HDPE (high-density polyethylene) film welding method in refuse landfill

A landfill and welding method technology, applied in the field of HDPE film welding, can solve welding quality problems and other problems, and achieve the effect of not easy to crack and good laying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

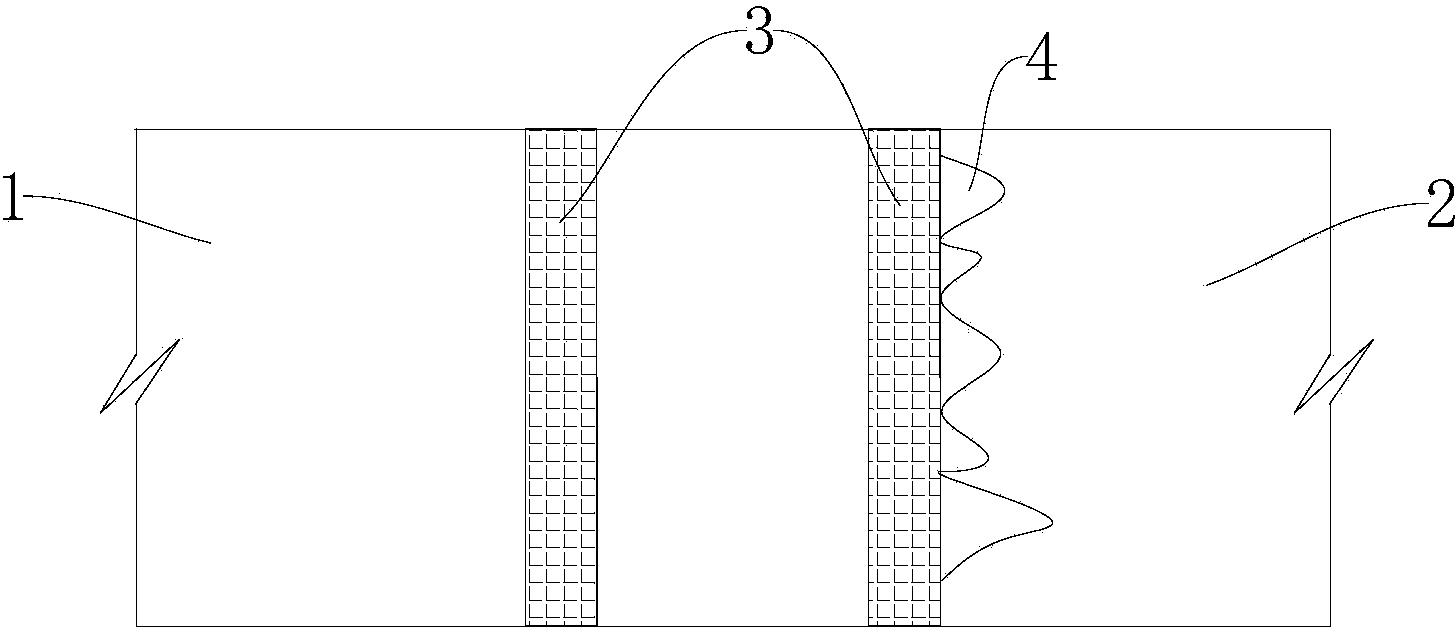

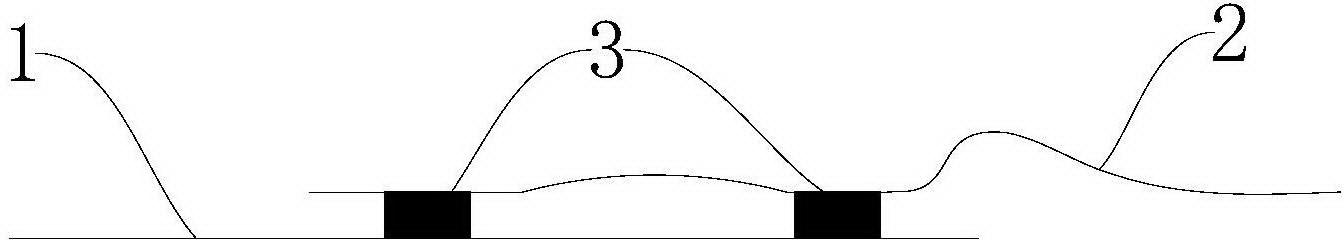

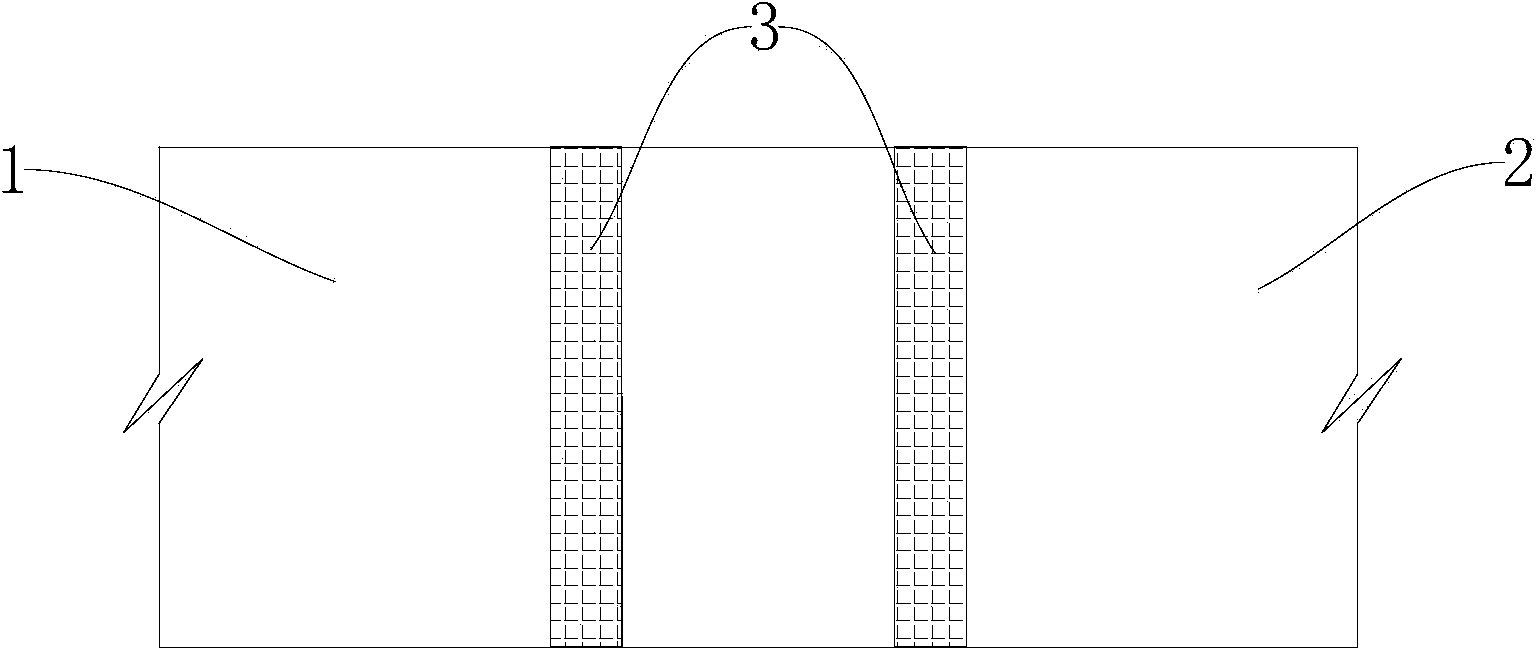

Embodiment 1

[0052] In winter, lay a 1.5mm thick glossy HDPE film, and laminate 50mm between the films; let it air for 1 hour; take two small pieces of 1.5mm thick smooth HDPE film with a size of 30cm×30cm, laminate 50mm, and use Swiss LEISTER The double-track hot-melt welding machine manufactured by the company uses the existing hot wedge double-track welding method. The welding speed is 2.2m / min, the welding temperature is 430°C, and the ejector pin pressure is 800N. The film is pulled to both sides, and there is no phenomenon of disengagement or tearing. The welding speed of 2.2m / min, the welding temperature of 430°C, and the pressure of the ejector pin of 800N are used to weld the 1.5mm thick smooth HDPE film laid as a whole. Finally, the existing technology is used to pressurize and ventilate the empty groove in the two welds to detect the continuity of the welding, and there is no air leakage. load.

Embodiment 2

[0054] In summer, lay a 1.5mm thick glossy HDPE film, and laminate 50mm between the films; let it air for 1 hour; take two small pieces of 1.5mm thick smooth HDPE film with a size of 30cm×30cm, laminate 50mm, and use Swiss LEISTER The double-track hot-melt welding machine manufactured by