Patents

Literature

171results about How to "Reduce indentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

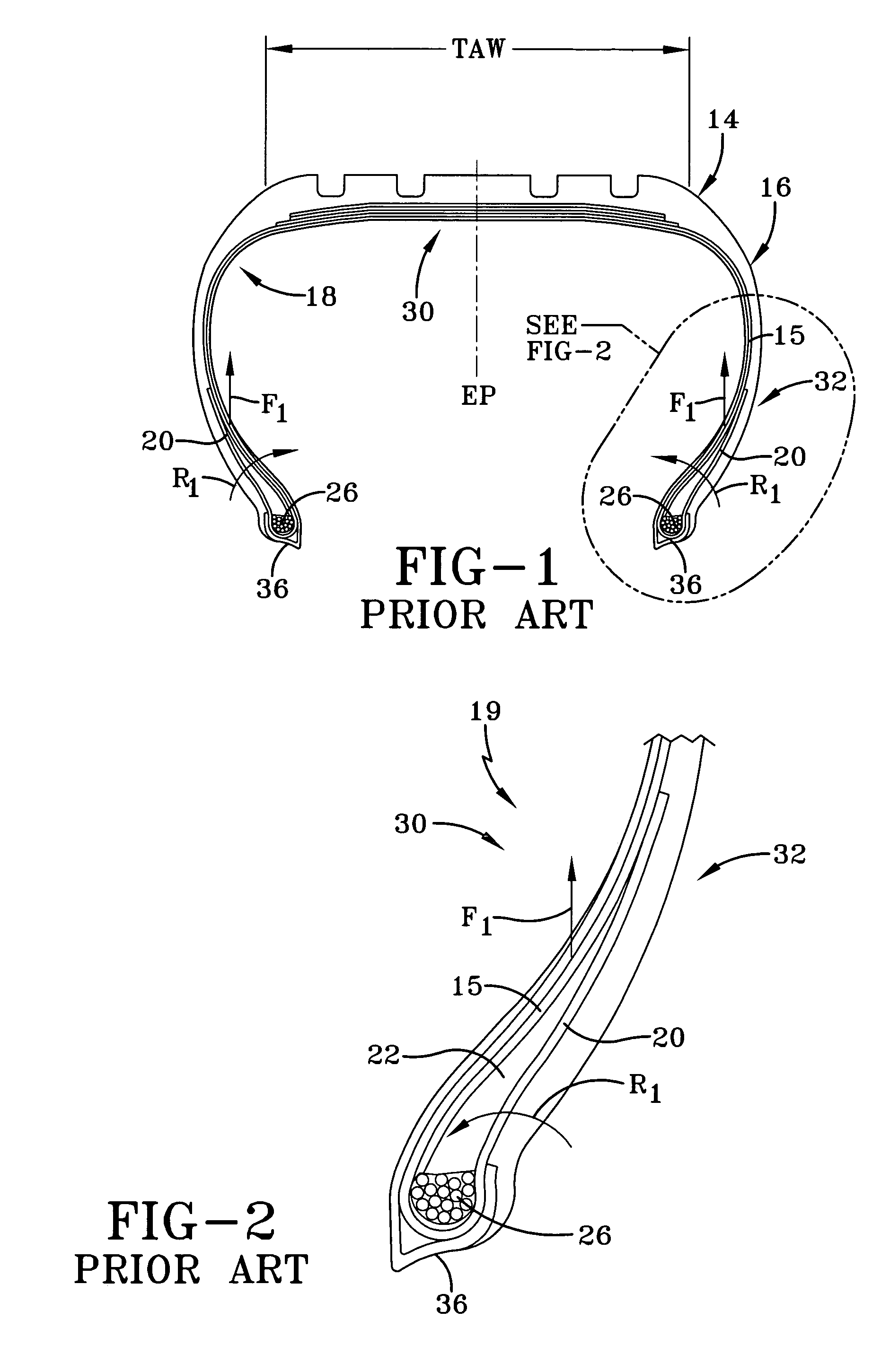

Tire with outside-in ply construction

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire with composite ply structure and method of manufacture

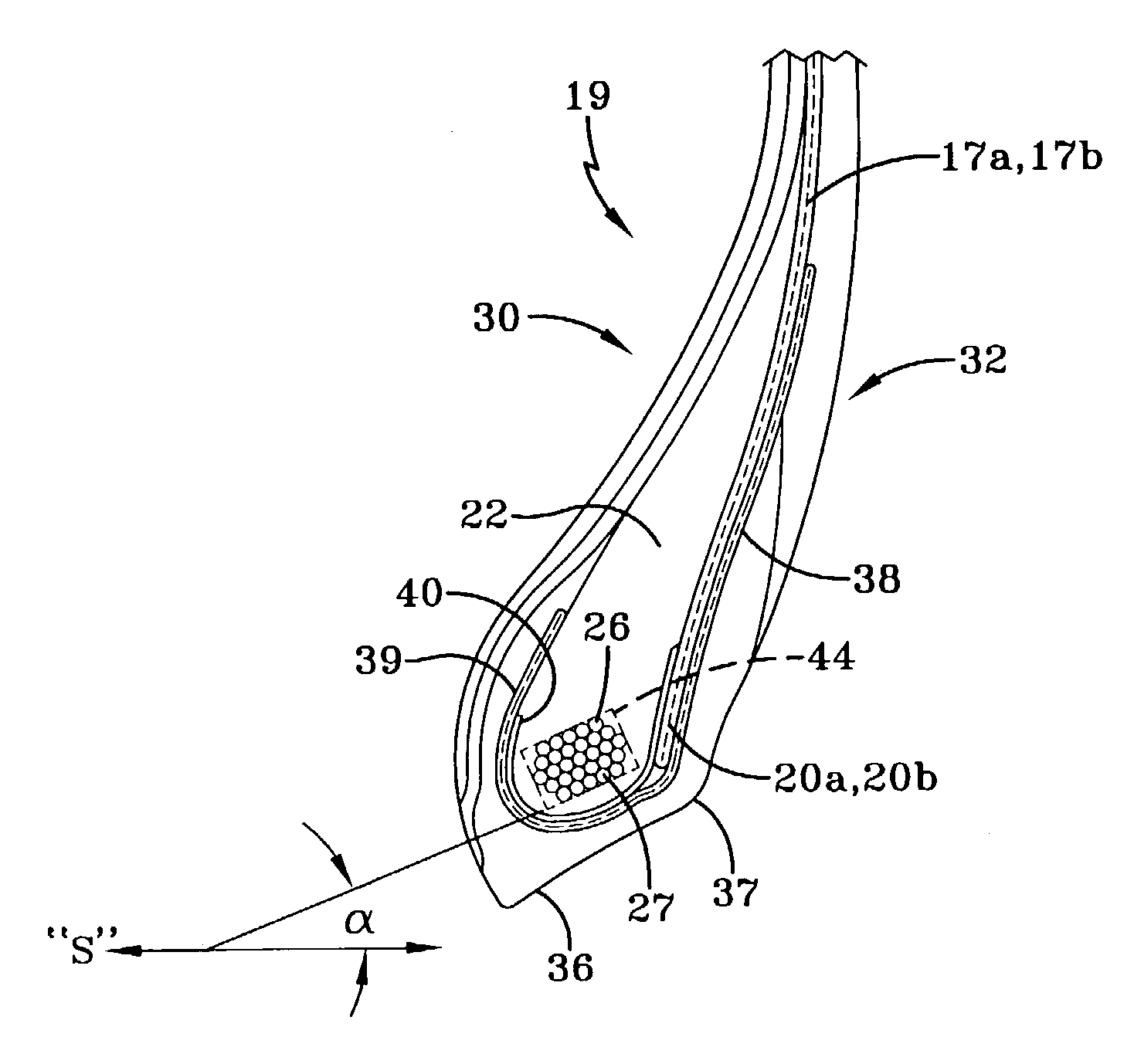

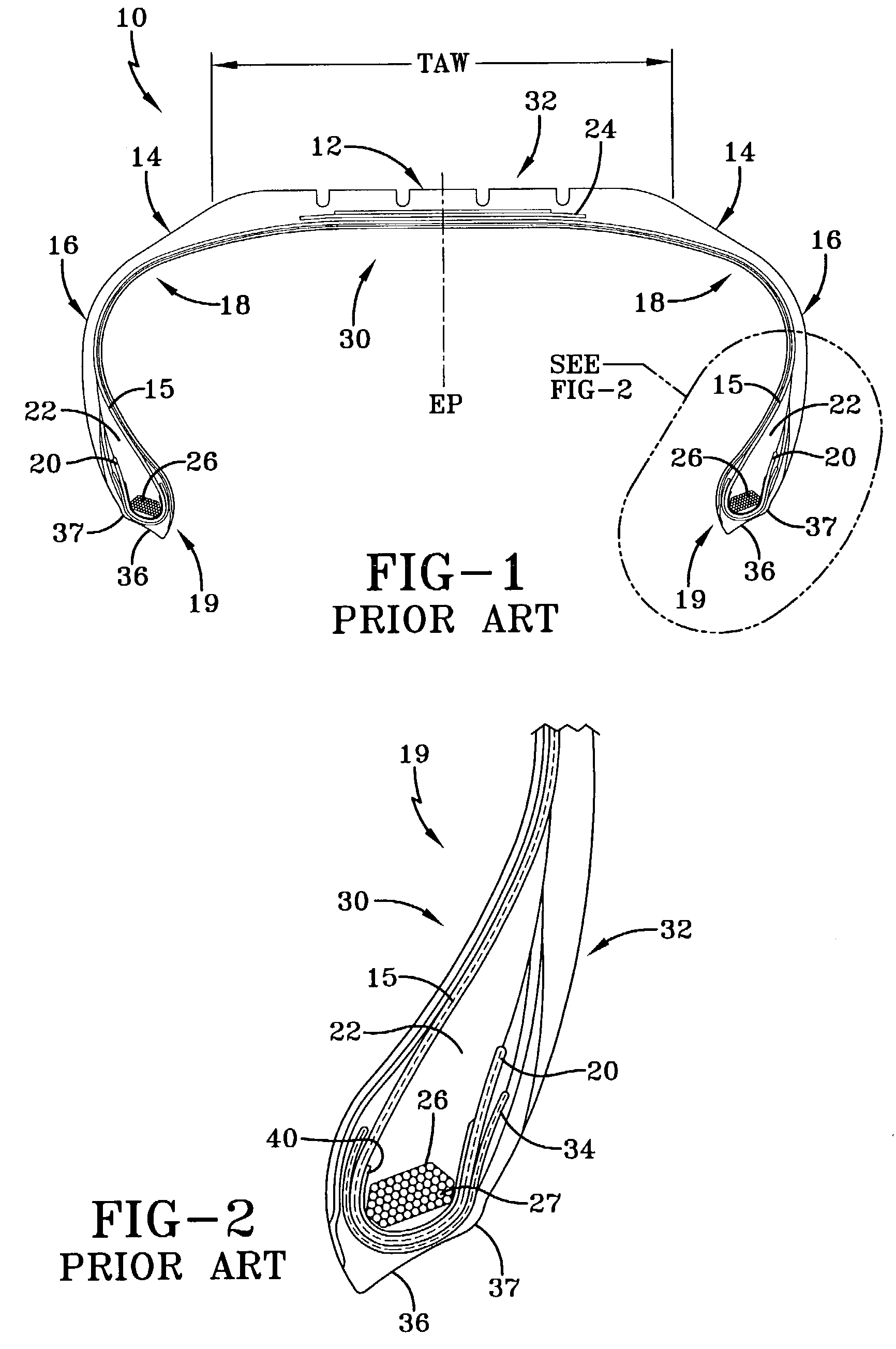

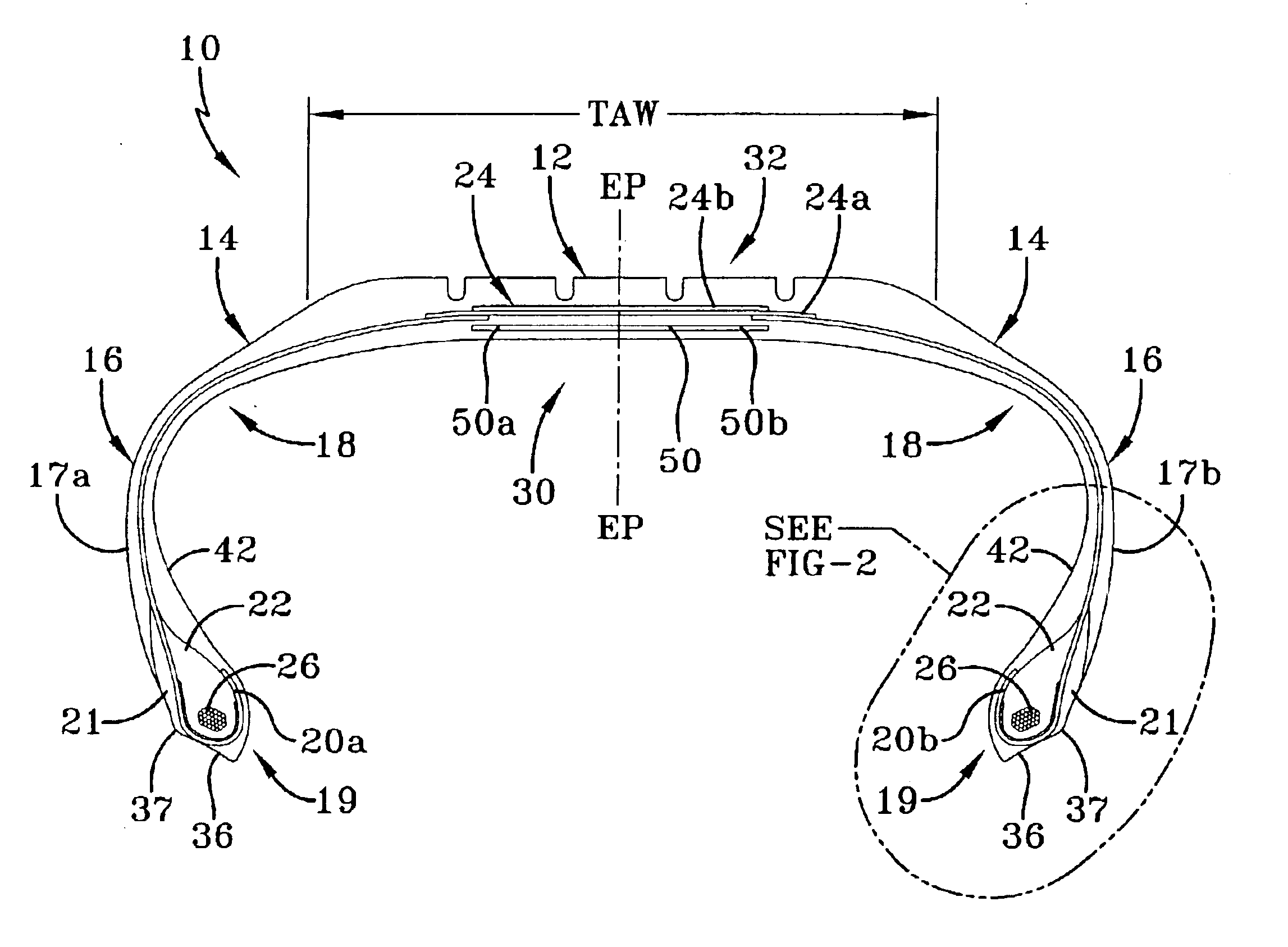

InactiveUS6913052B2Smooth connectionReduce rim indentationTyresPneumatic tyre reinforcementsEngineeringMechanical engineering

