Cement troweling device for building foundation

A technology of cement and foundation, which is applied in the field of construction, can solve problems such as gaps in automation and coordination, and achieve the effect of improving the effect, avoiding uneven falling, and wide-ranging operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

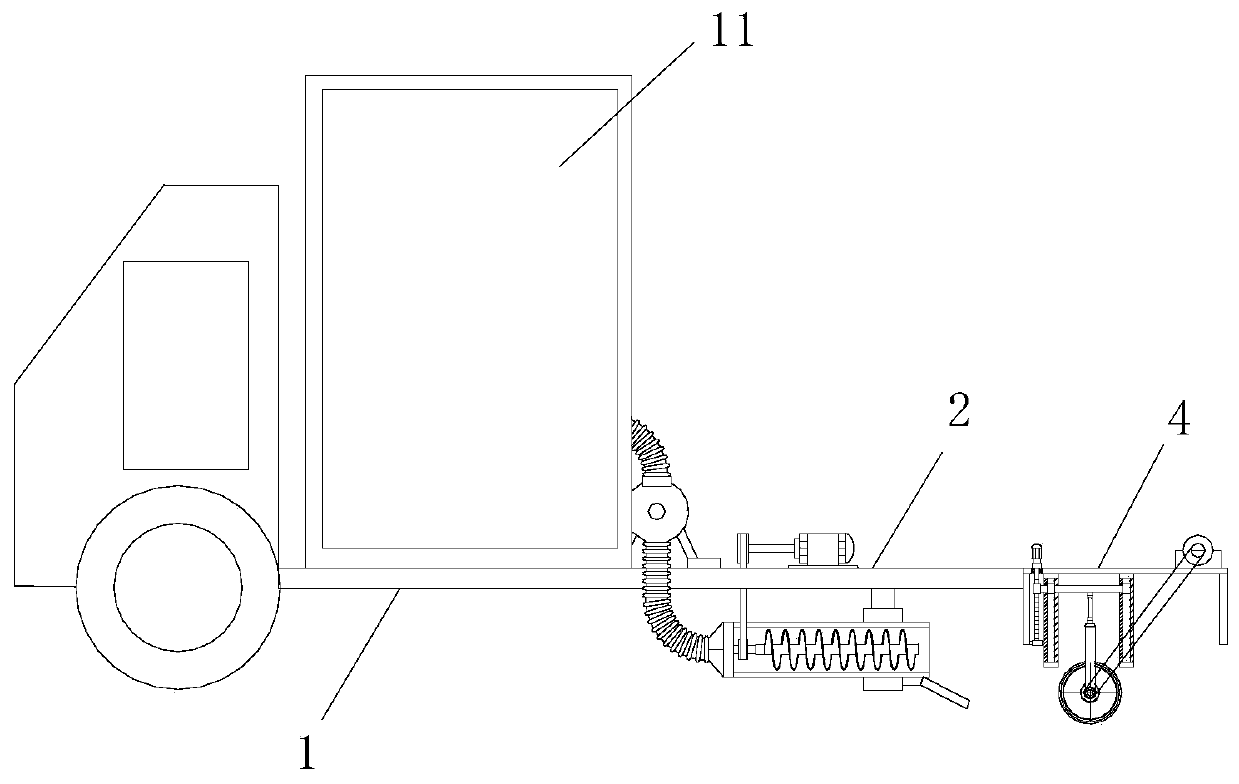

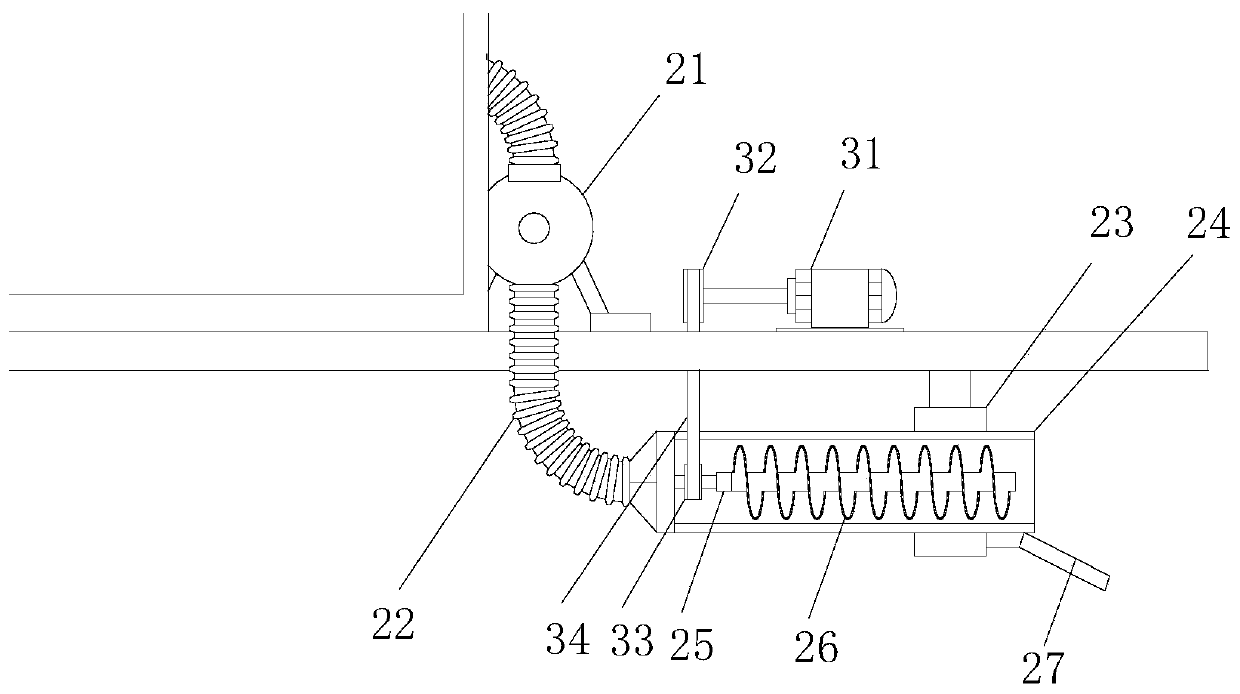

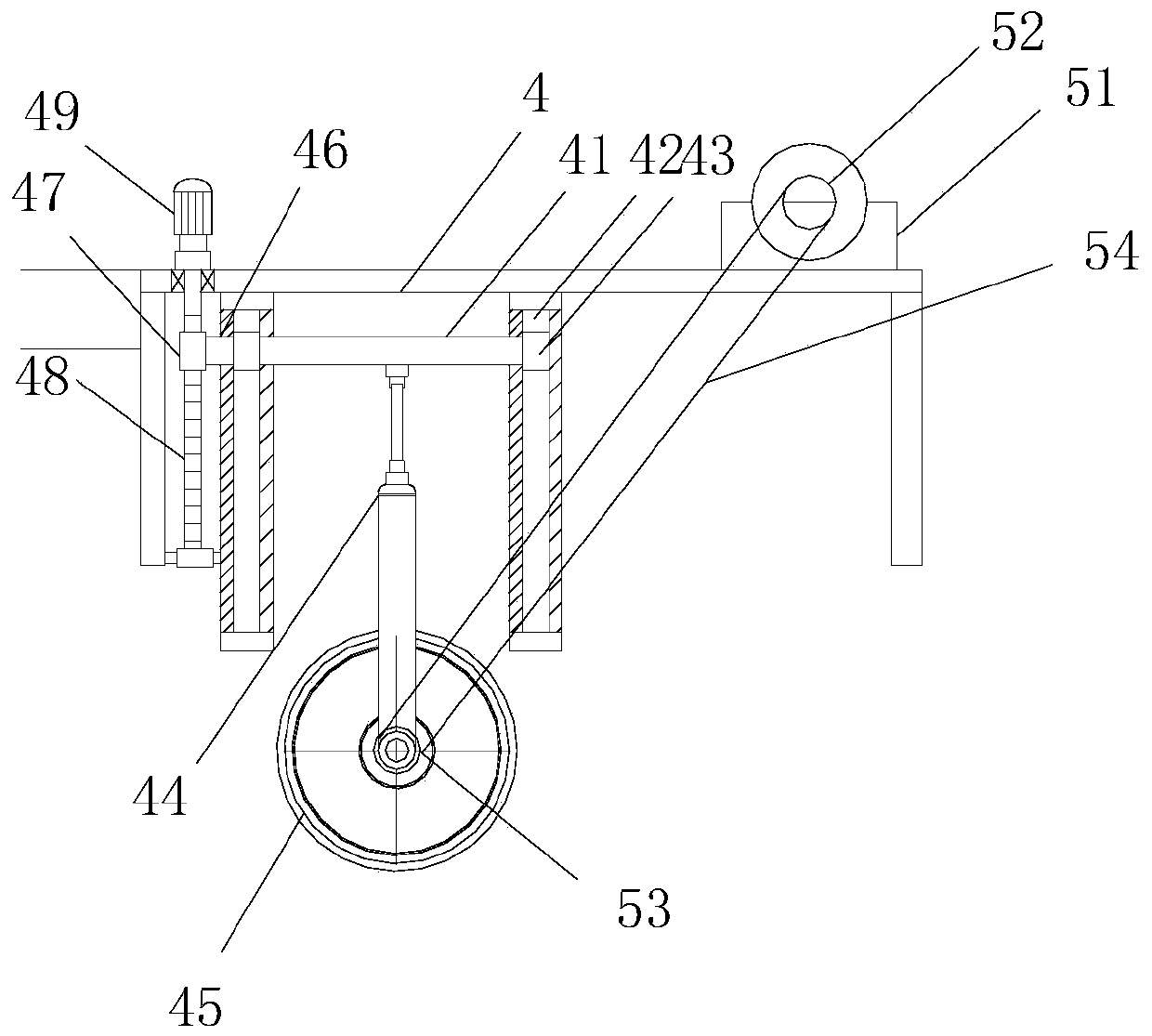

[0028] see figure 1 and figure 2 , a building foundation cement troweling device, comprising a vehicle frame 1, a cement mixing bucket 11 is installed on the vehicle frame 1, and a cement feeding mechanism 2 and a cement troweling mechanism 4 are respectively installed on the vehicle frame 1. The cement feeding mechanism 2 includes a mud pump 21 and a feed frame 