A lithium ion battery cathode material and a preparing method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor lithium-ion conductivity, improve volumetric energy density, improve lithium-ion conductivity, and avoid uneven adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

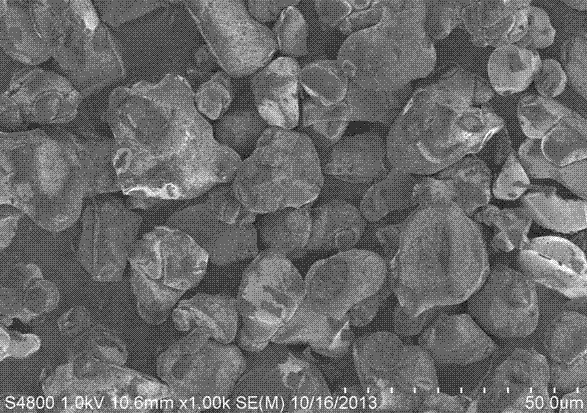

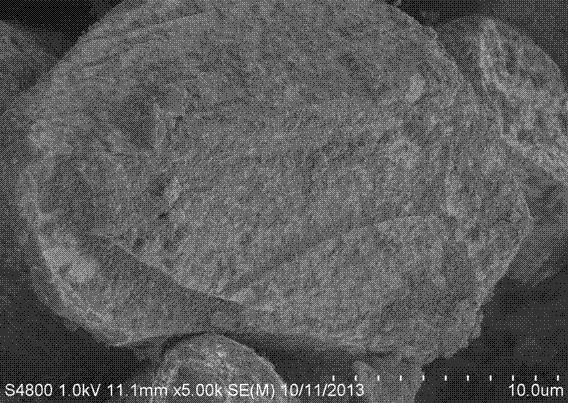

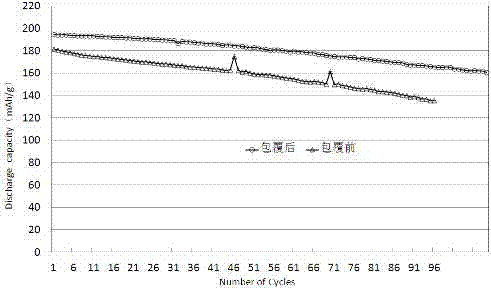

[0041] This embodiment provides a lithium battery positive electrode material, which includes an inner core and a cladding layer. The core structure is lithium cobalt oxide LiCoO 2 , the particle size is 15um, and the cladding structure is LiNi 0.8 mn 0.2 PO 4 , accounting for 2% by mass of the entire positive electrode material, and the thickness of the coating layer is 0.5um.

[0042] The preparation method is as follows:

[0043] Dissolve nickel sulfate and manganese sulfate according to the metal molar ratio of 0.80:0.20 to obtain a 2.0mol / L mixed salt solution, and 100g lithium cobaltate LiCoO 2 Add to 30ml mixed salt solution to form a slurry mixture, then add the mixture to (NH 4 ) 2 HPO 4 Fully stir the reaction in the solution, heat treatment at 400°C for 2 hours to obtain LiNi 0.8 mn 0.2 PO 4 Coated LiCoO 2 cathode materials for lithium batteries.

Embodiment 2

[0045] This embodiment provides a lithium battery positive electrode material, which includes an inner core and a cladding layer. The core structure is doped lithium cobalt oxide LiCo 0.8 Ni 0.2 o 2 , the particle size is 8um, and the cladding structure is LiNi 0.9 Al 0.1 PO 4 , accounting for 0.1% by mass of the entire positive electrode material, and the thickness of the coating layer is 0.01um.

[0046] The preparation method is as follows:

[0047] Dissolve nickel chloride and aluminum nitrate according to the metal molar ratio of 0.90:0.10 to obtain a 4.0mol / L mixed salt solution, and 100g doped lithium cobaltate LiCo 0.8 Ni 0.2 o 2 Add to 30ml mixed salt solution to form a slurry mixture, then add the mixture to NH 4 h 2 PO 4 Fully stir the reaction in the solution, heat treatment at 500°C for 1.5 hours to obtain LiNi 0.9 Al 0.1 PO 4 Coated LiCo 0.8 Ni 0.2 o 2 cathode materials for lithium batteries.

Embodiment 3

[0049] This embodiment provides a lithium battery positive electrode material, which includes an inner core and a cladding layer. The core structure is doped lithium cobalt oxide LiCo 0.9 Mg 0.1 o 2 , the particle size is 18um, and the cladding structure is LiMn 0.8 Fe 0.2 PO 4 , accounting for 5% by mass of the entire positive electrode material, and the thickness of the coating layer is 1um.

[0050] The preparation method is as follows:

[0051] Dissolve manganese sulfate and ferric nitrate according to the metal molar ratio of 0.80:0.20 to obtain a 0.1mol / L mixed salt solution, and 100g doped lithium cobaltate LiCo 0.9 Mg 0.1 o 2 Add to 30ml mixed salt solution to form a slurry mixture, then add the mixture to (NH 4 ) 3 PO 4 Fully stir the reaction in the solution, heat treatment at 800°C for 1 hour to obtain LiMn 0.8 Fe 0.2 PO 4 Coated LiCo 0.9 Mg 0.1 o 2 cathode materials for lithium batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Medium particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com