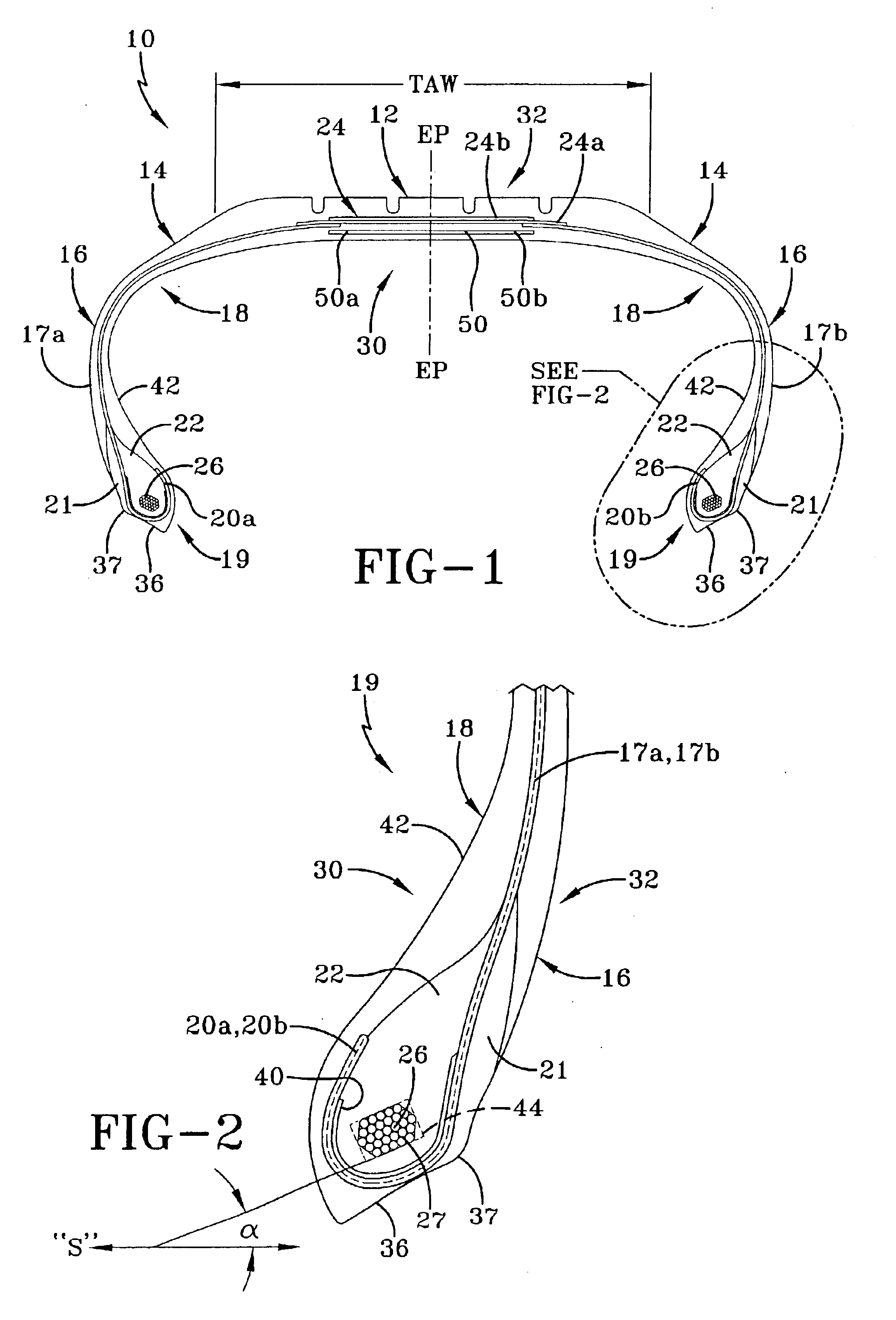

The tire construction and method of building a tire 10 comprises the steps of cylindrically applying a pair of radial cord reinforced sidewall plies 17a, 17b, fixing the axial spacing between the bead cores; applying a crown ply 50, turning up each sidewall ply 17a and 17b to overlap lateral edges of the crown ply 50; moving the carcass assembly 18 axially inwardly while shaping the carcass assembly 18 toroidially to form ply turnups 20a, 20b axially inwardly of the bead cores 26. The method further comprises the steps of applying one or more belt reinforcing layers to the carcass and first reinforcing layer and applying a tread to form a pneumatic radial ply tread tire.

Owner:THE GOODYEAR TIRE & RUBBER CO

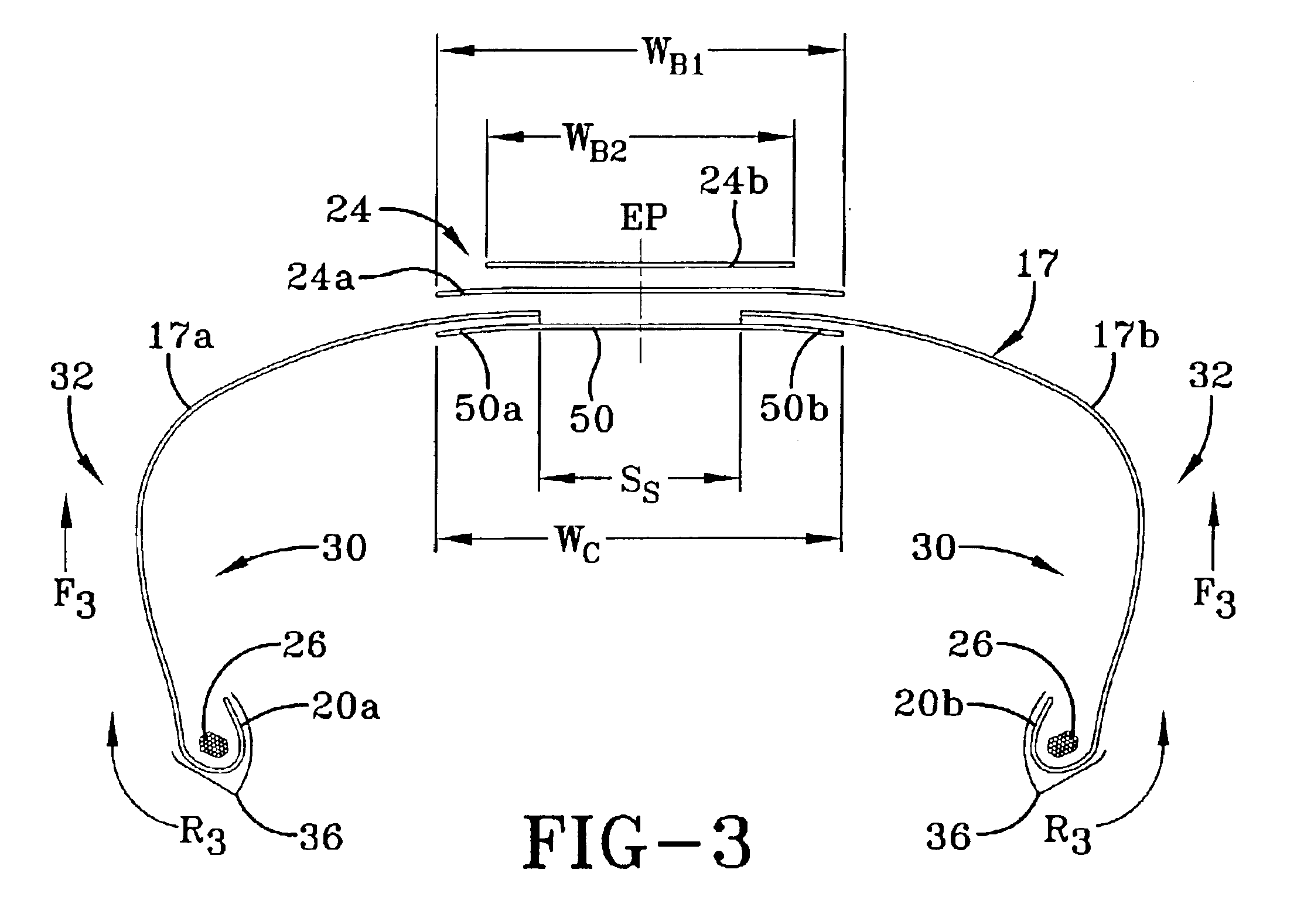

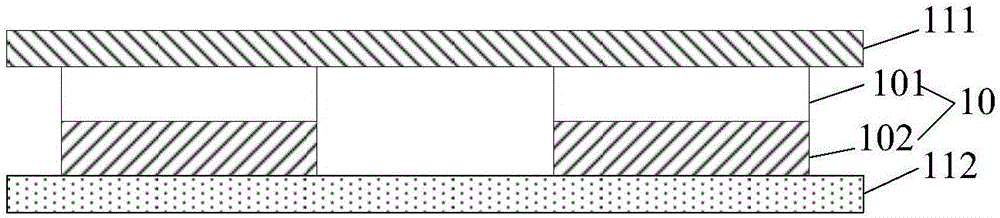

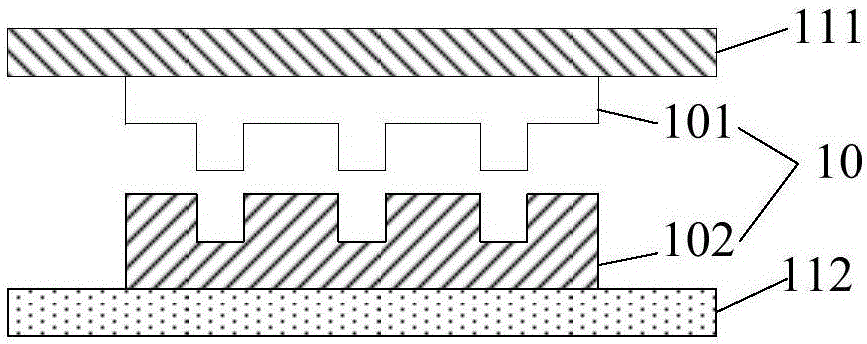

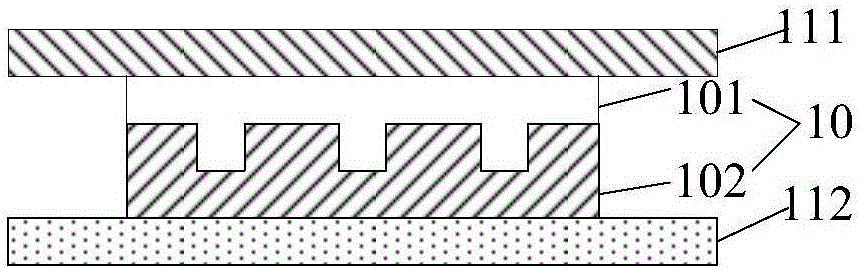

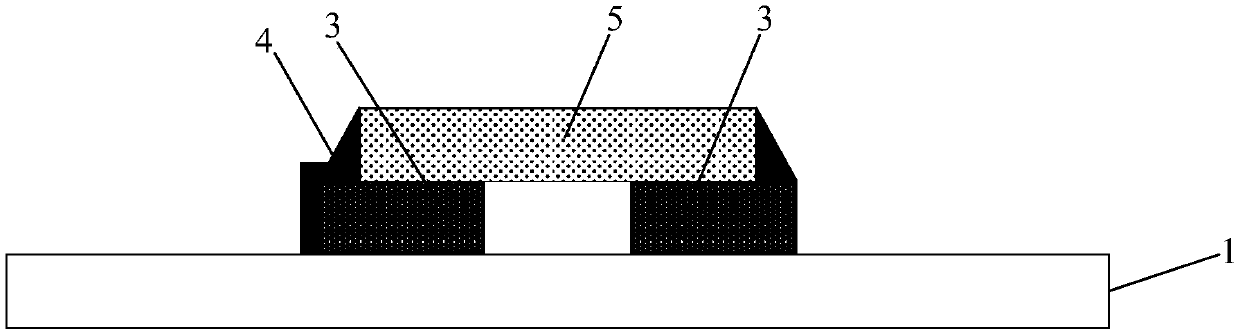

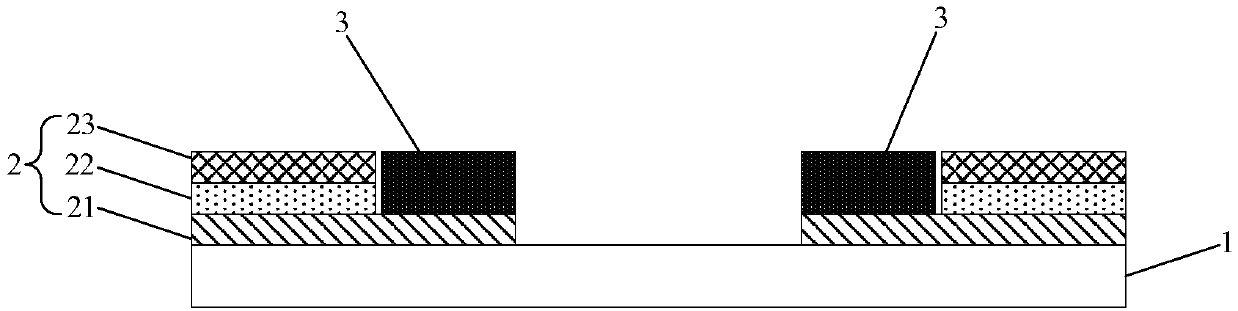

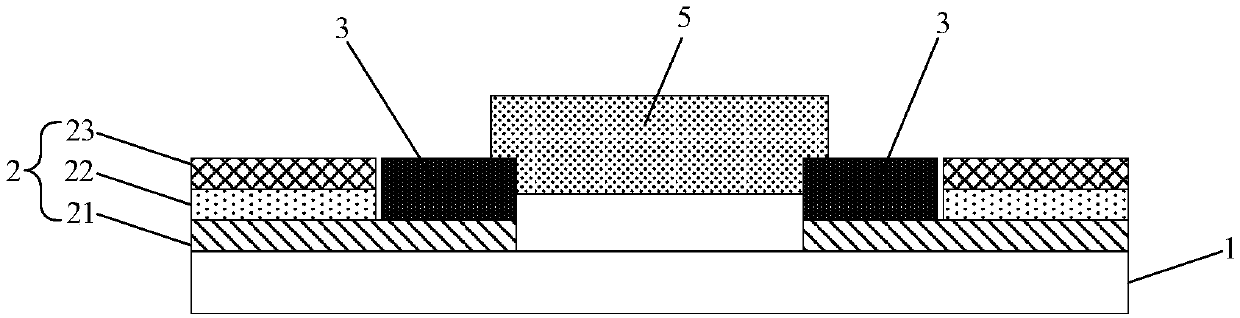

Display panel, display device and manufacturing method of display panel

ActiveCN106292080AReduce indentationIndentation is not easy to produceStatic indicating devicesNon-linear opticsDisplay deviceEngineering

