Copper-indium-gallium-selenium co-evaporation linear source apparatus and use method thereof

A copper indium gallium selenide, linear source technology, applied in vacuum evaporation plating, climate sustainability, ion implantation plating, etc., can solve problems such as uneven coating, achieve improved process effects, easy to implement, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

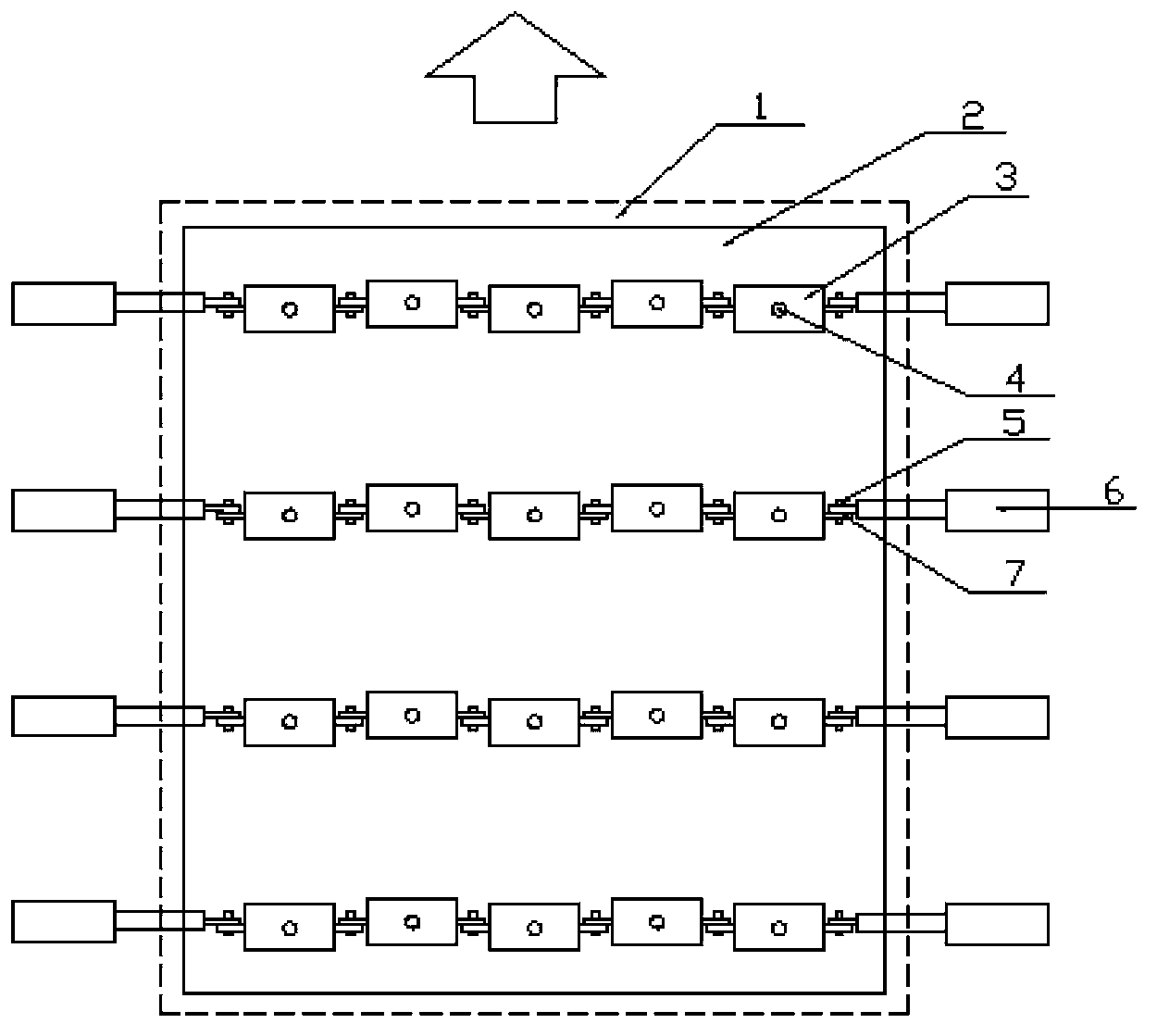

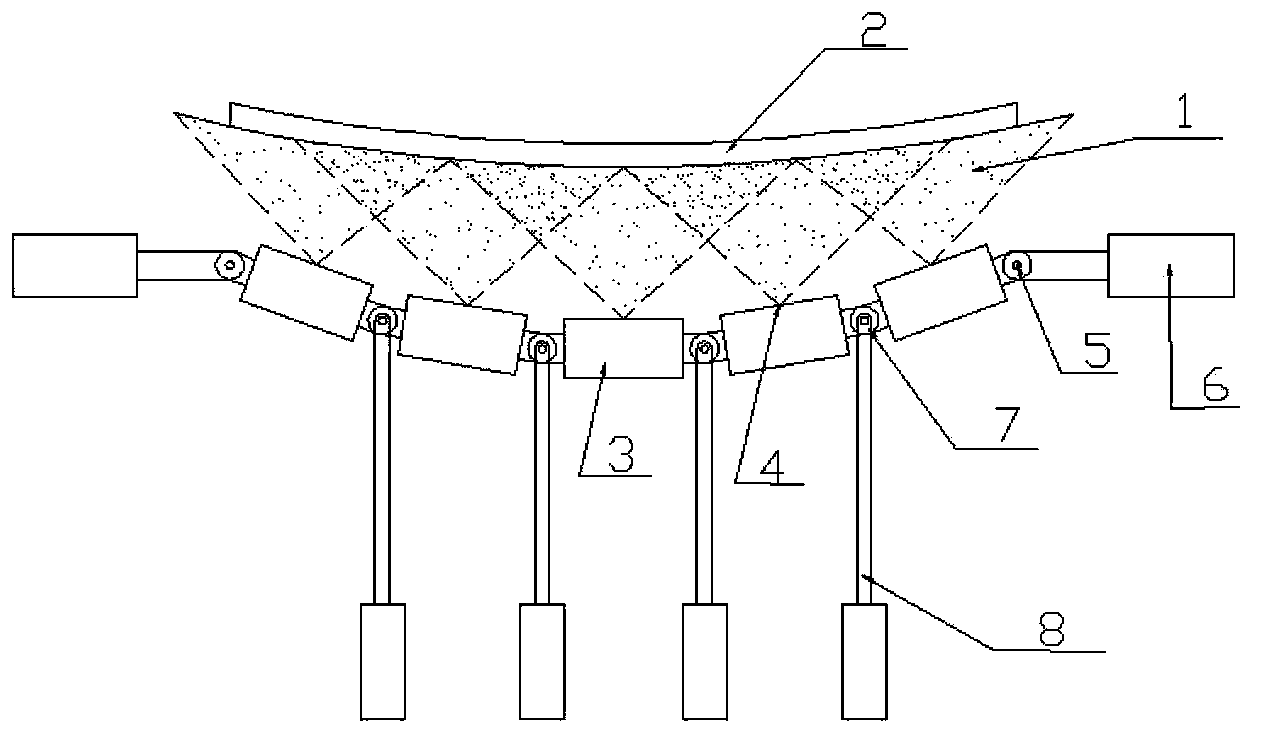

[0023] A copper indium gallium selenide co-evaporation linear source device, such as figure 1 and figure 2 As shown, it includes four groups of parallel segmented linear sources with adjustable curvature, which are evenly distributed in the evaporation zone 1 below the glass substrate.

[0024] The sectioned linear source includes five single-section linear sources 3 , and the single-section linear sources 3 are rotatably connected by joint bolts 5 and rotary joints 7 .

[0025] The two ends of the segmented linear source are provided with lateral tension regulators 6, which are rotatably connected to the two ends of the segmented linear source through joint bolts 5 and rotary joints 7. The revolving joint 7 is a semicircular revolving joint with the joint bolt 5 as a pivot.

[0026] The joint bolt 5 is also provided with a longitudinal tension regulator 8 .

[0027] Horizontal stretch regulator 6 is used to adjust the position of single-section linear source 3 in the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com