Method for uniform carbon coating on lithium iron phosphate surface

A lithium iron phosphate, uniform surface technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problem of high volume specific energy, achieve the effects of low cost, low cost, and avoid segregation of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

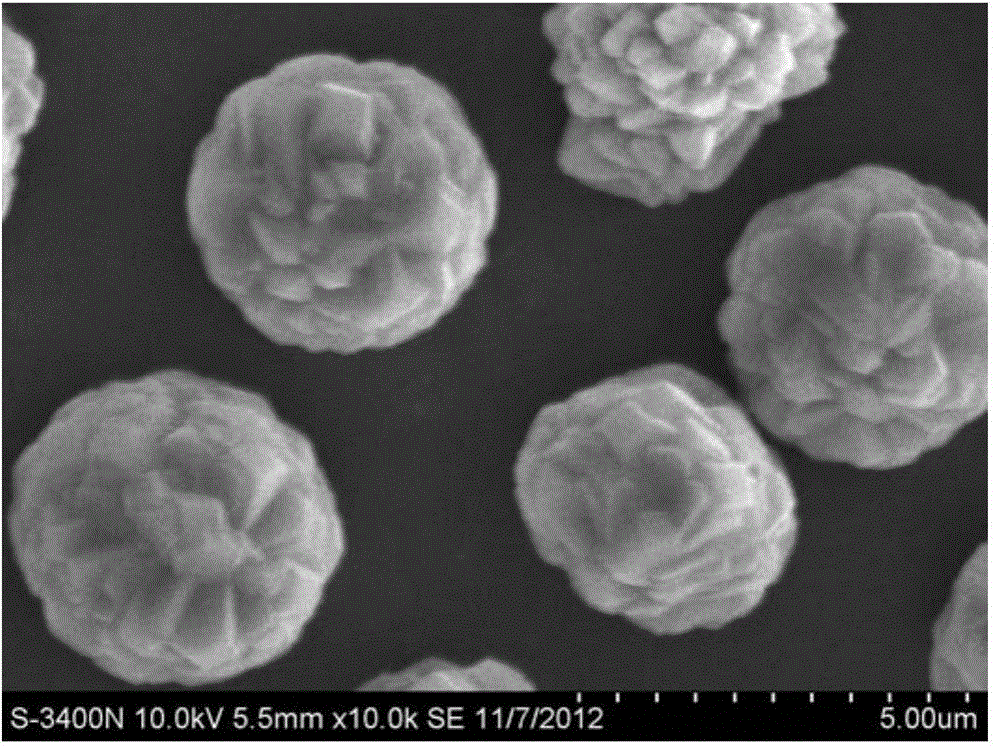

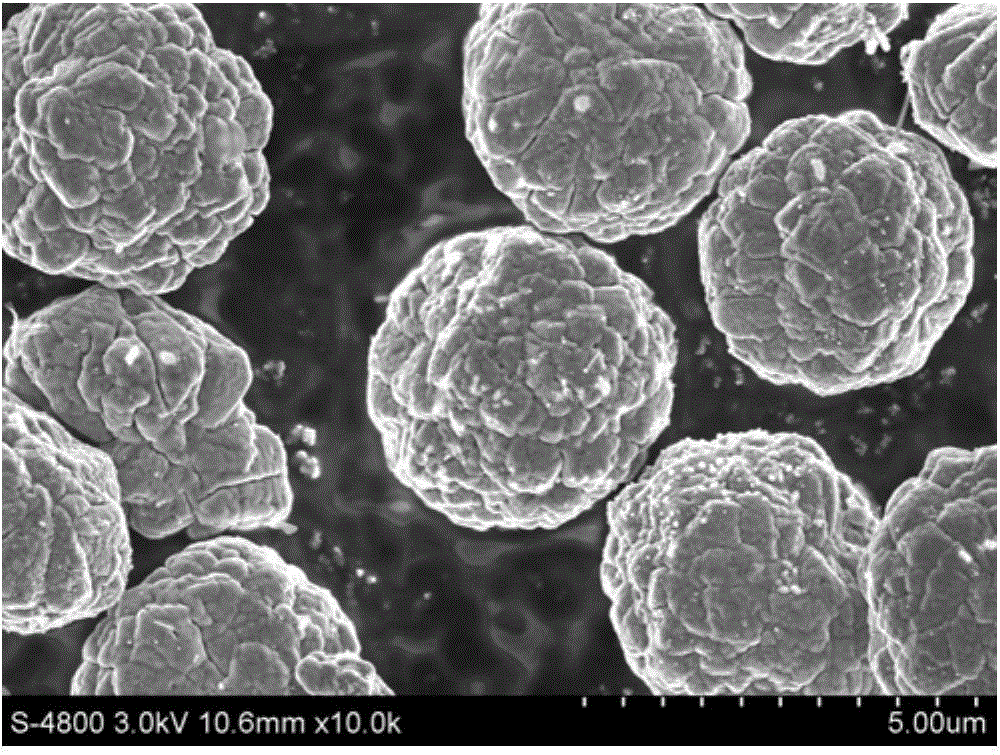

[0032] See attached figure 1 and figure 2 .

[0033] A method for uniform carbon coating on the surface of lithium iron phosphate, comprising the following process steps:

[0034] 1. Preparation of emulsion: Weigh polyvinylpyrrolidone and deionized water at a mass ratio of 1:1 to prepare an aqueous solution, heat to 80°C, add polyacrylamide with 1% polyvinylpyrrolidone mass to it, and stir rapidly for 30 minutes to form a uniform composition lotion.

[0035] 2. Coating of organic carbon source on the surface of ferric acid particles: adding spherical iron phosphate twice the mass of the emulsion into the emulsion, stirring and mixing for 4 hours to obtain a rheological body with uniform composition, and drying it in a flash dryer to obtain Iron phosphate powder coated with polyvinylpyrrolidone.

[0036] 3. The preparation of lithium iron acid lithium / carbon composite cathode material: according to molar ratio Fe:Li=1:1.2 carry out solid-phase mixing with dry ferric phosph...

Embodiment 2

[0038] A method for uniform carbon coating on the surface of lithium iron phosphate, comprising the following process steps:

[0039] 1. Preparation of emulsion: weigh polyvinyl alcohol and deionized water in a mass ratio of 1:1 to prepare an aqueous solution, heat to 100°C, add triglycerol monostearate with 1% polyvinyl alcohol mass, Stir rapidly for 60 min to form a uniform emulsion.

