Coating method and device of plasma substrate pattern layer

A plasma-based, plasma-based technology, applied in the coating field of ionic substrate layers, can solve the problems of low coating efficiency and uneven coating, and achieve the effect of improving coating efficiency and overcoming the problem of uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

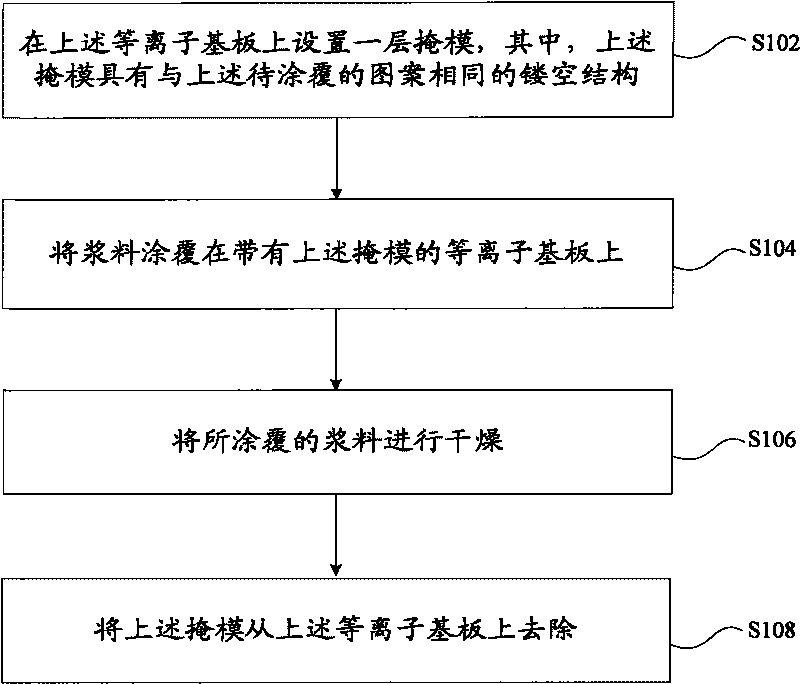

[0019] figure 1 It is a flowchart of a coating method of a plasma substrate layer according to an embodiment of the present invention. like figure 1 As shown, the coating method of the plasma substrate layer mainly includes:

[0020] S102, setting a layer of mask on the plasma substrate, wherein the mask has the same hollow structure as the pattern to be coated;

[0021] S104, coating the slurry on the plasma substrate with the above mask;

[0022] S106, drying the applied slurry;

[0023] S108, removing the mask from the plasma substrate.

[0024] Here, the mask may be an adhesive tape or a plastic film, or the mask may also be formed of other materials having a masking effect.

[0025] The following uses adhesive tape as an example to describe the characteristics of the mask, and the following characteristics are also applicable to plastic films or other materials that have a masking effect.

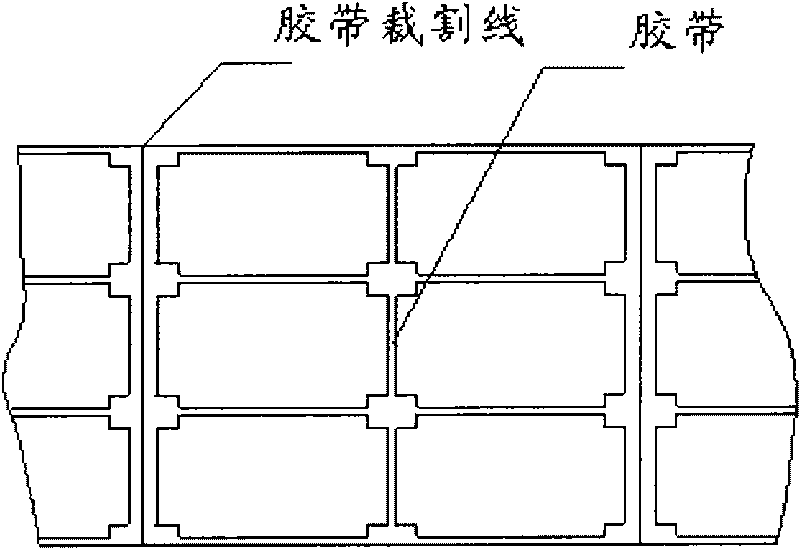

[0026] figure 2 A schematic plan view of an adhesive tape according to an ...

Embodiment 2

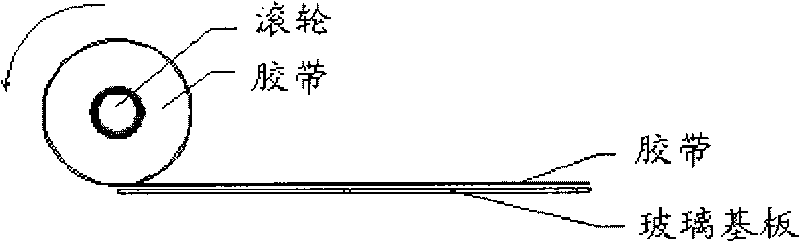

[0039] Figure 8 A schematic diagram of a coating device for a plasma substrate layer according to an embodiment of the present invention. The coating device of the plasma substrate layer mainly includes: a mask setting part 802, which is used to set a layer of mask on the plasma substrate, wherein the mask has the same hollow as the pattern to be coated structure; coating part 804, used for coating the slurry on the plasma substrate with the mask; drying part 806, used for drying the coated slurry; removing part 808, used for The mask is removed from the plasma substrate.

[0040] Here, the mask setting part 802 may be a roller; the coating part 804 may be a nozzle.

[0041] The mask is an adhesive tape or a plastic film, wherein the thickness of the mask is T<A+B, where A represents the thickness of the slurry to be coated on the plasma substrate, and B represents the thickness used to coat the plasma substrate. The gap between the nozzle of a slurry and the wet film form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com