Y2O3:Eu<3+> red powder having high specific surface area and preparation method thereof

A high specific surface, red powder technology, applied in the field of phosphor powder, can solve the problems of uneven coating, large specific surface area, large proportion of red powder in three primary colors, etc., and achieve the effect of reducing powder consumption and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

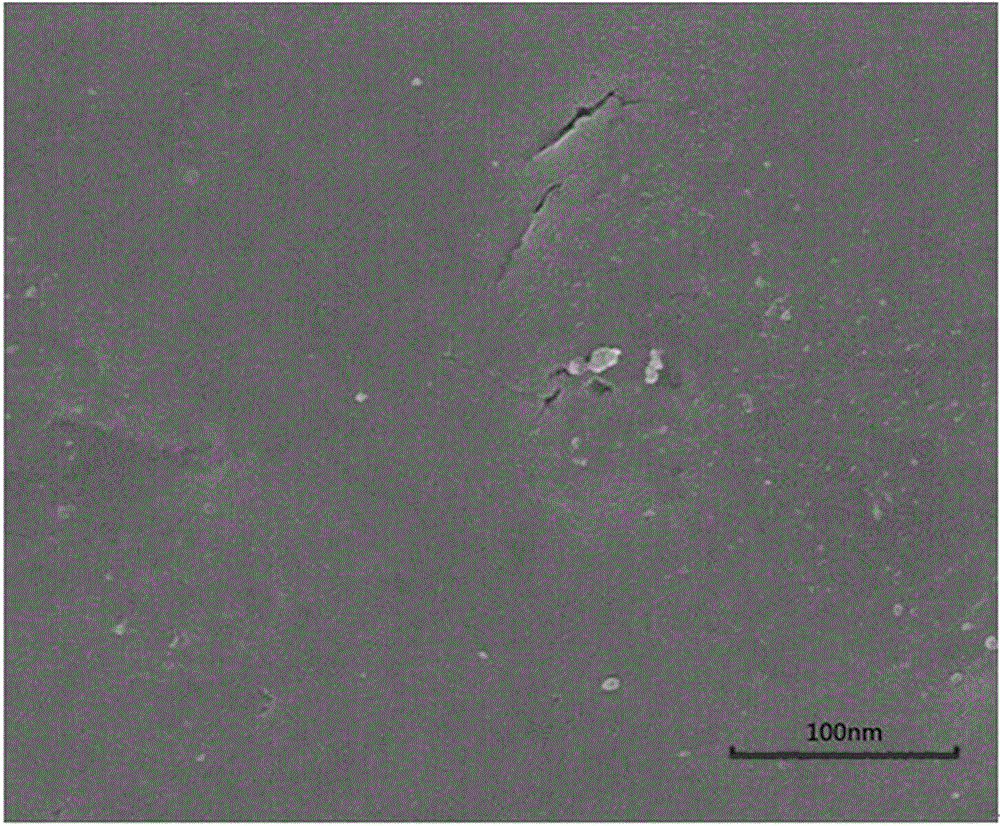

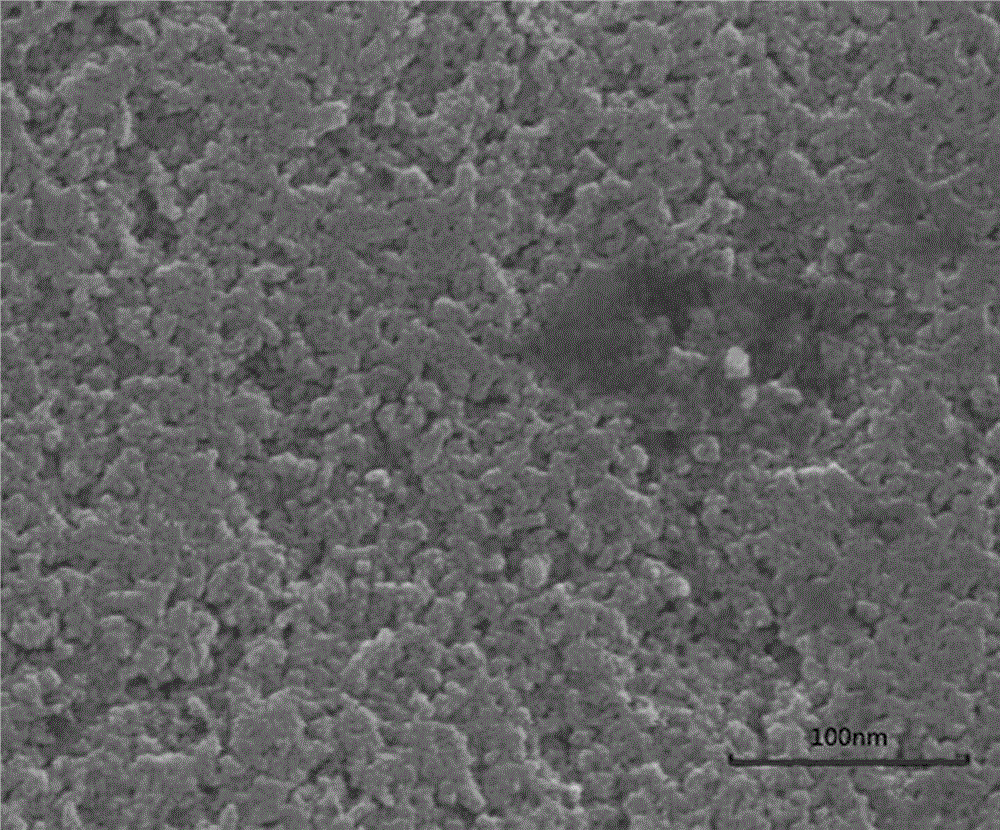

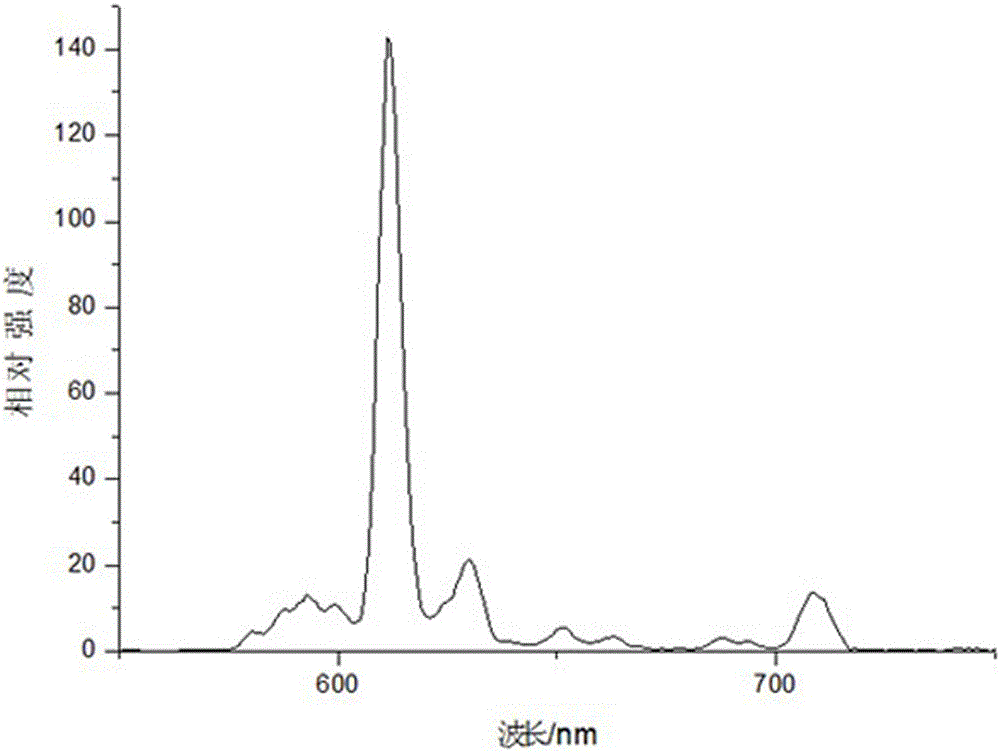

[0025] After mixing 50g of yttrium-europium co-precipitation with a mass fraction of 6.6% europium, 1g of KF and 0.5g of carbon powder, they were calcined at 1300°C for 4 hours, cooled and ground evenly.

Embodiment 2

[0027] Mix 50g of yttrium-europium coprecipitate with a mass fraction of 6.6% europium, 0.5g of KF, 0.5g of LiF and 0.5g of starch, after mixing evenly, calcining at 1275°C for 8h, cooling and grinding until uniform.

Embodiment 3

[0029] Mix 100g of yttrium-europium co-precipitate with a mass fraction of 6.6% europium, 1g of NaF, 0.5g of benzoic acid and 0.5g of starch, after mixing uniformly, calcinate at 1350°C for 6h, cool and grind evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com