The invention discloses a display panel. The display panel comprises a first substrate and a second substrate which are arranged oppositely. Multiple spacers are arranged between the first substrate and the second substrate at intervals, at least one spacer comprises a first supporting portion and a second supporting portion, the first supporting portion is arranged on the first substrate, the second supporting portion is arranged on the second substrate, the first supporting portion and the second supporting portion are fixedly connected, and the material for manufacturing the first supporting portion is smaller than the material for manufacturing the second supporting portion in elasticity modulus. The invention further discloses a display device and a manufacturing method of the display panel. By the adoption of the display panel, the problem that in the prior art, a supporting force is weak due to the pressure resisting capability of the spacers and the like and accordingly the display panel easily produces indentations is solved.

Owner:BOE TECH GRP CO LTD +1

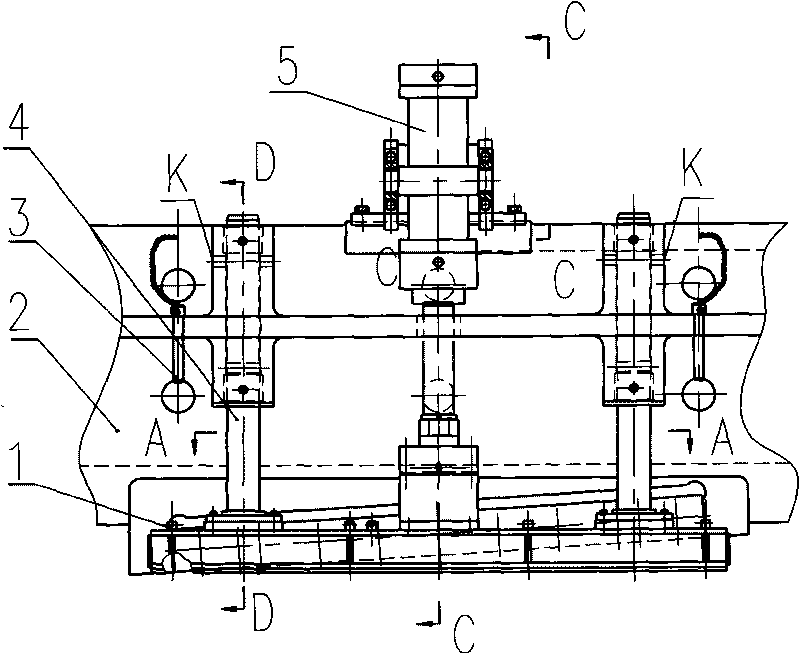

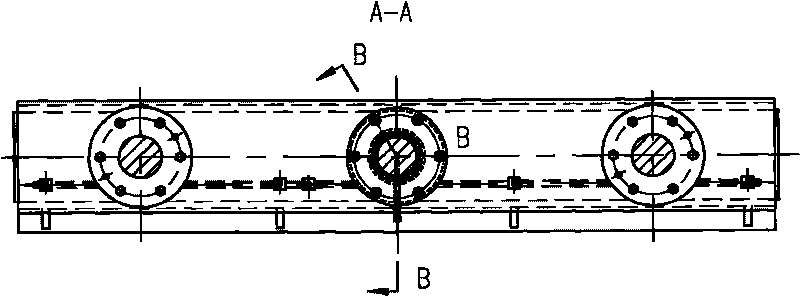

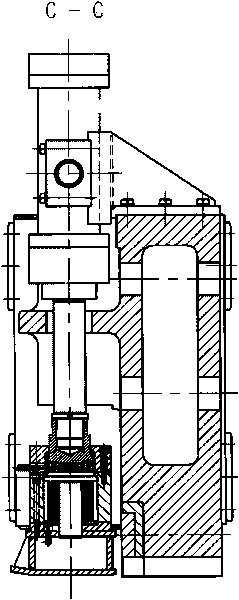

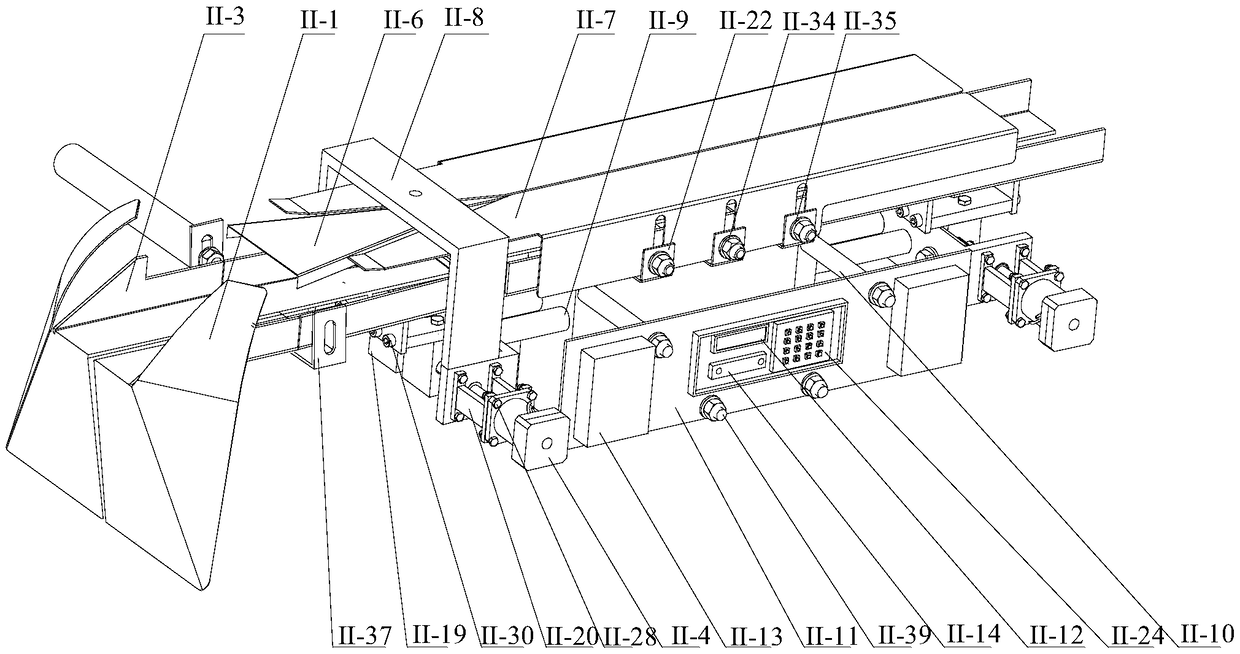

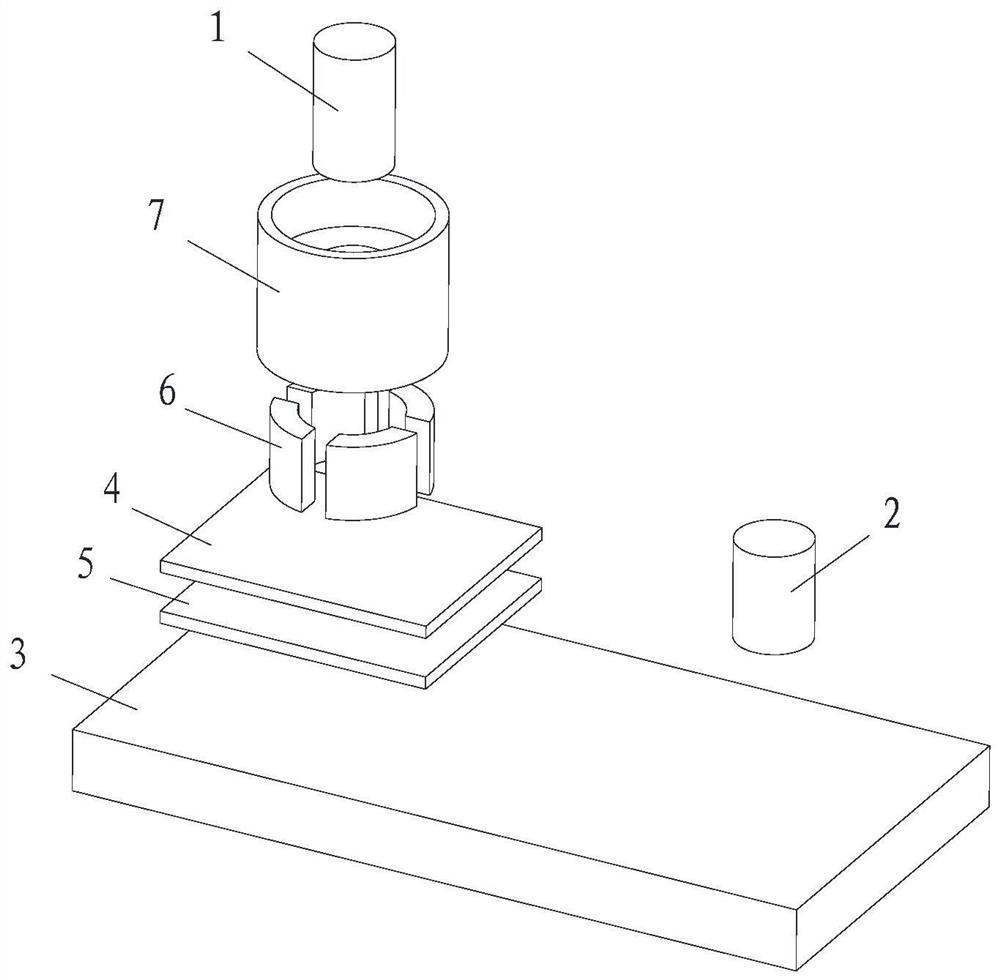

Huoluo hemisphere type pressure head base body of multi-pressure-head sheet forming device

