Coating method of nickel cobalt lithium manganate ternary positive electrode material

A technology of lithium nickel cobalt manganese oxide and positive electrode materials, which is applied in the direction of positive electrodes, electrical components, battery electrodes, etc., can solve the problems of uneven coating and poor performance, achieve short process time, reduce usage and cost, The effect of preventing destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

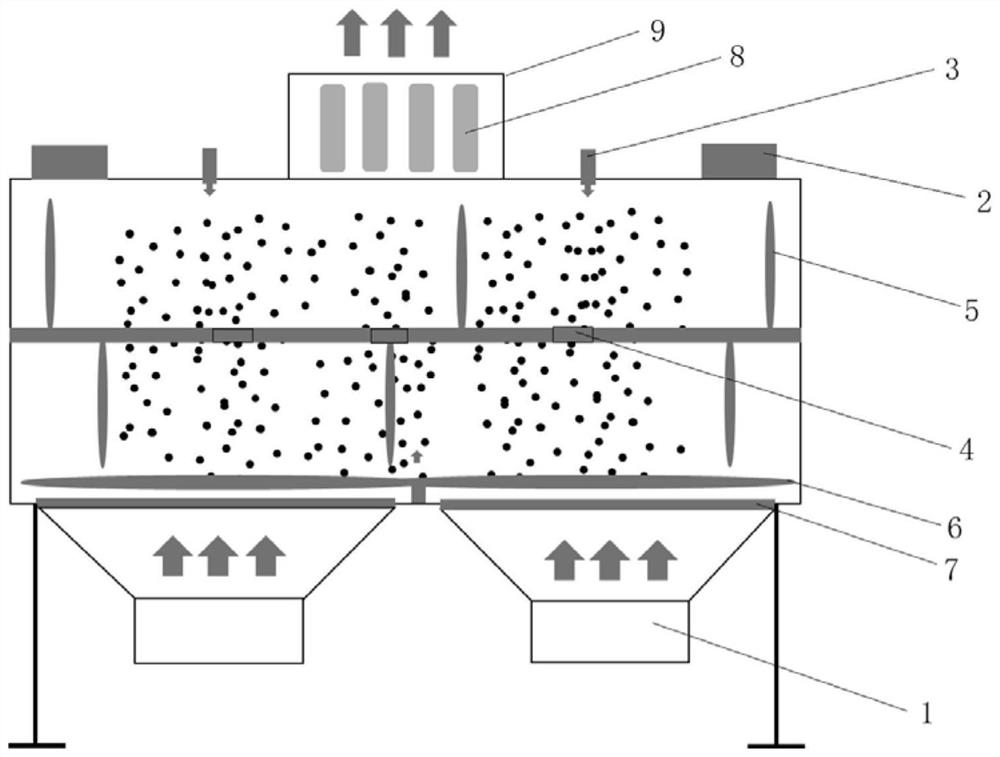

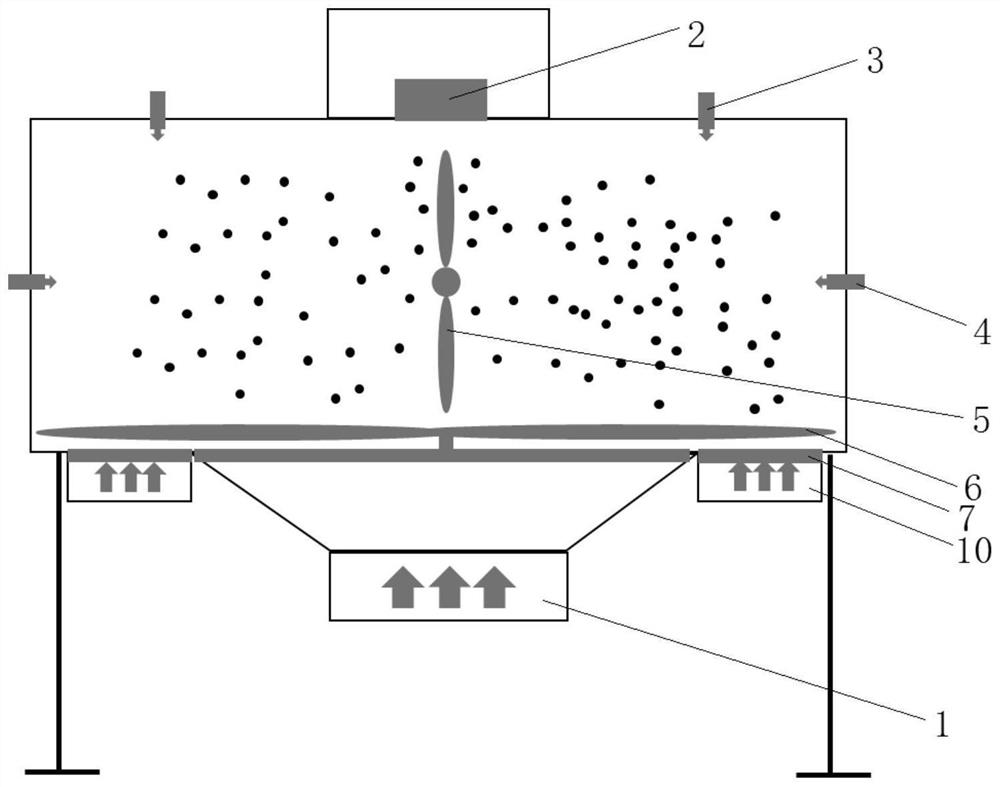

[0048] Fluidization of matrix material:

