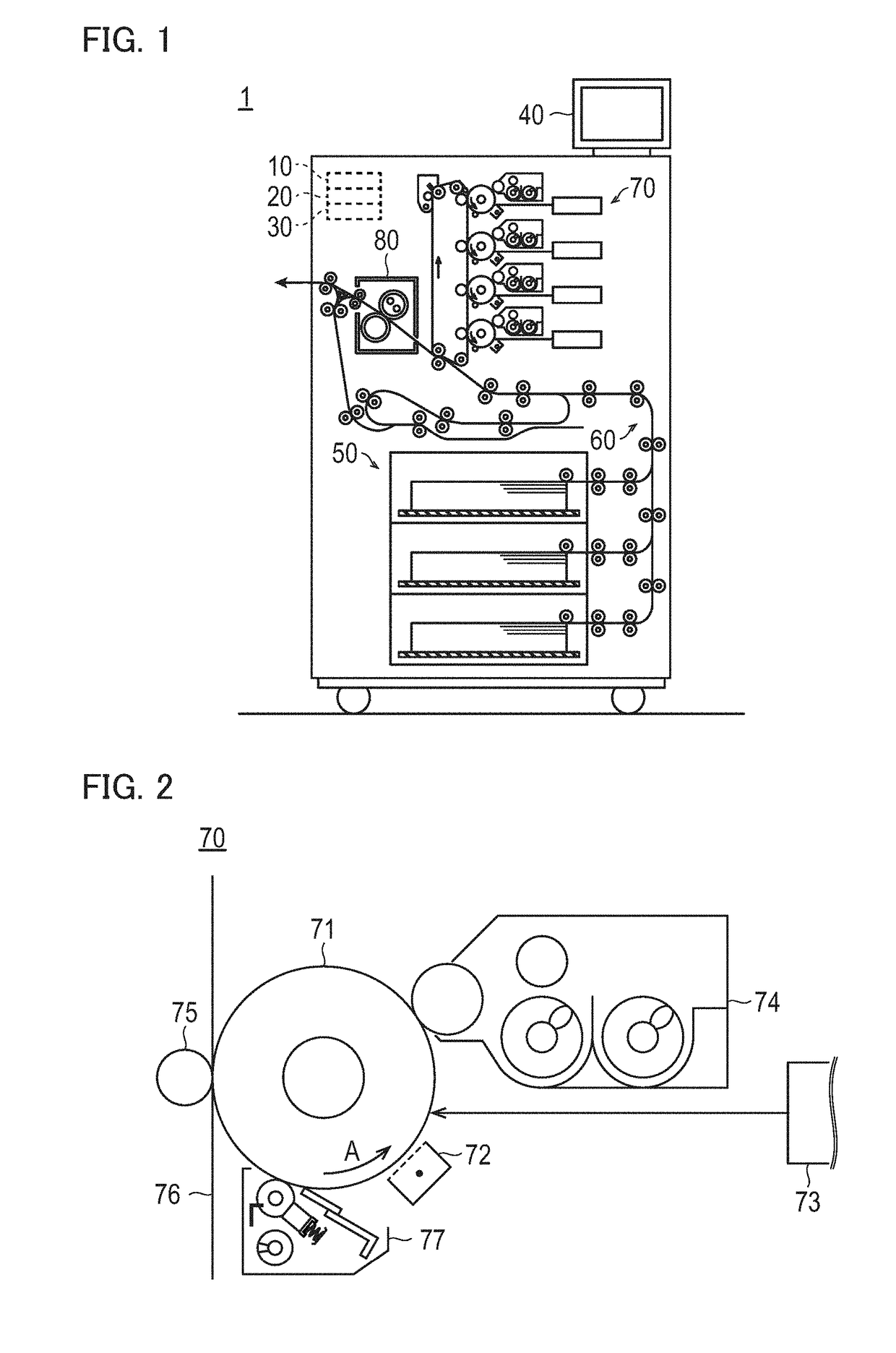

Gravure coating apparatus, and optical film

InactiveUS20050241573A1Avoid uneven coatingLiquid surface applicatorsRotary intaglio printing pressEngineeringCoating

According to the present invention, since the gravure roller with no load has a radial run out of 15 μm or less in all places of a pattern part in which cells are formed (the gravure plate cylinder) on the surface of the gravure roller, liquid accumulations (beads) are hardly affected by the radial run out of the roller surface, thereby making it possible to prevent coating nonuniformity.

Owner:FUJIFILM HLDG CORP

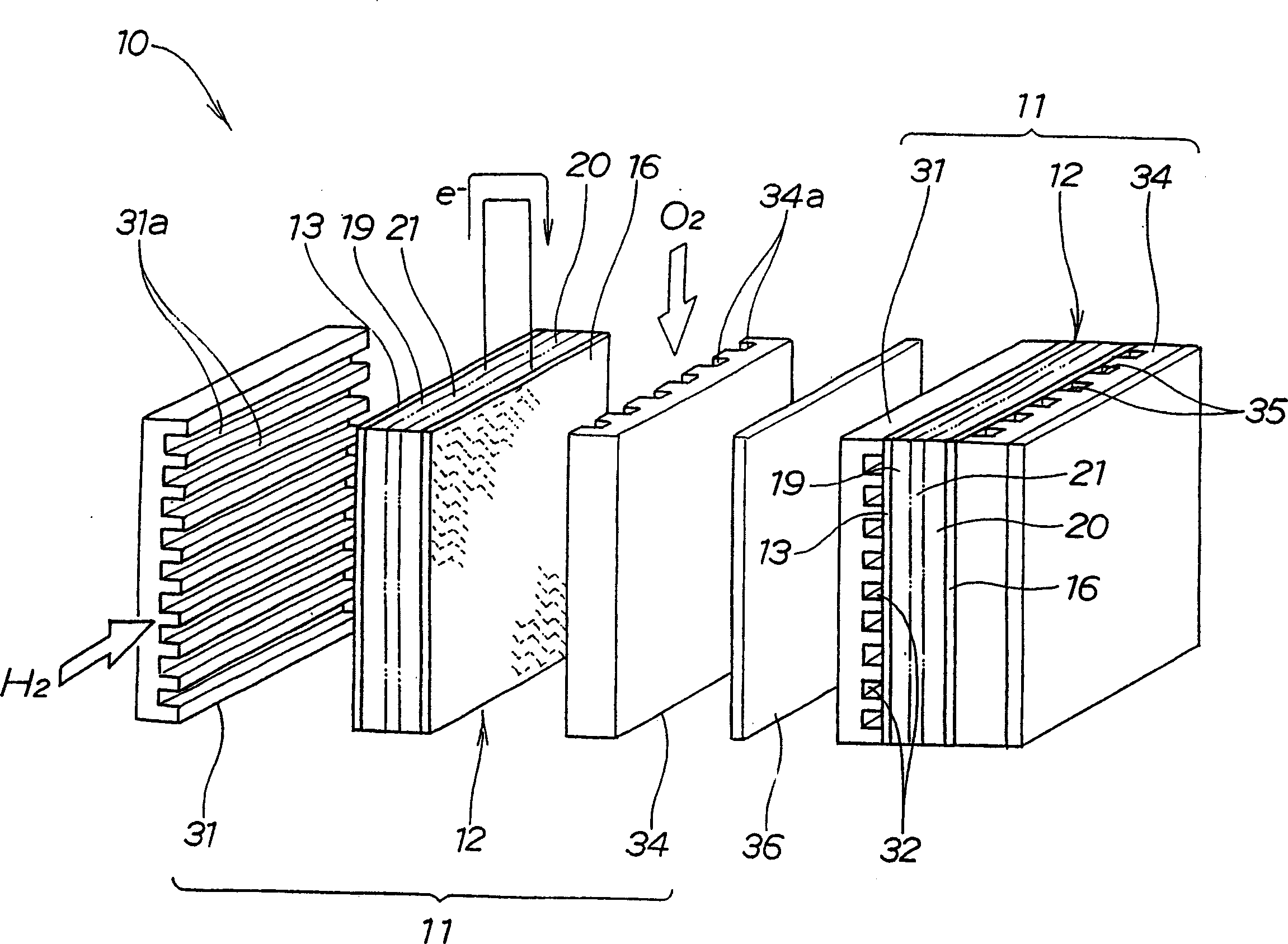

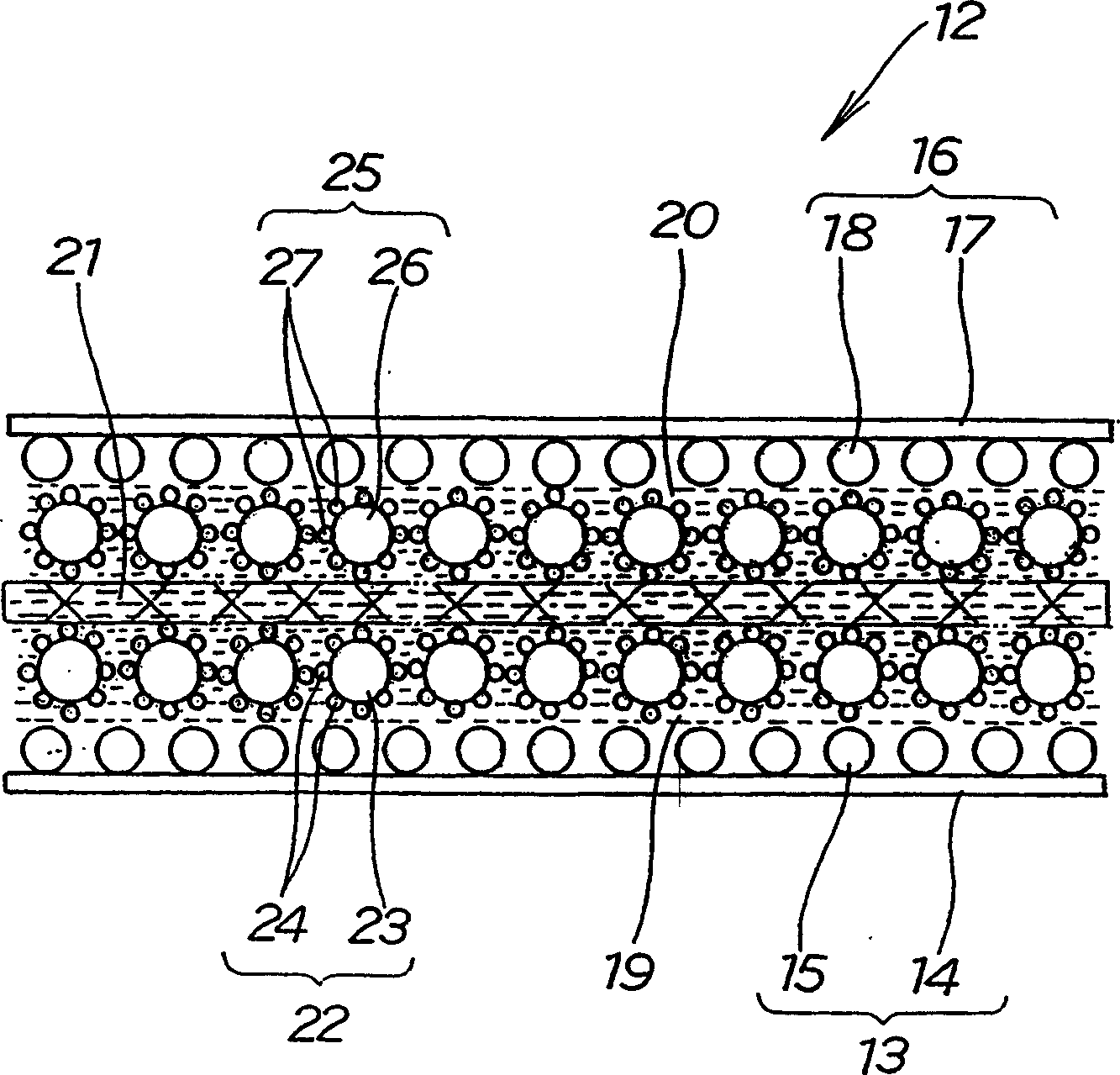

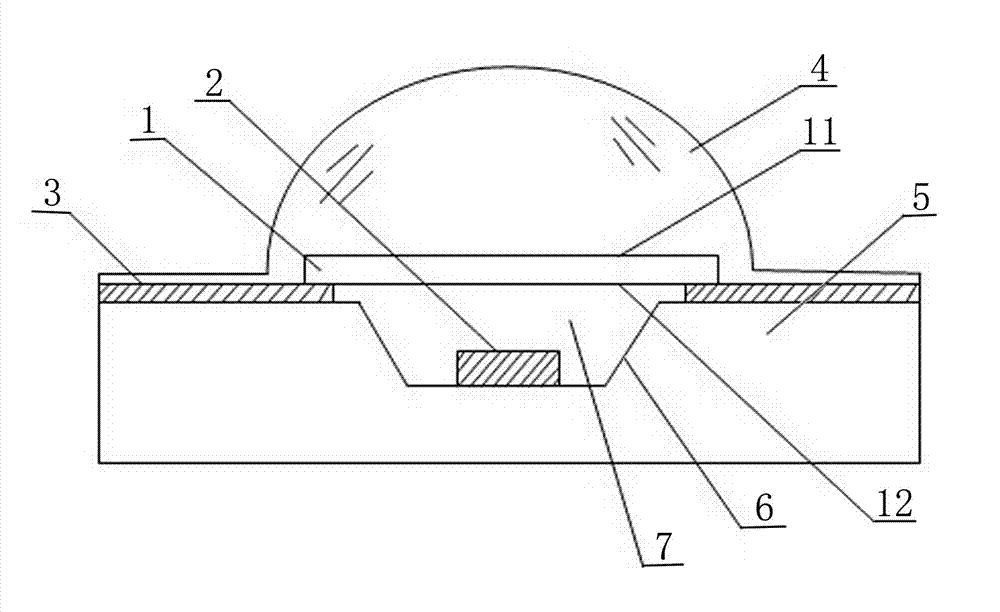

Method for manufacturing electrode for fuel cell

InactiveCN1613162AAvoid uneven coatingEfficient coatingCell electrodesFinal product manufactureFuel cellsIon-exchange membranes

The invention provides an electrode for a fuel cell, which comprises a positive electrode layer (20), a negative electrode layer (19) and an ion exchange membrane (21) placed therebetween. Before the solution for preparing one of the positive and negative electrodes is dried, the solution for preparing the ion exchange membrane is coated thereon, and then, the solution for preparing the ion exchange membrane is coated in a state where the solution for preparing the ion exchange membrane is not yet dried. solution for the other electrode. Since the layers are not yet dry, the adhesion between the layers is enhanced. By making the ion exchange membrane into solution, the coated membrane can be made very thin.

Owner:HONDA MOTOR CO LTD

Fluorescent and transparent polycarbonate grating for LED (light-emitting diode) and preparation method for same

InactiveCN103044892AControl shapeControl thicknessGrain treatmentsSemiconductor devicesColloidal silicaGrating

The invention provides a preparation method for a fluorescent and transparent polycarbonate grating for an LED (light-emitting diode). The materials of the fluorescent and transparent polycarbonate grating for an LED are composed of polycarbonate, fluorescent powder, an antioxidant, a coupling agent and a light dispersing agent. The fluorescent and transparent polycarbonate grating for an LED is formed by performing the preparation processes of sieving, preparing, mixing, drying, matching with auxiliaries, mixing, banburying, forming, annealing, cutting, etching and the like on the composition materials. The fluorescent and transparent polycarbonate grating can be used for an LED lamp bead / lamp, for adjusting the colour temperature of the LED, and solving the problems of the glare of the LED, the non-uniform distribution of the traditional silica gel fluorescent powder, and the like. The problem of non-uniform coating of the fluorescent powder is effectively solved, so that the light-emitting efficiency, the service life and the light spectrum stability of the white-light LED are improved; and moreover, the fluorescent and transparent polycarbonate grating is relatively simple in structure and preparation process, high in reliability, low in cost, good in plasticity and capable of being widely applied to LED manufacturing, as well as opens up unprecedented flexibility and creativity for the field of light sources.

Owner:SOUTH CHINA NORMAL UNIVERSITY

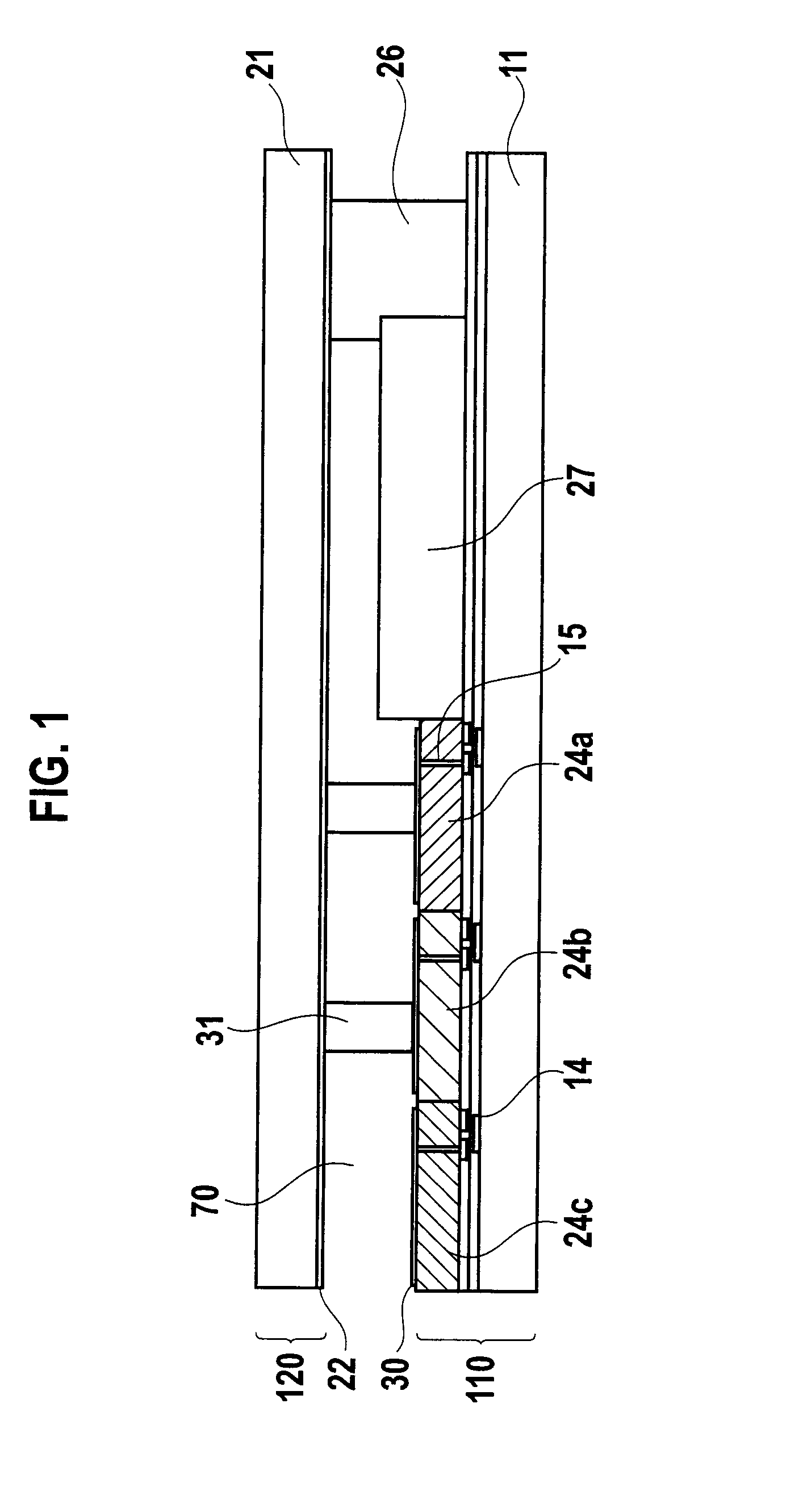

Liquid crystal display panel

Disclosed herein is a liquid crystal display panel of a transverse electric field system, including: a liquid crystal layer; and a pair of substrates configured to be so disposed as to be opposed to each other and sandwich the liquid crystal layer. In the liquid crystal display panel, a first electrode and a second electrode for applying an electric field to the liquid crystal layer and an alignment film are formed in a plurality of pixel areas that form a display area in one of the pair of substrates, a planarization insulating film is formed on a surface of at least one of the first electrode and the second electrode and across an entire surface of the pixel areas, and the alignment film is formed on a surface of the planarization insulating film.