Owner:WUHAN UNIV OF TECH

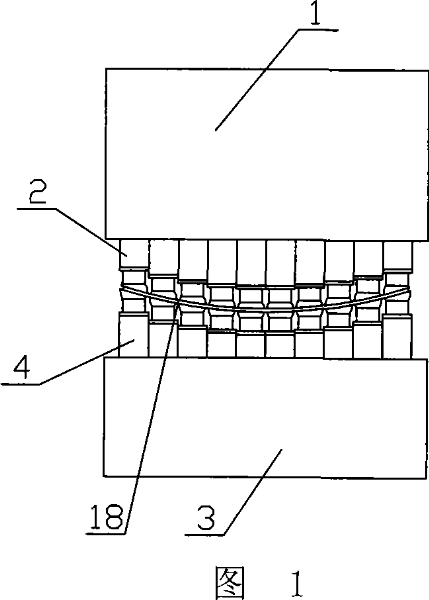

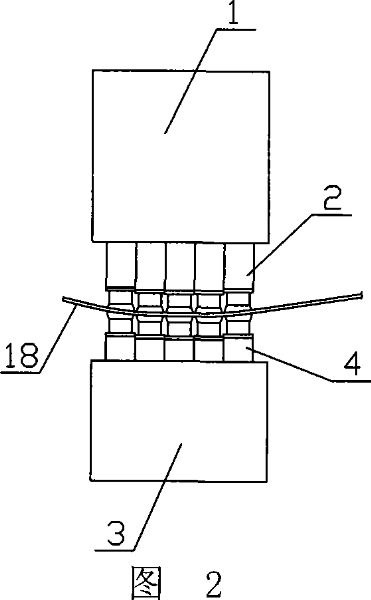

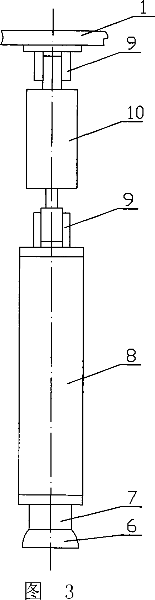

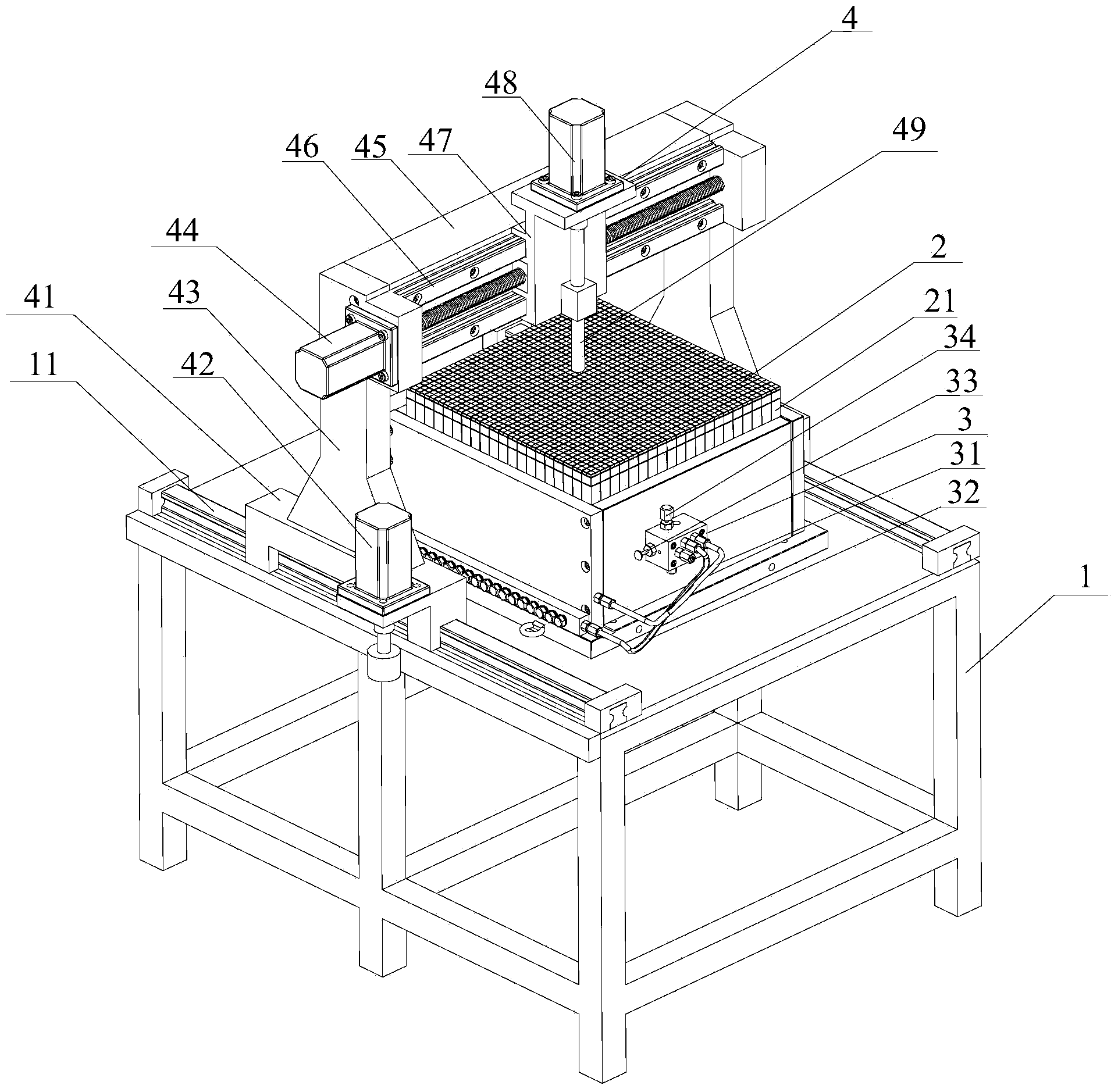

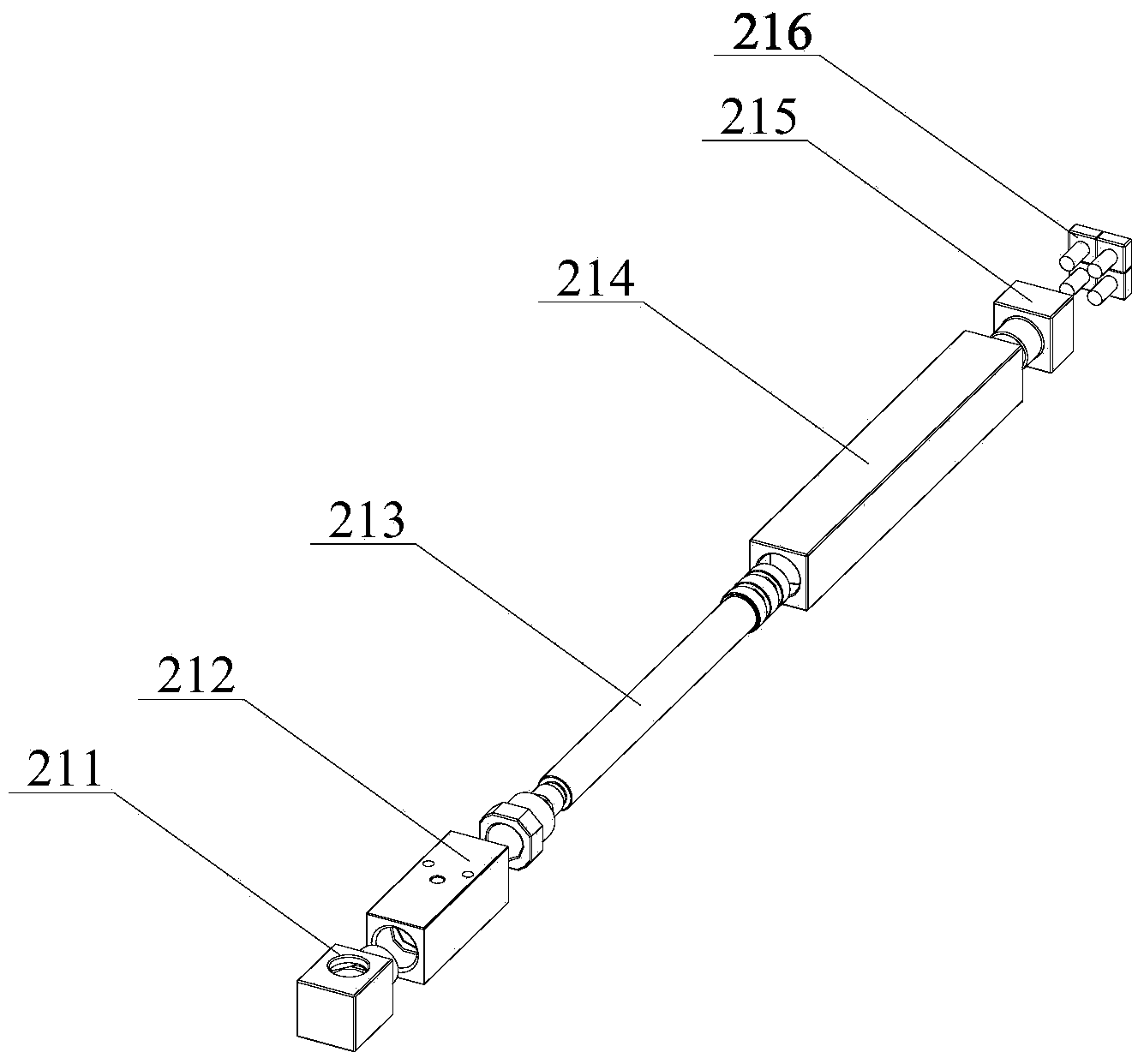

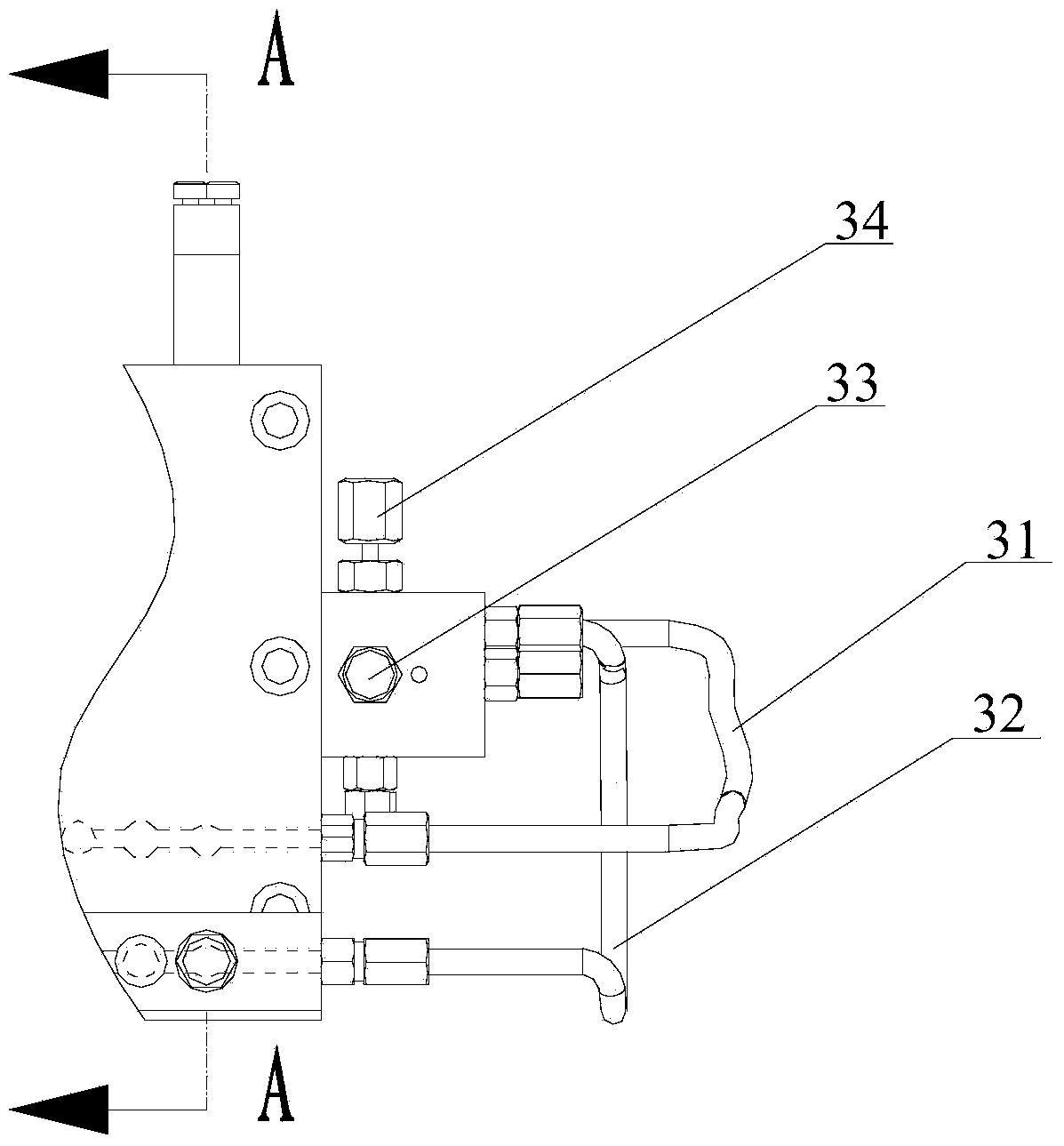

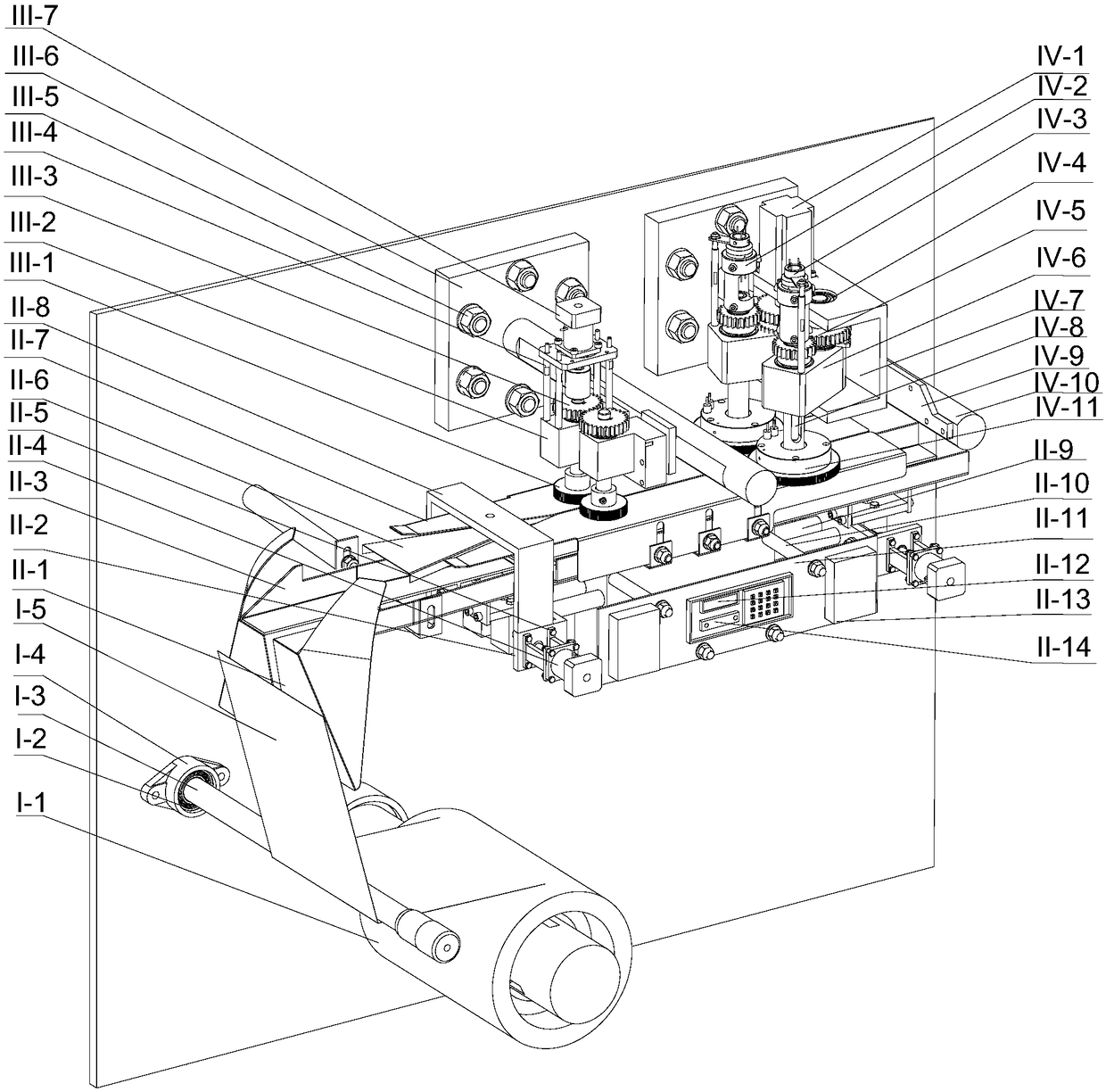

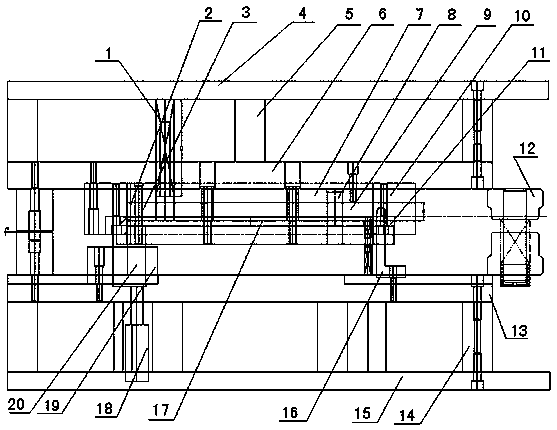

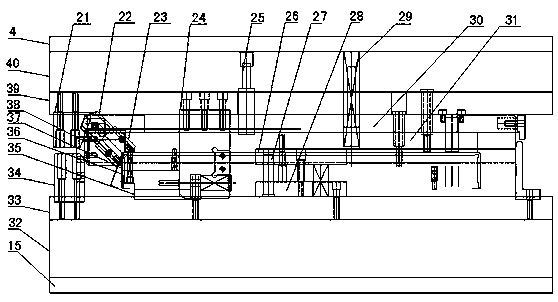

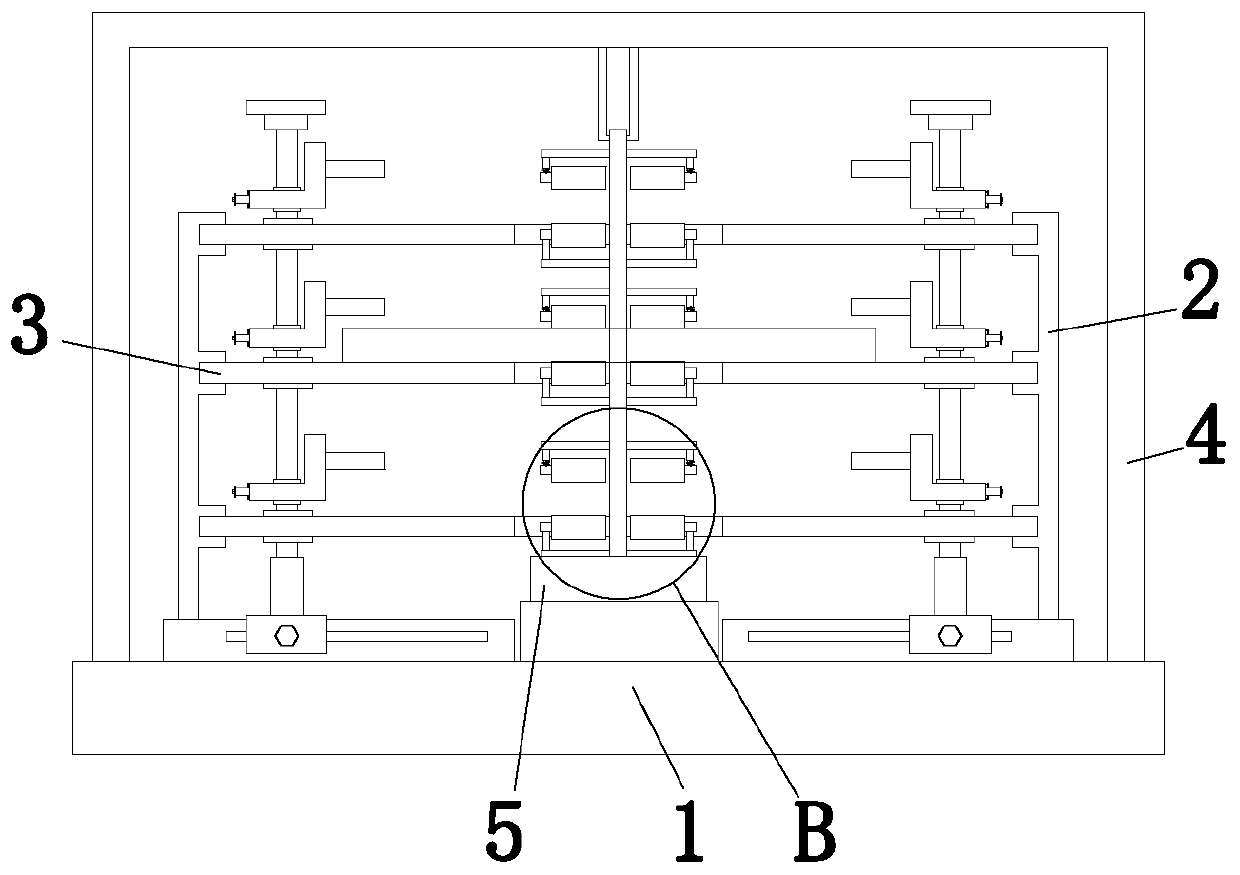

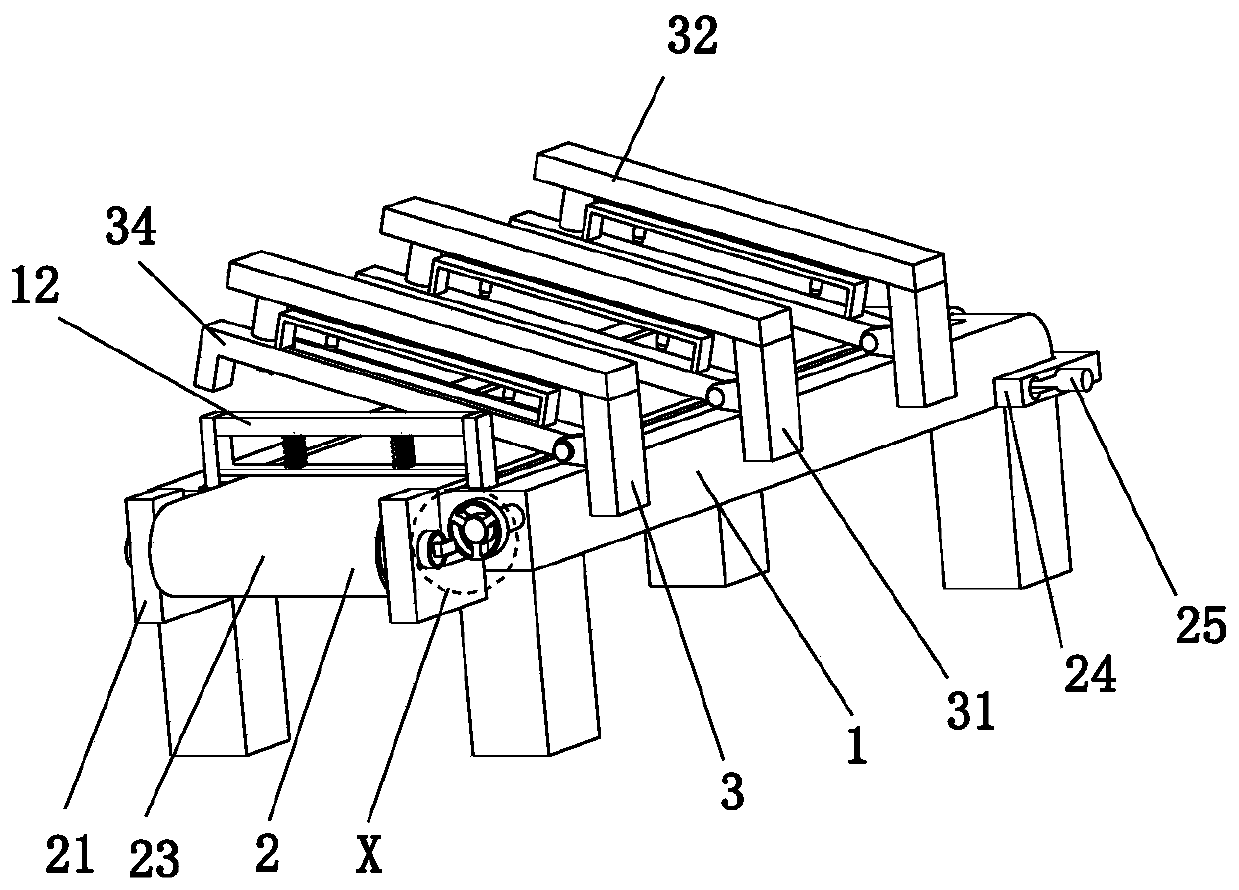

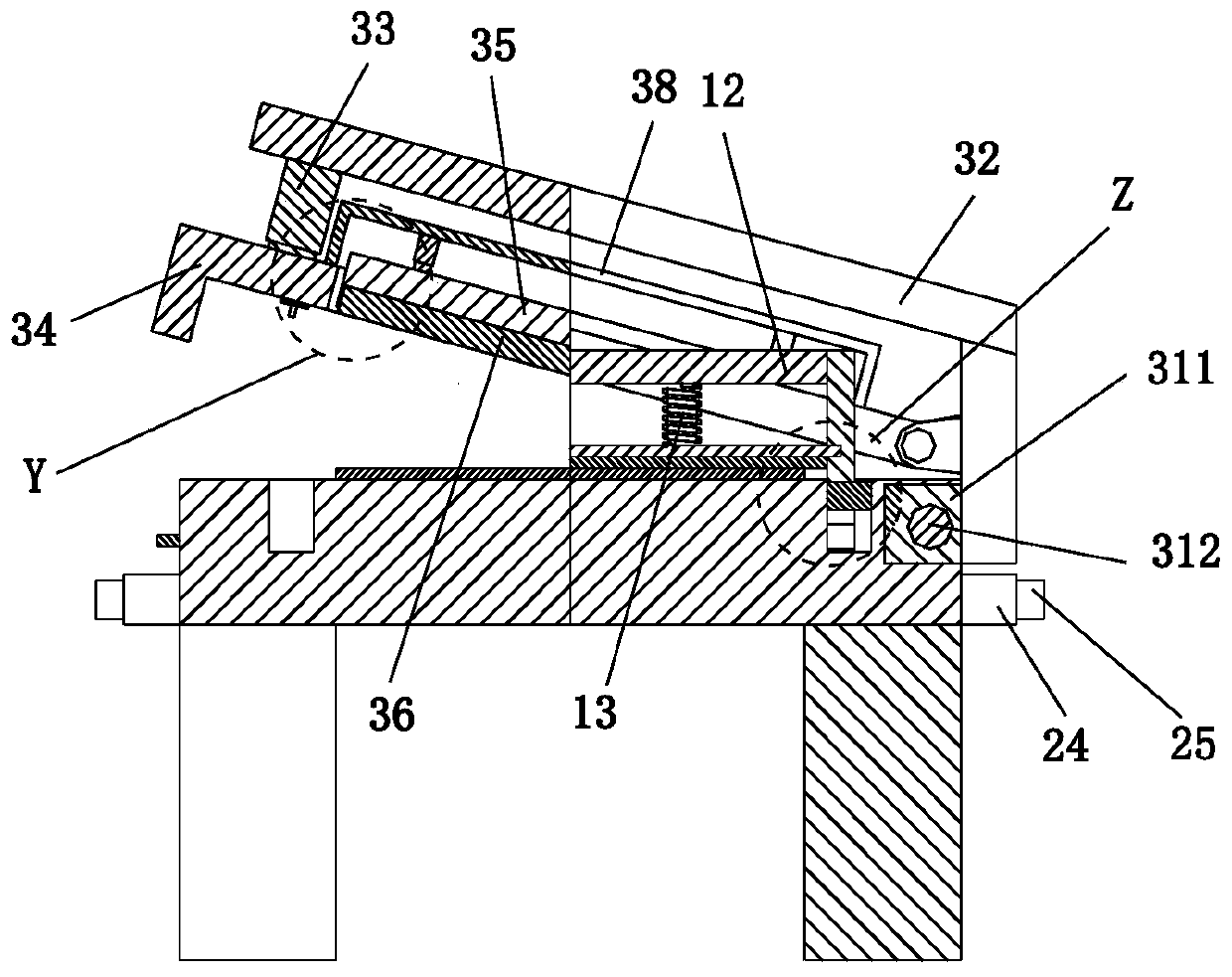

Reconfigurable die and forming device for same

The invention discloses a reconfigurable die. The reconfigurable die comprises a plurality of closely arranged hydraulic telescopic units and a hydraulic system connected with the hydraulic telescopic units, wherein each hydraulic telescopic unit comprises a pressure maintaining cylinder, a telescopic unit hydraulic valve, a hydraulic cylinder and a pressure head; the hydraulic system comprises an oil inlet line, a pressure maintaining oil line and a regulating valve used for switching between the oil inlet line and the pressure maintaining oil line. The invention also discloses a forming device for the reconfigurable die. A die point control mechanism is used for performing point control over the hydraulic telescopic units in the configurable die to form required curved surfaces. The reconfigurable die is low in cost and high in efficiency; through the closely arranged hydraulic telescopic units, unit contact points of the reconfigurable die and parts are increased, the smoothness of the curved surfaces formed by the reconfigurable die is improved, folds and indentation of punched parts can be reduced, internal residual stress of plates after punching is reduced, and the reconfigurable die is favorable for industrial popularization and application.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