[0049] LiN with a particle size of 3 μm 0.50 co 0.20 mn 0.30 o 2 The finished material (produced by Peking University Xianxing Company) is added into the fluidized bed cavity through the upper feed fluidization port of the fluidized bed, and the frequency of the main air inlet fan of the blower, the auxiliary air inlet fan of the blower and the induced draft fan are set to 40Hz in turn , 50Hz and 20Hz, set the air inlet temperature of the blower to 200°C, so as to quickly dry the coated material. Both the motor frequency of the horizontal stirring paddle and the vertical stirring paddle are set to 50HZ. Set the fluidization time of the matrix material to 20 minutes, and the matrix material realizes disordered and uniform fluidization in the chamber under the multiple effects of the main air inlet of the blower and the auxiliary air inlet of the blower, its own gravity, horizontal stirring and vertical stirring.

[0050] Configure ...

Embodiment 2

[0056] Fluidization of matrix material:

[0057] LiNi with a particle size of 5 μm 0.60 co 0.20 mn 0.20 o 2 The finished material (produced by Peking University Xianxing Company) is added into the fluidized bed cavity through the upper feed fluidization port of the fluidized bed, and the frequency of the main air inlet fan of the blower, the auxiliary air inlet fan of the blower and the induced draft fan are set to 40Hz in turn , 50Hz and 20Hz, set the air inlet temperature of the blower to 180°C to quickly dry the coated material. Both the motor frequency of the horizontal stirring paddle and the vertical stirring paddle are set to 50HZ. Set the fluidization time of the matrix material to 40 minutes, and the matrix material realizes disordered and uniform fluidization in the cavity under the multiple actions of the main air inlet of the blower and the auxiliary air inlet of the blower, its own gravity, horizontal stirring and vertical stirring.

[0058] Configure coating...

Embodiment 3

[0070] The fluidization process of the matrix material and the process of configuring the coating solution are the same as in Example 2.

[0072] The coating solution was fed into the cavity from the top and middle atomization ports of the fluidized bed by a top-middle common atomization method through a peristaltic pump, and the feeding rate was 25 mL / min. The coating solution is atomized to coat the matrix material, and the coating solution is completely atomized and dried at 80° C. for 20 minutes. Stop the blower, induced draft fan, and vertical paddle motor successively, and set the frequency of the horizontal paddle motor to discharge frequency 15Hz. Open the discharge port, take out the dry coating material and turn off the motor of the horizontal stirring paddle.

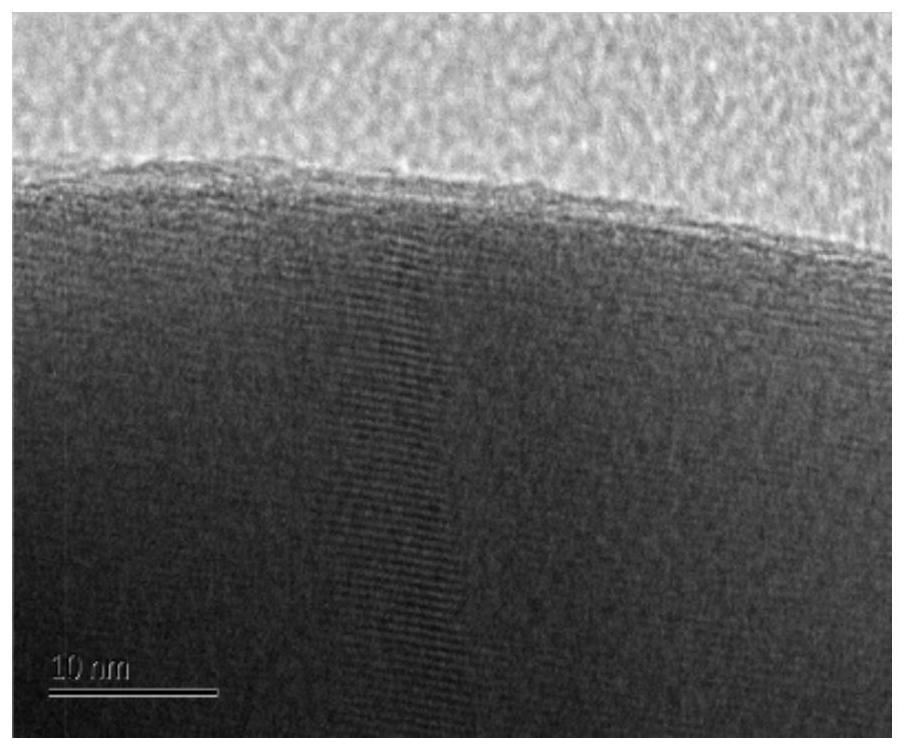

[0073] The coated material was sintered at 750° C. for 7 hours in an air atmosphere, and the sintered material was crushed to obtain a coated nickel-cobalt-lithium-manganese-oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com