Reaction chamber and processing method used for PVD film coating

A reaction chamber and processing method technology, applied in the field of PVD coating reaction chamber, can solve the problems of poor selectivity of film-forming materials, difficulty in maintaining discharge phenomenon, and long electron mean free path, so as to improve performance and avoid product coating failure. Uniform, efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

[0030] A processing method for PVD coating, comprising:

[0031] Vacuum extraction: place the coated workpiece on the top of the chamber, and use a vacuum pump to evacuate the chamber to vacuum.

[0032] Heating the target material: Select the target material according to the requirements of the explosion-proof film product, rotate the required target material to the upper end of the electron gun, start the electron gun, and heat the target material to evaporate it.

[0033] Coating: The target material is heated and evaporated to the top of the chamber by the electron gun, and deposited on the product workpiece on the top of the chamber.

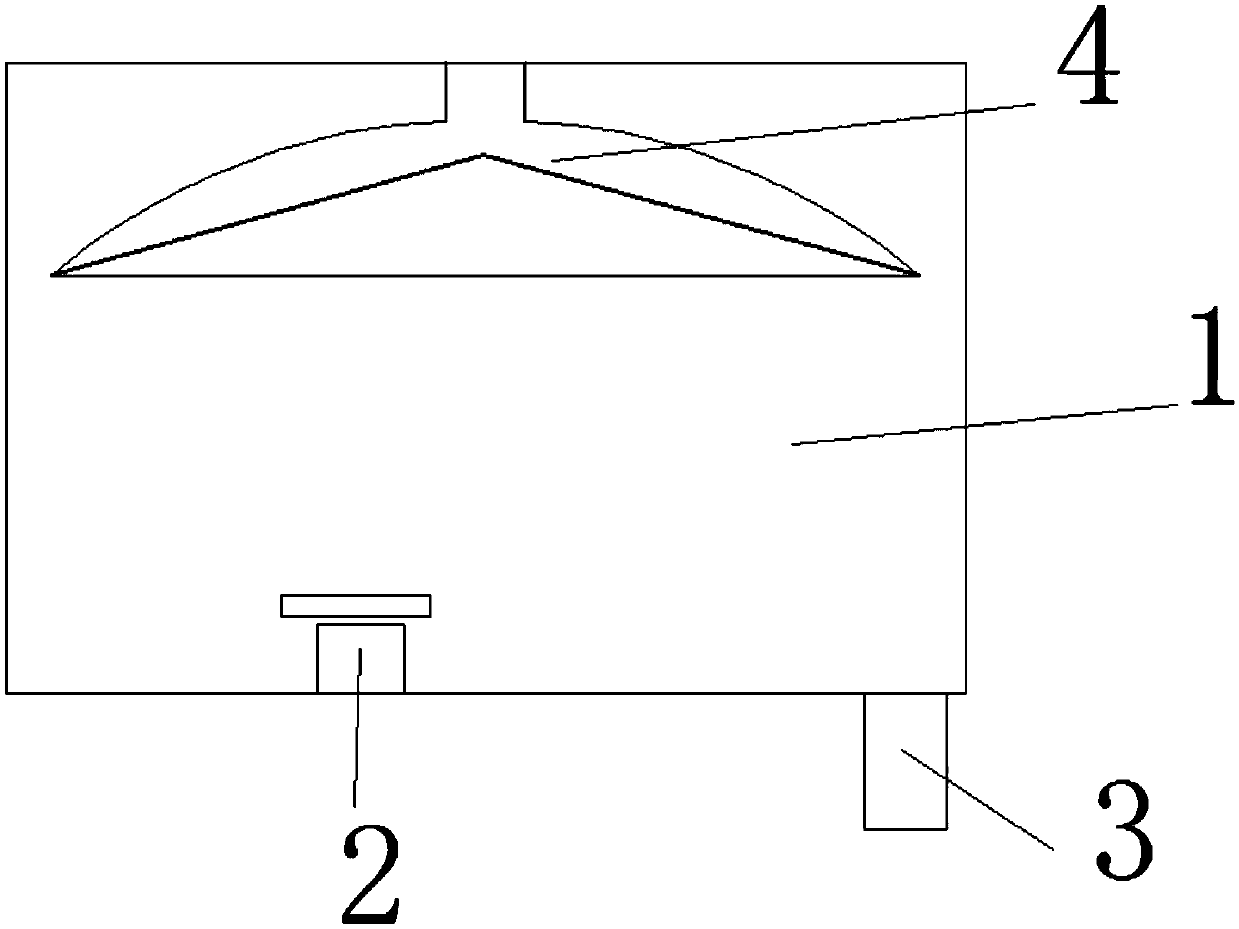

[0034] A reaction chamber for PVD coating, comprising: a reaction chamber body 1, an electron gun crucible platform 2, a vacuum pump 3, and a product station 4 to be coated, wherein the product station 4 to be coated is installed on the side of the reaction chamber body 1 At the top, an electron gun crucible platform 2 is installed at the ...

specific Embodiment example 2

[0037] A processing method for PVD coating, comprising:

[0038] Vacuum extraction: place the coated workpiece on the top of the chamber, and use a vacuum pump to evacuate the chamber to vacuum.

[0039] Heating the target material: Select the target material according to the requirements of the explosion-proof film product, rotate the required target material to the upper end of the electron gun, start the electron gun, and heat the target material to evaporate it.

[0040] Coating: The target material is heated and evaporated to the top of the chamber by the electron gun, and deposited on the product workpiece on the top of the chamber.

[0041]A reaction chamber for PVD coating, comprising: a reaction chamber body 1, an electron gun crucible table 2, a vacuum pump 3, and a product station 4 to be coated, wherein the product station 4 to be coated is installed on the side of the reaction chamber body 1 At the top, an electron gun crucible platform 2 is installed at the bott...

specific Embodiment example 3

[0044] A processing method for PVD coating, comprising:

[0045] Vacuum extraction: place the coated workpiece on the top of the chamber, and use a vacuum pump to evacuate the chamber to vacuum.

[0046] Heating the target material: Select the target material according to the requirements of the explosion-proof film product, rotate the required target material to the upper end of the electron gun, start the electron gun, and heat the target material to evaporate it.

[0047] Coating: The target material is heated and evaporated to the top of the chamber by the electron gun, and deposited on the product workpiece on the top of the chamber.

[0048] A reaction chamber for PVD coating, comprising: a reaction chamber body 1, an electron gun crucible table 2, a vacuum pump 3, and a product station 4 to be coated, wherein the product station 4 to be coated is installed on the side of the reaction chamber body 1 At the top, an electron gun crucible platform 2 is installed at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com