Preparation method of silicon carbon lithium ion battery cathode material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of material performance impact, high operating cost, uneven carbon coating, etc., and achieve capacity improvement, cycle performance improvement, Avoid the effect of surface oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a negative electrode material of a silicon-carbon lithium-ion battery, comprising:

[0030] a) mixing the polymer solution with silicon powder and graphite to obtain a mixed solution;

[0031] b) freeze-drying the mixed solution to obtain a solid mixture;

[0032] c) sintering the solid mixture to obtain a silicon-carbon lithium-ion battery negative electrode material.

[0033] According to the present invention, the polymer solution can also be called a polymer carbon source solution, preferably an aqueous solution obtained by dissolving a water-soluble polymer material in water, and the water-soluble polymer material is preferably polyethylene glycol, polyvinyl alcohol , glucose, citric acid, sucrose. Then graphite and silicon powder are mixed according to the weight ratio of (1~9):(1~9) to obtain a composite powder, and the composite powder is mixed with the polymer solution and dispersed evenly, and the method used for...

Embodiment 1

[0039] (1) Preparation of silicon / graphite composite particles

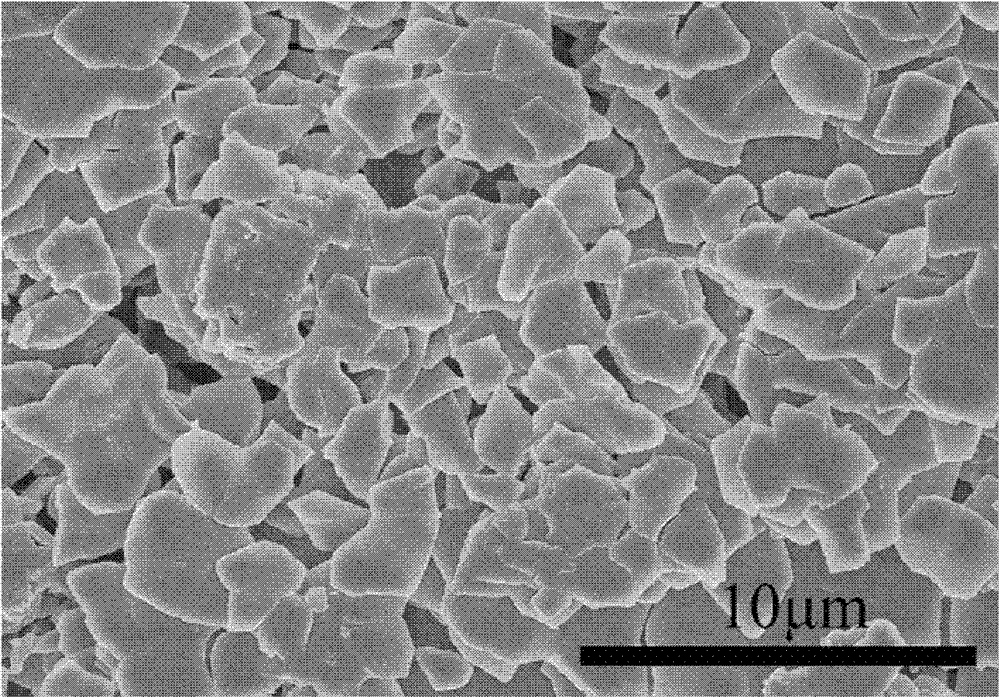

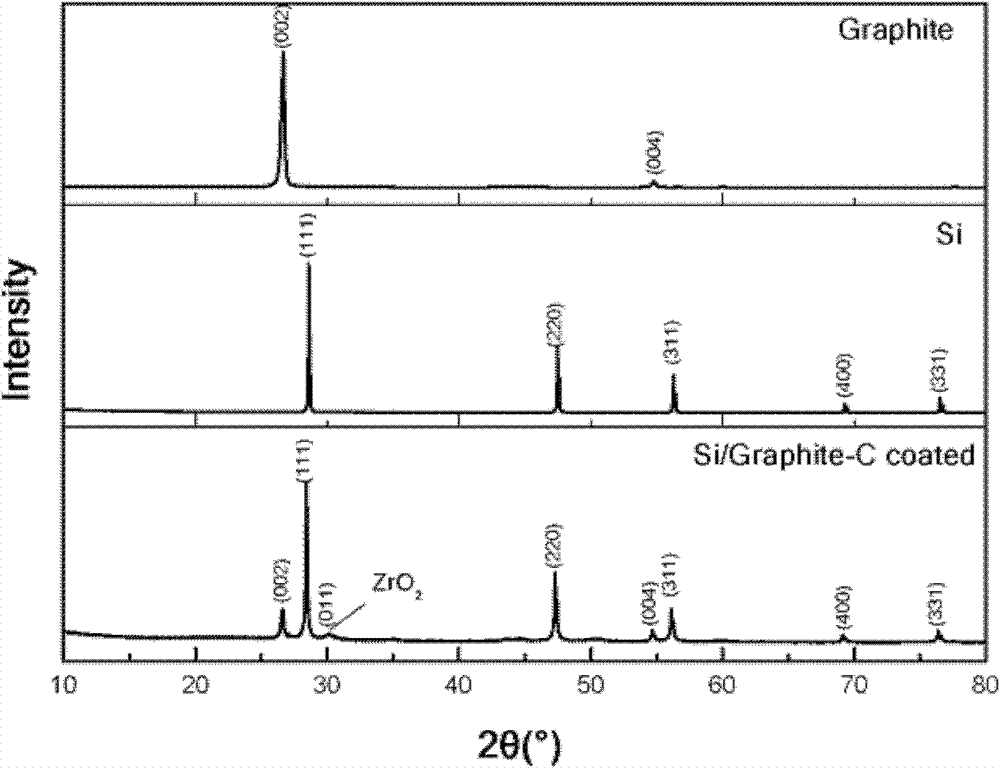

[0040] Dissolve 10g of citric acid in 50mL of deionized water, disperse 0.6g of silicon powder (200 mesh, purity 99.9%) and 0.4g of graphite flakes (2μm) in the above solution, pour them into a 100ml stainless steel ball mill jar together, and use oxidation Zirconium grinding balls were milled for 10 h at 300 rpm in an oscillating nano-impact mill. The particle size of silicon in the obtained composite powder is 200-300nm.