Owner:JAPAN DISPLAY INC

Method for uniform carbon coating on lithium iron phosphate surface

InactiveCN105655548AStabilized carbon coating effectAvoid uneven coatingCell electrodesCarbon compositesPhosphoric acid

Belonging to the technical field of lithium ion battery anode materials, the invention relates to a method for uniform carbon coating on a lithium iron phosphate surface. The method includes the steps of: (1) preparation of an emulsion: preparing an organic carbon source and water into an aqueous solution, conducting heating to 50-100DEG C, adding an additive, and performing stirring to form an emulsion; (2) coating of the lithium iron phosphate surface with the organic carbon source: adding spherical iron phosphate into the emulsion, performing mixing for 0.5-8h to obtain a rheological body, and conducting drying to obtain iron phosphate powder; and (3) preparation of a lithium iron phosphate / carbon composite cathode material: mixing iron phosphate powder with a lithium source according to a Fe-Li mole ratio of 1:1-1:1.2, placing the mixture into an argon protective atmosphere sintering furnace, conducting heat preservation at 250-400DEG C for 2-6h, then raising the temperature to 550-700DEG C and performing heat preservation for 6-16h, and carrying out furnace cooling and sieving so as to obtain the lithium iron phosphate / carbon composite cathode material. The method provided by the invention has the advantages of stable process, simplicity and easy control, low cost, safety and environmental protection, high utilization ratio of the organic carbon source, high volumetric specific energy of the material, and easy industrialization, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

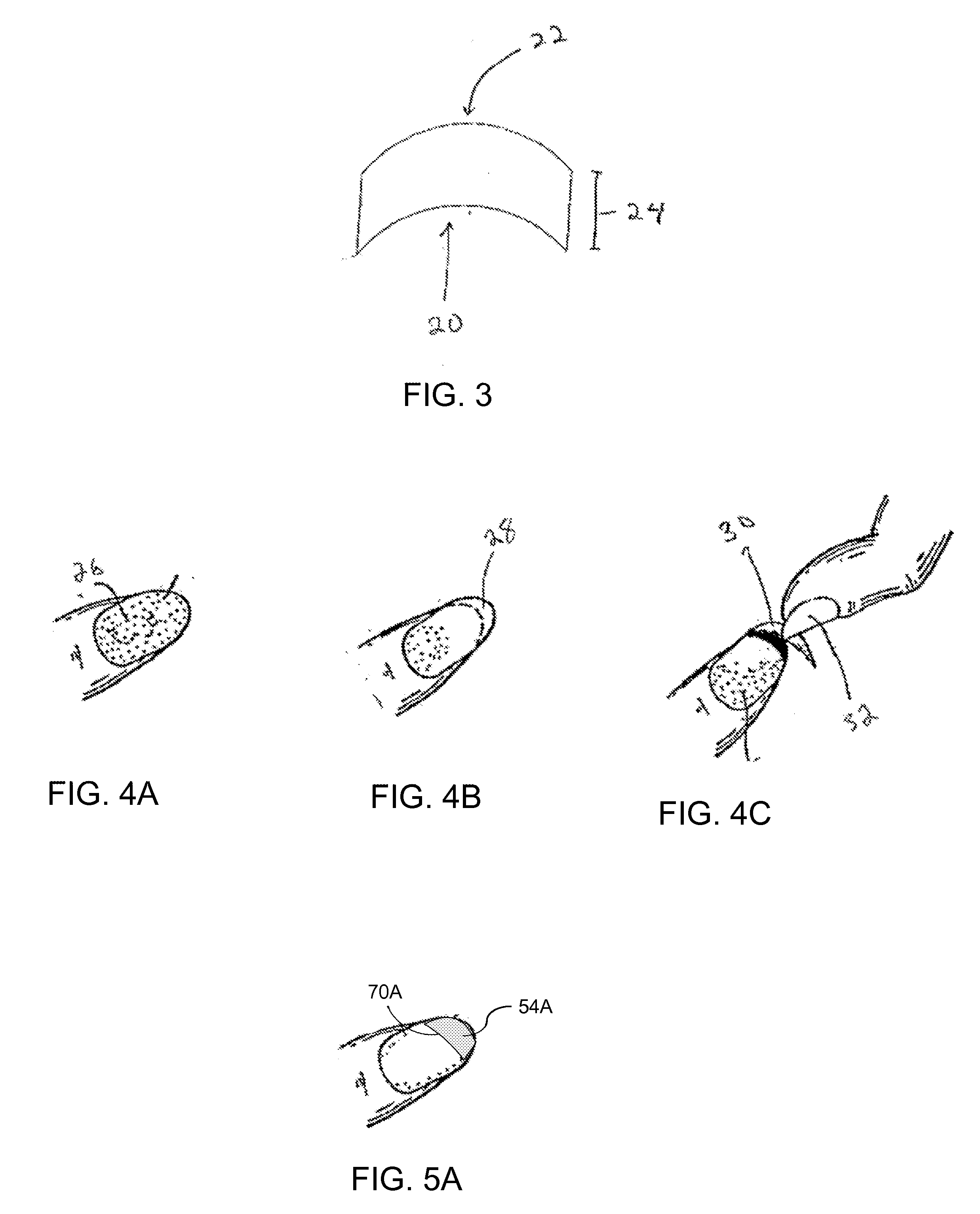

Method and product for attaining a french manicure using a dry nail appliqué

InactiveUS20130206157A1Avoid streaksAvoiding uneven coatingManicure/pedicureMedicineBiomedical engineering

Owner:PARK GLOBAL HLDG

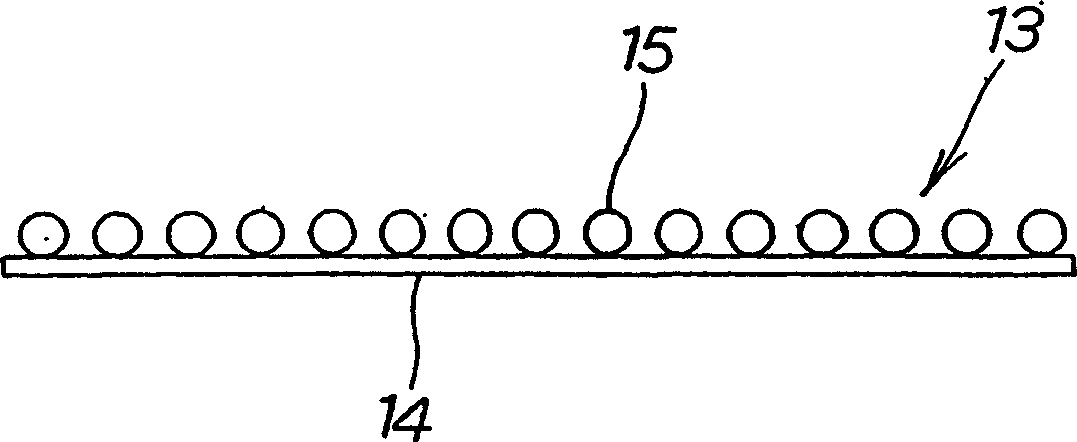

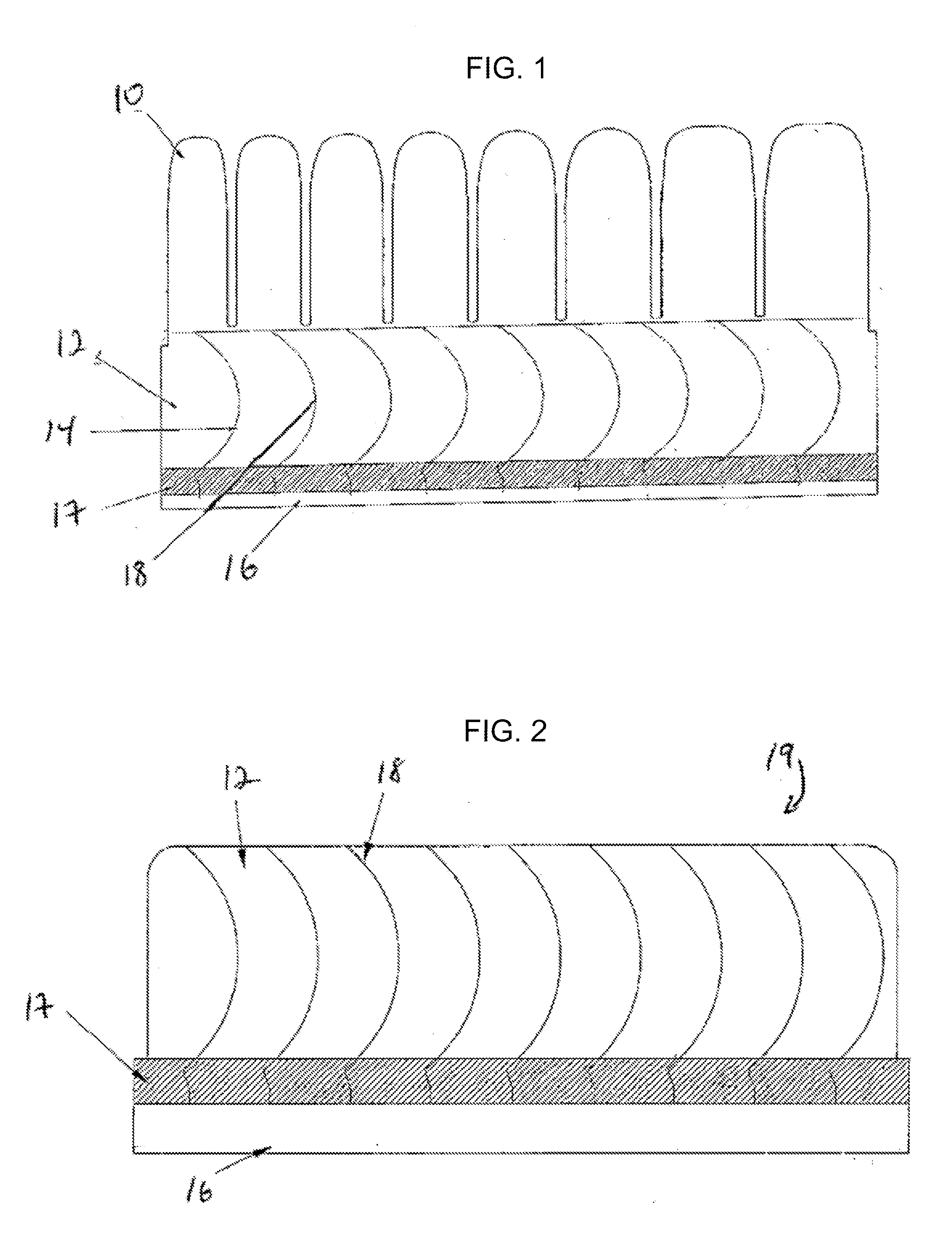

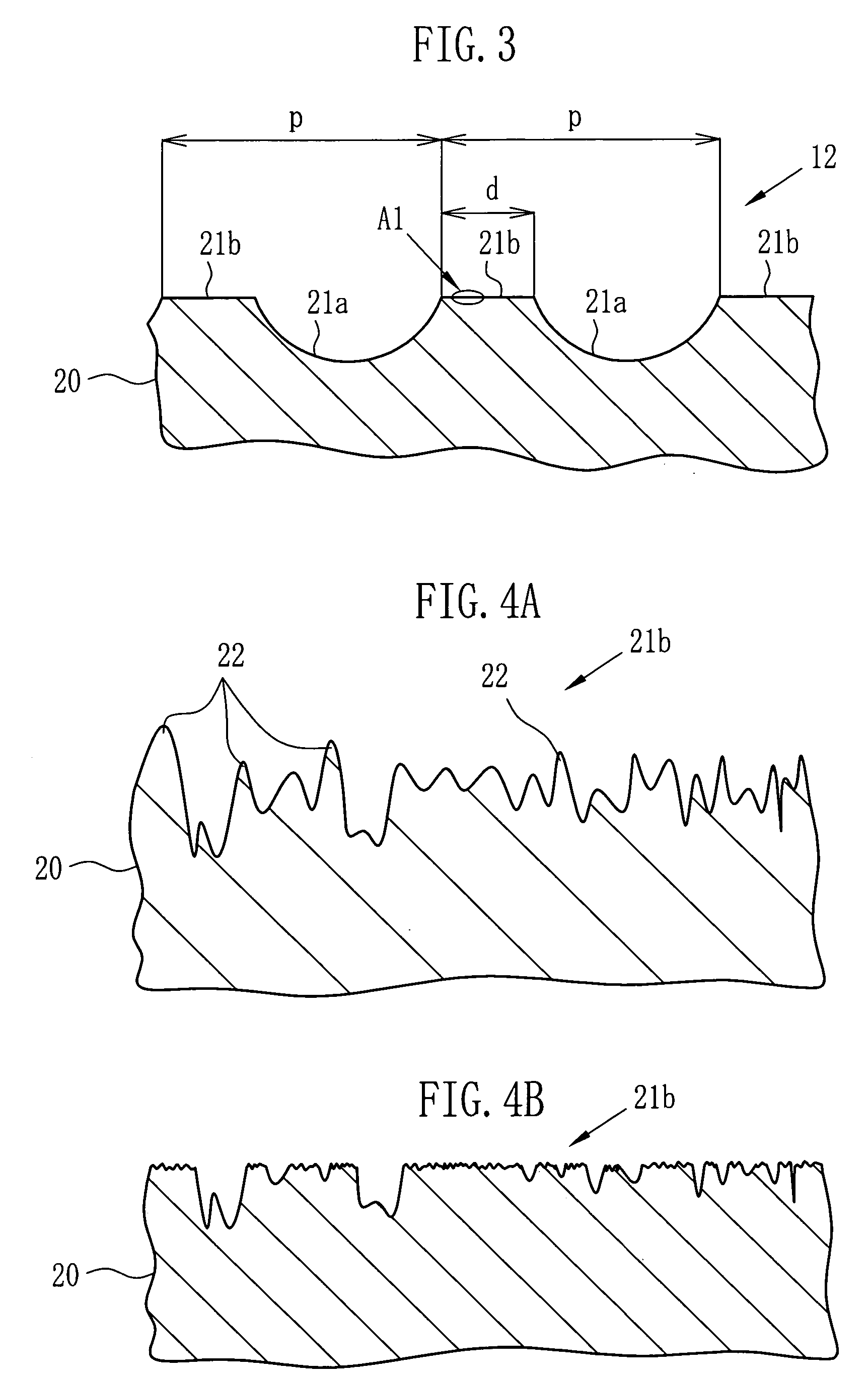

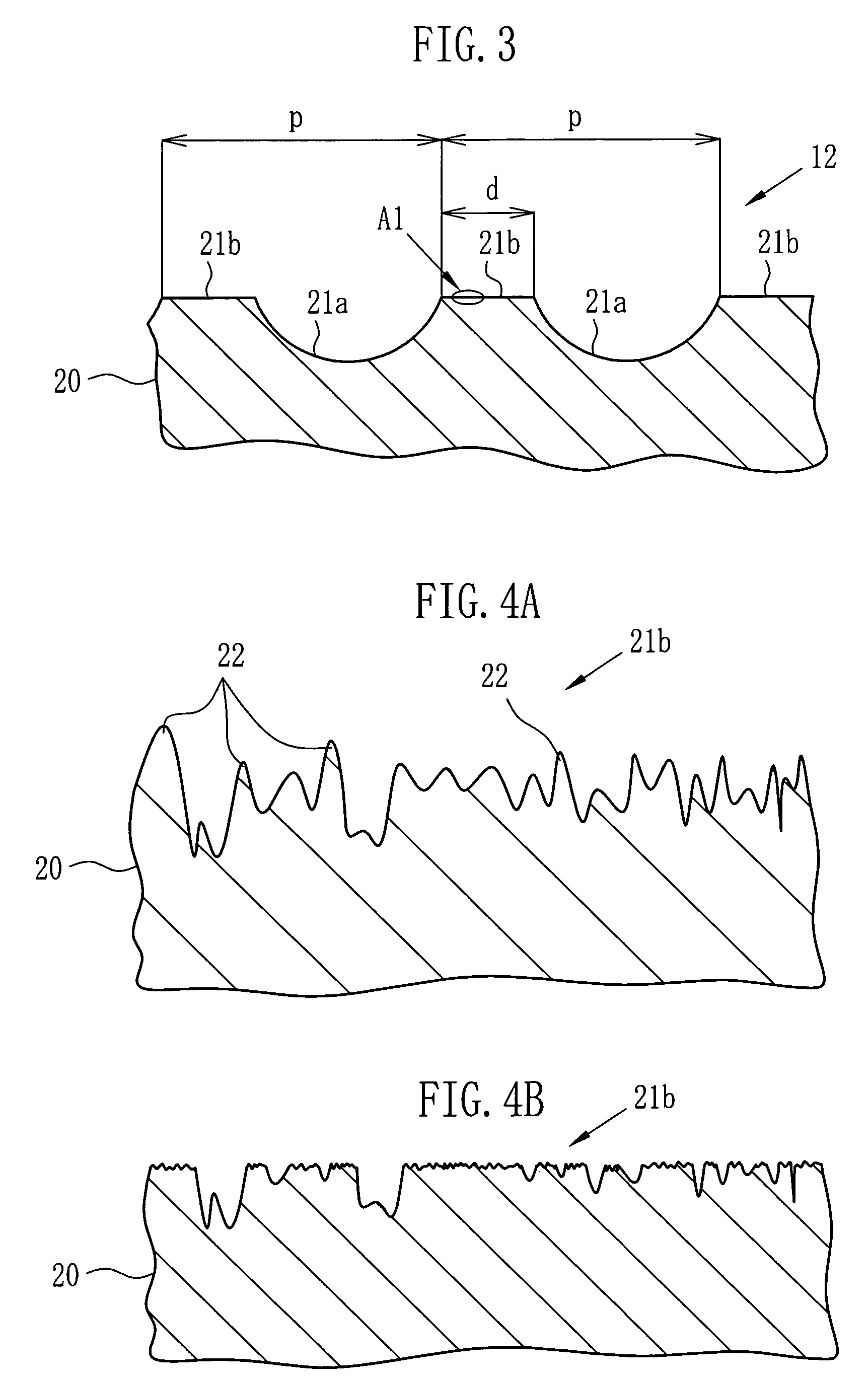

Coating rod and producing method therefor

InactiveUS20050109272A1Avoid unevennessAvoid scratchesLiquid surface applicatorsLapping machinesCoated surfaceEngineering

A peripheral surface of a coating rod has an area where grooves (convex portions) are formed. This area is ground by a grinding apparatus by which a maximum height Ry of the rod surface is adjusted to 15 μm or less. Further, a ratio of D / W is adjusted to 0.01 or more, wherein D is a total distance of the convex portions of the rod actually abutting on a web in an axial direction of the rod, and W is a coating width of the web. Furthermore, straightness of the rod is adjusted to 30 μm or less per 1 m, and roundness of the rod is adjusted to 10 μm or less. Micro-projections are removed by grinding so that scratches of a coating surface are prevented from occurring. Coating unevenness is prevented by improving the straightness and the roundness.

Owner:FUJIFILM CORP

Novel silica membrane for packaging solar cell module and preparation method

InactiveCN107245303AGood adhesionGood light transmissionNon-macromolecular adhesive additivesFilm/foil adhesivesRubber membraneAging resistance

The invention relates to a novel silica membrane for packaging a solar cell module and a preparation method. The preparation method of the silica membrane comprises the following steps: dissolving 15 to 50 parts of silicone resin into 30 to 50 parts of silicone oil, and adding 5 to 15 parts of curing agent, 0.5 to 1 part of catalyst and 1 to 10 parts of reinforcing agent, and preparing a membrane forming rubber solution; and smearing the rubber solution onto a base material by utilizing a smearing device, and heating and curing for 1 to 5 min at 120 to 160 DEG C to form a membrane. The silica membrane prepared by the invention is used for packaging a solar cell, and compared with the traditional EVA rubber membrane, the ultraviolet permeability and aging resistance are higher, and the high temperature and low temperature resistance and the adhesive property are excellent.

