Fast-charging graphite negative electrode material based on amorphous carbon coating and preparation method of fast-charging graphite negative electrode material

A graphite anode, fast charging technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of not meeting market demand, low charging performance, etc., to achieve perfect coating effect, improve charging performance, and reduce polarization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

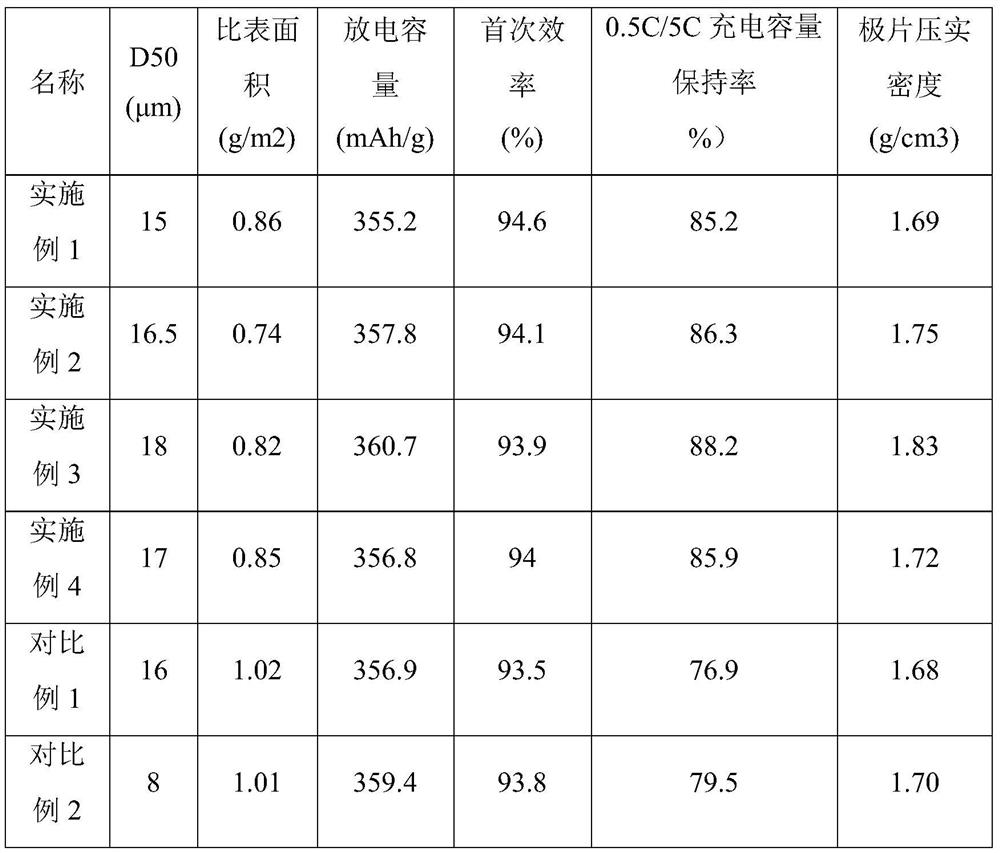

Examples

Embodiment 1

[0026] This embodiment provides a fast-charging graphite negative electrode material and a preparation method based on amorphous carbon coating, including the following steps:

[0027] 1) Firstly, the calcined petroleum coke is coarsely pulverized, finely pulverized, and then shaped and classified to obtain a fine powder with a D50 particle size of 8 μm;

[0028] 2) Put the fine powder obtained in step 1) into a graphitization furnace for graphitization, the graphitization temperature is 3000°C, and the graphitization time is 56h to obtain a graphitization precursor;

[0029] 3) Mix the graphitized precursor obtained in step 2) with the organic solvent of the phenolic resin according to the ratio of 1:20, wherein the ratio of the phenolic resin to the organic solvent is 1:10, and then spray dry to obtain the precursor, wherein the spray The drying temperature is 180°C;

[0030] 4) The spray-dried precursor obtained in step 3) was carbonized in a pusher kiln at 850° C. for 10 ...

Embodiment 2

[0035] This embodiment provides a fast-charging graphite negative electrode material and a preparation method based on amorphous carbon coating, including the following steps:

[0036] 1) Coarsely pulverizing and finely pulverizing the needle coke raw coke, and then performing shaping and grading to obtain a fine powder with a D50 particle size value of 6 μm;

[0037] 2) Put the fine powder obtained in step 1) into a graphitization furnace for graphitization, the graphitization temperature is 3100°C, and the graphitization time is 60h to obtain a graphitized precursor;

[0038] 3) Mix the graphitized precursor obtained in step 2) with the organic solvent of asphalt according to the ratio of 1:25, wherein the ratio of the phenolic resin to the organic solvent is 1:12, and then spray dry to obtain the precursor, wherein the spray-dried The temperature is 200°C;

[0039] 4) The spray-dried precursor obtained in step 3) was carbonized in a pusher kiln at 1050° C. for 12 hours und...

Embodiment 3

[0044] This embodiment provides a fast-charging graphite negative electrode material and a preparation method based on amorphous carbon coating, including the following steps:

[0045] 1) Firstly, the calcined needle coke is coarsely pulverized, finely pulverized, and then shaped and classified to obtain a fine powder with a D50 particle size of 7 μm;

[0046] 2) Put the fine powder obtained in step 1) in a graphitization furnace for graphitization, the graphitization temperature is 3200°C, and the graphitization time is 75h to obtain a graphitization precursor;

[0047] 3) Mix the graphitized precursor obtained in step 2) with the organic solvent of the phenolic resin according to the ratio of 1:30, wherein the ratio of the phenolic resin to the organic solvent is 1:10, and then spray dry to obtain the precursor, wherein the spray The drying temperature is 250°C;

[0048] 4) The spray-dried precursor obtained in step 3) was carbonized in a pusher kiln at 1200° C. for 8 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com