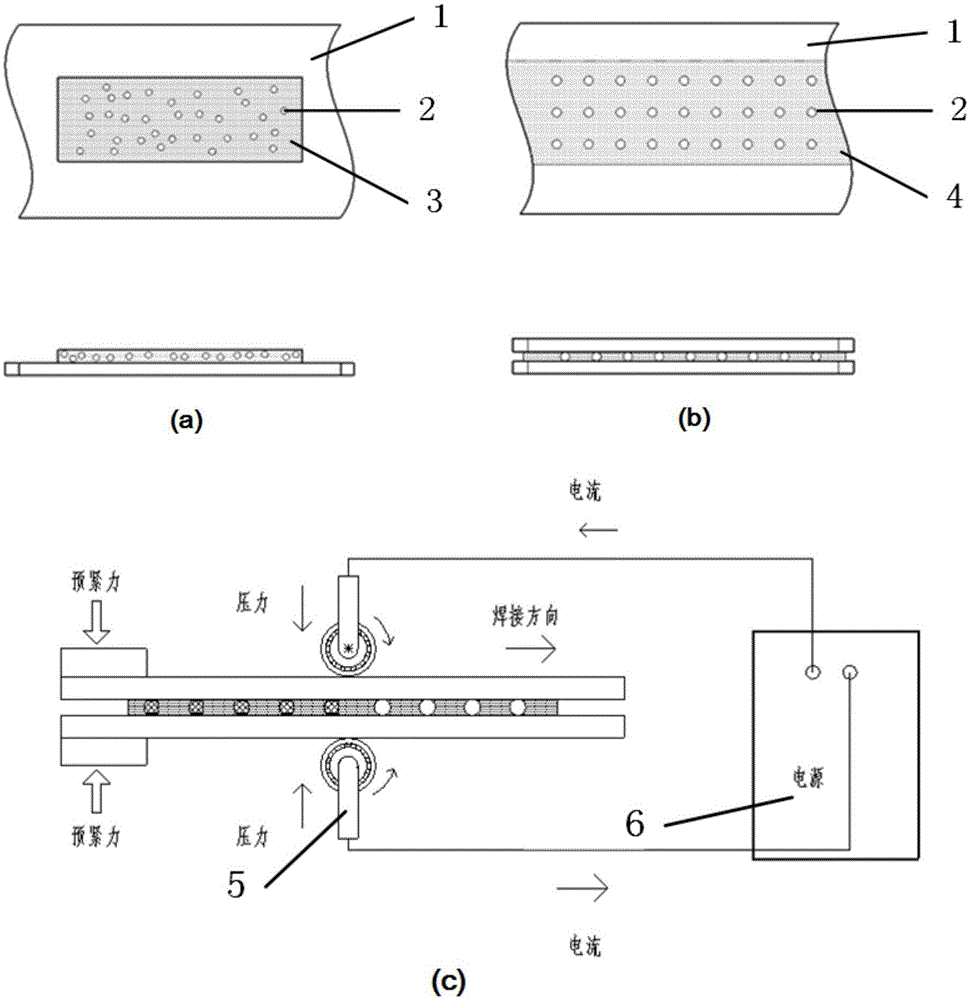

Ultrasonic wave-electrical resistance composite welding method

InactiveCN104907715AImprove welding qualityIncrease solder joint sizeWelding/soldering/cutting articlesMetal working apparatusMolten stateLiquid metal

The invention discloses an ultrasonic wave-electrical resistance composite welding method, wherein the method comprises that, at the pre-pressing stage, a welding contact face of a workpiece to be welded is maintained to be contacted; upper and lower electrode welding heads are respectively set at two sides of the workpiece to be welded and the electrode welding heads are maintained at the same shaft; the electrode welding heads are shared by the electrical resistance welding and the ultrasonic wave welding for use; at the welding stage, current is communicated between the electrode welding heads while applying ultrasonic wave; the vibration and friction heat produced by the electrical resistance heat and ultrasonic wave are utilized to heat the workpiece to be welded to reach at a molten state to form a molten core; at the cooling crystallization stage, after the size of the molten core of the workpiece to be welded reaches at a preset size, the pressure of the electrode welding heads are maintained constantly; the electrical resistance welding current and the ultrasonic wave are stopped; or the electrical resistance welding current is cut off, after the ultrasonic wave works until the preset time; and until the liquid state metal is cooled to form a welding spot / a welding joint. According to the invention, the contact between workpieces to be welded is increased by utilizing the high frequency vibration produced by the ultrasonic wave; and the indentation welding defects are reduced, thus the mechanical property of a welding joint is improved.

Owner:DALIAN UNIV OF TECH

Hydraulic shear pressing device of aluminium sheet strip rolling mill

InactiveCN101733470ANovel structureReasonable designMetal rolling arrangementsShearing machine accessoriesHydraulic cylinderStrip mill

The invention belongs to the technical field of metallurgical industry equipment, and discloses a hydraulic shear pressing device of an aluminium sheet strip rolling mill, which is provided with an upper knife rest body provided with a heavy hydraulic shear; a pressing device is installed on the upper knife rest body; the pressing device consists of a hydraulic cylinder, guide posts and a press plate, wherein the press plate has a through long structure, the hydraulic cylinder is arranged on the hydraulic cylinder, the two guide posts are respectively positioned at the left and the right sides of the hydraulic cylinder, each guide post passes through a guide post hole arranged on the upper knife rest body, and the lower ends of the guide posts are connected with the press plate by flanges; a piston rod of the hydraulic cylinder is connected with the press plate by a ball head and a buffer device; and the press plate is driven to move downwards by the hydraulic cylinder and is contacted with the material so as to firmly press and fix the material. As the hydraulic cylinder is adopted to drive the press plate to press the material, little impression is generated on strip material, the heavy hydraulic shear can be ensured to work normally regardless of the width of the strip material, and the working effect is good.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Adjustable width packaging bag forming device, bag making device, packaging machine and method

InactiveCN109353596AAvoid designAchieve molding effectPhotovoltaic supportsGeneral water supply conservationEngineeringPackaging machine

The invention discloses an adjustable width packaging bag forming device, a bag making device, a packaging machine and a method. The bag making device is included. A traction device and a heat seal device are arranged above the bag making device. A width adjusting device adjusts the distance between different sub bottom plates in a front bottom plate and a rear bottom plate through a lead screw sliding block mechanism, and accordingly bottom plate width adjustment is achieved. The lead screw sliding block mechanism is adopted as the width adjusting device for an automatic adjustable width noodle packaging bag forming device system, the four bottom plates are fixed to the width adjusting device, when the lead screw sliding block mechanism works, the adjusting range is accurate, the adjustable width packaging bag forming device is suitable for multiple widths of packaging bags, and a very important significance is achieved for the three-dimension forming effect of the packaging bags.