Owner:CHANGZHOU CHIKE PHOTOELECTRICITY TECH CO LTD

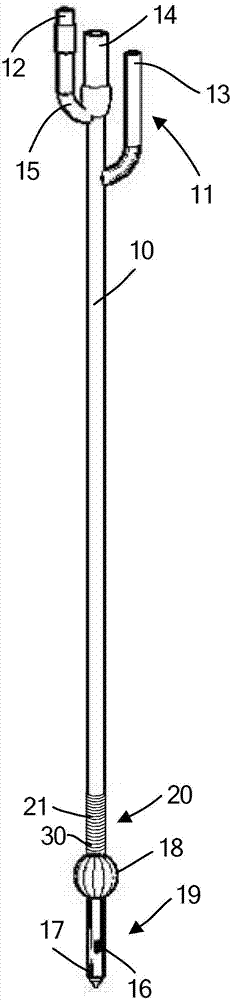

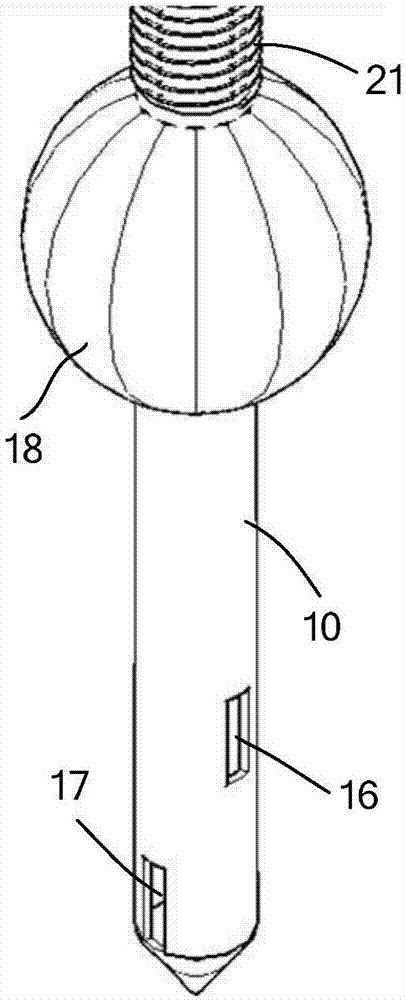

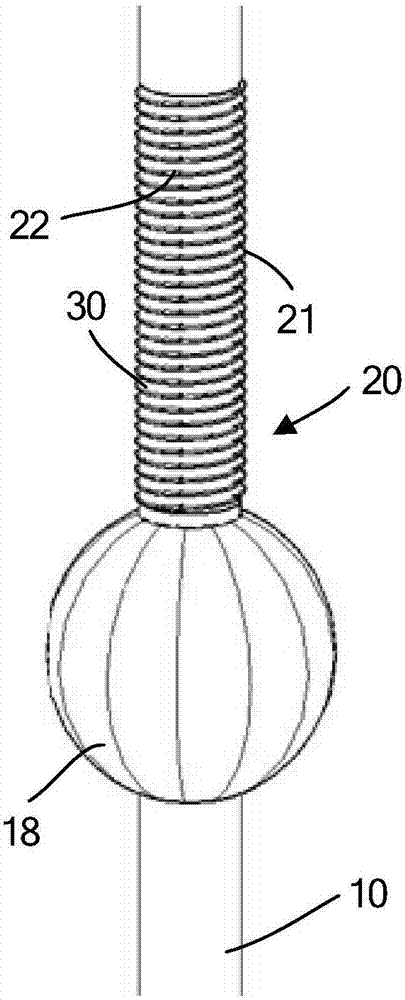

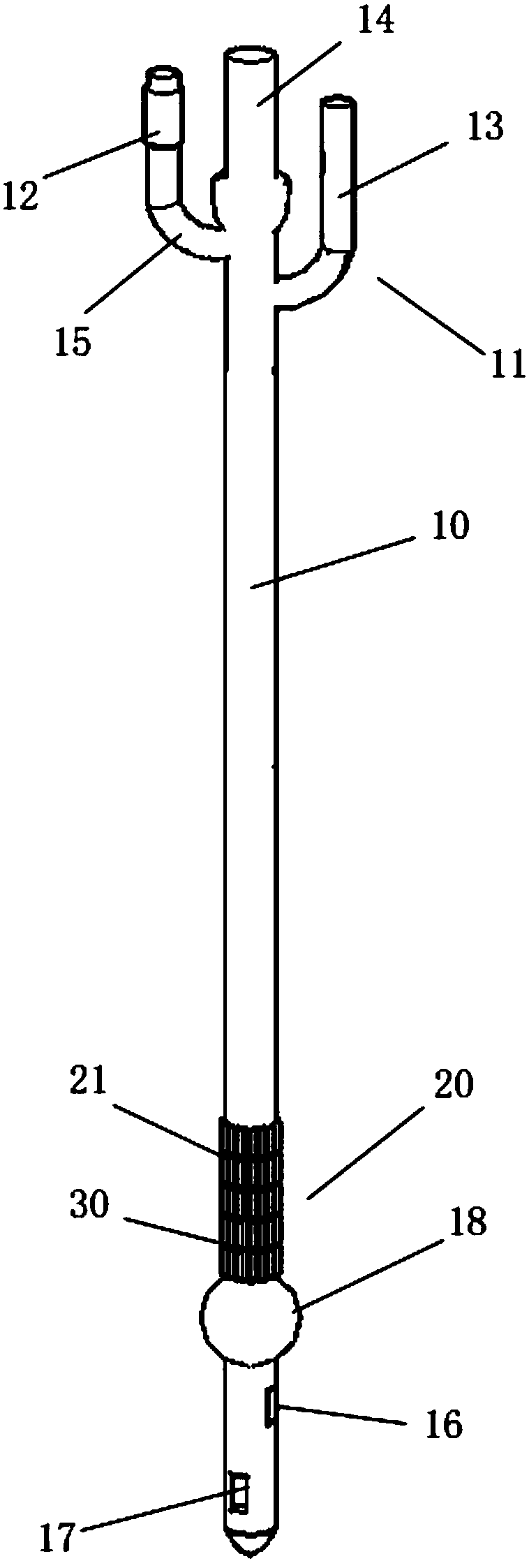

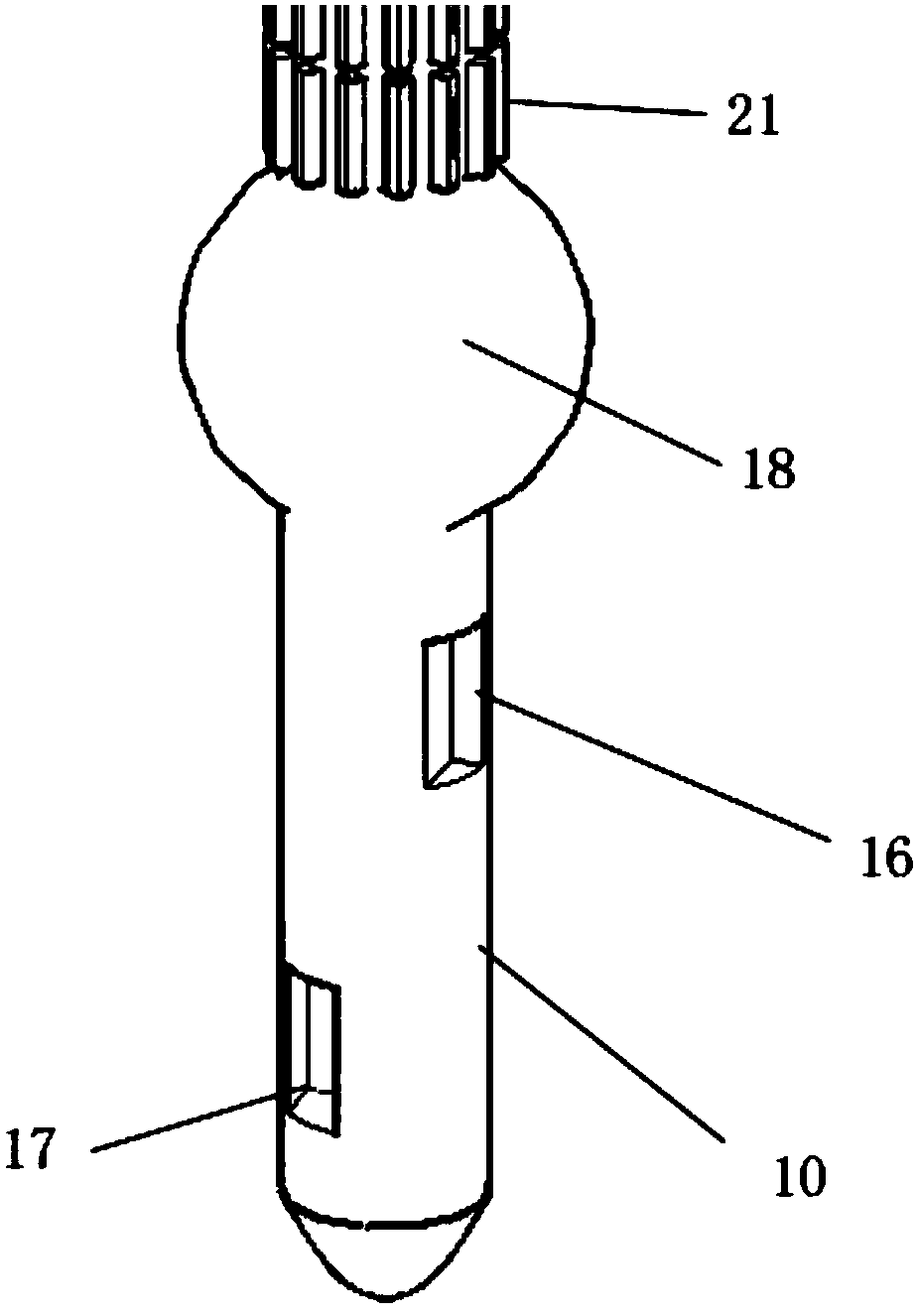

Threaded catheter with coating

PendingCN107497034AIncrease coating areaGood healing effectBalloon catheterMedical devicesToxic doseCoating

The invention discloses a threaded catheter with a coating. The threaded catheter comprises a catheter body, a balloon is arranged at the position of the catheter body close to the front end of the catheter body, threaded projections are arranged at the position of the outer surface of the catheter body close to the balloon to form a threaded section, grooves are formed in the threaded section along the length direction of the catheter body and the periphery of the threaded section at intervals, a Se-SiO2 coating is sprayed on the periphery of the threaded section of the catheter body, nano-Se-SiO2 materials and chitosan are mixed to form the Se-SiO2 coating, and porous SiO2 wraps Se particles to form the nano-Se-SiO2 materials. According to the threaded catheter with the coating, on one hand, the coating area of the coating is increased, on the other hand, oxidative stress of a prostate wound surface is restrained, the toxic dose caused by rapid releasing of the Se particles is avoided, and rapid rehabilitation of postoperative prostate is facilitated.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL

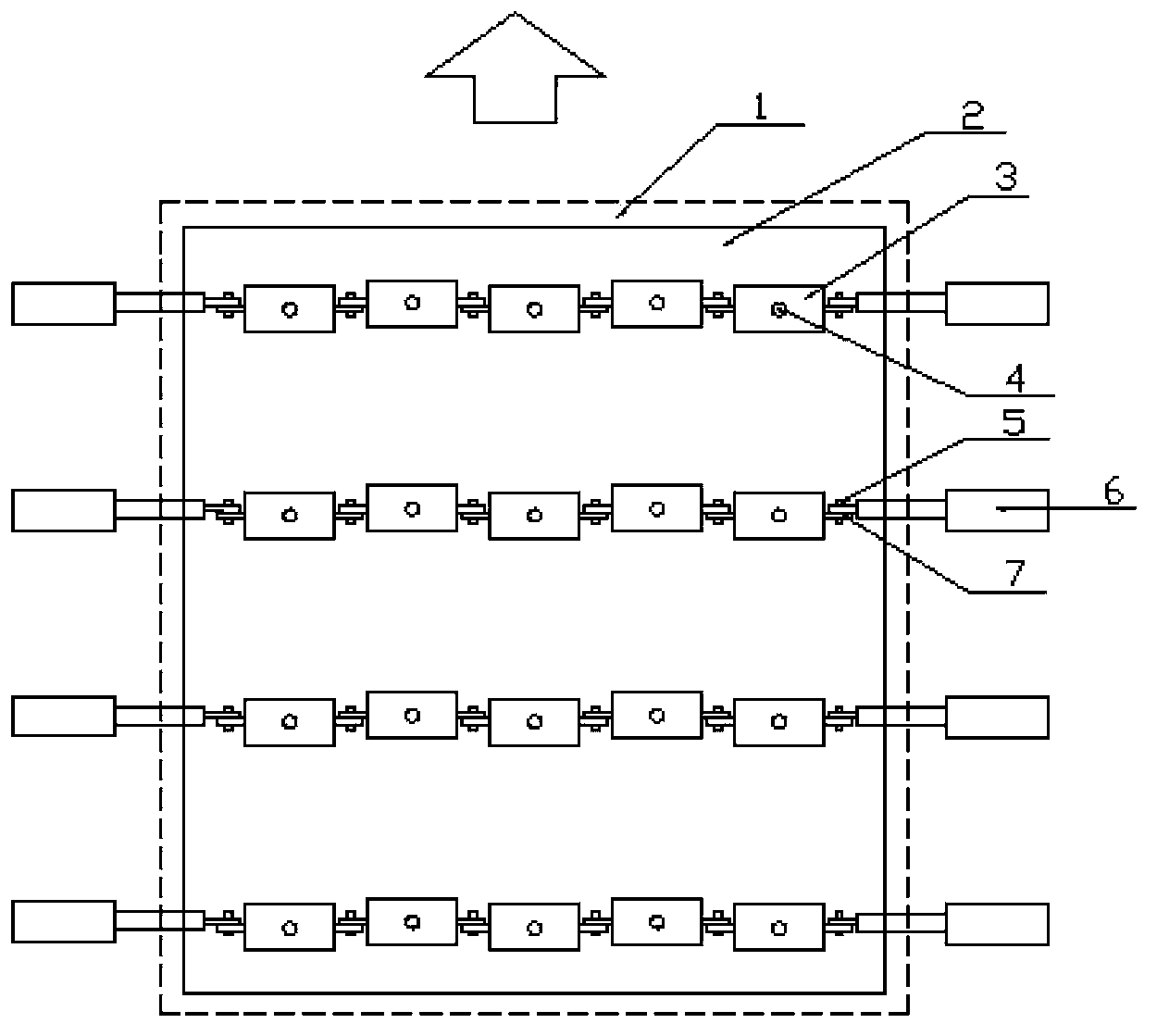

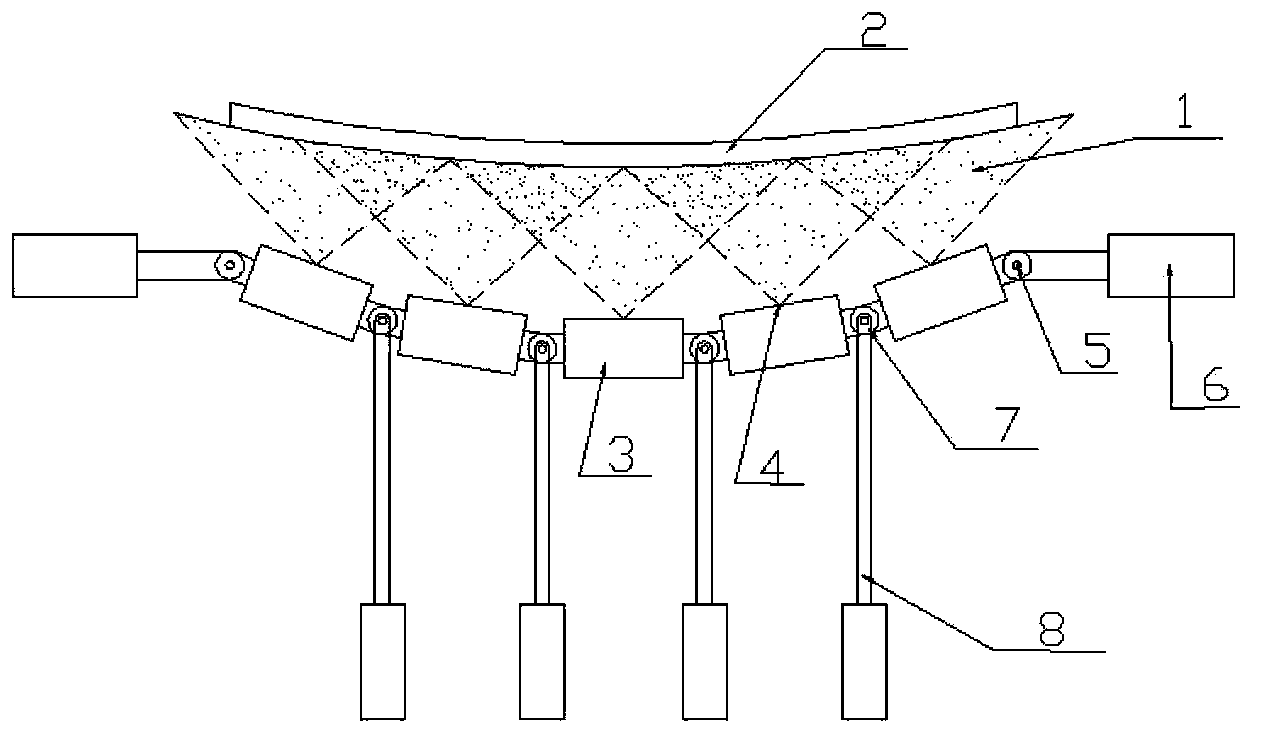

Copper-indium-gallium-selenium co-evaporation linear source apparatus and use method thereof

ActiveCN103898450AAvoid uneven coatingImprove craftsmanshipFinal product manufactureVacuum evaporation coatingIndiumEvaporation

The present invention relates to a copper-indium-gallium-selenium co-evaporation linear source apparatus and a use method thereof, particularly to a segmented copper-indium-gallium-selenium co-evaporation linear source apparatus with adjustable curvature, and a use method thereof. The apparatus comprises plural sets of parallel linear sources, wherein the linear source is a segmented linear source with adjustable curvature. According to the present invention, the problem that drooping due to glass substrate self-weight causes change of the distance between the glass substrate and the liner source so as to cause the non-uniform plated film is well solved with the apparatus, the process effect is improved, and the apparatus has characteristics of simple structure and easy performing, and is suitable for industrial production.

Owner:紫石能源有限公司

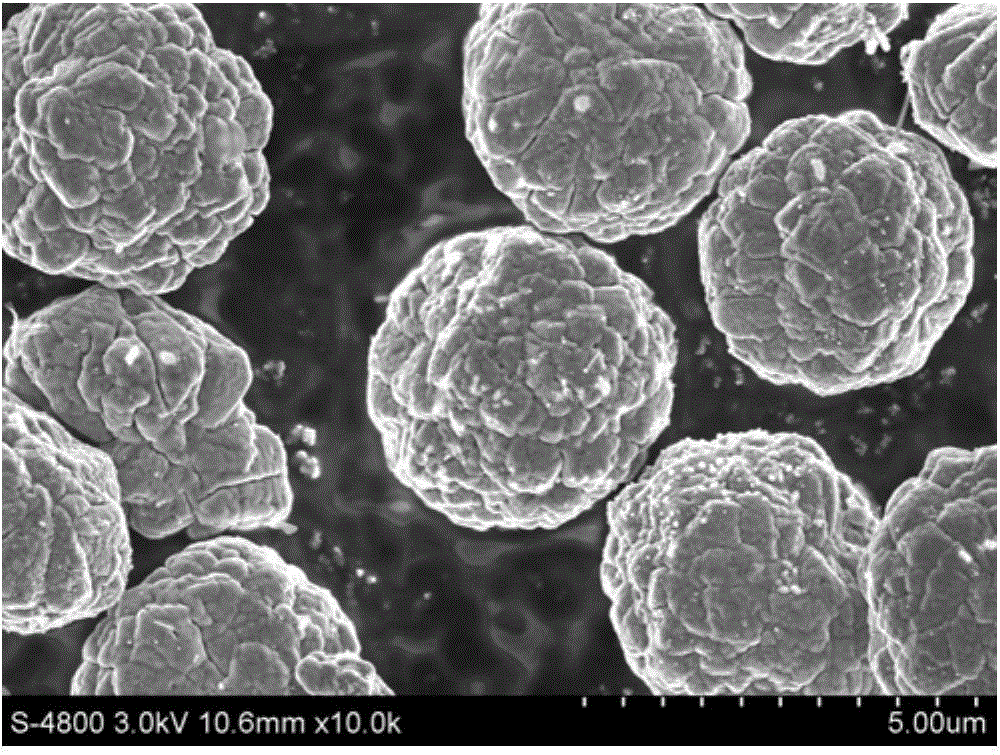

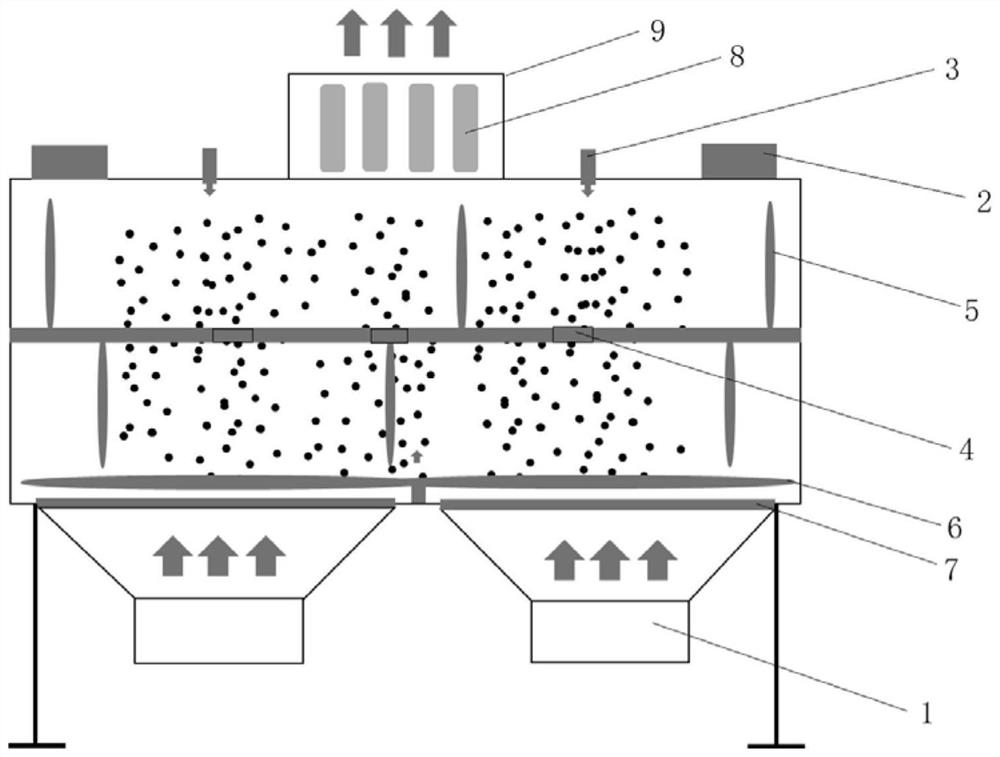

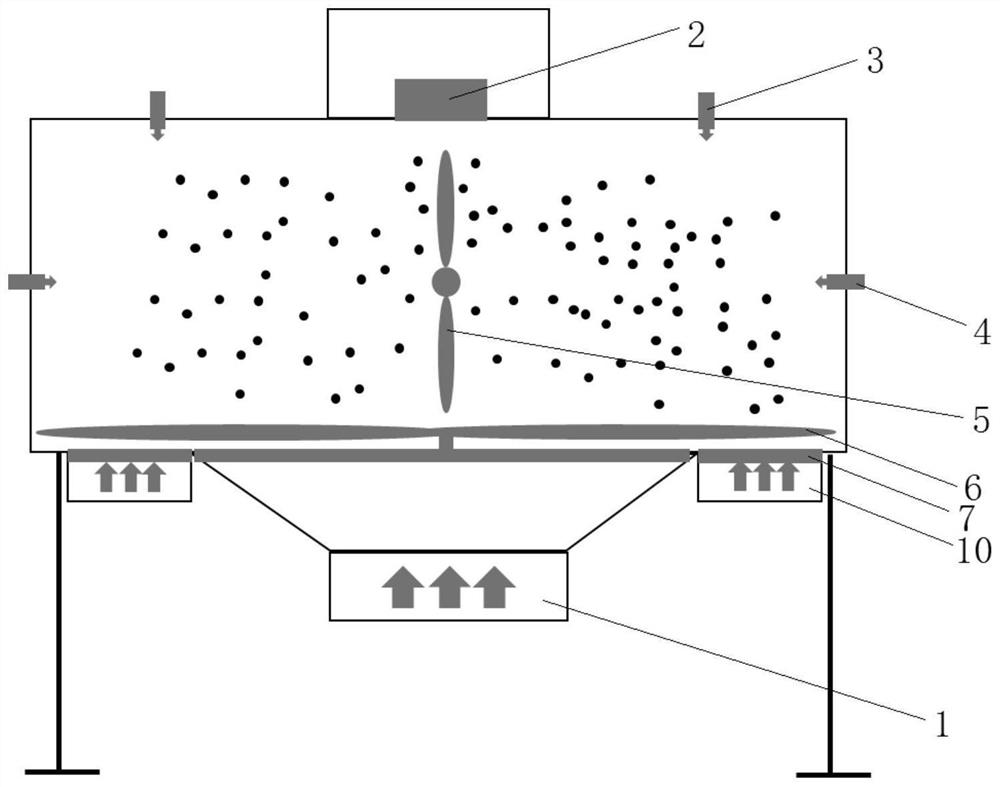

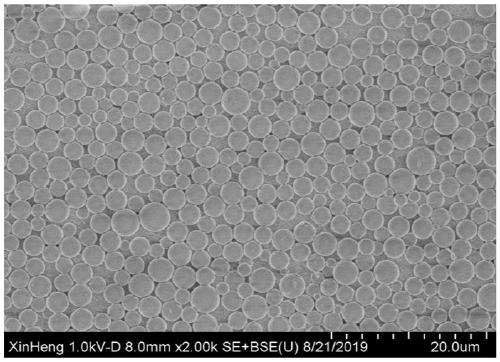

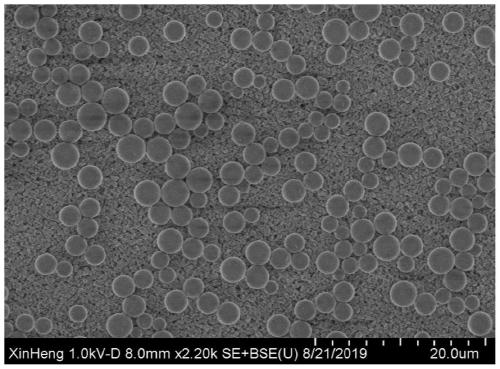

Coating method of nickel cobalt lithium manganate ternary positive electrode material

ActiveCN111769273AEvenly dispersedAvoid uneven coatingSecondary cellsPositive electrodesPtru catalystManganese oxide

The invention discloses a coating method of a nickel cobalt lithium manganate ternary positive electrode material, and belongs to the technical field of preparation of lithium ion battery electrode materials. The method comprises the following steps of: 1) adding the nickel cobalt lithium manganate ternary positive electrode material into a cavity of a fluidized bed for fluidization to obtain a fluidized nickel cobalt lithium manganate ternary positive electrode material; 2) atomizing a coating solution at an atomizing port of the fluidized bed to obtain an atomized coating solution; and 3) adding the atomized coating solution into the cavity of the fluidized bed, carrying out mist flow coating on the fluidized lithium nickel cobalt manganese oxide ternary positive electrode material, anddrying to obtain a coated lithium nickel cobalt manganese oxide ternary positive electrode material. The catalyst prepared by the method is high in activity, easy to separate after reaction, reusable,simple in preparation process and low in cost.