23, the feed end of the mud pump 21 is installed at the discharge port of the mixing tank 11, and the feed end of the mud pump 21 is equipped with a feed Conduit 22, described feeding frame 23 is equipped with feeding channel 24, and described feeding conduit 22 is connected with feeding channel 24, and described feeding channel 24 is built-in and installed with feeding roller shaft 25, and described feeding roller shaft 25 is installed with Screw feeding auger 26, a feeding motor 31 is installed on the vehicle frame 1, a drive wheel 32 is installed on the driving end of the feeding motor 31, a driven wheel 33 is ins...

Embodiment 2

[0034] see Figure 5 and Figure 6, this embodiment is a further optimization of Embodiment 1. On the basis of it, a cement pressing mechanism 6 is also provided between the cement feeding mechanism 2 and the cement smoothing mechanism 4, and the cement pressing mechanism 6 is built with a Fixed guide rail 61, described fixed guide rail 61 is built-in and is equipped with movable rod 62, and the bottom end of described movable rod 62 is installed with pressing plate 63, and the top rod end of described movable rod 62 is externally connected with transmission connecting rod 64, and described transmission connecting rod 64, one end is connected with the movable rod 62, and the other end of the transmission link 64 is fixed on the side frame of the cement pressing mechanism 6, and the swinging motor 65 is also installed on the cement pressing mechanism 6, and the swinging motor 65 A swing rod 66 is installed at the driving end of 65, and an arc-shaped groove 67 is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com