Bare concrete

A technology of clear-water concrete and water-reducing agent, which is applied in the field of building materials, can solve the problems that clear-water concrete is easily corroded by rainwater, shortens the service life of clear-water concrete, etc., and achieves favorable cross-linking network, easy mixing and uniform dispersion, and improved corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

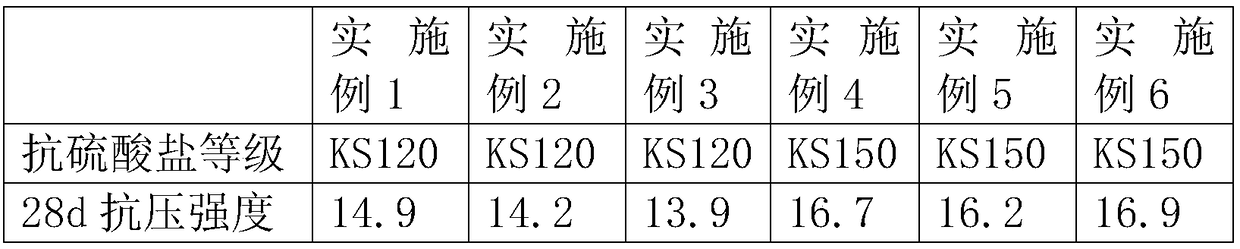

Examples

Embodiment 1

[0060] A kind of fair-faced concrete, comprises the component of following mass parts:

[0061] Water 7.5kg; Portland cement 15kg; medium sand 45kg; crushed stone 60kg; water reducing agent 0.75kg; carbon fiber 3kg; rubber emulsion 10.5kg; silane coupling agent 3.75kg.

[0062] The preparation method of fair-faced concrete is as follows:

[0063] (1) In the cement mixer, under normal temperature conditions, add 15kg of Portland cement and stir at a speed of 200r / min;

[0064] (2) While stirring, add 7.5kg of water, 0.75kg of water reducer, 3kg of carbon fiber, 10.5kg of rubber emulsion, and 3.75kg of silane coupling agent, and stir to obtain a premix;

[0065] (3) Add 45kg of medium sand and 60kg of crushed stone to the sand and gravel mixer at normal temperature, stir at a speed of 200r / min, and obtain aggregate after stirring evenly;

[0066] (4) In the concrete mixer, under normal temperature conditions, add the premix and aggregate, and stir at a speed of 200r / min;

[0...

Embodiment 2

[0071] A kind of fair-faced concrete, comprises the component of following mass parts:

[0072] 8.75kg of water; 17.5kg of Portland cement; 52.5kg of medium sand; 70kg of gravel; 0.87kg of water reducing agent; 3.5kg of carbon fiber; 12.25kg of rubber emulsion;

[0073] The preparation method of fair-faced concrete is as follows:

[0074] (1) In the cement mixer, under normal temperature conditions, add 17.5kg of Portland cement and stir at a speed of 200r / min;

[0075] (2) Add 8.75kg of water, 0.87kg of water reducer, 3.5kg of carbon fiber, 12.25kg of rubber emulsion, and 4.38kg of silane coupling agent while stirring, and stir to obtain a premix;

[0076] (3) Add 52.5kg of medium sand and 70kg of gravel to the sand mixer at room temperature, and stir at a speed of 200r / min to obtain aggregate;

[0077] (4) In the concrete mixer, under normal temperature conditions, add the premix and aggregate, and stir at a speed of 200r / min;

[0078] (5) Brush the release agent on the m...

Embodiment 3

[0082] A kind of fair-faced concrete, comprises the component of following mass parts:

[0083] 10kg of water; 20kg of Portland cement; 60kg of medium sand; 80kg of gravel; 1kg of water reducing agent; 4kg of carbon fiber; 14kg of rubber emulsion; 5kg of silane coupling agent.

[0084] The preparation method of fair-faced concrete is as follows:

[0085] (1) In the cement mixer, under normal temperature conditions, add 20kg of Portland cement and stir at a speed of 200r / min;

[0086] (2) Add water 10kg, water reducer 1kg, carbon fiber 4kg, rubber emulsion 14kg, silane coupling agent 5kg while stirring, after stirring evenly, obtain the premix;

[0087] (3) Add 60kg of medium sand and 80kg of crushed stone to the sand and gravel mixer at normal temperature, and stir at a speed of 200r / min to obtain aggregate after stirring evenly;

[0088] (4) In the concrete mixer, under normal temperature conditions, add the premix and aggregate, and stir at a speed of 200r / min;

[0089] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com