Method for manufacturing electrode for fuel cell

A fuel cell and electrode technology, which can be used in fuel cells, fuel cell components, battery electrodes, etc., to solve problems such as productivity obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

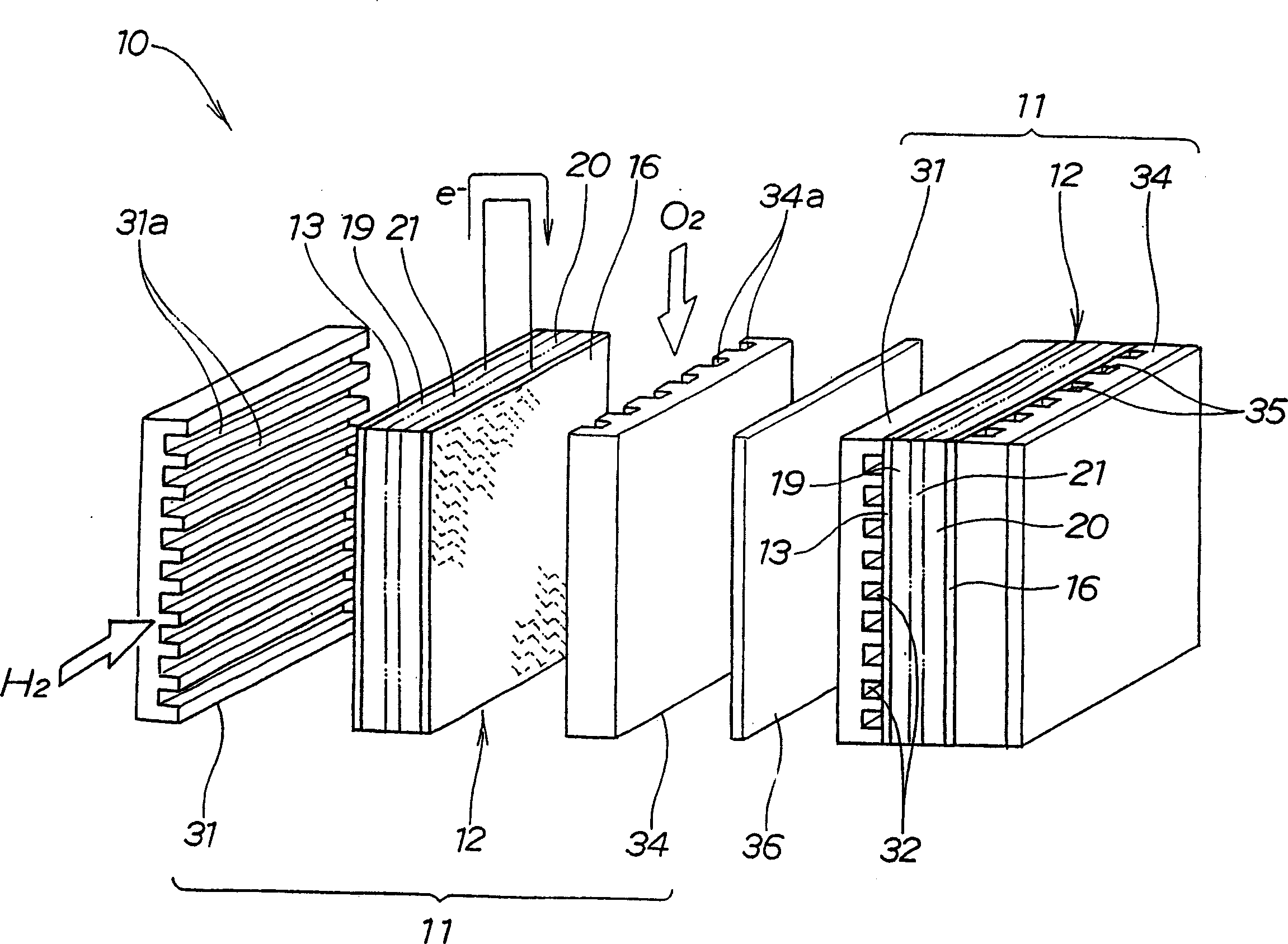

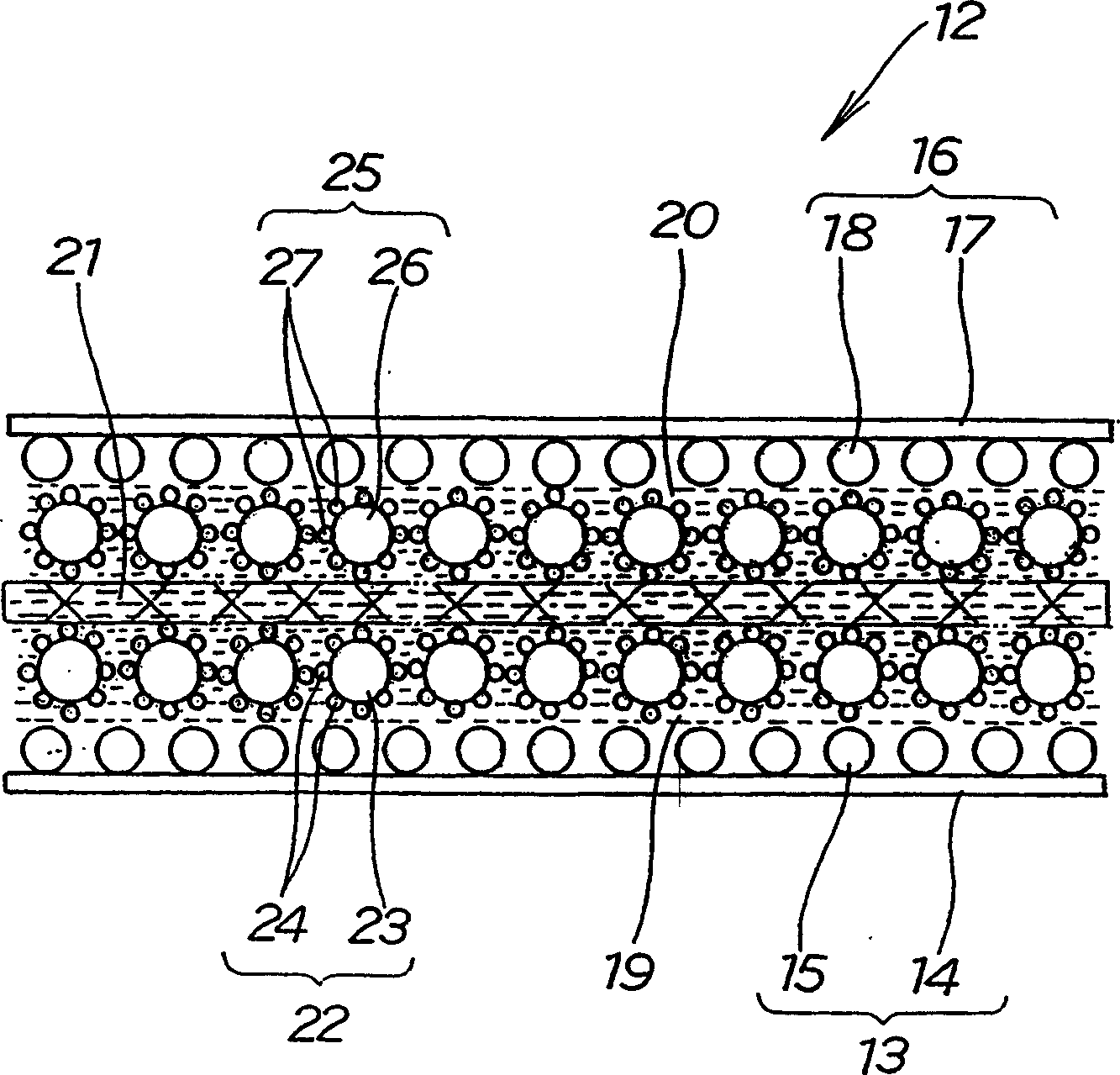

[0119] The electrode 12 of Example 1 has the negative electrode layer 19 and the positive electrode layer 20 located inside the negative electrode diffusion layer 13 and the positive electrode diffusion layer 16 respectively, and the ion exchange membrane 21 is located between the negative electrode layer 19 and the positive electrode layer 20 .

