A fluorophosphate lithium ion-electron mixed conductor modified lithium cobalt oxide composite material and preparation method thereof

A fluorophosphate, mixed conductor technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of cycle performance, poor rate performance compatibility, etc., and achieve improved cycle stability, good lithium ion conduction characteristics, and improved rate. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

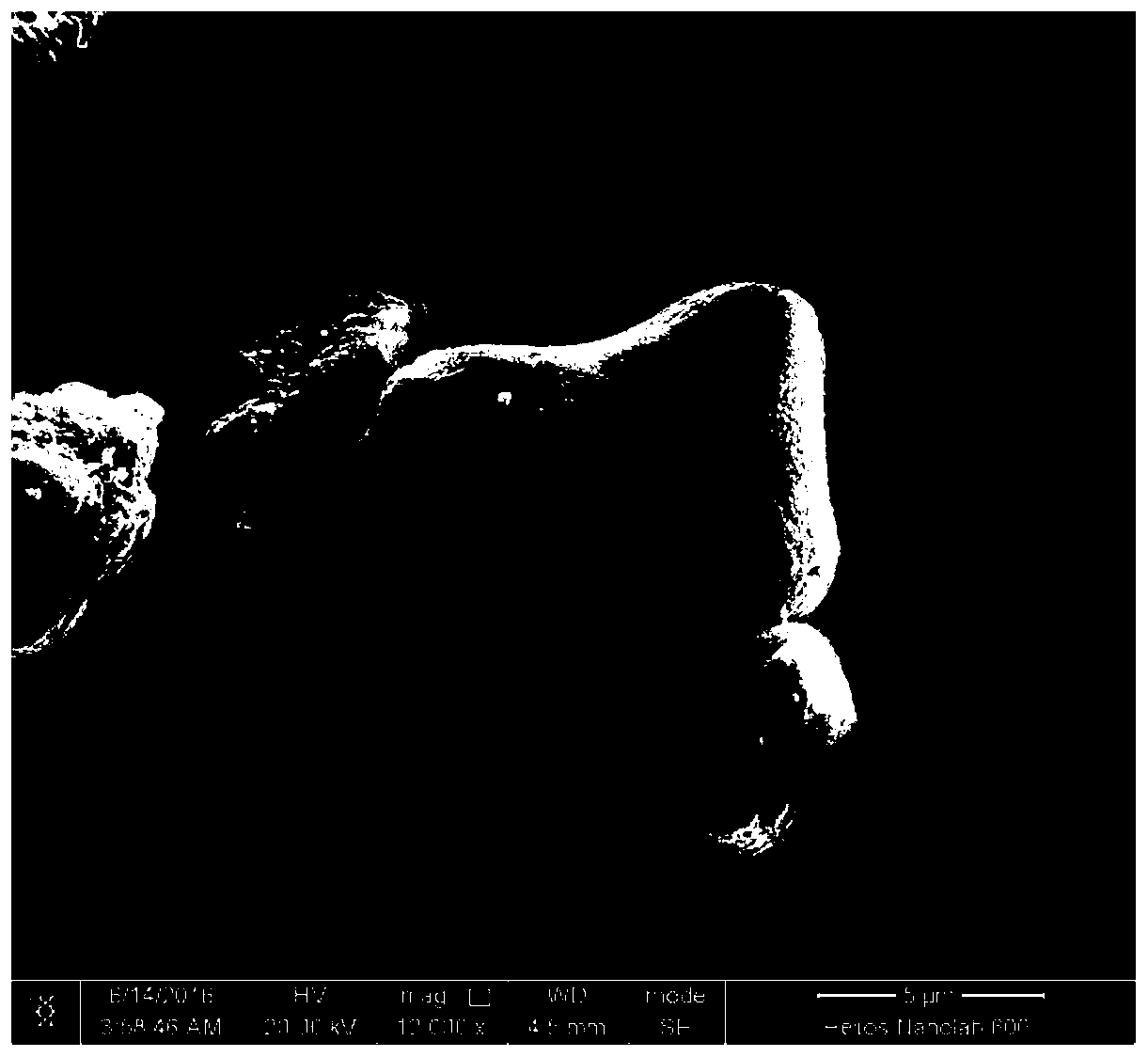

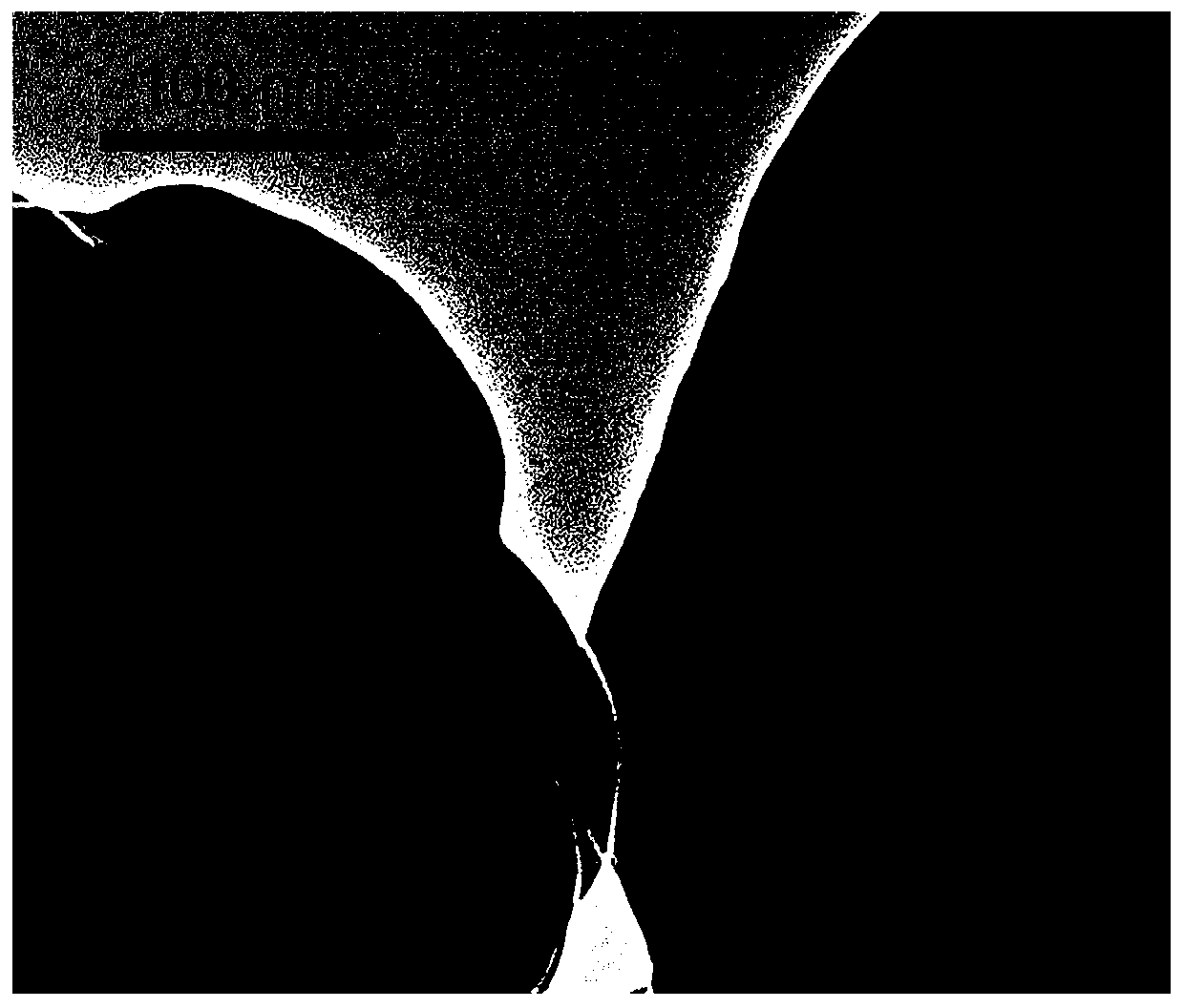

Image

Examples

specific Embodiment approach 1

[0027] Embodiment 1: In this embodiment, a fluorophosphate-based lithium ion-electron mixed conductor modified lithium cobalt oxide composite material is a lithium cobalt oxide positive electrode material coated with a layer of lithium-containing fluorophosphate, wherein the coated The lithium cobalt oxide cathode material is a layered material with the chemical formula LiCo 1-x m x o 2 , where 0≤x≤0.2, M is one or more combinations of Mg, Ca, Cu, Ni, Al, Fe, Ti, Mn and Zr; the chemical formula of the cladding layer material is LiM'PO 4-y f 1+y , 0≤y≤1.2, where M′ is Zr, Fe, Sm, Pr, Nb, Ga, Zn, Y, Mg, Al, Cr, Ca, Ti, Cu, Sr, Ba, Ce, Sn, Sb, La and one or more combinations of Bi.

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass ratio of the cladding layer material to the lithium cobalt oxide positive electrode material is 0.005-0.1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the thickness of the cladding layer material is 2-200 nm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com