Coating method for frame sealing glue

A coating method and technology for sealing frame glue, which can be applied to devices for coating liquid on the surface, coatings, etc., can solve problems such as uneven coating of frame sealing glue, and achieve the effect of avoiding uneven coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

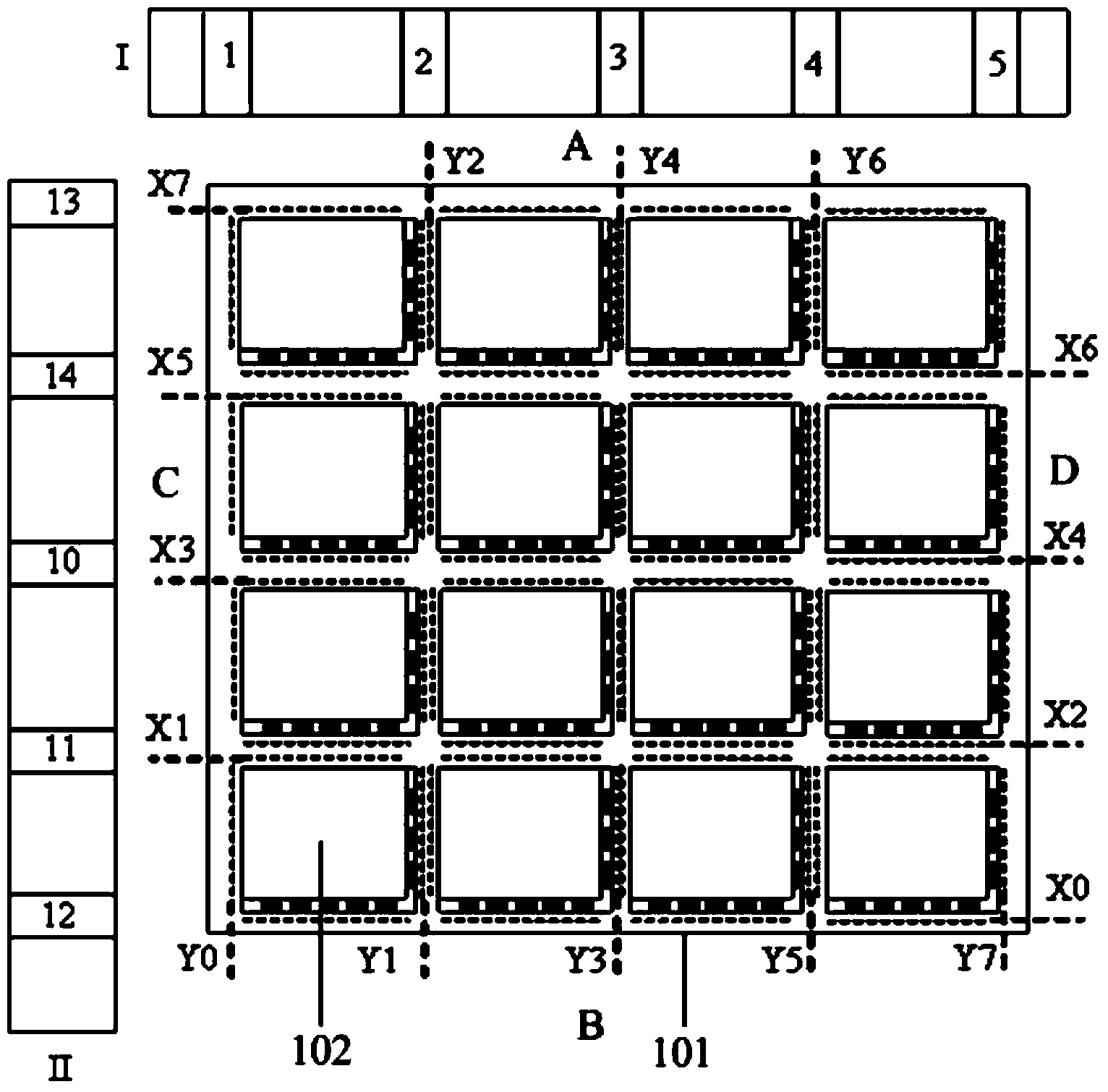

[0040] The specific implementation of the coating method of the frame sealant provided by the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0041] The shape and size of each display area on the substrate in the drawings do not reflect the actual scale, and the purpose is only to schematically illustrate the content of the present invention.