Owner:QINGDAO HAIKEJIA ELECTRONCE EQUIP MFG +1

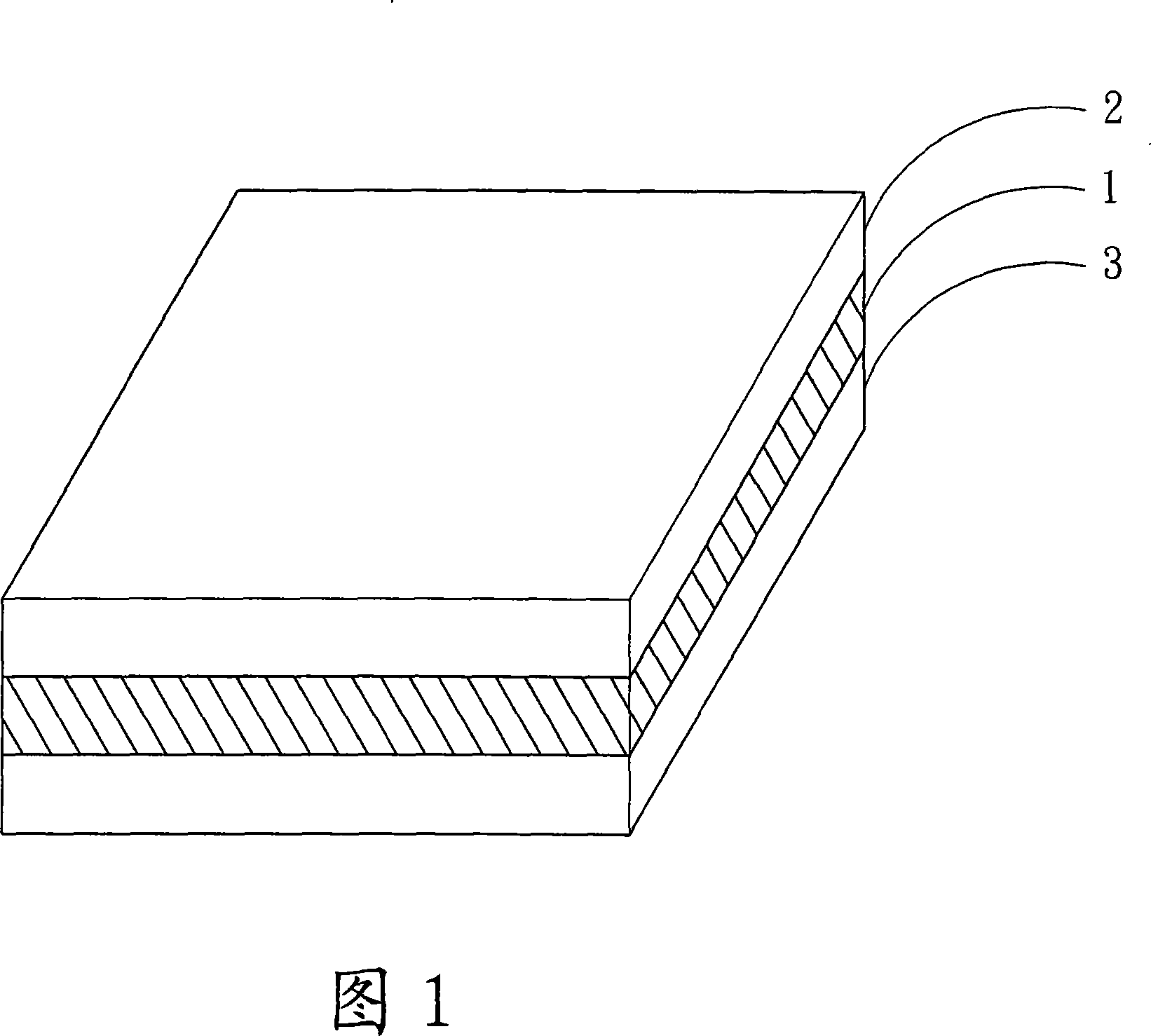

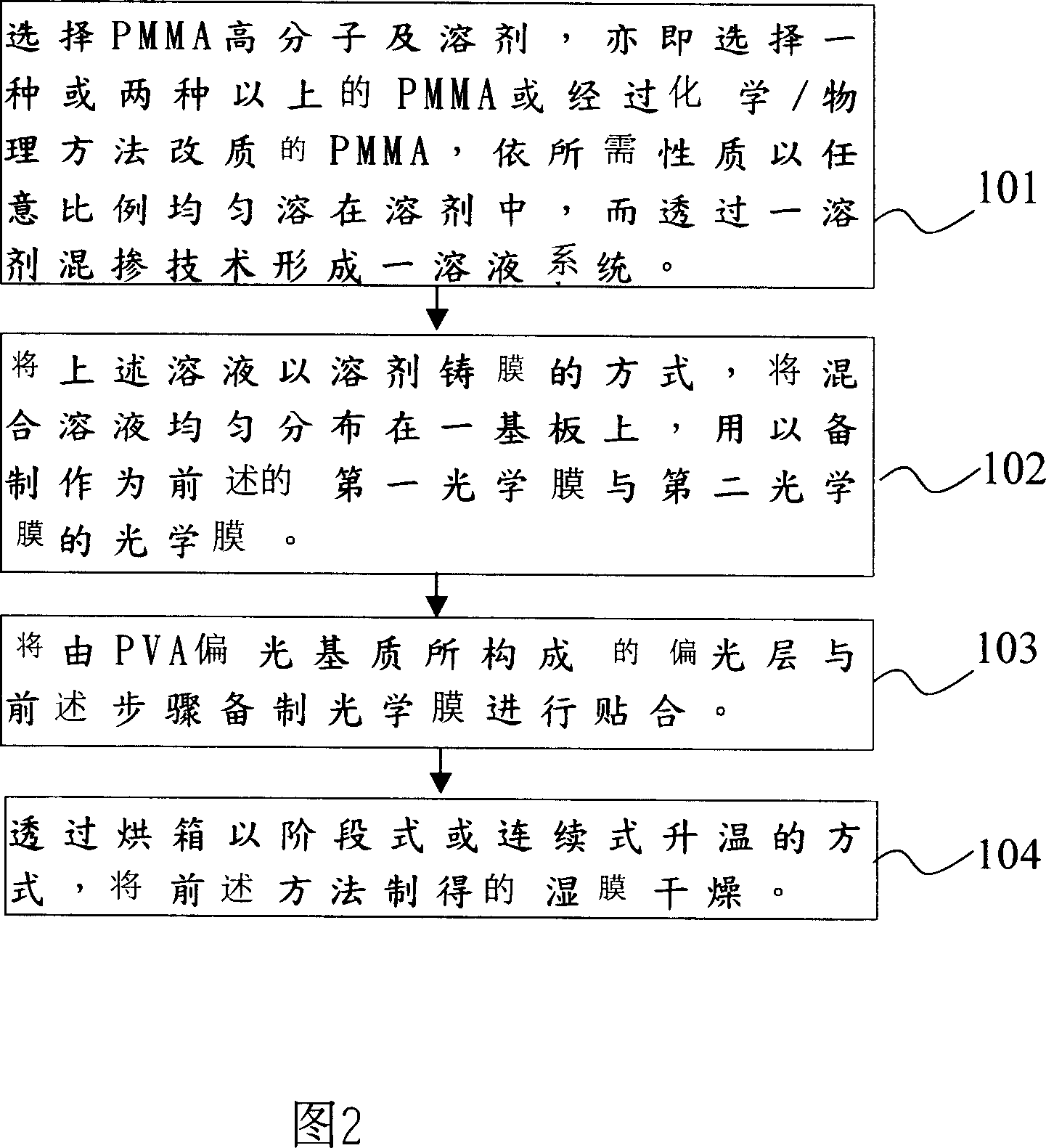

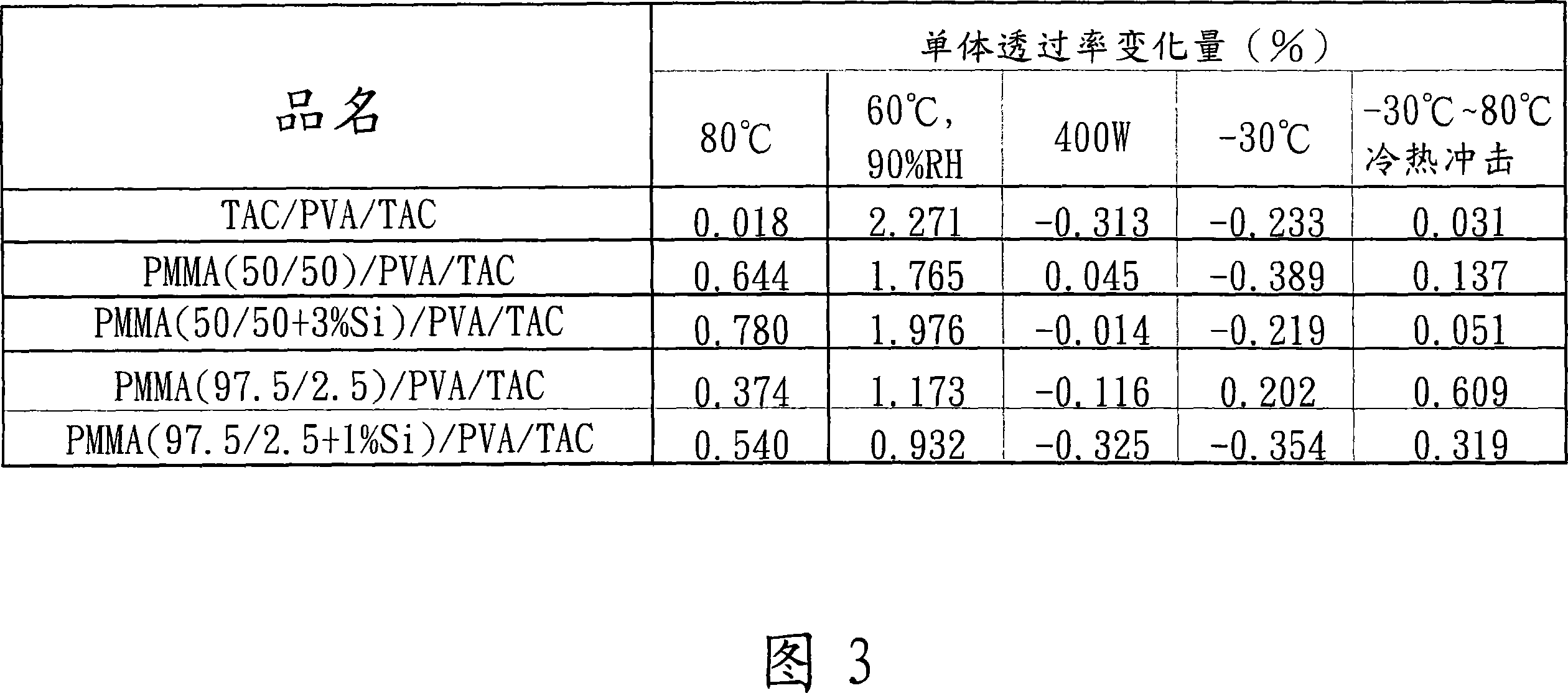

Polarized plate structure

InactiveCN101097269AGood heat resistanceModerate mechanical propertiesPolarising elementsBoard structureOptical film

The present invention relates to a polarized light board structure which is provided with a polarized light layer, a first optical film and a second optical film, the first optical film is formed above the polarized light layer and the second optical film is formed below the polarized light layer, wherein, at least one optical film selected from the first optical film and the second optical film is polymethyl methacrylate optical film. Into the bargain, the optical film is formed by pasting the mixed solution to the polarized light board and doing heat treatment when penetrating the mixed solution and distributing on the substrate to prepare for making have finished, or the optical film is formed by penetrating the mixed solution and distributing on the substrate and doing thermal treatment.

