PMMA polymer coating diaphragm and preparation method thereof

A technology of polymer coating and diaphragm, which is applied in the field of PMMA polymer coating diaphragm and its preparation, can solve the problems of poor solubility of PMMA powder, uneven coating, uneven coating of PMMA polymer, etc., and achieve the improvement of anti-oxidation Sexuality and long-term cycle performance, improve the dispersion effect, solve the effect of uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A kind of preparation method of the above-mentioned PMMA polymer coating separator of the present invention, comprises the following steps:

[0041] Step 1, prepare PMMA coating slurry

[0042] Weigh 15-25 parts of PMMA powder in a container, add 1-5 parts of dispersing aid to it for pre-mixing; add 40-60 parts of deionized water to the pre-mixed powder, at a speed of Stir at 700-1000r / min and disperse for 10-20min. The dispersion process reduces the distance between polar and non-polar substances, increases the potential energy and surface energy, and may cause a decrease in temperature, which is a normal phenomenon; and then Add 3-7 parts of the first binder and 0.02-0.1 parts of the second binder, and disperse for 15-30 minutes under stirring at a speed of 700-1000r / min; then add 3-8 parts of thickener Disperse again for 10-20min under stirring at a rotating speed of 700-1000r / min, and finally add 0.1-0.4 parts of surfactant, and disperse for 10-20min under stirring...

Embodiment 1

[0047] A kind of preparation method of PMMA polymer coating separator of the present embodiment, comprises the following steps:

[0048] Weigh 20 parts of PMMA powder in a container, add 2 parts of dispersing aid to it for pre-mixing; add 40 parts of deionized water to the pre-mixed powder, and stir at a speed of 900r / min Disperse for 10 minutes; then add 3 parts of the first binder and 0.06 parts of the second binder, and disperse for 20 minutes under stirring at a speed of 900r / min; then add 5 parts of thickener again at a speed of 900r / min Disperse for 10min under stirring at a speed of 900r / min, and finally add 0.15 parts of surfactant, and disperse for 10min under stirring at a rotational speed of 900r / min to obtain a uniformly mixed water-based coating slurry.

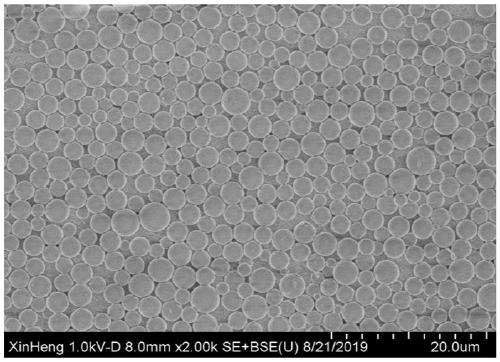

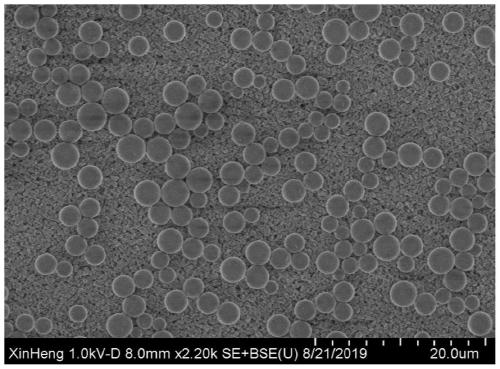

[0049] The PMMA coating slurry is coated on one side of the base film by gravure coating. The base film for coating is a 12-micron separator, and the thickness of the coating is controlled to be 2 μm by gravure c...

Embodiment 2

[0051] A kind of preparation method of PMMA polymer coating separator of the present embodiment, comprises the following steps:

[0052] Weigh 15 parts of PMMA powder in a container, add 2 parts of dispersing aid to it for pre-mixing; add 45 parts of deionized water to the pre-mixed powder, and stir at a speed of 900r / min Disperse for 10 minutes; then add 3 parts of the first binder and 0.06 parts of the second binder, and disperse for 20 minutes under stirring at a speed of 900r / min; then add 5 parts of thickener again at a speed of 900r / min Disperse for 10min under stirring at 900r / min, and finally add 0.2 parts of surfactant, and disperse for 10min under stirring at a rotating speed of 900r / min to obtain a uniformly mixed water-based coating slurry.

[0053] The gravure coating method is used to coat the PMMA coating slurry on one side of the base film. The gravure coating controls the coating thickness to 2 μm to ensure that the coated particles form a uniform coating on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com