[0042] A method for coating a frame sealant provided in an embodiment of the present invention includes:

[0043] Use a plurality of nozzles to coat the sealant on each area to be coated on the substrate along the longitudinal coating line and the transverse coating line; wherein,

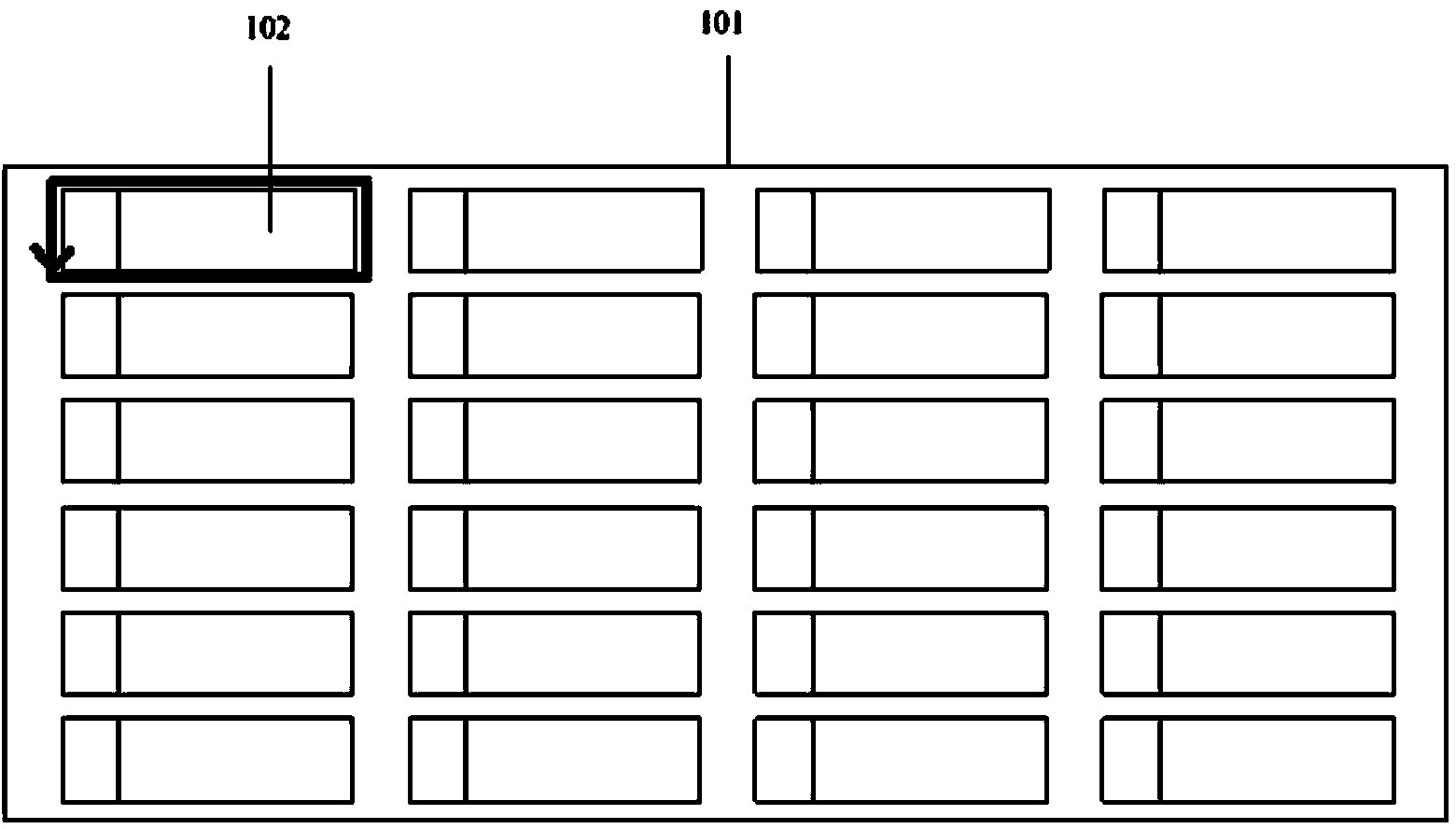

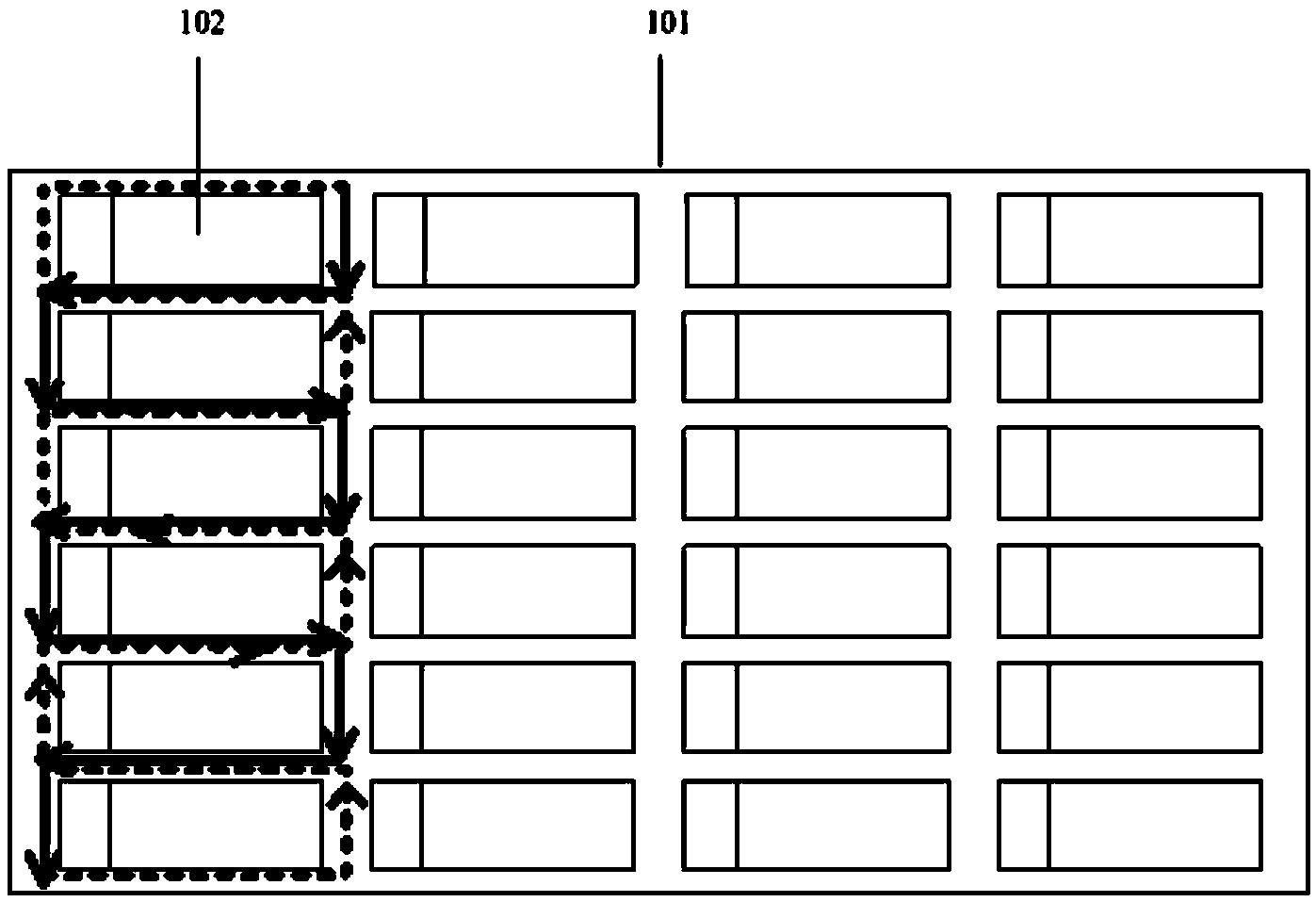

[0044] like image 3As shown, the substrate 101 has a plurality of rectangular display areas 102 arranged in a matrix, and the area to be coated (such as image 3 Shown by the dotted line) surrounds the display area 102; the parts on the same vertical line in each area to be coated form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com