[0040] 2. Coating of organic carbon source on the surface of ferric acid particles: add spherical iron phosphate twice the mass of the emulsion into the emulsion, stir and mix for 6 hours to obtain a rheological body with uniform composition, and dry it in a flash dryer to obtain Iron phosphate powder coated with organic carbon source.

[0041]3. Preparation of lithium iron oxide / carbon composite positive electrode material: according to the molar ratio Fe:Li=1:1.1, dry iron phosphate powder and lithium carbonate are mixed in solid phase, put into argon protective atmosphere sintering furnace...

Embodiment 3

[0043] A method for uniform carbon coating on the surface of lithium iron phosphate, comprising the following process steps:

[0044] 1. Preparation of emulsion: Weigh glycerin and deionized water at a mass ratio of 1.5:1 to prepare an aqueous solution, heat to 50°C, add TH-908 with 1% glycerin mass, and stir rapidly for 20 minutes to form an emulsion with uniform composition.

[0045] 2. Coating of organic carbon source on the surface of ferric acid particles: adding spherical ferric phosphate twice the mass of the emulsion into the emulsion, stirring and mixing for 2 hours to obtain a rheological body with uniform composition, and drying it in a flash dryer to obtain Iron phosphate powder coated with organic carbon source.

[0046] 3. Preparation of lithium iron phosphate / carbon composite positive electrode material: carry out solid-phase mixing of dried ferric phosphate powder and lithium hydroxide according to molar ratio Fe:Li=1:1, put into argon protective atmosphere sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com