A kind of preparation method of modified lithium iron phosphate cathode material for lithium battery

A lithium iron phosphate and cathode material technology, which is applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of reducing the packing density of lithium iron phosphate materials, and achieve good lithium ion conduction characteristics. , good ionic conductivity, the effect of improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

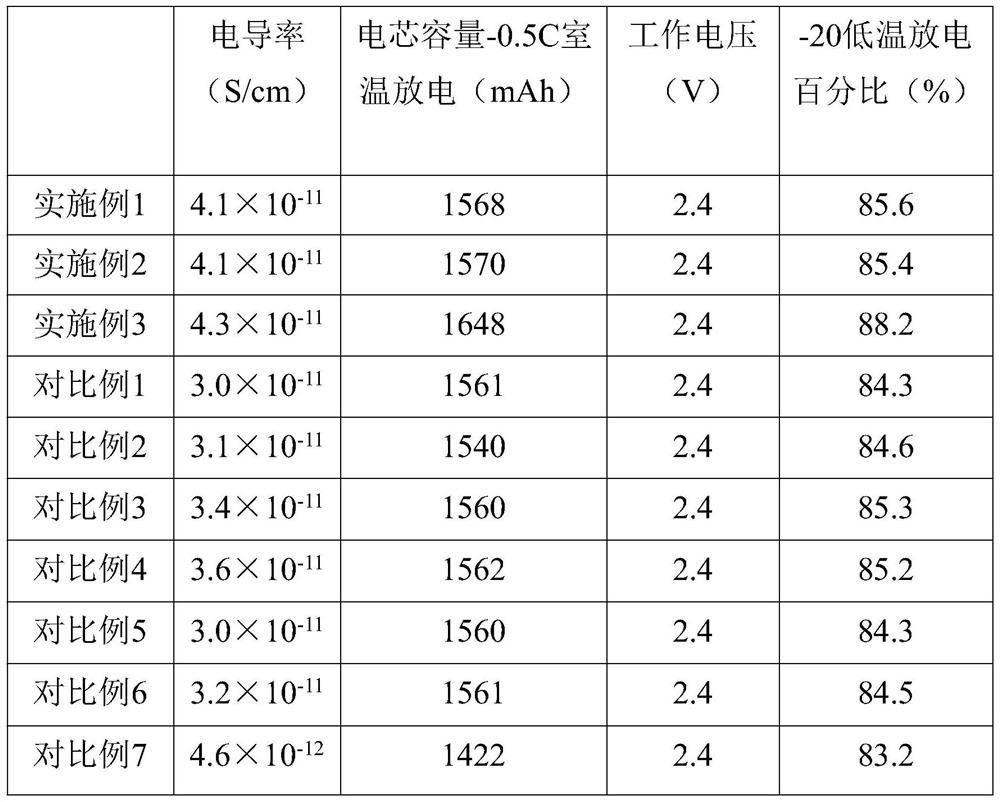

Examples

Embodiment 1

[0024]A preparation method of a modified lithium iron phosphate cathode material for lithium batteries includes the following steps:

[0025](1) Put the graphene and carbon nanotubes with a mass ratio of 1:1 into the solvent, and after the preliminary ultrasonic pulverization treatment, mix and stir at room temperature for 4-6 minutes, and then use 2 to 4 The temperature is increased to 40~60℃ at a rate of ℃ / min, and then kept for 4~6h, and then cooled to room temperature naturally to obtain a mixed solution;

[0026](2) Crush the lithium iron phosphate to a particle size of 3-6um, and put the lithium iron phosphate into the stirred tank. Slowly add distilled water according to the mass ratio of lithium iron phosphate and distilled water=1:2~7, and add even After the coupling agent and the conductive agent are quickly stirred for 10-16 minutes, the mixed solution in step (1) is added to the stirring tank and stirred evenly to obtain the modified intermediate;

[0027](3) Add the modified int...

Embodiment 2

[0032]The content of this embodiment is basically the same as that of embodiment 1, and the similarities will not be repeated. The difference is that the step (1) puts graphene and carbon nanotubes in a solvent with a mass ratio of 2:1 and passes After the initial ultrasonic pulverization treatment, mix and stir at room temperature for 4-6 minutes, then heat up to 40-60℃ at a rate of 2-4℃ / min under the protection of inert gas, keep it for 4-6h, and then cool to At room temperature, a mixed solution is obtained;

Embodiment 3

[0034]The content of this embodiment is basically the same as that of embodiment 1, and the similarities will not be repeated. The difference is that the step (1) puts graphene and carbon nanotubes with a mass ratio of 1.5:1 into the solvent and passes After the initial ultrasonic pulverization treatment, mix and stir at room temperature for 4-6 minutes, then heat up to 40-60℃ at a rate of 2-4℃ / min under the protection of inert gas, keep it for 4-6h, and then cool to At room temperature, a mixed solution is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com