the company uses the existing hot wedge double-track welding method. The welding speed is 2.8m / min, the welding temperature is 410°C, and the ejector pin pressure is 750N. The film is pulled to both sides, and there is no phenomenon of disengagement or tearing. The welding speed of 2.8m / min, the welding temperature of 410°C, and the pressure of the ejector pin of 750N are used to weld the 1.5mm thick smooth HDPE film laid as a whole. Finally, the existing technology is used to pressurize and ventilate the empty groove in the two welds to detect the continuity of the welding, and there is no air leakage. load.

Embodiment 3

[0056] In summer, lay a 1.5mm thick glossy HDPE film, and laminate 50mm between the films; let it air for 1 hour; take two small pieces of 1.5mm thick smooth HDPE film with a size of 30cm×30cm, laminate 50mm, and use Swiss LEISTER The double-track hot-melt welding machine manufactured by the company uses the existing hot wedge double-track welding method;

[0057] First, the welding speed is 2.8m / min, the welding temperature is 410°C, and the pressure of the ejector pin is 750N. Conduct a test welding, and pull the small piece of HDPE film welded to both sides, and there is a slight disengagement and tearing phenomenon;

[0058] Continue to take two small pieces of glossy HDPE film with a size of 30cm×30cm, laminate them with a thickness of 50mm, adjust the welding speed to 2.4m / min, the welding temperature to 425°C, and the ejector pin pressure to 760N for trial welding. The small piece of HDPE film is pulled to both sides, and there is no detachment or tearing phenomenon;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com