Owner:HAIKE GRP RES INST OF INNOVATION & TECH

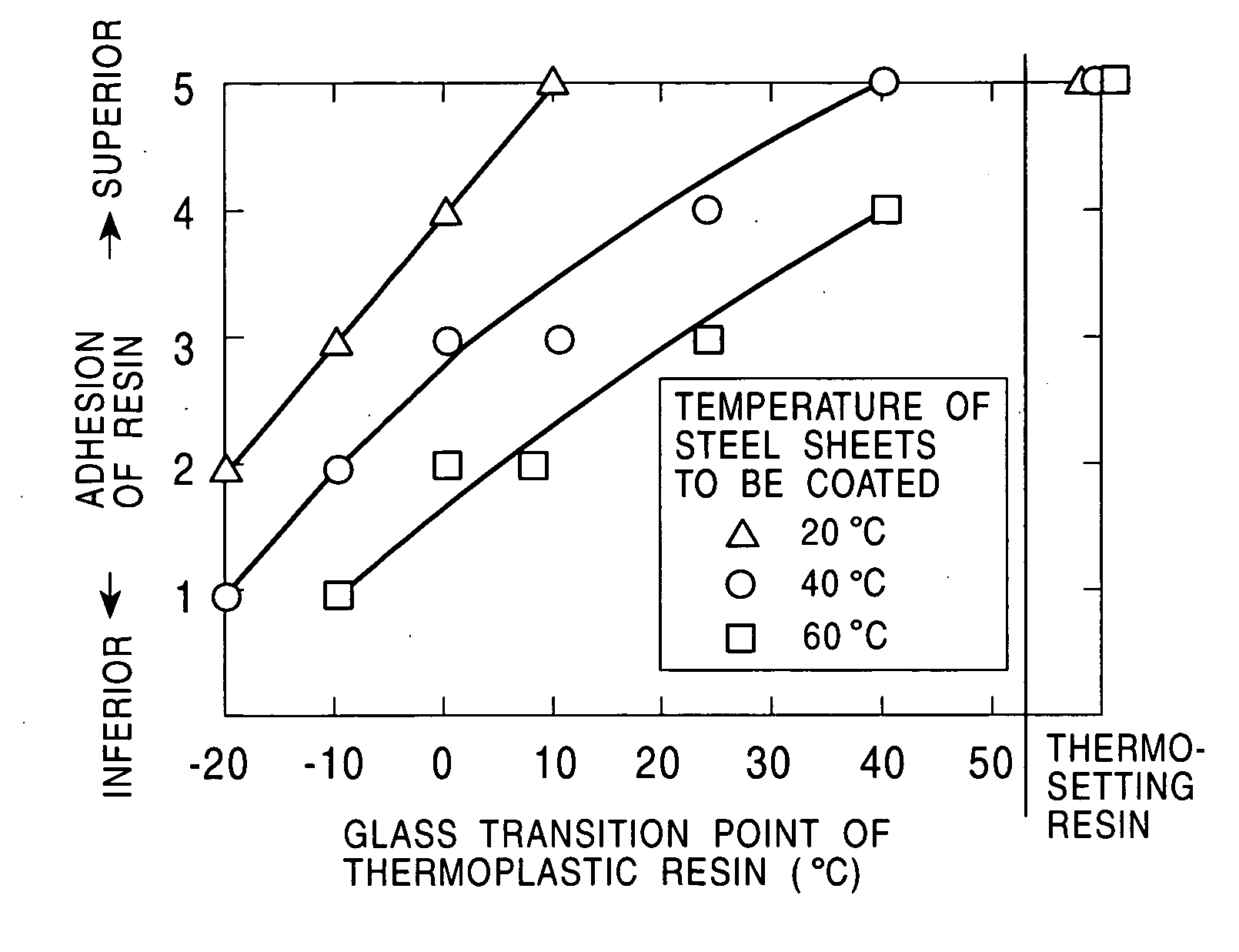

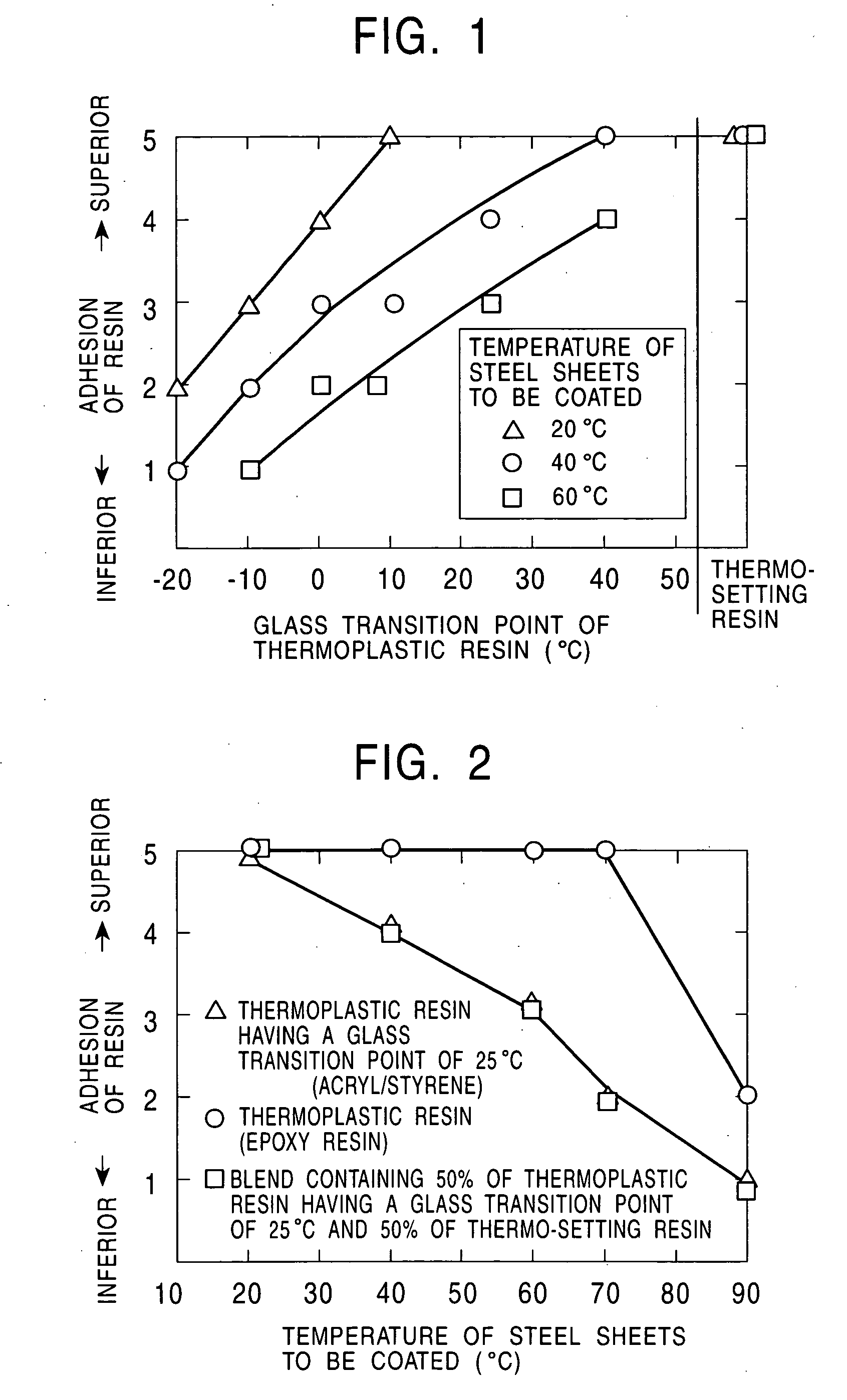

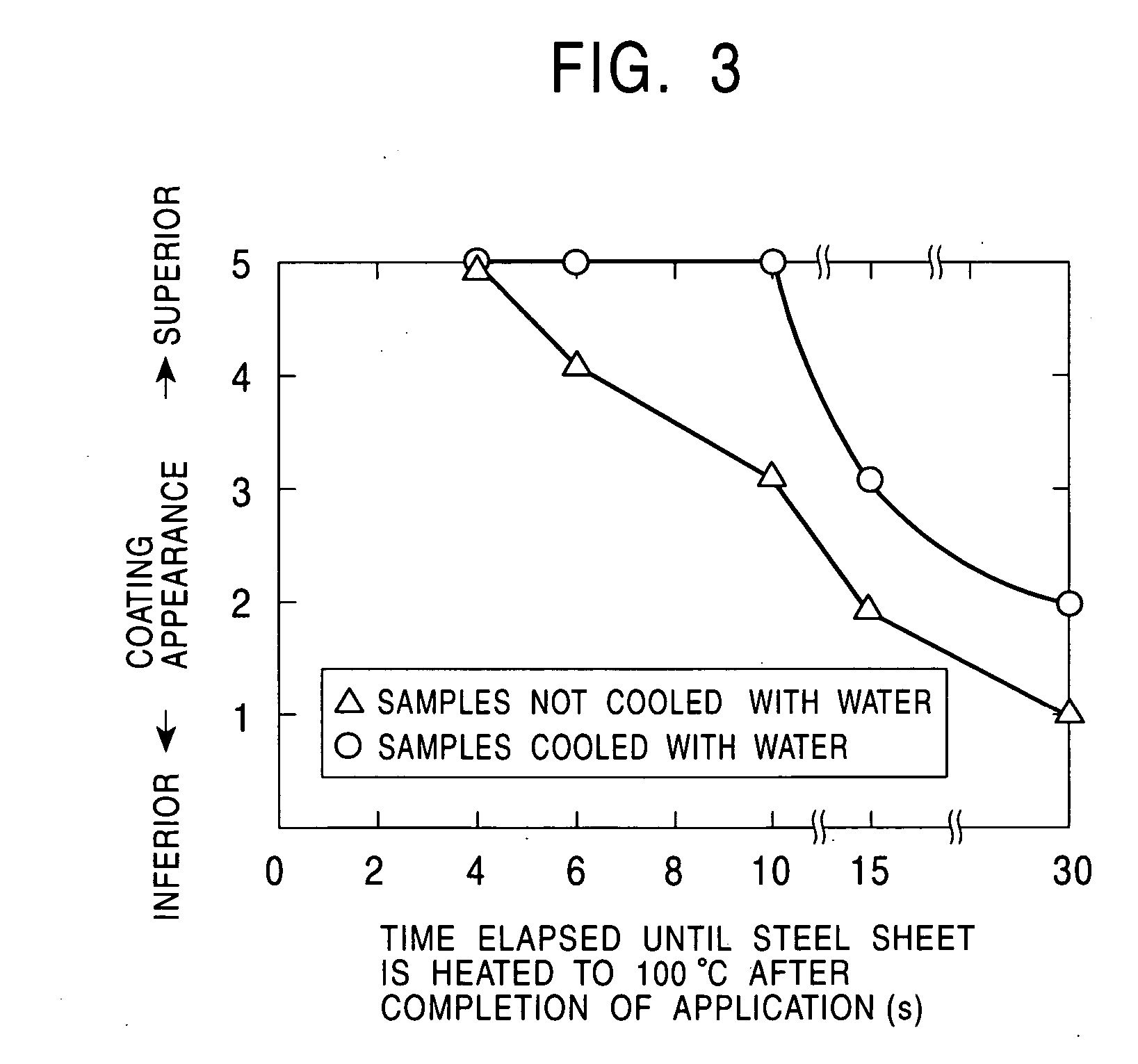

Method for producing coated steel sheet

ActiveUS20050064107A1Improve film propertiesAvoid uneven coatingDielectric heatingInduction heatingMetallurgyMaterials science

In a process for manufacturing a coated steel sheet such as a coated electromagnetic steel sheet using a water-based coating liquid containing an organic resin, to perform steps subsequent to an annealing step continuously at high speed without causing appearance defects such as coating unevenness; to provide an electromagnetic steel sheet having an insulating film thereon, in which properties of the film are satisfactory, superior weldability and punchability can be obtained without deteriorating the space factor, and the satisfactory film properties can be maintained even if the electromagnetic steel sheet having the insulating film thereon is temper-rolled. A coating liquid is applied onto an untreated steel sheet. The applied liquid is heated on the side close to the steel sheet in such a manner that the time elapsed until the steel sheet temperature is increased to 100° C. after the application is completed is 10 seconds or less, thereby drying the coating liquid. The steel sheet temperature is further increased to a predetermined temperature, thereby forming a coating film. When insulating films for electromagnetic steel sheets are formed, the coating liquid preferably further contains a water based inorganic component.

Owner:JFE STEEL CORP

SMT subtraction high-density packaged multilayer circuit board structure and manufacturing method thereof

ActiveCN103607841AUnlimited accuracyGood dimensional stabilityElectrical connection printed elementsMultilayer circuit manufactureEpoxyEtching

The invention relates to an SMT subtraction high-density packaged multilayer circuit board structure and a manufacturing method thereof. The structure comprises an inner circuit layer (1) and an outer circuit layer (3), connecting copper columns (2) are arranged between the inner circuit layer (1) and the outer circuit layer (3), local etching is conducted on the middle of the inner circuit layer (1) to form a fill area (4), tin layers (5) are arranged on the surface of the inner circuit layer (1) etched locally, elements (6) are arranged on the tin layers (5) in a surface-mounted mode, the inner portion of the fill area (4), the peripheries of the tin layers (5) and the peripheries of the elements (6) are filled with epoxy resin (7) and the surface of the outer circuit layer (3) and the periphery of the outer circuit layer (3) are coated with light-sensitive insulating materials (8). The SMT subtraction high-density packaged multilayer circuit board structure and the manufacturing method of the SMT subtraction high-density packaged multilayer circuit board structure have the advantages that a solid surface-mounted welding area formed through tin cream coating is replaced, and therefore high-performance electric connection and good reliability are realized on the basis of high-density circuit design and manufacturing.

Owner:JCET GROUP CO LTD

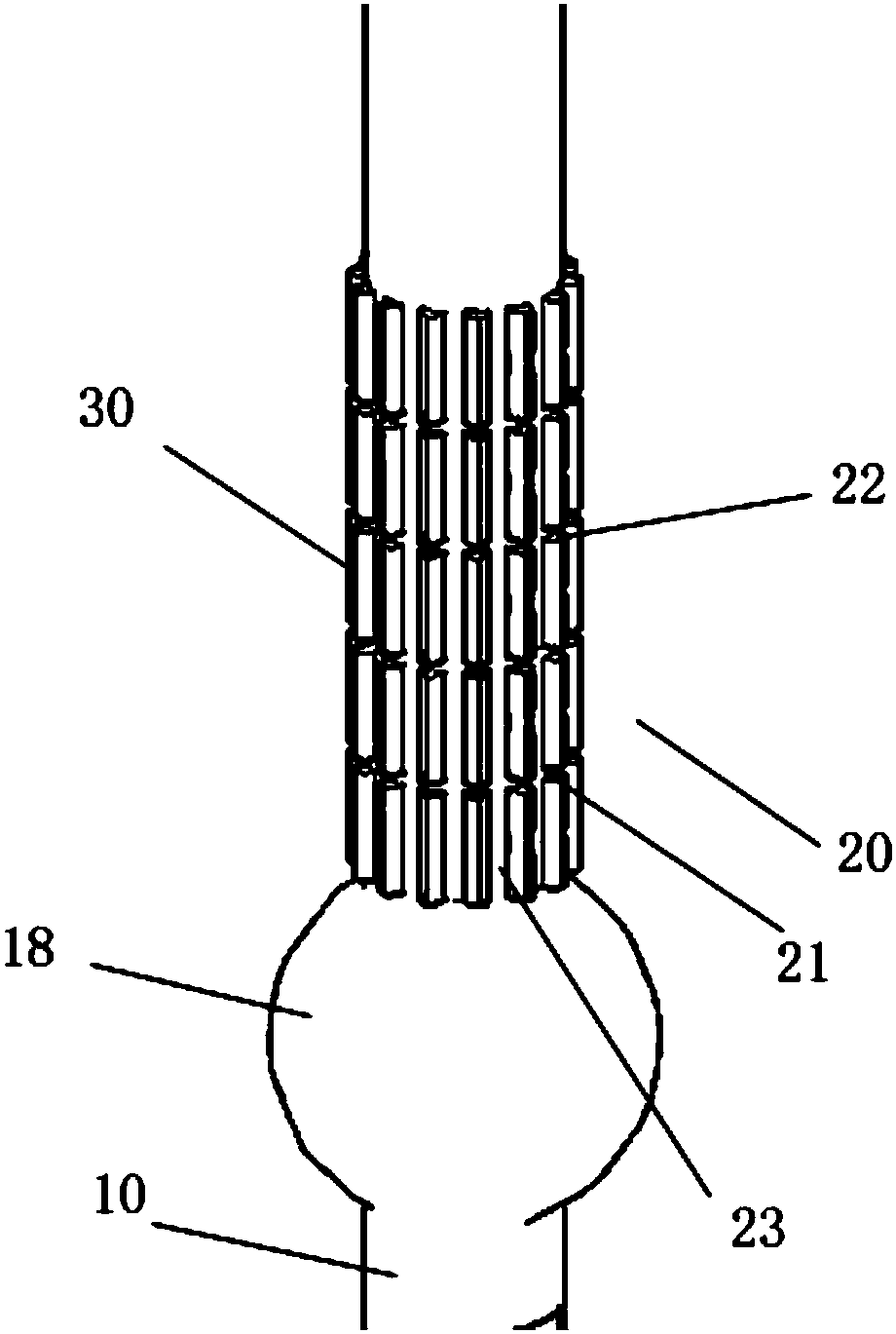

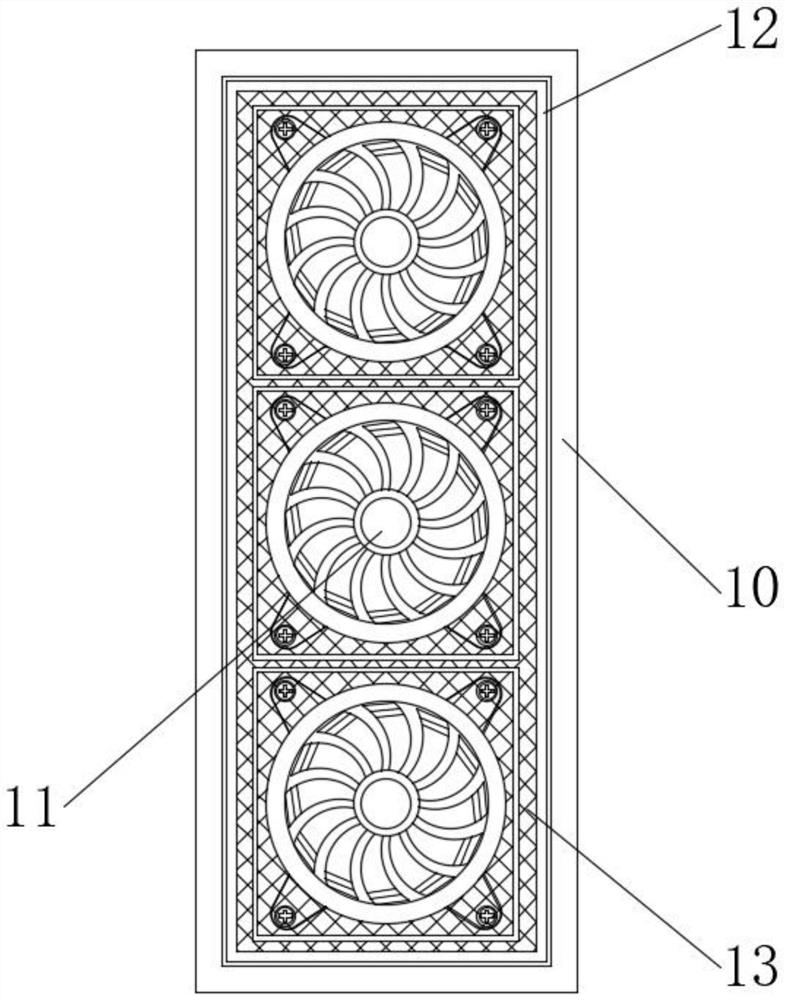

Catheterizing device for promoting wound healing and bringing convenience to drainage

PendingCN107648724AEasy to drainIncrease coating areaBalloon catheterMedical devicesUrine productionWound healing

The invention relates to a catheterizing device for promoting wound healing and bringing the convenience to drainage. The catheterizing device comprises a catheter body, and the two ends of the catheter body are the head end and the tail end respectively; three cavities are formed in the tail end of the catheter body, and are the water injection cavity, the drug injection cavity and the liquid discharging cavity respectively; a ball sac is arranged at the portion, close to the head end, on the catheter body; stripe protrusions are formed in the portion, tightly close to the ball sac, of the outer surface of the catheter body, and are distributed in the radial direction of the periphery face of the catheter body to form a stripe section, guide grooves are formed between the adjacent stripeprotrusions, and are distributed in the axial direction of the catheter body, and the periphery of the stripe section of the catheter body is also coated with a coating. The catheterizing device has the advantages that the superficial area of the outer coating of a catheter is increased, a coating material can have longer effect time, and therefore the higher effect is achieved; meanwhile, urine can be drained, and infection is avoided.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL