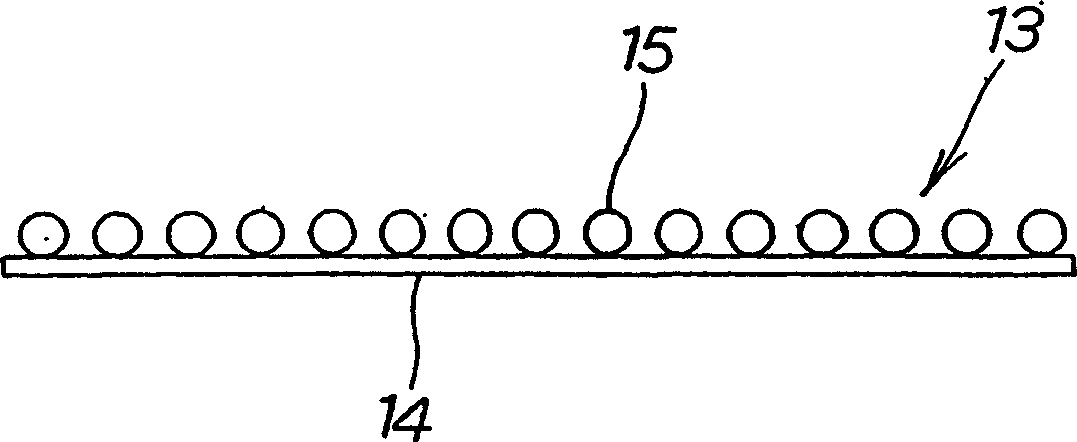

[0120] The negative-electrode-side diffusion layer 13 is a sheet composed of the negative-electrode-side carbon paper 14 and the negative-electrode-side adhesive layer 15 .

[0121] The positive-side diffusion layer 16 is a sheet composed of a positive-side carbon paper 17 and a positive-side adhesive layer 18 .

[0122] The binder constituting the negative electrode side binder layer 15 is a fluorocarbon resin, and the binder has excellent hydrophilicity. The binder constituting the positive electrode side binder layer 18 is a carbon polymer having excellent hydrophobicity. A substance obtained by introducing sulfonic acid into the...

Embodiment 3

[0220] In Embodiment 3, the fuel cell electrode 72 has a positive electrode layer 70 (ie, the first electrode layer) and a negative electrode layer 19 (ie, the second electrode layer) inside the positive electrode side diffusion layer 16 and the negative electrode side diffusion layer 13, respectively, and the negative electrode layer There is an ion exchange membrane 21 between layer 19 and positive electrode layer 70 . That is, only the positive electrode layer 70 of the fuel cell electrode 72 in Example 3 is different from the fuel cell electrode 62 in Example 2, and the rest of the structure is the same as in Example 2. The positive electrode layer 70 will be described below.

[0221] The positive electrode layer 70 is divided into the first layer 70a away from the ion exchange membrane 21 side (i.e. in contact with the positive side diffusion layer 16 side); and the second layer 70b in contact with the ion exchange membrane 21 side, when the porosity is by the following ...

Embodiment 4

[0245] In Example 4, the fuel cell electrode 112 has the negative electrode layer 19 and the positive electrode layer 20 inside the negative electrode diffusion layer 113 and the positive electrode diffusion layer 116, respectively, and has the ion exchange membrane 21 between the negative electrode layer 19 and the positive electrode layer 20.

[0246] The positive-electrode-side diffusion layer 116 is a sheet composed of a positive-electrode-side carbon paper 117 that is a first carbon paper and a positive-electrode-side adhesive layer 118 that is a first adhesive layer.

[0247] The anode-side diffusion layer 113 is a sheet composed of the anode-side carbon paper 114 which is the second carbon paper and the anode-side adhesive layer 115 which is the second adhesive layer.

[0248] The solution of the negative electrode side adhesive layer 115 contains, for example, carbon particles 115a and an ion exchange resin serving as an adhesive resin 115b excellent in adhesiveness. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com