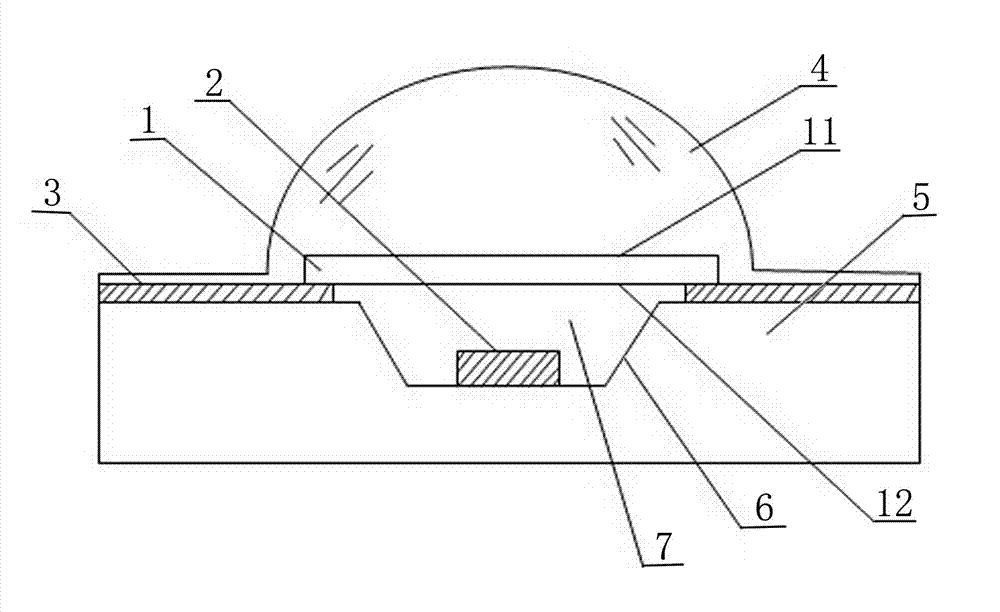

Fluorescent and transparent polycarbonate grating for LED (light-emitting diode) and preparation method for same

A polycarbonate, transparent technology, applied in the direction of electrical components, circuits, grain processing, etc., can solve the problems of polycarbonate composition light transmittance drop, visual fatigue, human eye irritation, etc., to improve glare and uneven light distribution , improve yield and consistency, solve the effect of uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the fluorescent transparent polycarbonate grating for LED of the present invention, comprises the following steps:

[0052] A) Sieve material, use a 150-mesh test to screen out polycarbonate powder with a particle size of 30-90um

[0053] B) Prepare materials, weigh polycarbonate powder and fluorescent powder with a particle size of 30-90um according to the mass ratio, and obtain raw materials

[0054] C) Mixing, put the weighed raw materials into the frequency conversion planetary ball mill for mixing, the speed of the frequency conversion planetary ball mill is 160-250r / min, and the mixing time is 1-5h to obtain the mixture

[0055] D) Drying, putting the mixed material into a vacuum constant temperature drying oven for drying, the drying temperature is 50-120° C., and the drying time is 3-20 hours to obtain a dried mixed material. The maximum moisture content of polycarbonate powder is <0.020%

[0056] E) Compounding additives, weigh tetra...

Embodiment 1

[0063] Embodiment 1: Prepare the raw materials required for preparing the product of the present invention: polycarbonate powder, yellow fluorescent powder, antioxidant 1010, antioxidant 168, organic silicon light diffusing agent, the specific ratio of each component is as described in Table 1 . The implementation steps are as follows:

[0064] A) Sieve material, use a 150-mesh test to screen out polycarbonate powder with a particle size of 30-90um

[0065] B) Prepare materials, according to the mass ratio of the components in Example 1 in Table 1, weigh polycarbonate and yellow phosphor with a particle size of 30-90um

[0066] C) Mixing, put the weighed polycarbonate powder and fluorescent powder into a variable frequency planetary ball mill for mixing, the speed of the variable frequency planetary ball mill is 160-250r / min, and the mixing time is 1-5h to obtain a mixture

[0067] D) Drying, putting the mixed material into a vacuum constant temperature drying oven for dryin...

Embodiment 2

[0077] Only the ingredients in steps B) and E) in Example 1 are changed to the ingredients according to the mass ratio of the components in Example 2 in Table 1, and the rest are the same as the description in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com