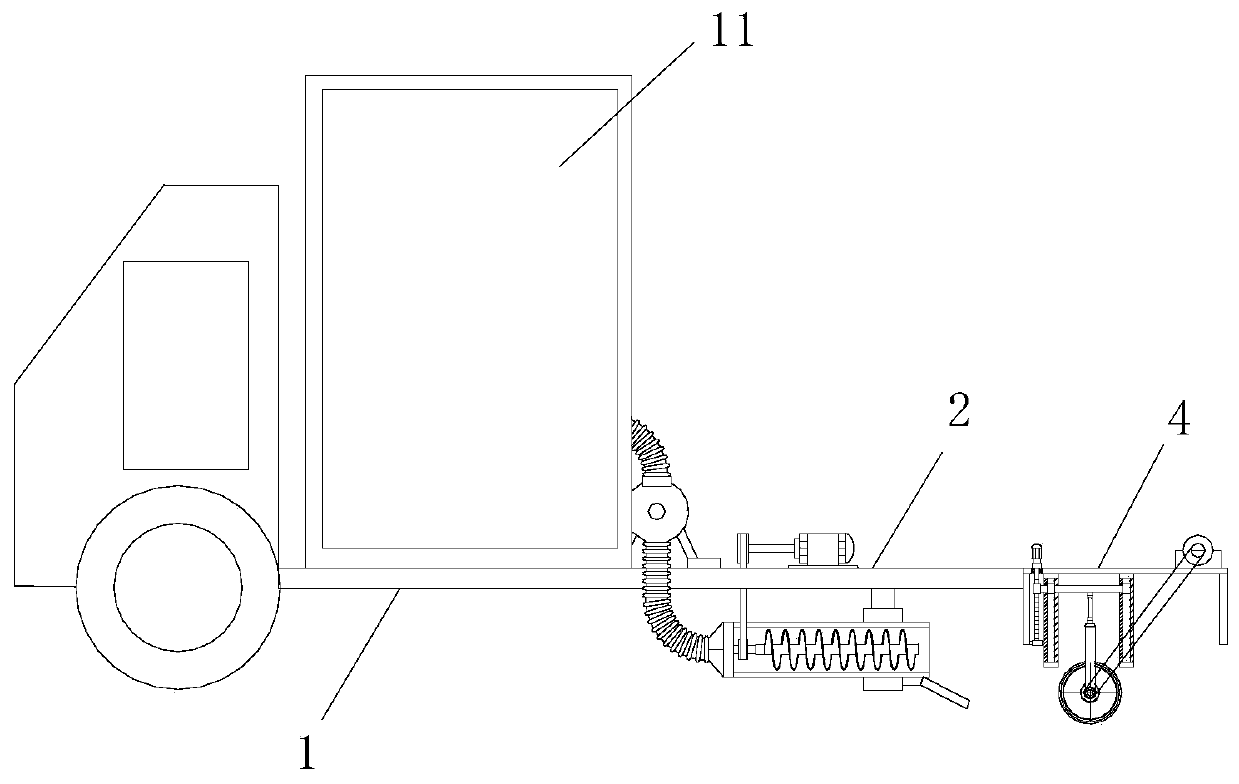

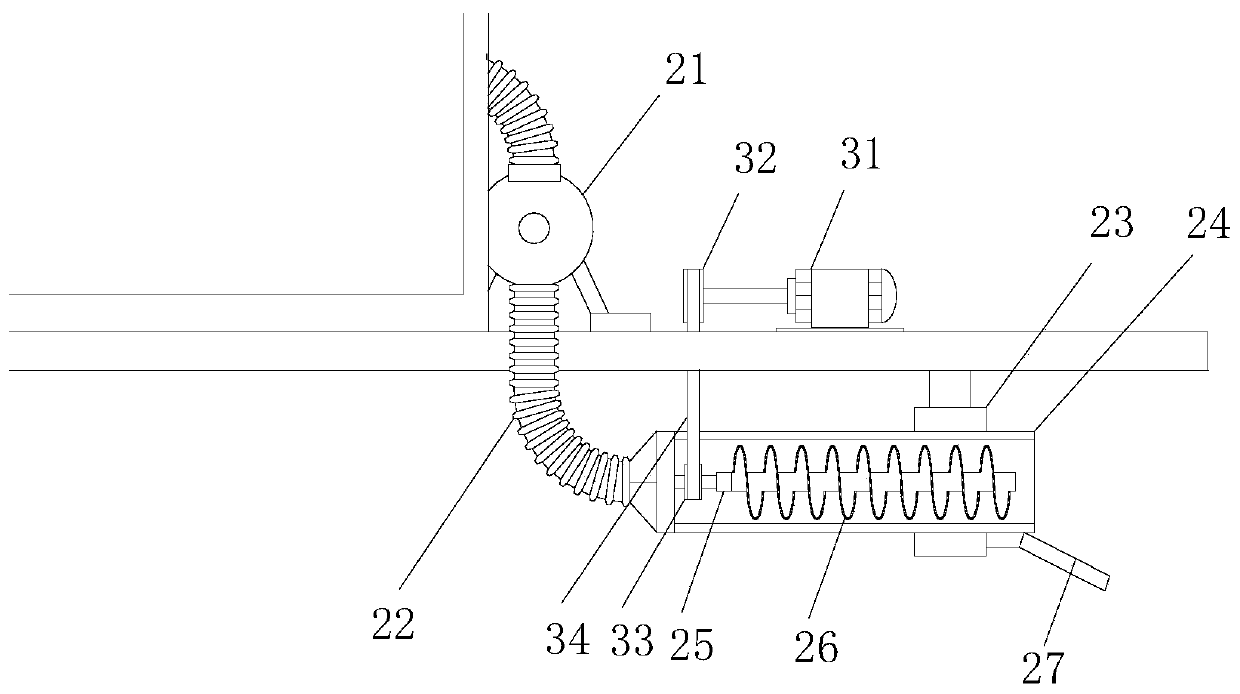

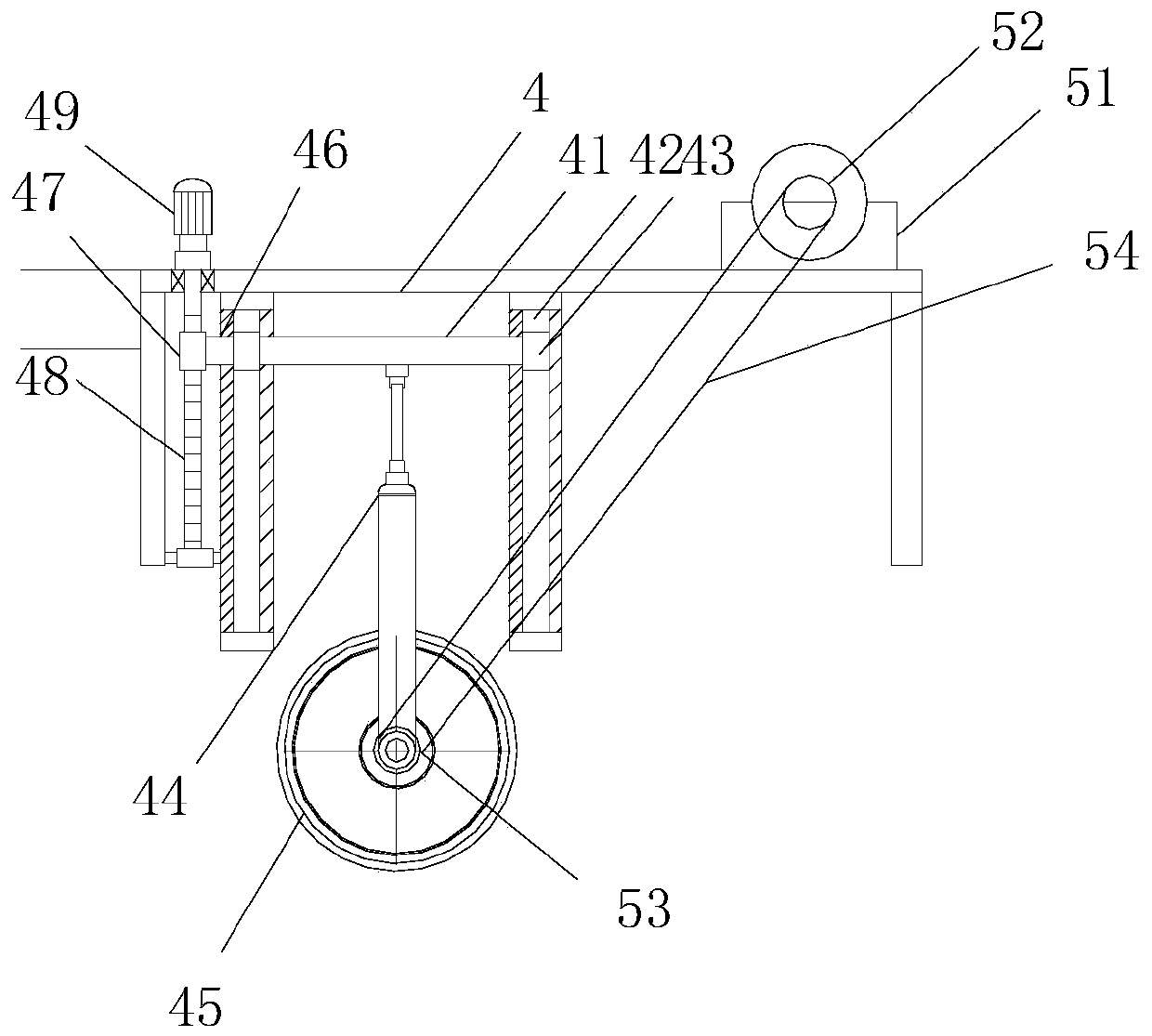

Cement troweling device for building foundation

InactiveCN110644332AAvoid uneven fallingImprove laying effectRoads maintainenceVehicle frameArchitectural engineering

The invention relates to the field related to construction, and particularly discloses a cement troweling device for a building foundation. The cement troweling device for the building foundation comprises a vehicle frame, a cement mixing barrel is mounted on the vehicle frame, a cement feeding mechanism and a cement troweling mechanism are mounted on the vehicle frame respectively, the cement feeding mechanism includes a cement conveying pump and a feeding rack, the feeding rack is provided with a feeding channel, a feeding roller shaft is mounted in the feeding channel in a built-in mode, aspiral feeding auger is mounted on the feeding roller shaft, a lifting frame is mounted in the cement troweling mechanism in a built-in mode, a work frame is mounted at the bottom of the lifting frame, a troweling roller is mounted on the work frame, the lifting frame is externally connected with an outer edge rod, a threaded sleeve is mounted at the rod end of the outer edge rod, a lifting screwis arranged at the side edge of the cement troweling mechanism, and the threaded sleeve is arranged on the lifting screw lifting in threaded fit in a sleeving mode. According to the cement troweling device for the building foundation, uniformity of spreading of cement can be improved, and the cement troweling device for the building foundation adapts to cement foundations of various heights

Owner:蔡新新

Coating rod and producing method therefor

InactiveUS7470327B2Avoid unevennessAvoid scratchesLiquid surface applicatorsLapping machinesCoated surfaceEngineering

A peripheral surface of a coating rod has an area where grooves (convex portions) are formed. This area is ground by a grinding apparatus by which a maximum height Ry of the rod surface is adjusted to 15 μm or less. Further, a ratio of D / W is adjusted to 0.01 or more, wherein D is a total distance of the convex portions of the rod actually abutting on a web in an axial direction of the rod, and W is a coating width of the web. Furthermore, straightness of the rod is adjusted to 30 μm or less per 1 m, and roundness of the rod is adjusted to 10 μm or less. Micro-projections are removed by grinding so that scratches of a coating surface are prevented from occurring. Coating unevenness is prevented by improving the straightness and the roundness.

Owner:FUJIFILM CORP

PMMA polymer coating diaphragm and preparation method thereof

PendingCN111354907AAvoid uneven coatingImprove adhesionSecondary cellsCell component detailsPolymer sciencePolymer chemistry

The invention discloses a PMMA polymer coating diaphragm and a preparation method thereof, and belongs to the field of battery diaphragms. The PMMA polymer coating diaphragm comprises a base membraneand a PMMA polymer coating coated on at least one surface of the base membrane; the PMMA polymer coating contains PMMA powder, a dispersing aid, a first binder and a second binder. The preparation method comprises the following steps: preparing PMMA coating slurry, and enabling the surface of a base film to coated with the PMMA coating slurry; the solubility of the PMMA in a water system can be improved, the PMMA powder can be effectively dispersed in a water system, the bonding strength of the diaphragm and the pole piece is enhanced, the problem of non-uniform coating of a PMMA polymer partis better solved, meanwhile, the phenomena of swelling and deformation of the battery are effectively inhibited, the hardness and consistency of the battery are improved, and the oxidation resistanceand long-term cycle performance of the battery are improved.

Owner:安徽金力新能源有限公司

A lithium ion battery cathode material and a preparing method thereof

InactiveCN104752690AGood electrochemical performance and capacity retention performance of the batteryGood lithium ion conductivityCell electrodesSecondary cellsLithium electrodeSalt solution

The invention discloses a lithium ion battery cathode material and a preparing method thereof, and particularly relates to a phosphate-coated lithium ion battery cathode material and a preparing method thereof. The chemical constitution of a coating layer is M1M2PO4, wherein the M1 is Ni, Mn and Co, and the M2 is Cr, Al, Mg, Fe, Ti, V, Ga, Cu, Zn, Be, Sc, Ca, Sr, Ba, Zr, Li and La. The cathode material can be normally used under a high cut-off voltage for charging (4.4-4.7 V), and has high thermal stability. A lithium ion battery using the cathode material has a higher volume energy density and better cycle performance. The preparing method of the cathode material includes mixing a cathode material core and a salt solution at least comprising Ni, Mn or Co, adding a phosphate, reacting, forming the phosphate coating layer at least comprising the Ni, the Mn or the Co on at least a part of the surface of the cathode material, and performing heat treatment to obtain the lithium ion battery cathode material.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

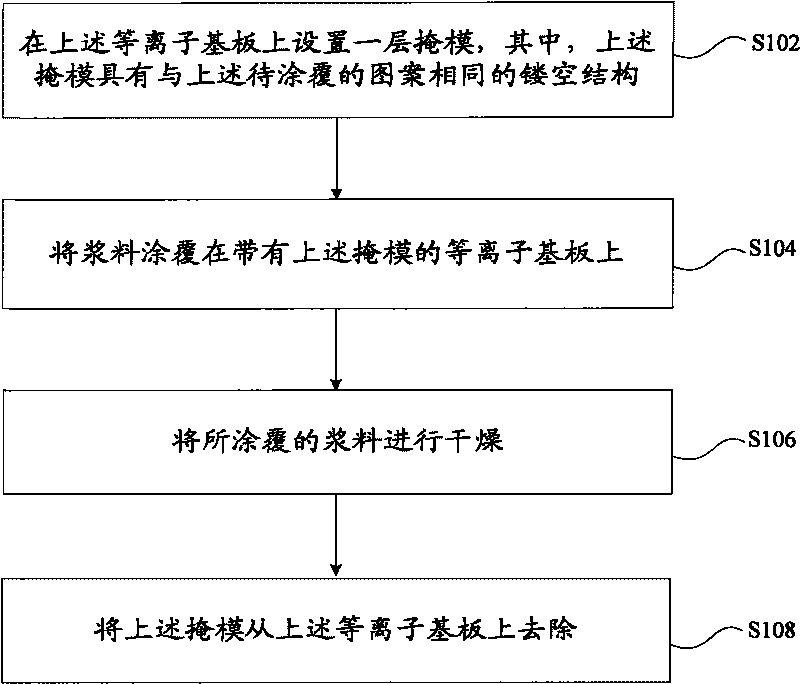

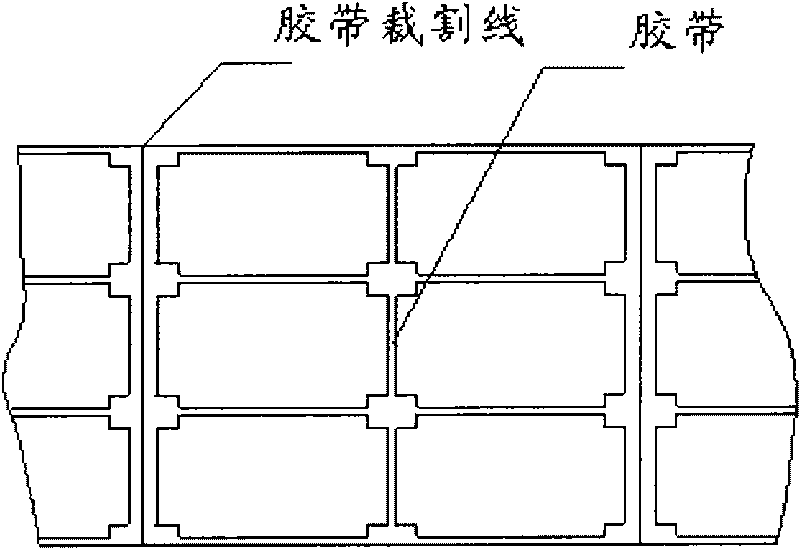

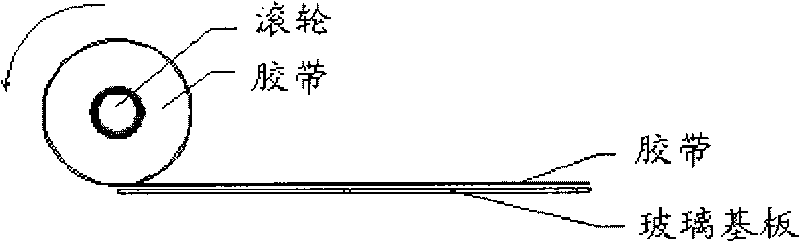

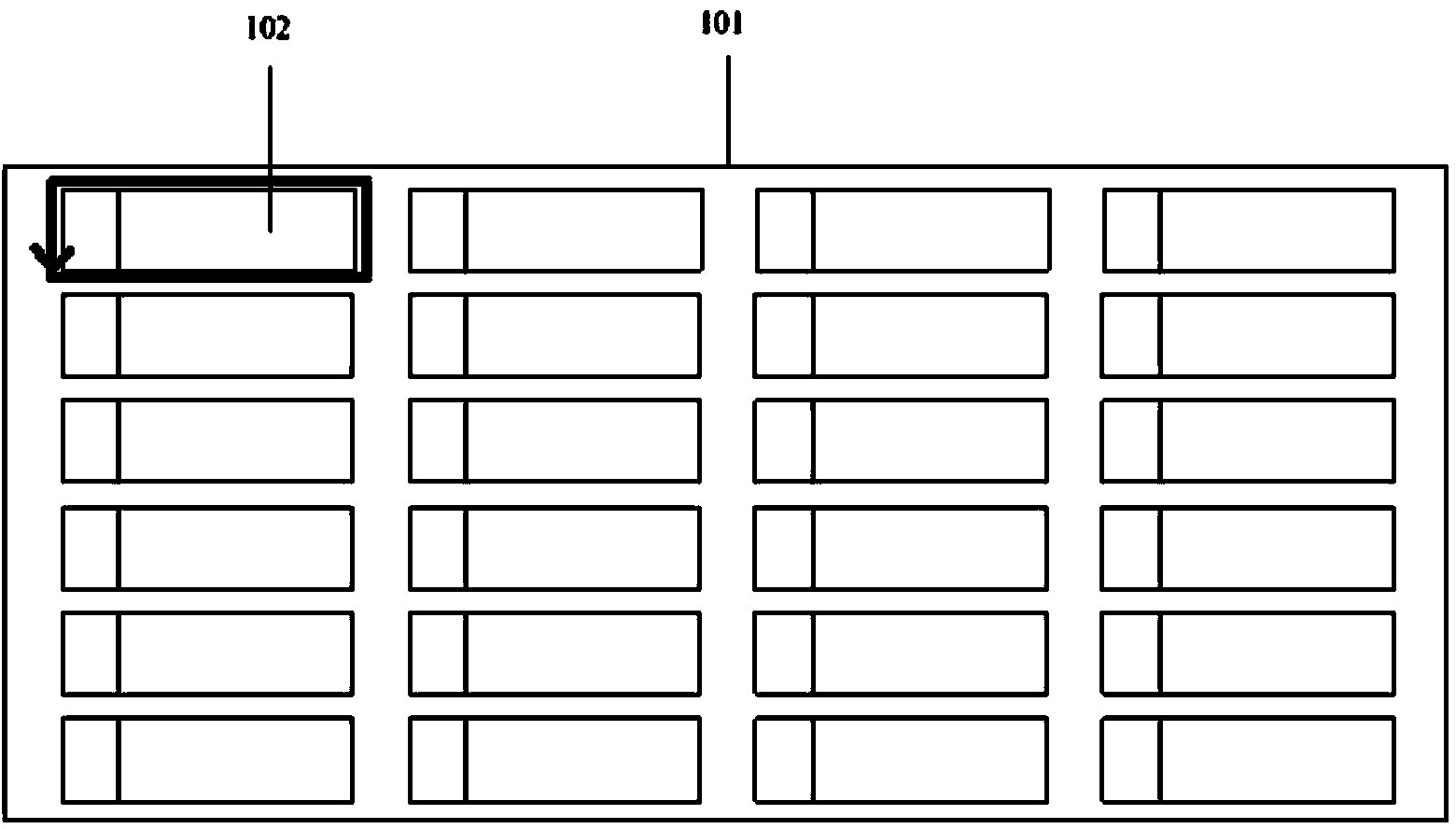

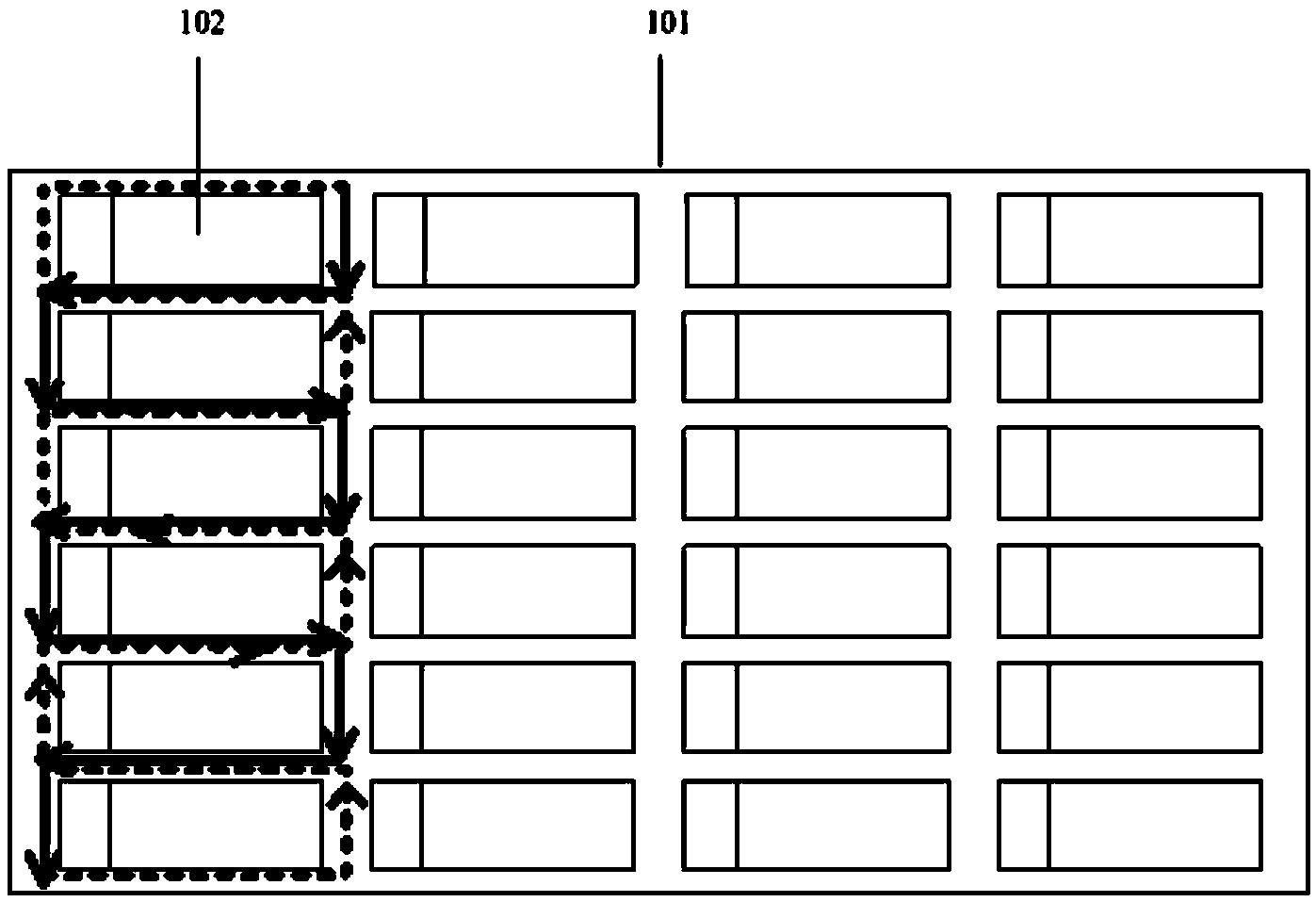

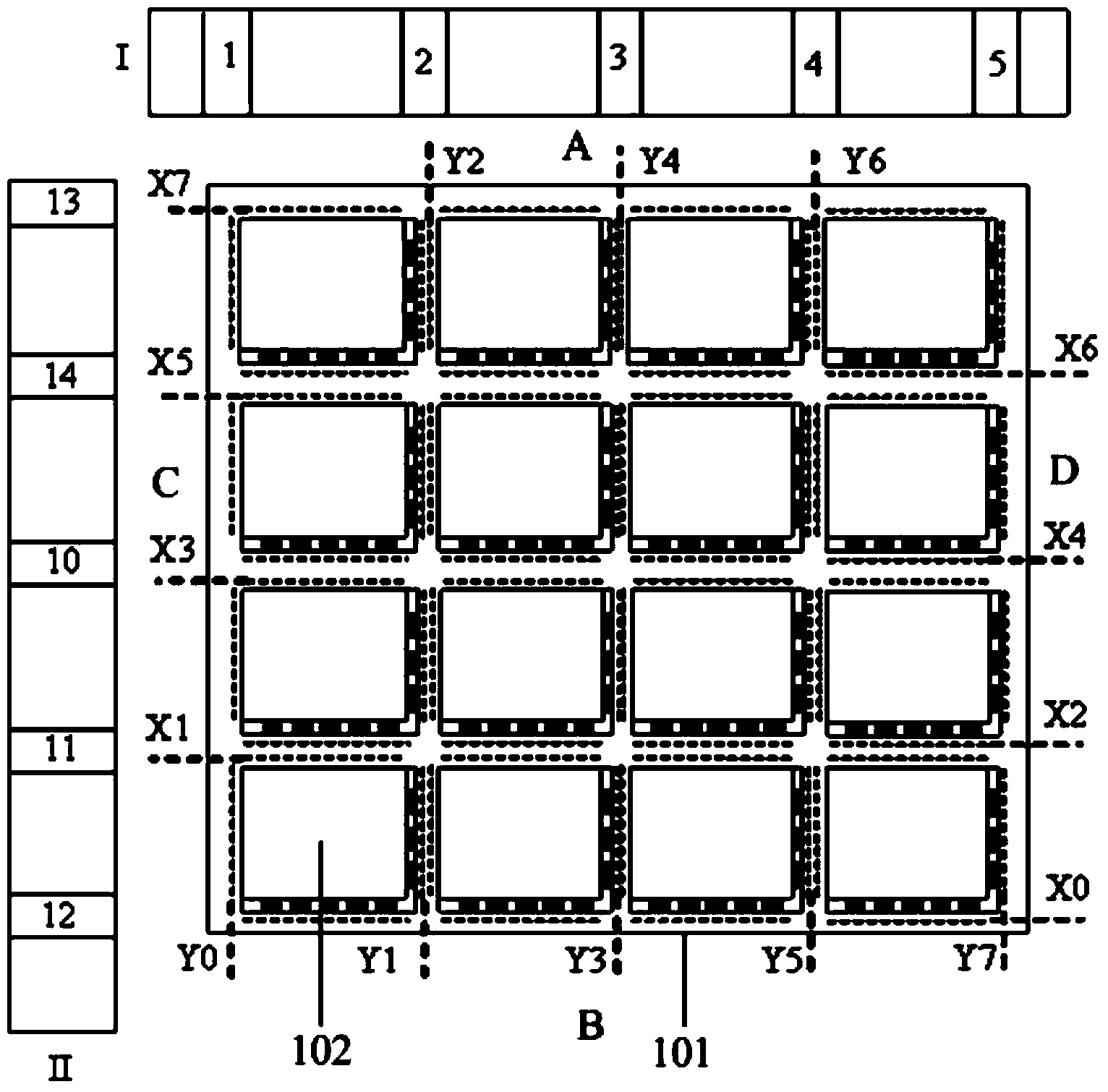

Coating method and device of plasma substrate pattern layer

InactiveCN101728152AAvoid uneven coatingImprove coating efficiencyTube/lamp screens manufactureSlurryMaterials science

The invention provides coating method and device of a plasma substrate pattern layer, wherein the coating method comprises the following steps of: arranging a mask on a plasma substrate, wherein the mask has a hollow structure the same as a pattern to be coated; coating slurry on the plasma substrate with the mask; drying the coated slurry; and removing the mask from the plasma substrate. Because the mask is arranged on the substrate, the problem of non-uniform coating is overcome. In addition, due to the existence of the mask, continuous coating can be realized so as to achieve the effect of improving the coating efficiency.

