Highway bridge roadbed and pavement construction device and construction method thereof

A technology for highway bridges and construction devices, applied to bridges, bridge parts, bridge construction, etc., to achieve the effects of improving speed and efficiency, saving manpower, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

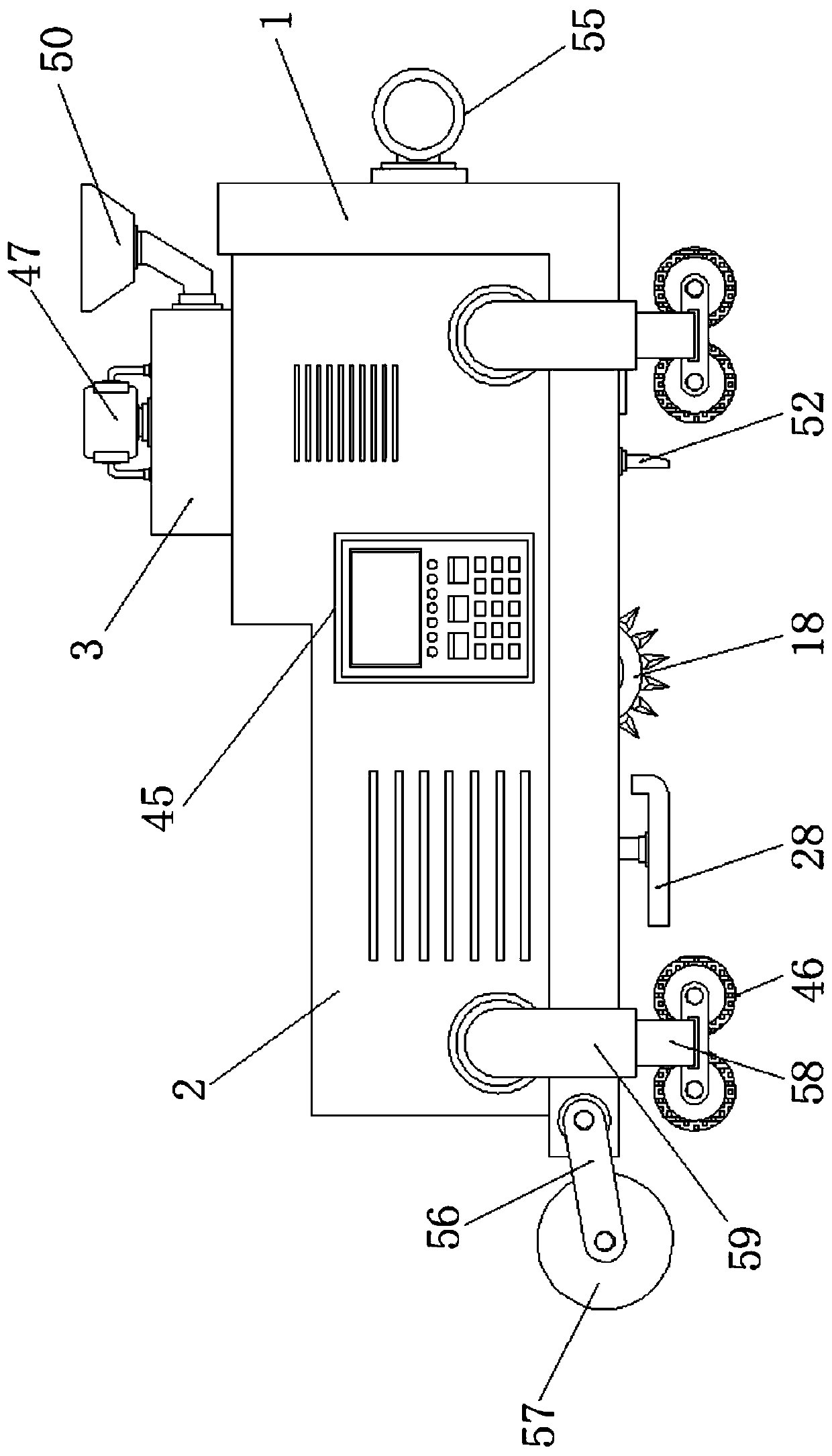

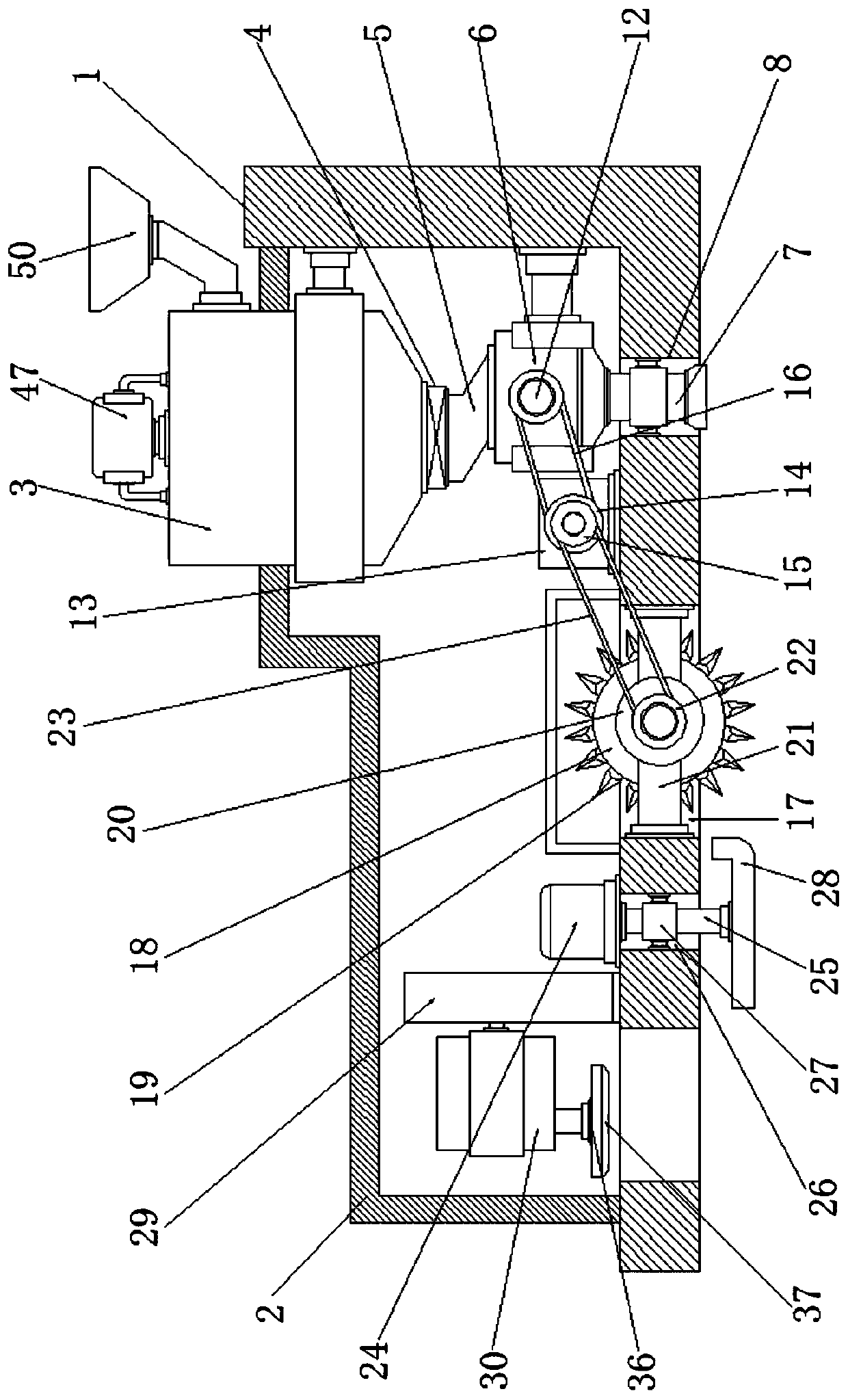

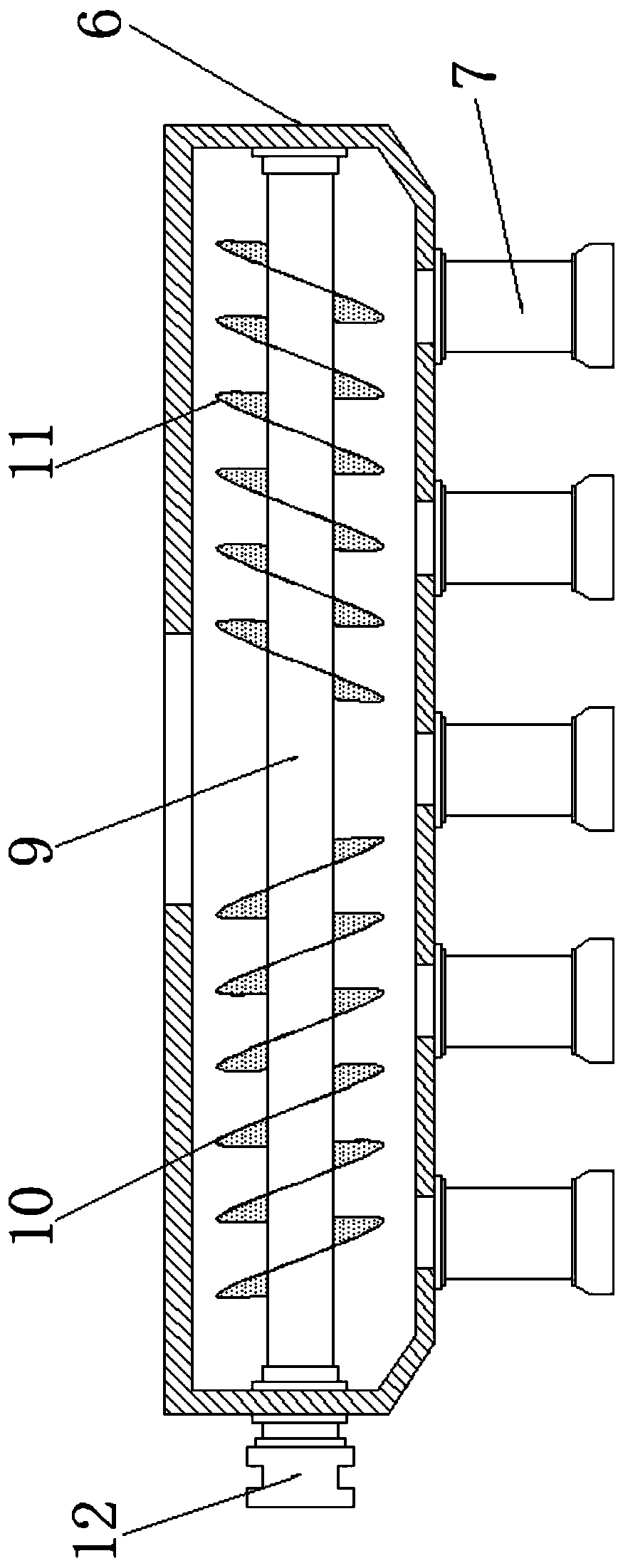

[0043] Embodiment one, such as Figure 1-10 As shown, a road bridge embankment pavement construction device according to an embodiment of the present invention includes a support base 1, a housing 2 is installed on the top of the support base 1, and a barrel 3 is installed on the top side of the housing 2, and the The bottom end of the barrel 3 runs through the shell 2 and extends to the inside of the shell 2, the bottom of the barrel 3 is equipped with an electromagnetic