[0041] (2) Freeze drying

[0042]Ultrasonic the mixed solution after milling for half an hour to further disperse the material in the solvent. Immediately freeze with liquid nitrogen after sonication, transfer to a freeze dryer after the solution condenses into ice, and vacuumize. The temperature of the cold trap of the freeze dryer is -30°C, and the vacuum degree is kept at 10Pa. After 20 hours, the material was a dry foamy solid.

[0043] (3) Pyrolysis of organic carbon

[0044] The s...

Embodiment 2

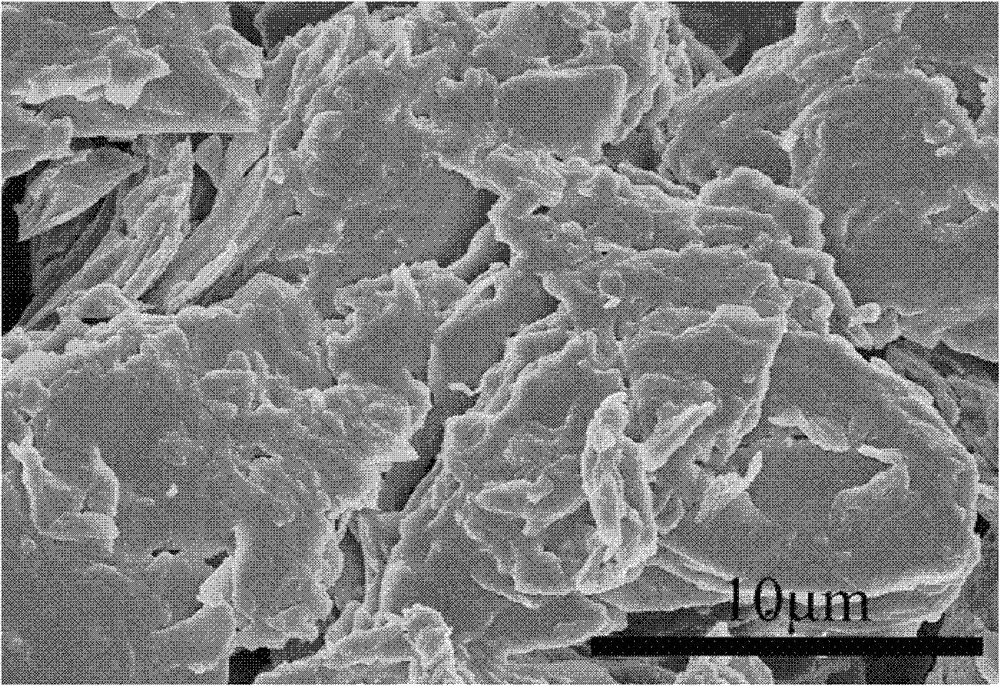

[0047] 0.4g of silicon powder (200 mesh, purity 99.9%) and 0.6g of graphite sheet (20μm) were ball milled in deionized water with 20g of glucose in the manner described in Example 1 for 20h, and the obtained powder slurry was ultrasonicated again for 30min , carry out freeze-drying according to the method described in Example 1, and the foamy solid obtained after drying is heated up to 800°C at a heating rate of 5°C / min under an Ar protective atmosphere in a tube furnace, and cooled naturally after holding for 4 hours to obtain the negative electrode material .

[0048] The negative electrode material prepared in this example, carbon black and polyvinylidene fluoride (PVDF) were made into slurry in N-methylpyrrolidone (NMP) medium at a mass ratio of 75:15:10, and coated on copper foil , and made into electrodes after drying. Using metal lithium foil as the counter electrode, a model CR-2032 button battery was prepared. It was charged and discharged at a current density of 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com