Owner:SICHUAN COC DISPLAY DEVICES

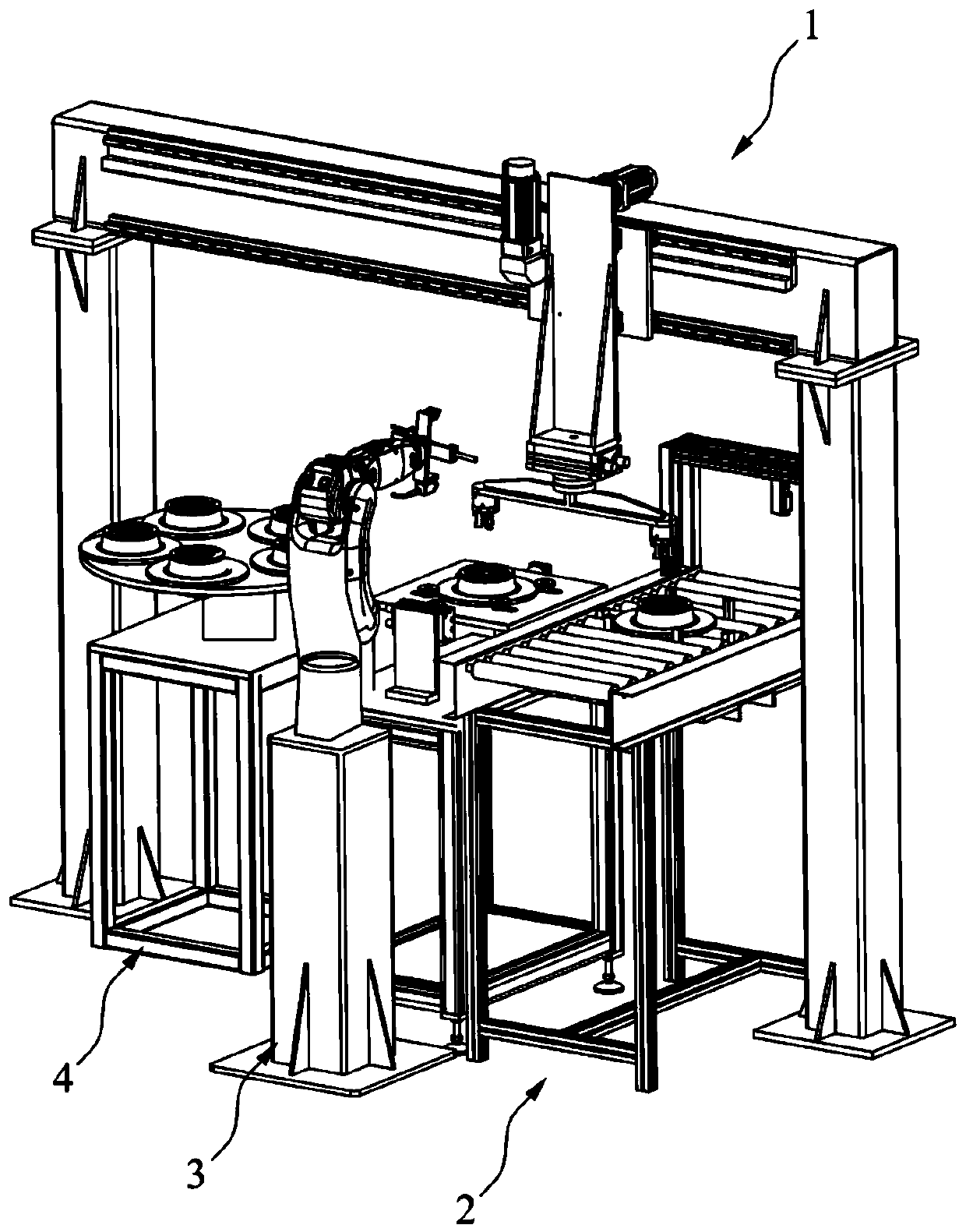

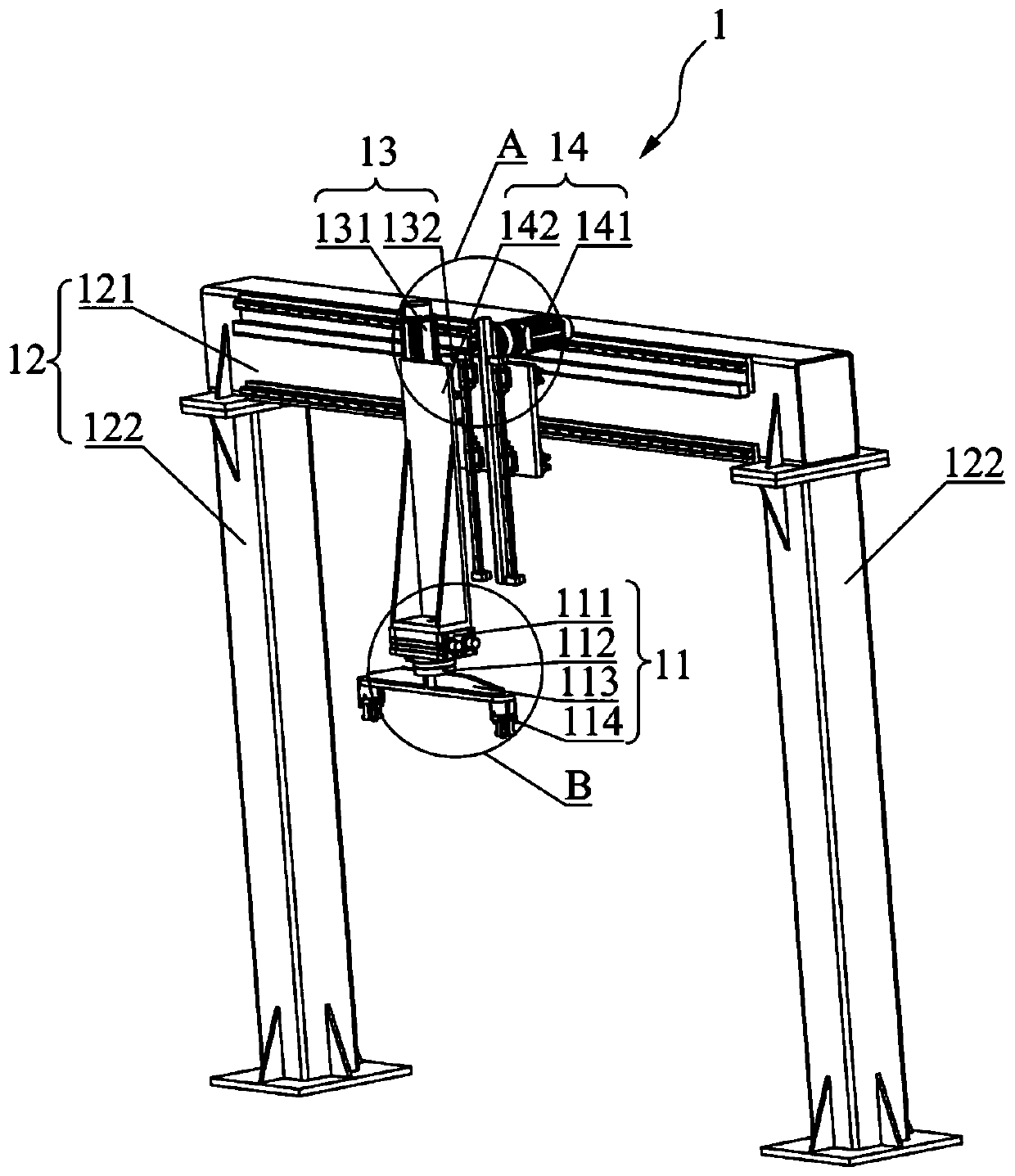

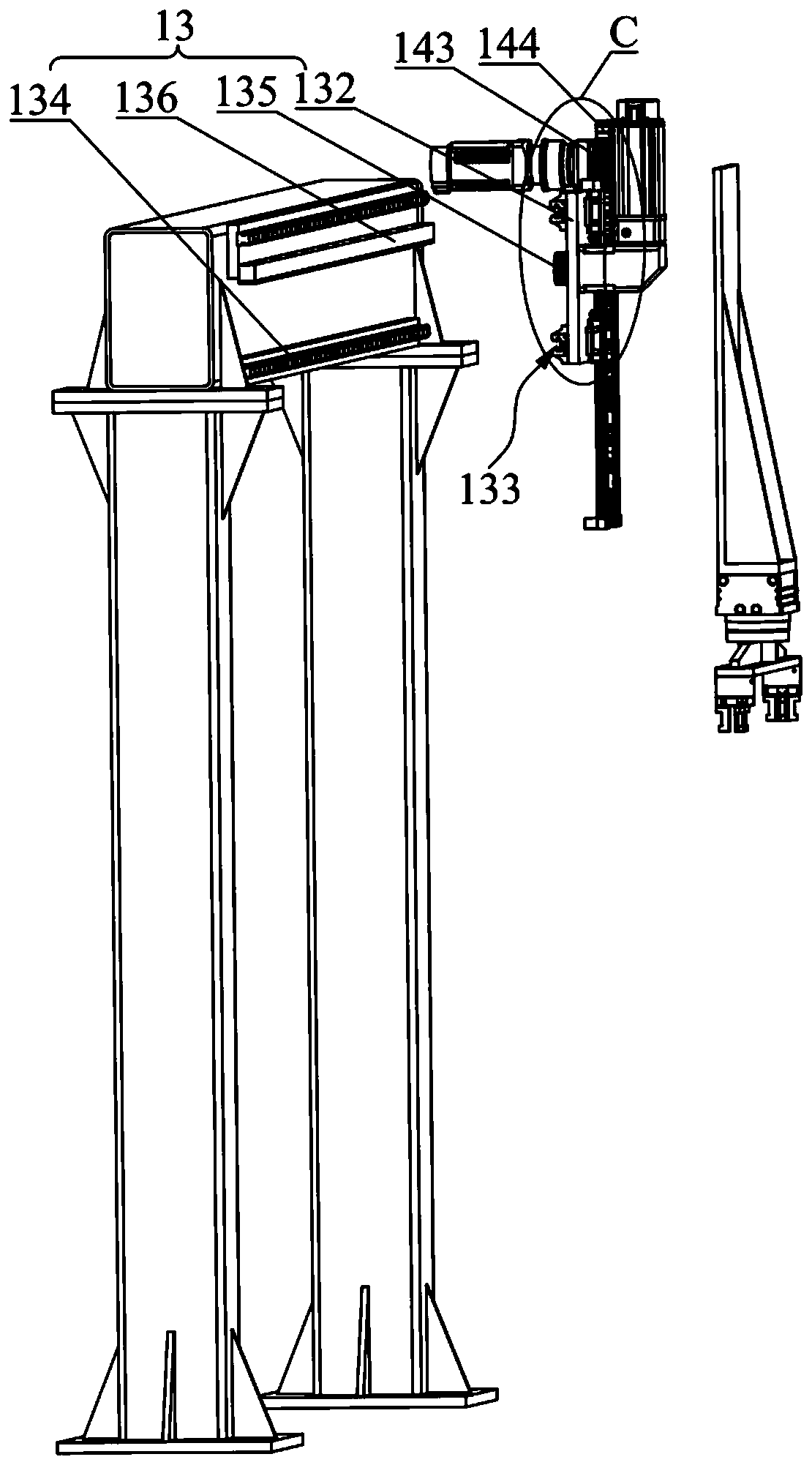

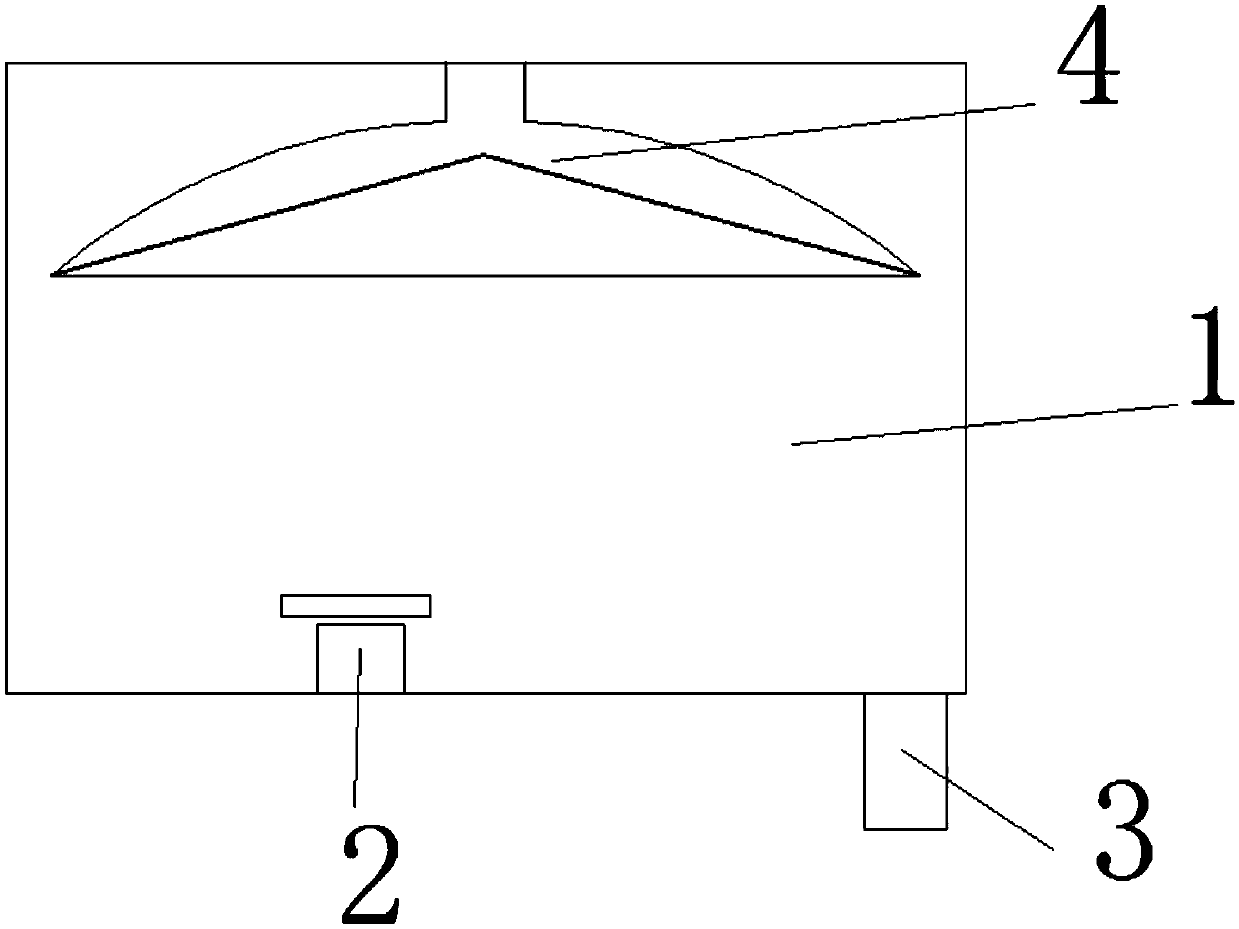

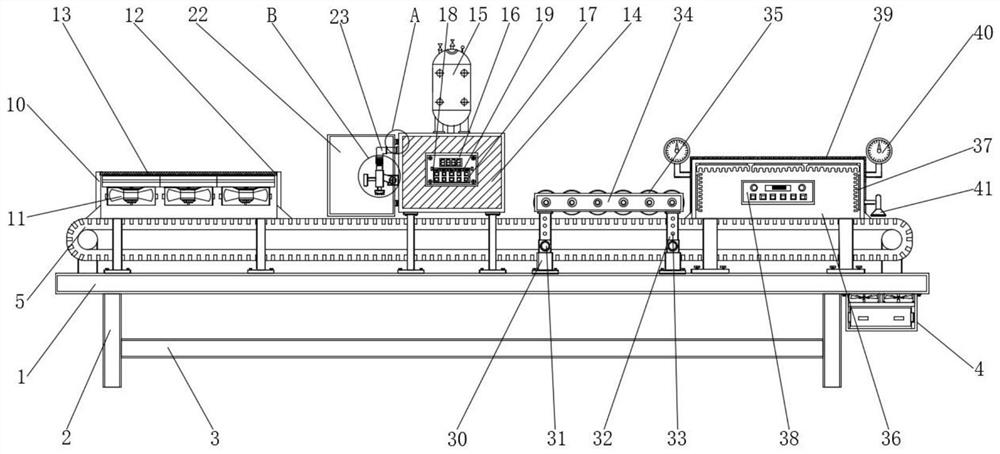

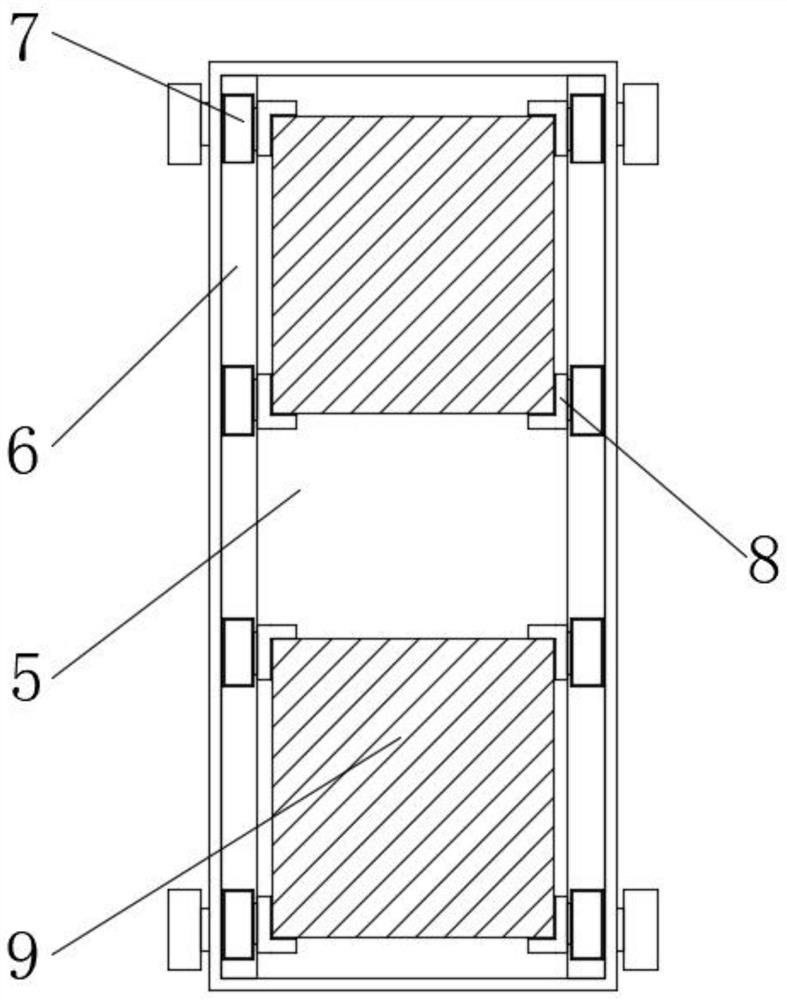

Coating layer thickness detection device

The invention discloses a coating layer thickness detection device, and belongs to the technical field of detection tools. The coating layer thickness detection device comprises a grabbing mechanism,a conveying mechanism, a detection mechanism and a control mechanism; wherein the grabbing mechanism comprises a mechanical arm, the conveying mechanism is arranged below the grabbing mechanism, the mechanical arm is used for picking up products placed on the conveying mechanism, the detection mechanism is arranged on one side of the conveying mechanism so as to detect the coating layer thicknessof the products, and the control mechanism is electrically connected to the detection mechanism. In applications, firstly, a to-be-detected product is conveyed to a designated position through the conveying mechanism, then the product is grabbed using the grabbing mechanism, and the mechanical arm is used for placing the grabbed product on the detection mechanism to detect the coating layer thickness. The device can be used for detecting the thickness of paint and paint coating layerss of products and preventing the problem of non-uniform coating.