valve 4, and the bottom of the electromagnetic valve 4 is equipped with a connecting pipe 5, so The bottom of the connecting pipe 5 is equipped with a distributing bin 6, and the bottom of the distributing bin 6 is evenly equipped with a number of distributing pipes 7, and the position corresponding to the distributing pipe 7 on the support base 1 is provided with strips. Shaped groove one 8, and the bottom end of described distributing pipe 7 all runs through described strip groove one 8 and extends to the b...

Embodiment 2

[0044] Embodiment two, such as figure 1 , 2 , 8, the top of the barrel 3 is fixedly installed with a motor four 47, the bottom of the motor four 47 is equipped with a rotating shaft 48, and the bottom end of the rotating shaft 48 runs through and extends to the barrel 3 Inside, the outer side of the bottom end of the rotating shaft 48 is staggered with stirring rods 49, and the top of one side of the barrel 3 is equipped with a feed funnel 50; through the motor four 47 and the rotating shaft 48 And the interaction of the stirring rod 49 can stir the concrete to prevent it from solidifying, so that the laying operation can be better carried out, and the feeding funnel 50 is convenient to carry out the feeding operation better, and then It is convenient to better meet the needs of people.

Embodiment 3

[0045] Embodiment three, such as figure 1 , 9 As shown, a strip plate 51 is installed on the bottom of the support seat 1 and is located on the side of the strip groove one 8 close to the strip groove two 17, and the bottom of the strip plate 51 is evenly equipped with teeth Slice 52; through the strip plate 51 and the tooth sheet 52, the concrete can be better distributed, so that the concrete laying operation can be better performed, and the use needs of people can be better met.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com