Owner:SHANGHAI JINGZHI IND CO LTD

Reaction chamber and processing method used for PVD film coating

InactiveCN107620047AEasy to operateAvoid uneven product coatingVacuum evaporation coatingSputtering coatingChemistryFilm coating

A reaction chamber and processing method for PVD film coating, comprising: vacuum extraction, target heating, and film coating. The PVD coating reaction process is carried out in a completely sealed vacuum reaction chamber, and the target is heated by an electron gun to evaporate the target to the surface of the workpiece to form a coating. Using the above PVD reaction chamber, including the reaction chamber body, electron gun crucible table, vacuum pump and product station to be coated, wherein the electron gun crucible table has multiple concave grooves, and different target materials are placed in each groove, which can According to the needs of the explosion-proof film, the concave cavity where the required target material is located is heated separately, the structure is simple, the use is convenient, and the practicability is strong.

Owner:苏州安江源光电科技有限公司

Coating method for frame sealing glue

The invention discloses a coating method for frame sealing glue. According to the method, the frame sealing glue is coated on the areas to be coated on a substrate along longitudinal coating lines and the horizontal coating lines by means of a plurality of nozzles. Due to the way of coating the frame sealing glue in a cross way of longitudinally coating and horizontally coating by means of the nozzles, the nozzles cannot be cornered in the coating paths, and the problem that the frame sealing glue is unevenly coated due to the cornering is solved.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

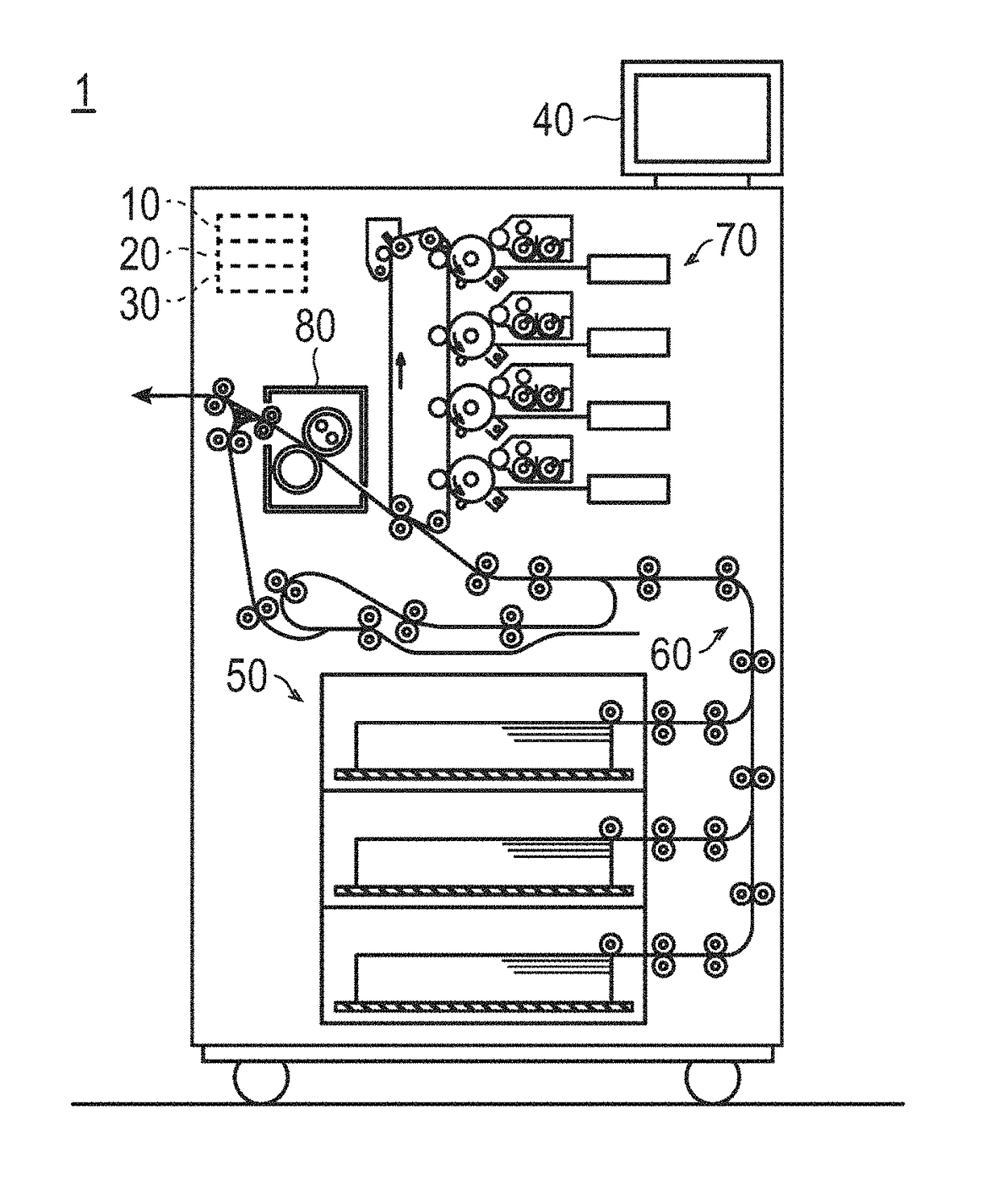

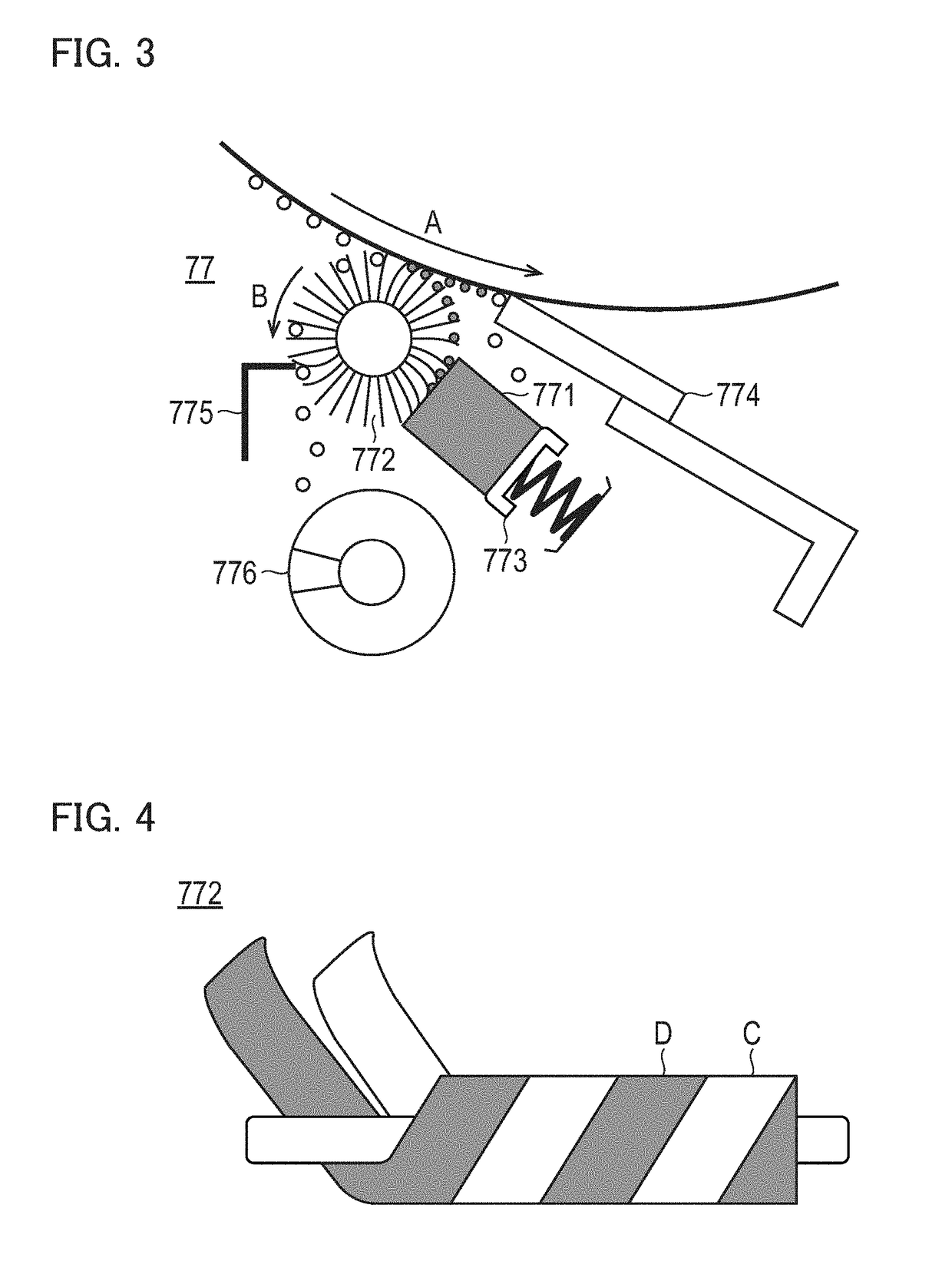

Lubricant coating device and image forming apparatus

ActiveUS20180328535A1Avoid uneven coatingLiquid surface applicatorsSpraying apparatusFiberMetallurgy

A lubricant coating device preventing coating unevenness of lubricant powders is provided. The lubricant coating device includes a solid lubricant, a coating member and a film shaping member. The coating member in which first fibers composed of a material located on a positive polarity side and second fibers composed of a material located on a negative polarity side, on a triboelectric series with respect to the material of the solid lubricant are implanted, coats lubricant powders scraped off from the solid lubricant onto the image supporter. The film shaping member comes in contact with the image supporter and presses the lubricant powders onto the image supporter, to shape the lubricant powders into a form of a film. A scraping amount of the lubricant powders by the first fibers and a scraping amount of the lubricant powders by the second fibers are set to become substantially identical.

Owner:KONICA MINOLTA INC

Lithium supplementing device and method for lithium ion battery pole piece

PendingCN112234168AIncrease energy densityImprove energy efficiencyElectrode rolling/calenderingFinal product manufactureMetallic lithiumCooling chamber

The invention provides a lithium supplementing device and method for a lithium ion battery pole piece. The lithium supplementing device for the lithium ion battery pole piece comprises an inert gas chamber, the inert gas chamber comprises a cooling chamber and a containing chamber which are arranged in a spaced mode, and the lithium supplementing device for the lithium ion battery pole piece further comprises a lithium liquid supply liquefaction pool, an extrusion spraying device, a first double-roller device, a second double-roller device and a comma roller device which are arranged in the containing chamber. An inner cavity of the lithium liquid supply liquefaction pool is a containing cavity used for containing metal lithium, the containing cavity, the extrusion spraying device, the first double-roller device and the comma roller device are provided with heating structures, and the heating structures are used for melting the metal lithium and better infiltrating the lithium liquid.According to the lithium supplementing device for the lithium ion battery pole piece, the consistency of a lithium supplementing pole piece can be remarkably improved, a lithium supplementing amount and the thickness of the pole piece after lithium supplementing are accurately controlled, the lithium supplementing operation is simplified, the energy density of a lithium ion battery is improved, and the performance of a product is greatly increased.

Owner:东莞赣锋电子有限公司

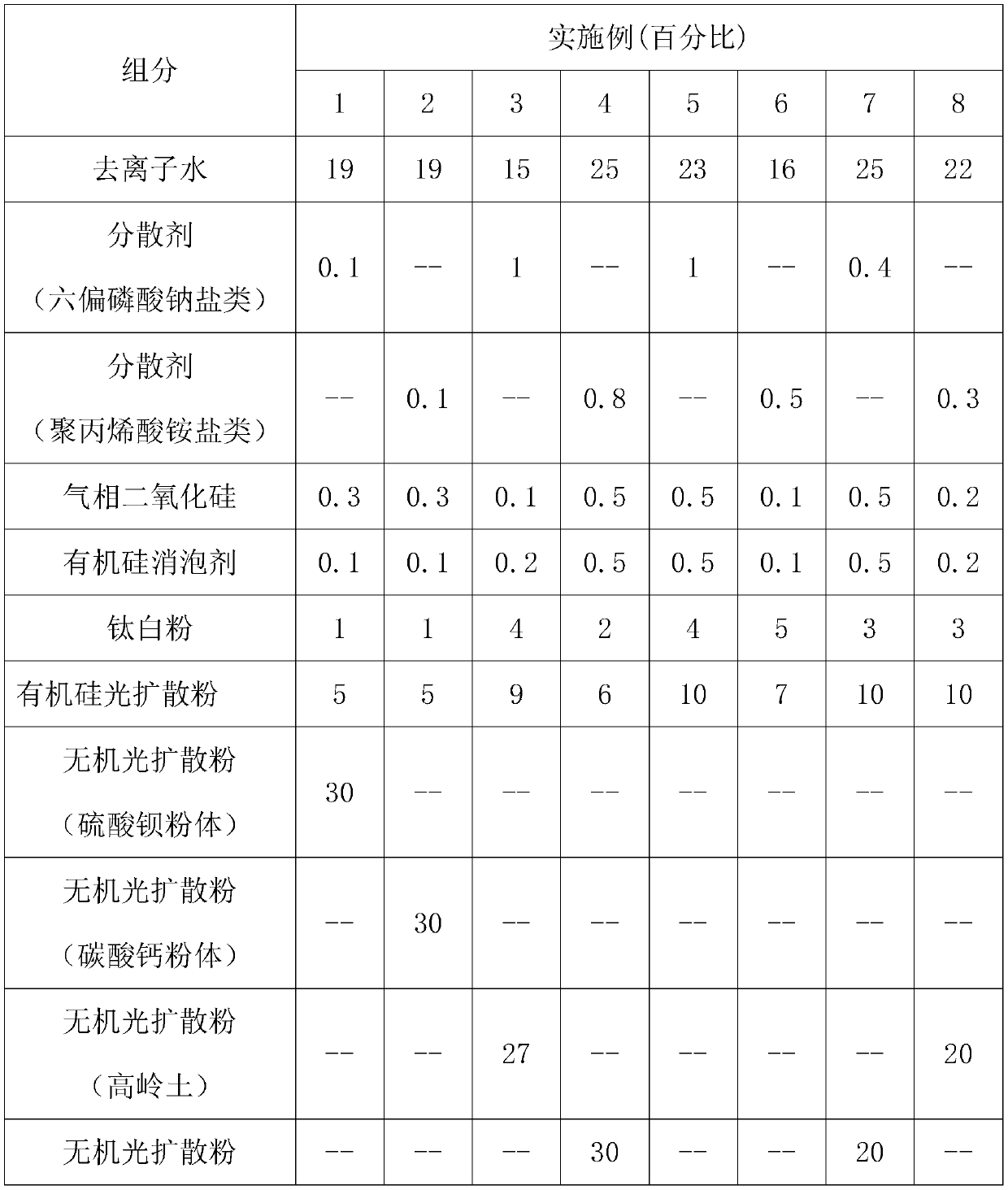

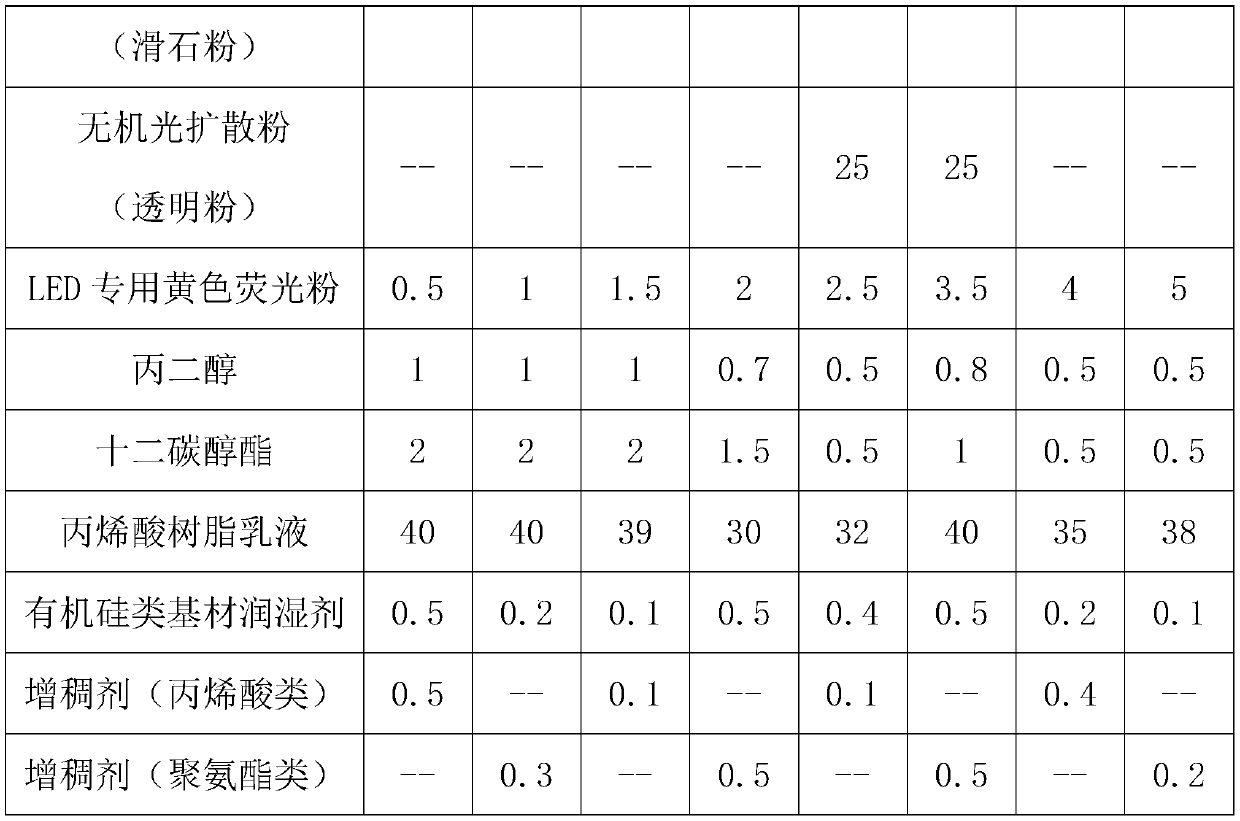

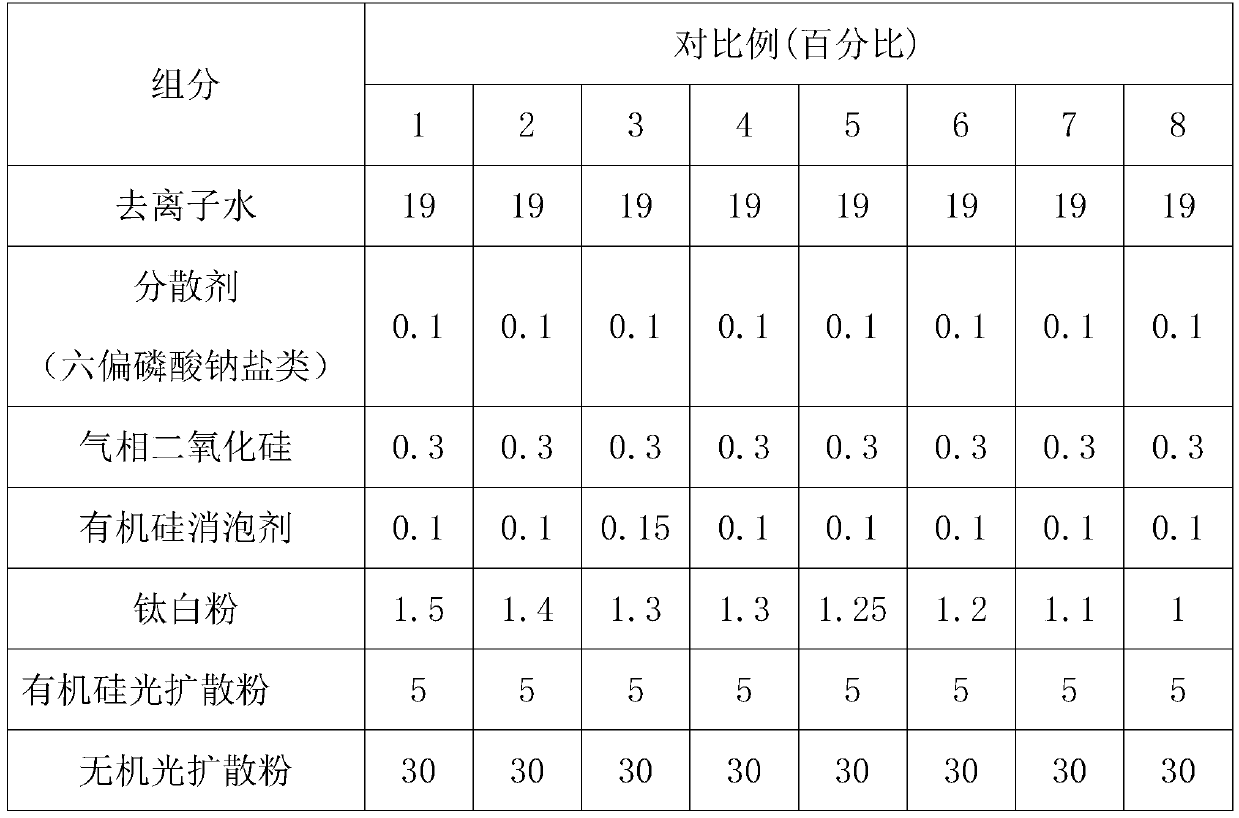

Water-based light diffusion coating capable of eliminating blue light, preparation method and LED lampshade adopting water-based light diffusion coating

InactiveCN109762416AEliminate blue lightHigh elimination rate and reliabilityCoatingsSemiconductor devices for light sourcesWater basedAcrylic resin

The invention discloses a water-based light diffusion coating capable of eliminating blue light, a preparation method and an LED lampshade adopting the water-based light diffusion coating. The coatingcomprises the raw materials in percentage by mass as follows: 15%-25% of deionized water, 0.1%-1% of a dispersant, 0.1%-0.5% of fumed silica, 0.1%-0.5% of a defoaming agent, 1%-5% of titanium dioxide, 5%-10% of organic silicon light diffusion powder, 20%-30% of inorganic light diffusion powder, 0.5%-5% of yellow fluorescent powder, 0.5%-1% of propylene glycol, 0.5%-2% of texanol, 30%-40% of acrylic resin emulsion, 0.1%-0.5% of a wetting agent and 0.1%-0.5% of a thickening agent. Light emitted by an LED lamp needs to be transmitted through the LED lampshade coated with the water-based light diffusion coating capable of eliminating blue light, so that all blue light can be eliminated, and the elimination rate is high and reliable.

Owner:FOSHAN COMWIN LIGHT & ELECTRICITY

Automatic coating device for metal plates

InactiveCN113477434AImprove cleanlinessAvoid inhalationPretreated surfacesCleaning using toolsEngineeringStructural engineering

The invention discloses an automatic coating device for metal plates, and particularly relates to the related technical field of metal plate machining. The automatic coating device for the metal plates comprises a machining table and a dust collection mechanism, a supporting column is welded to the bottom end of the machining table, a material placing plate is welded to the outer wall of the supporting column, the dust collection mechanism is connected to the bottom end of the machining table through screws, a thermometer is arranged at the top end of the outer wall of a drying oven, and a brush is arranged at the bottom end of the outer wall of the drying oven. Through the arrangement of an air blower, dust and water on the surface of the to-be-coated metal plates can be conveniently cleaned through a blowing fan in the air blower before the to-be-coated metal plates is coated, and uneven coating caused by dust and water remaining on the surface of the to-be-coated metal plates is avoided; and meanwhile, through a magnetic attraction strip and a dustproof net arranged on the surface of the top end of the air blower, external dust can be prevented from being sucked into the air blower when the air blower works, and cleanliness of the surfaces of the to-be-coated metal plates is guaranteed.

Owner:苏州邦得新材料科技有限公司

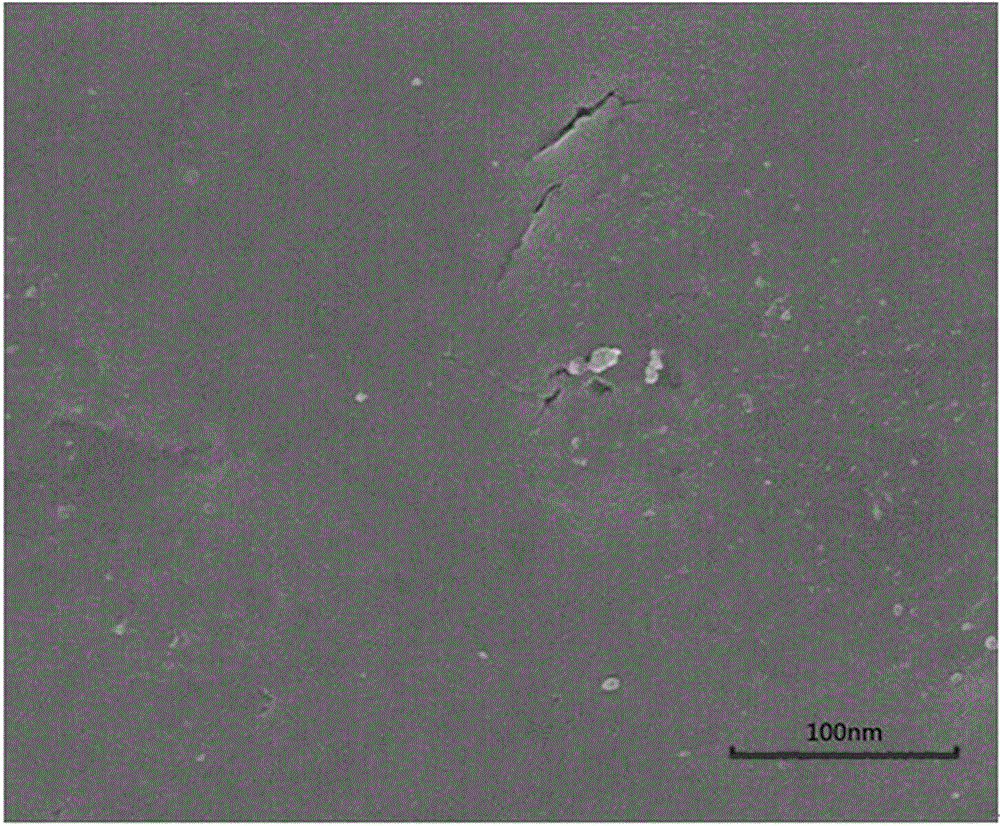

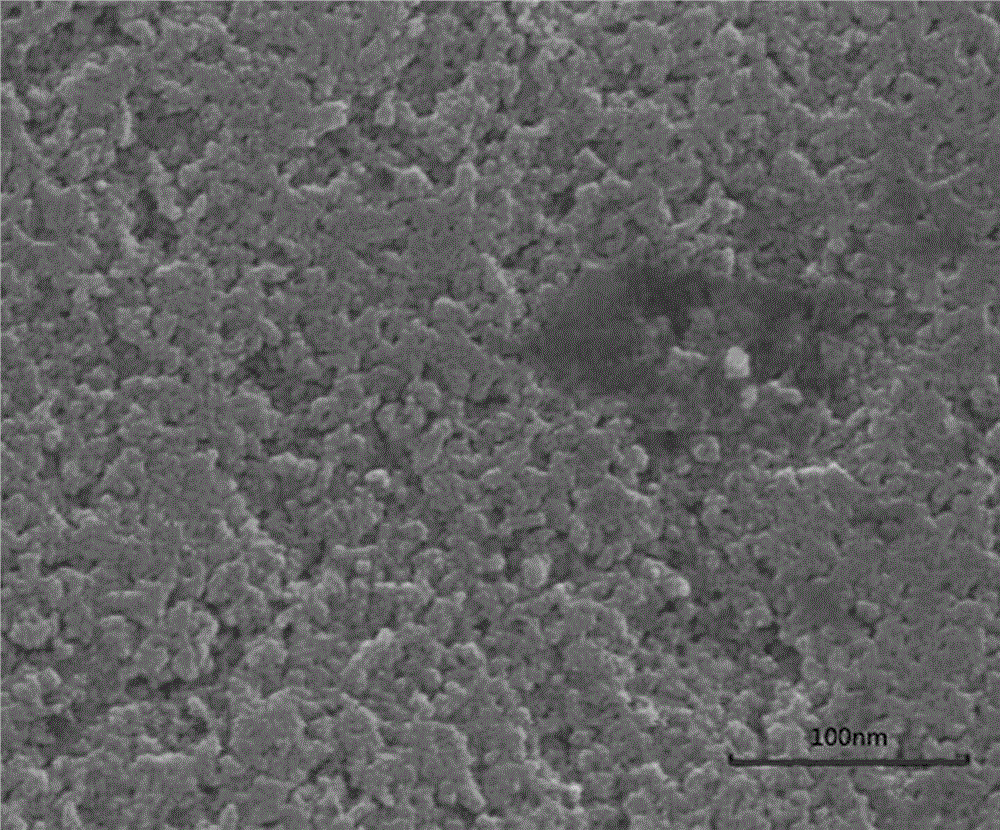

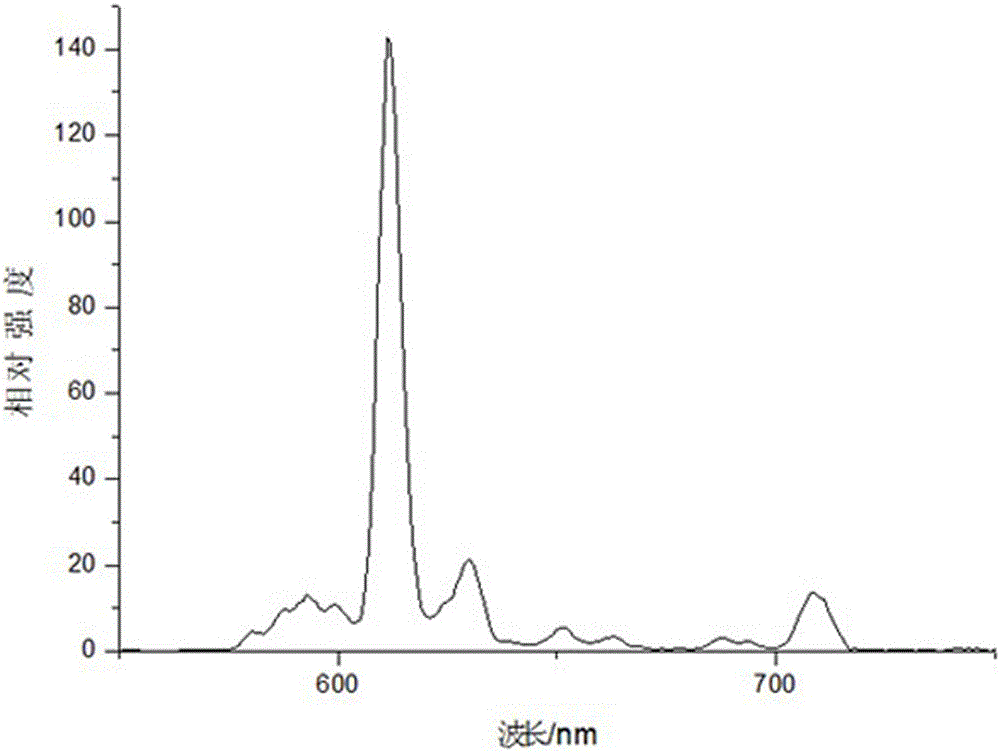

Y2O3:Eu<3+> red powder having high specific surface area and preparation method thereof

ActiveCN105038793AIncrease brightnessAvoid uneven coatingLuminescent compositionsSynthesis methodsRare earth

The invention relates to Y2O3: Eu<3+> red powder having high specific surface area and a preparation method thereof. The preparation method comprises the steps: co-precipitating yttrium and europium, mixing a fluxing agent and a hole-forming substance, and forming rare-earth three-base-color red powder having a porous structure in a synthesis method by means of a high-temperature solid-phase method. The method is simple, the synthesized three-base-color red powder has a porous structure, the specific surface area is relatively large, not only can the brightness of the red powder be improved, but also the loose porous structure solves the problem of the traditional red powder that a large specific gravity causes non-uniformity in coating a three-base-color lamp tube, and consumption of powder for coating can be reduced.

Owner:HAIMEN DADE INTPROP SERVICE CO LTD

Liquid crystal display device

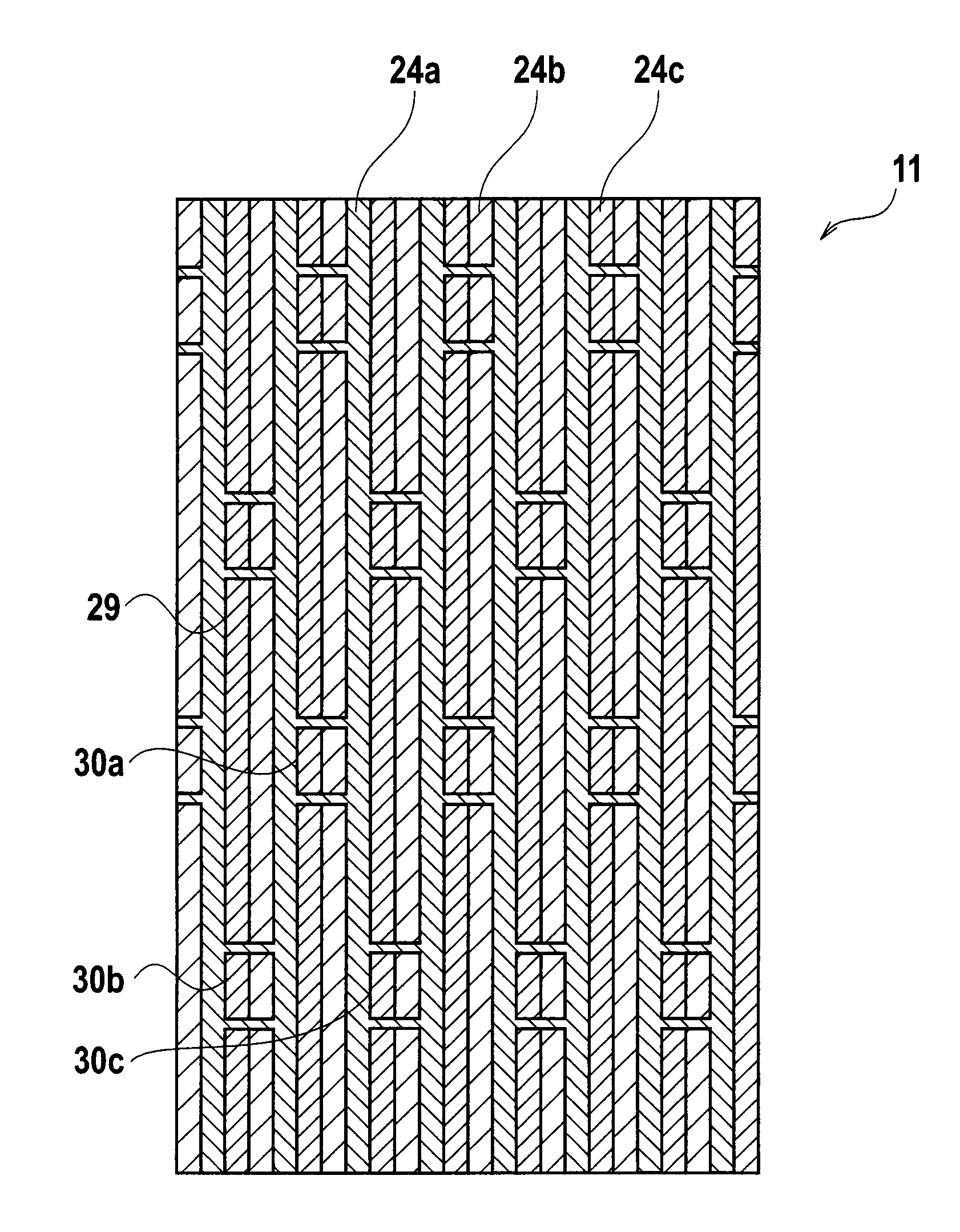

InactiveUS20080055524A1Reduce yieldAvoid uneven coatingNon-linear opticsGrid patternLiquid-crystal display

Provided is a liquid crystal display device that makes it possible to prevent coating unevenness of a colored layer from occurring. The liquid crystal display device includes a first colored layer, a second colored layer and a third colored layer, which layers are formed in a display area. In the liquid crystal display device, the first colored layer is arranged in a grid pattern in a manner of surrounding the second colored layer and the third colored layer. In addition, when (n, m) denotes the coordinates of a pixel having a grid square formed therein in the display area, grid squares are omitted in at least pixels of (n−1, m−1), (n−1, m+1), (n+1, m−1) and (n+1, m+1).

Owner:TOSHIBA MATSUSHITA DISPLAY TECH

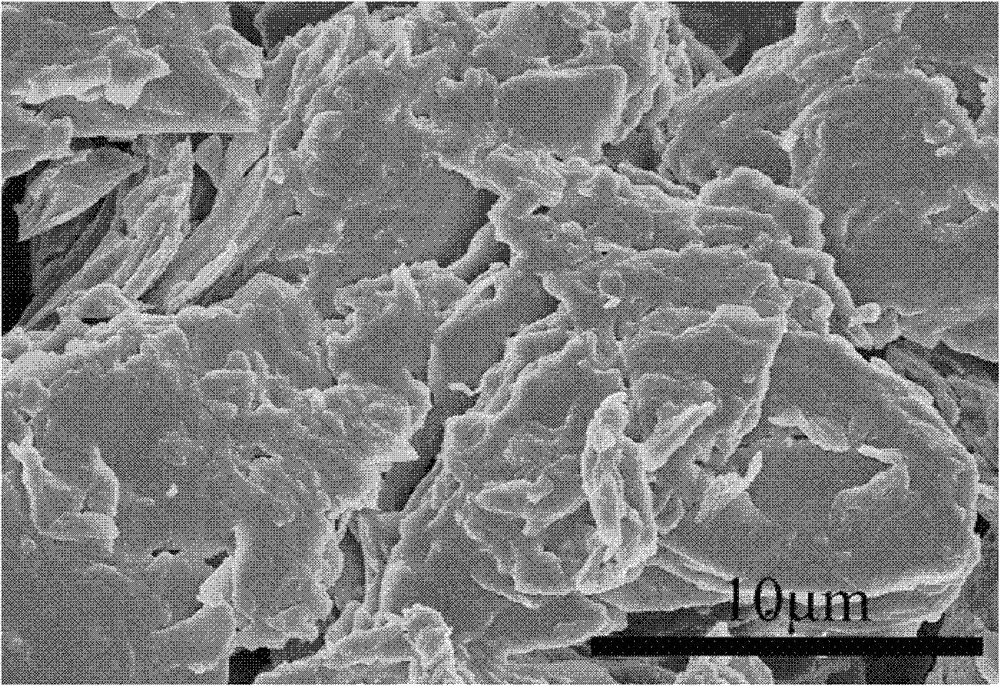

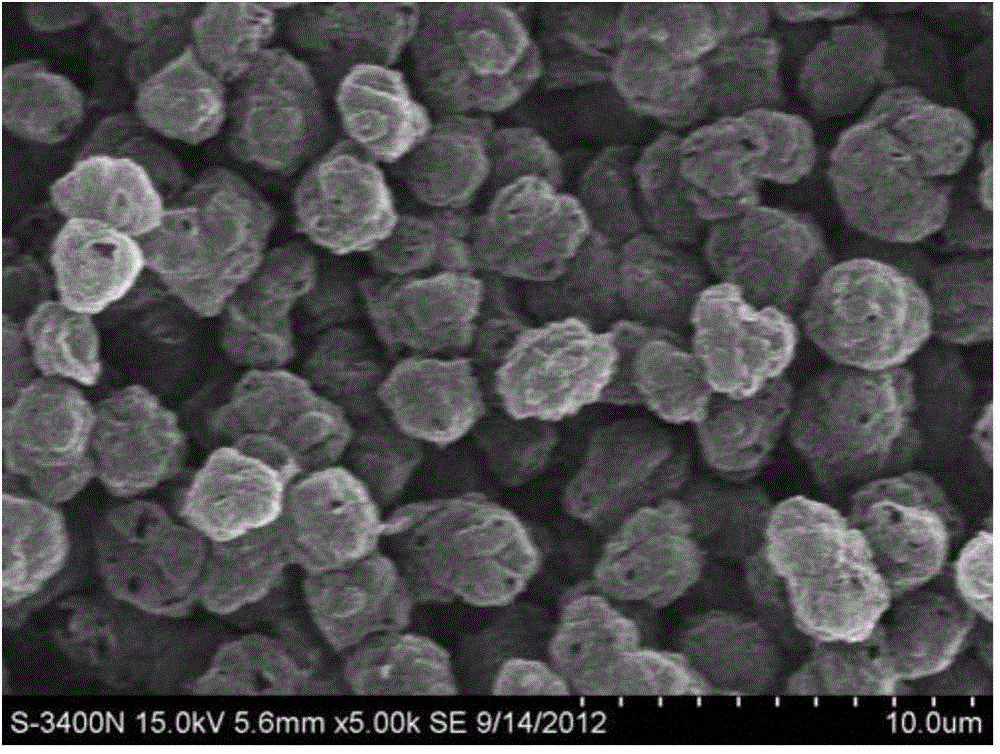

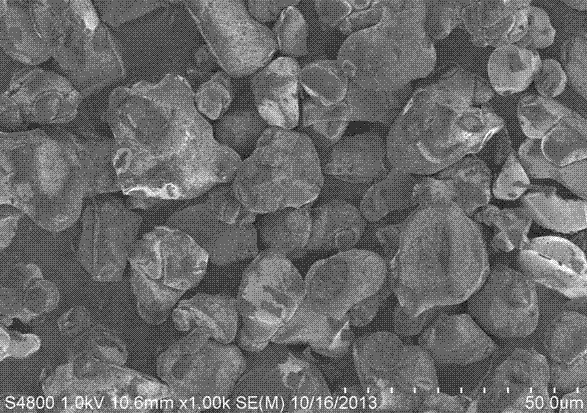

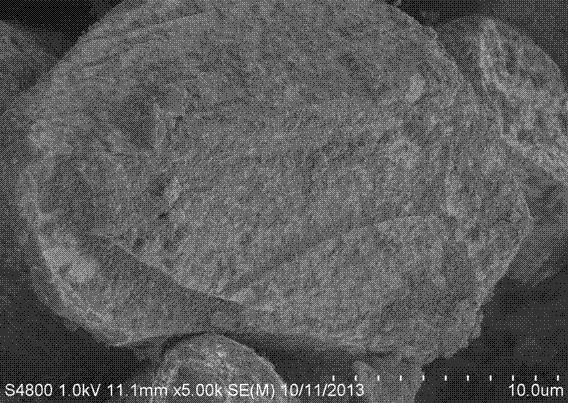

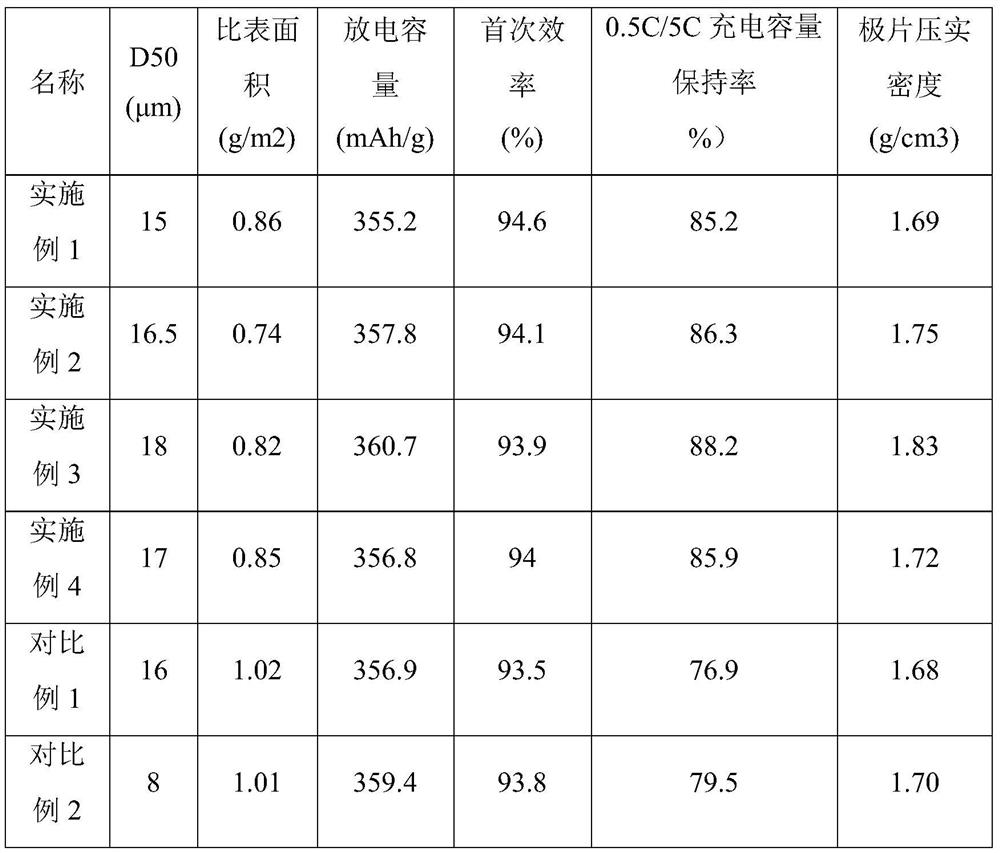

Fast-charging graphite negative electrode material based on amorphous carbon coating and preparation method of fast-charging graphite negative electrode material

The invention belongs to the field of lithium ion battery negative electrode materials, and relates to a fast-charging graphite negative electrode material based on amorphous carbon coating and a preparation method of the fast-charging graphite negative electrode material. The preparation method comprises the steps that a graphite raw material is prepared into powder, graphitization is performed to obtain a graphitized precursor, liquid coating is performed on the graphitized precursor to obtain a precursor, mixing and granulation are performed to obtain a granulation precursor, and carbonization is carried out to obtain the graphite negative electrode material. The process is simple, large-scale production is extremely easy, and the prepared lithium ion battery negative electrode material has the characteristics of uniform surface coating, high isotropy, good charging rate performance and the like.

Owner:大连宏光锂业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com