Owner:OPTIMAX TECHNOLOGY CORPORATION

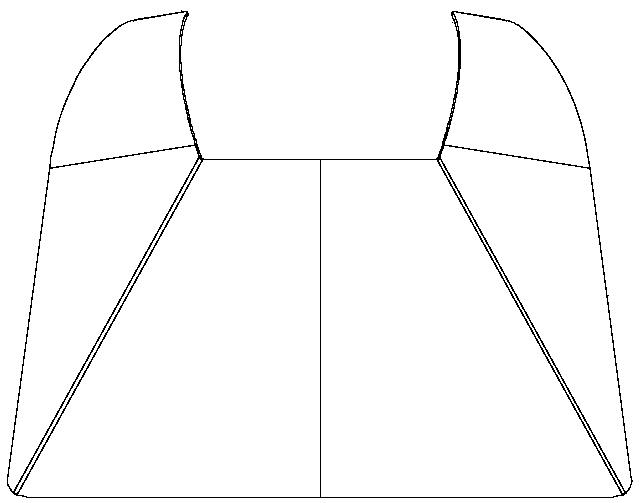

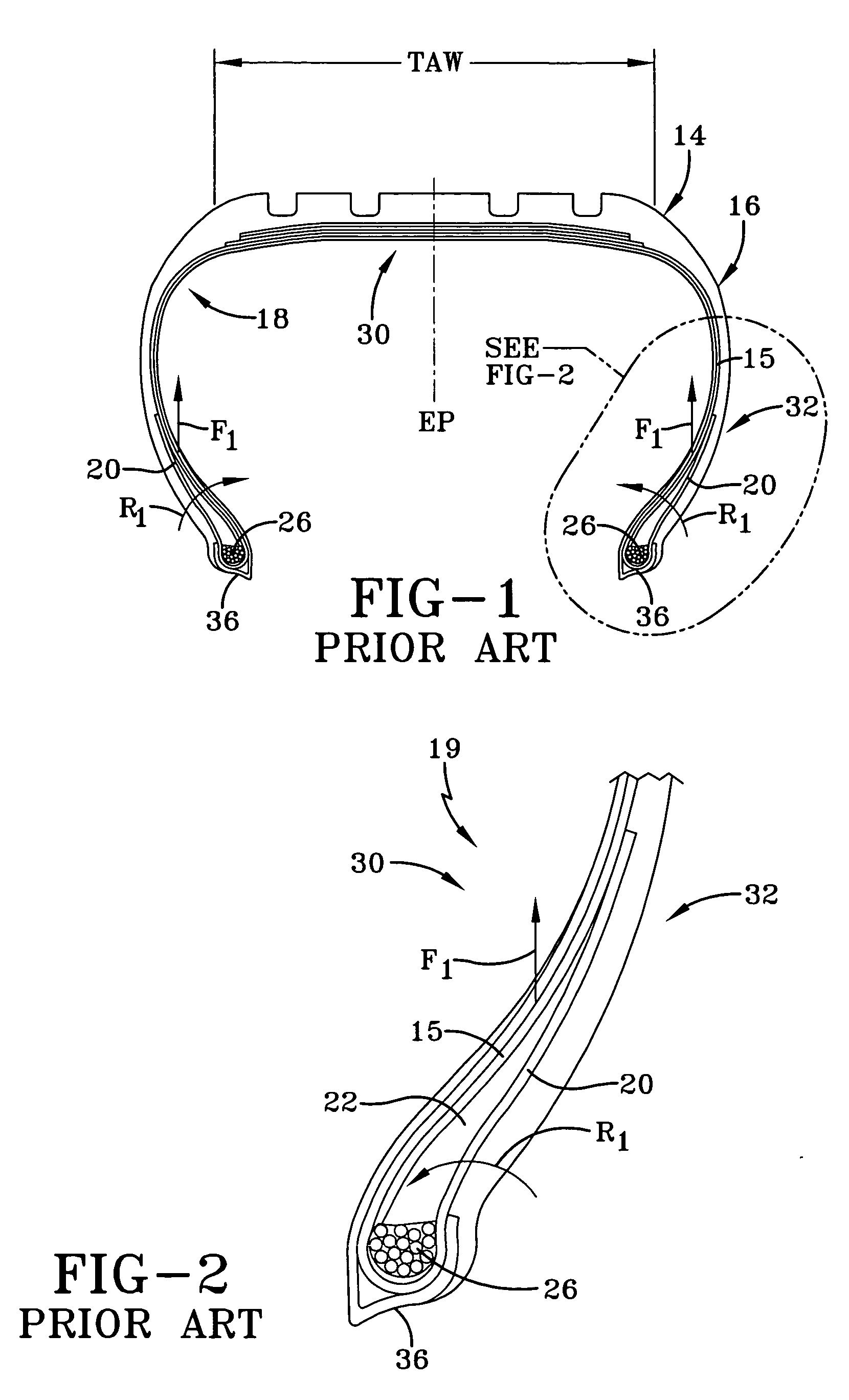

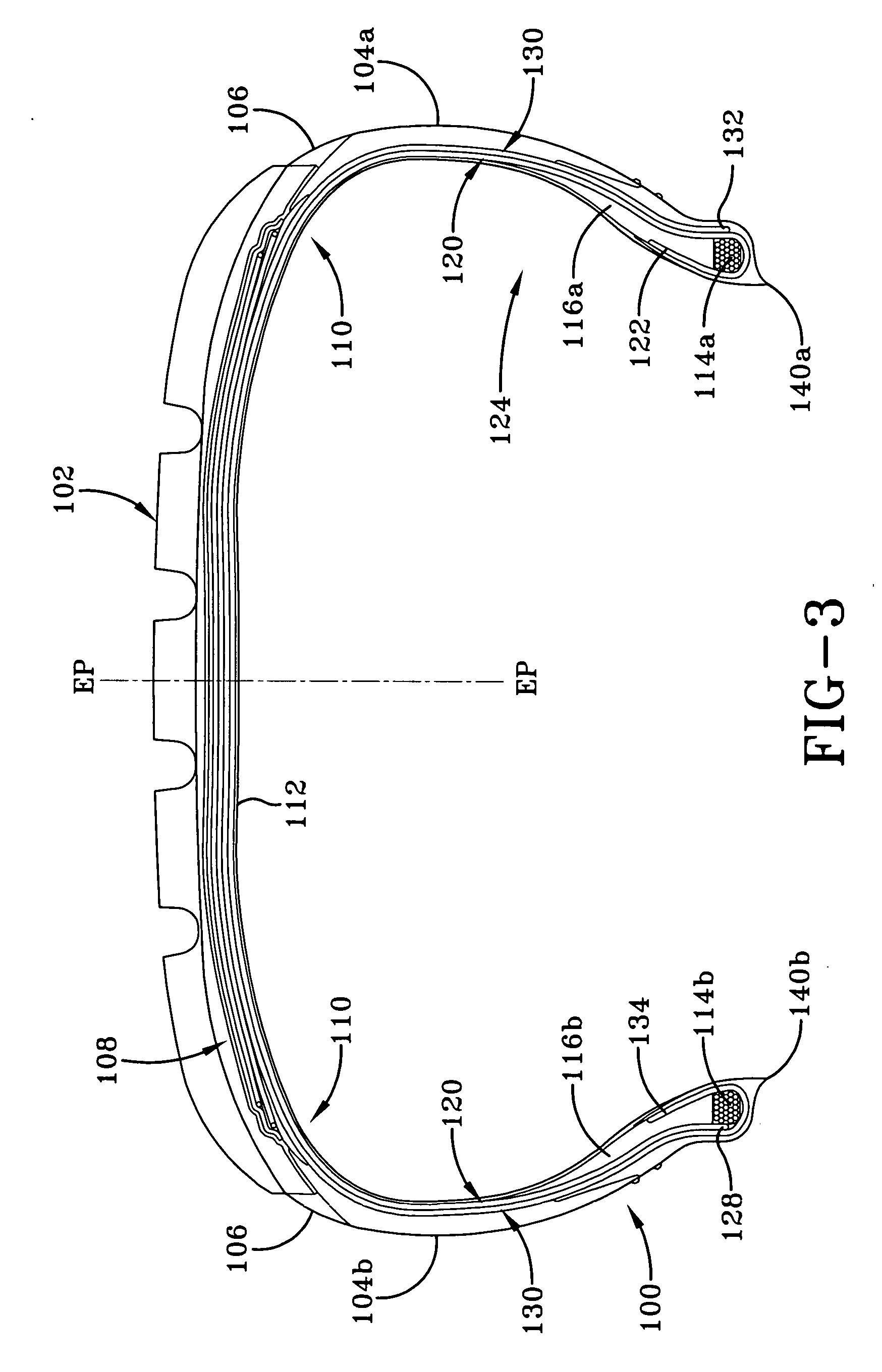

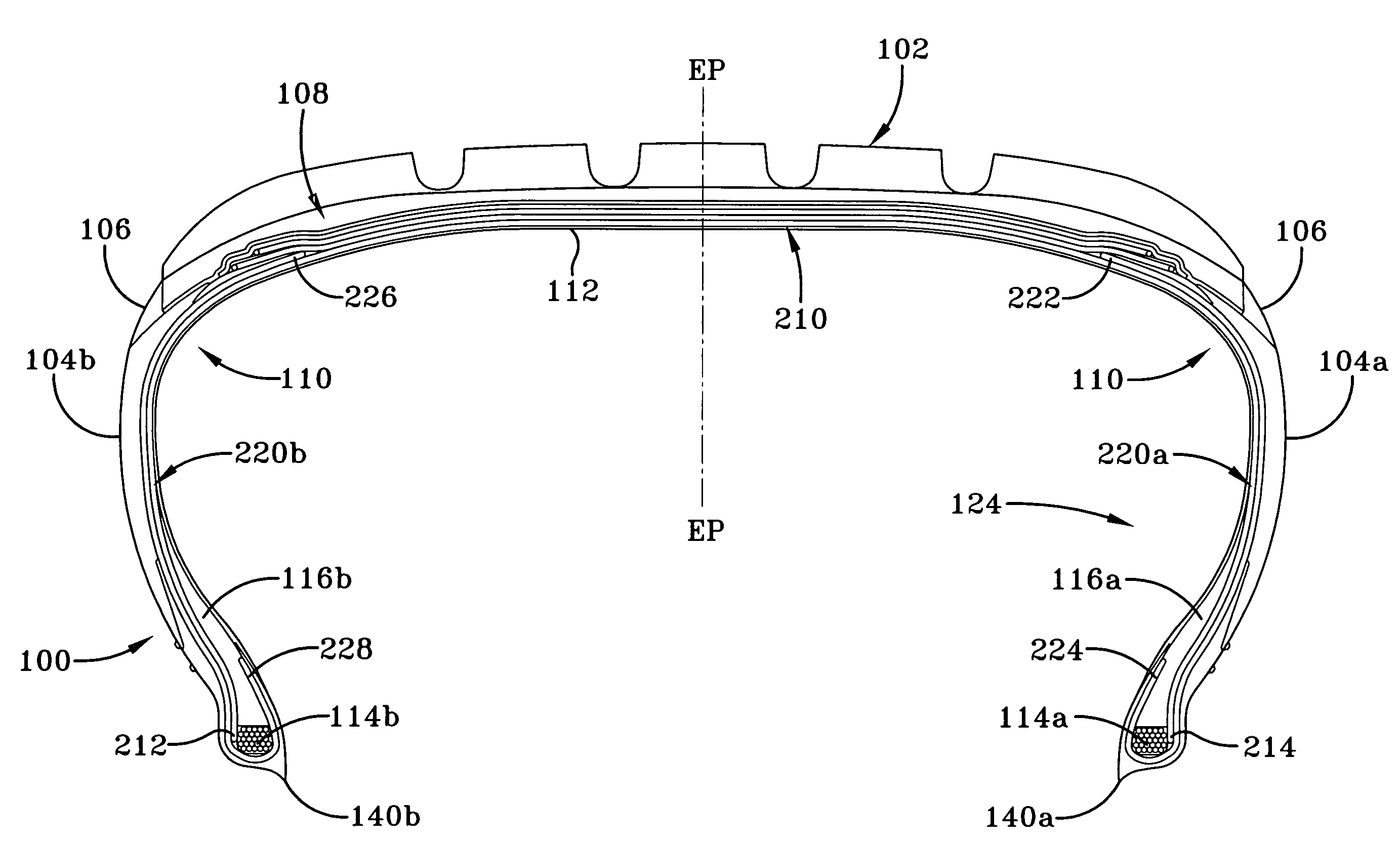

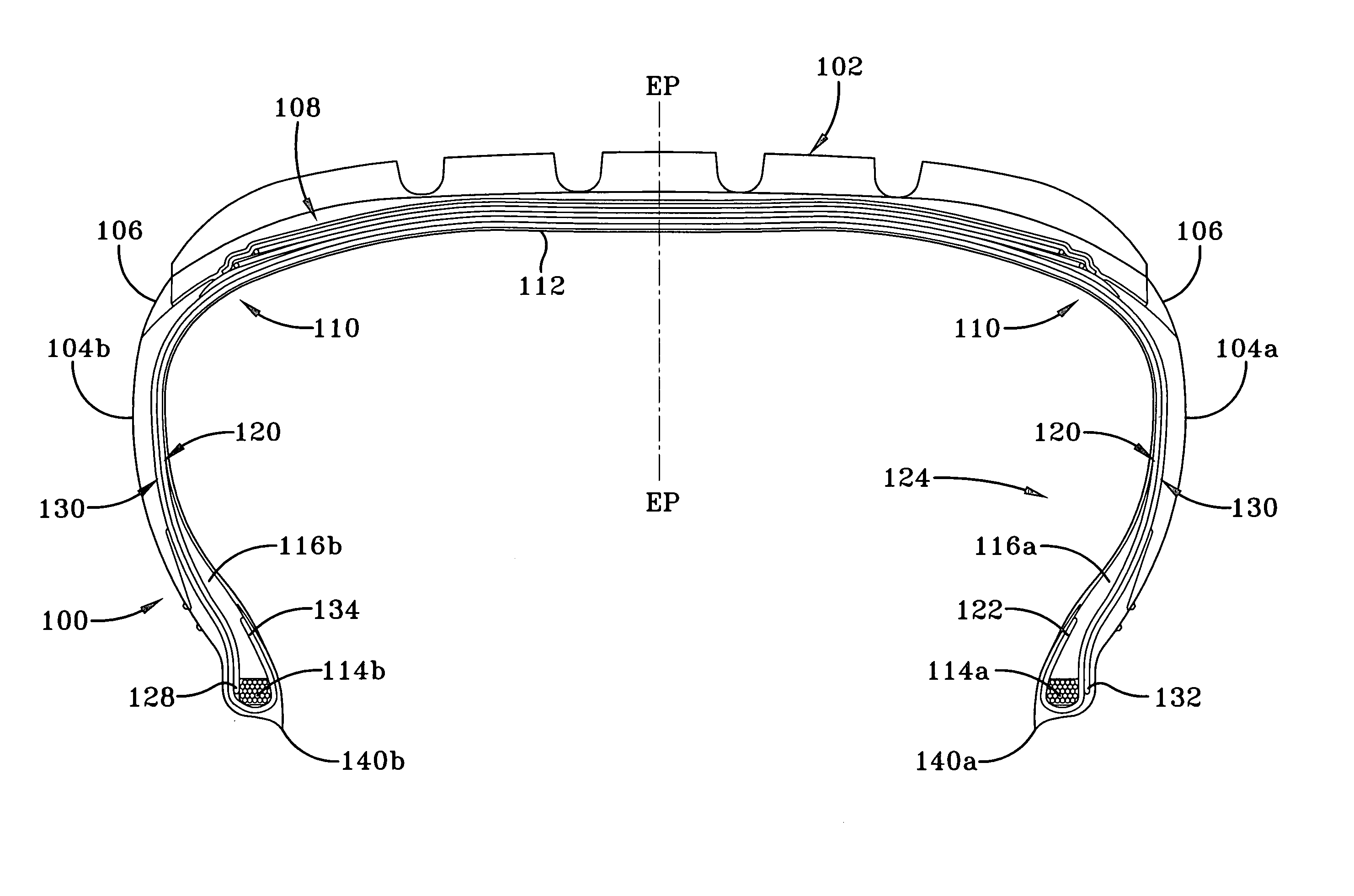

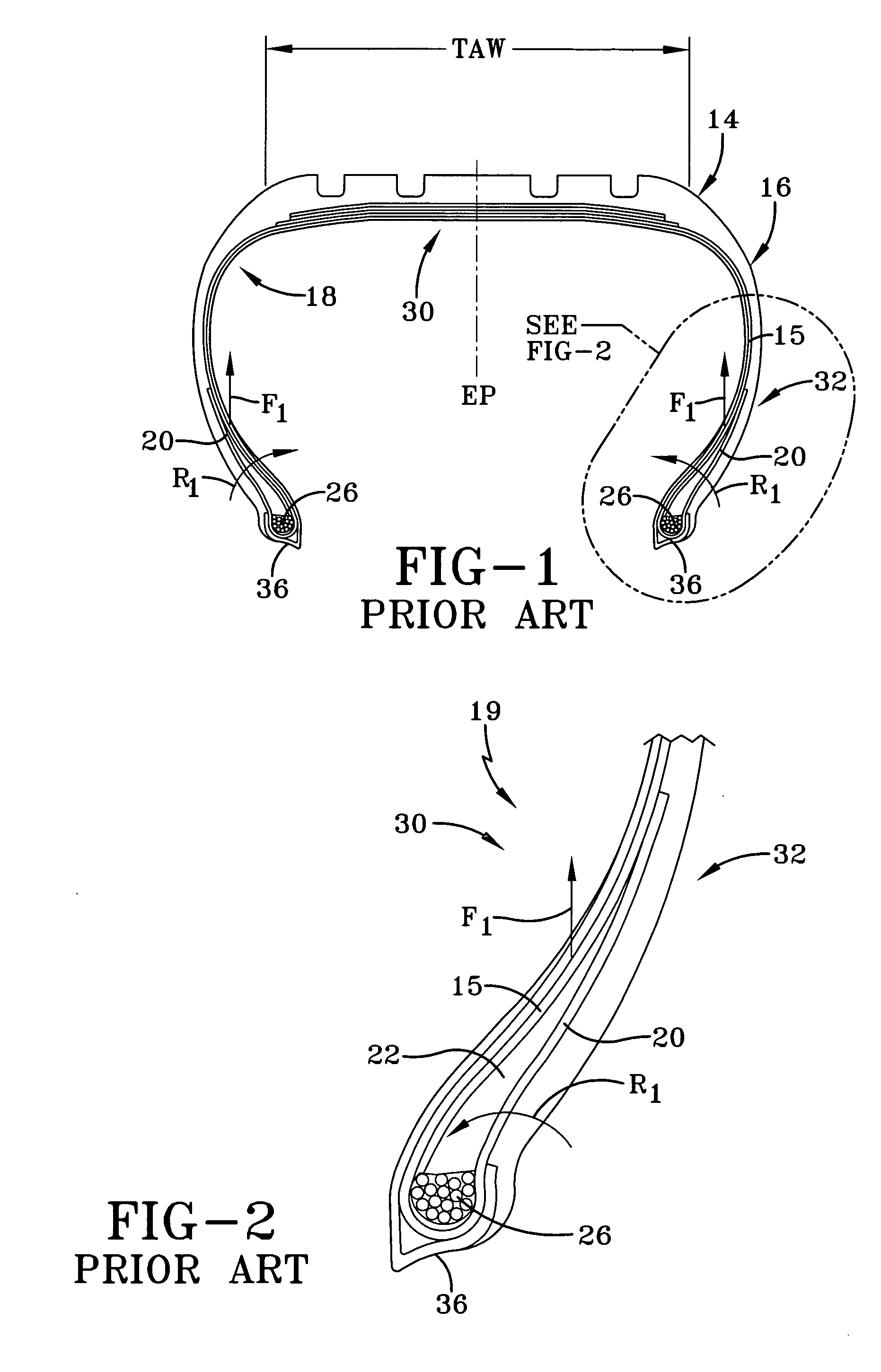

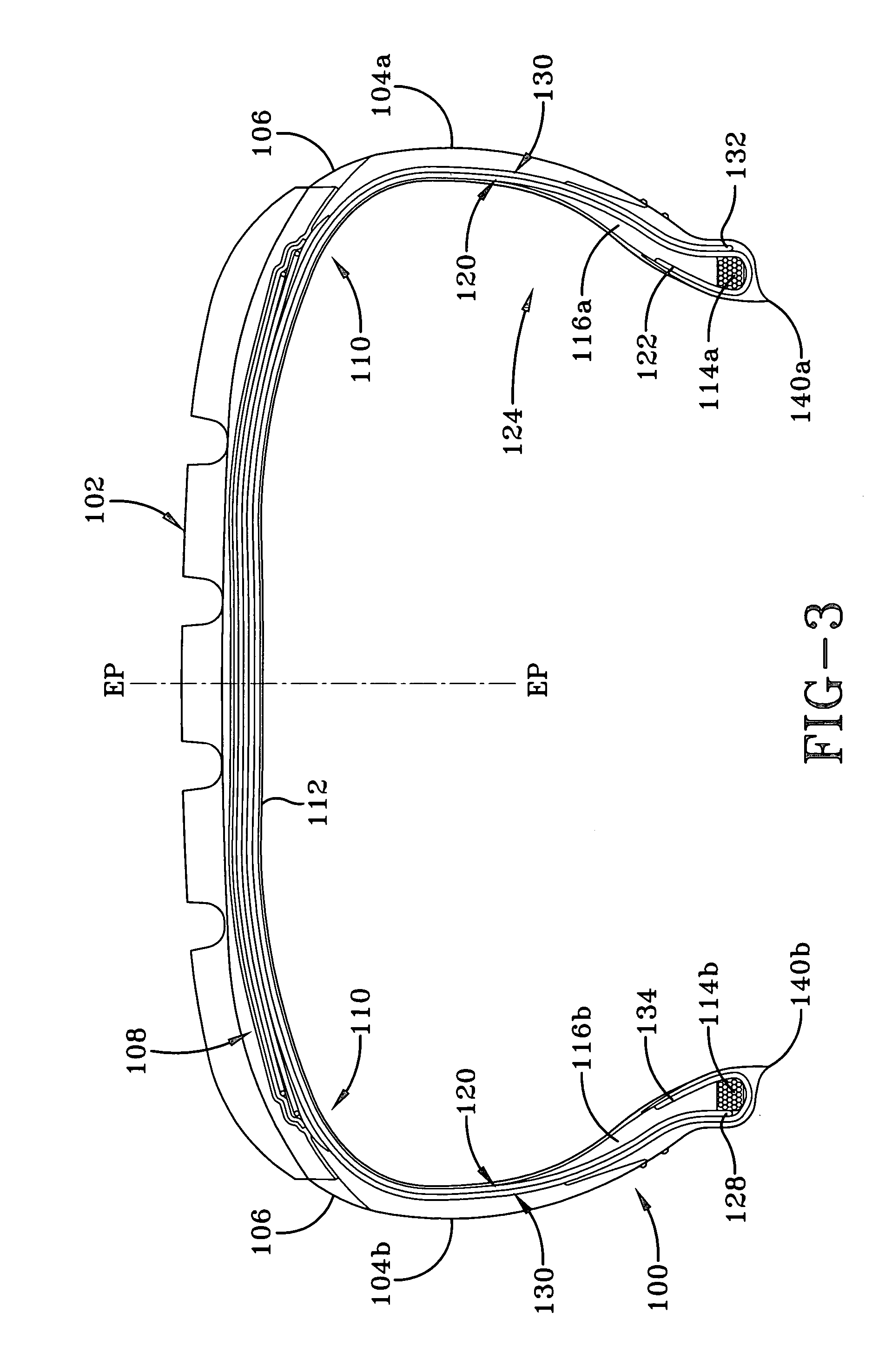

Tire with turned down ply construction

ActiveUS20070131333A1Smooth connectionReduce rim indentationTyresPneumatic tyre reinforcementsEngineeringMechanical engineering

The tire includes a first and second axially-spaced bead core, a carcass having at least one belt extending under a tread, and a first ply layer having first and second ends, a first end is located axially outside and adjacent a first bead core, and a second end that is located axially outside and adjacent a second bead core. The carcass further comprises first and second shoulder ply layers each shoulder ply layer having first and second ends, a first end is located under the tread belt, the shoulder ply extending down the side wall region with the second end folding from a position axially outside a respective bead core to a position axially inside and around the bead core. The carcass further comprises an additional reinforcement layer which wraps around the bead and is preferably positioned between the shoulder ply and the first ply layer, although not required.

Owner:THE GOODYEAR TIRE & RUBBER CO

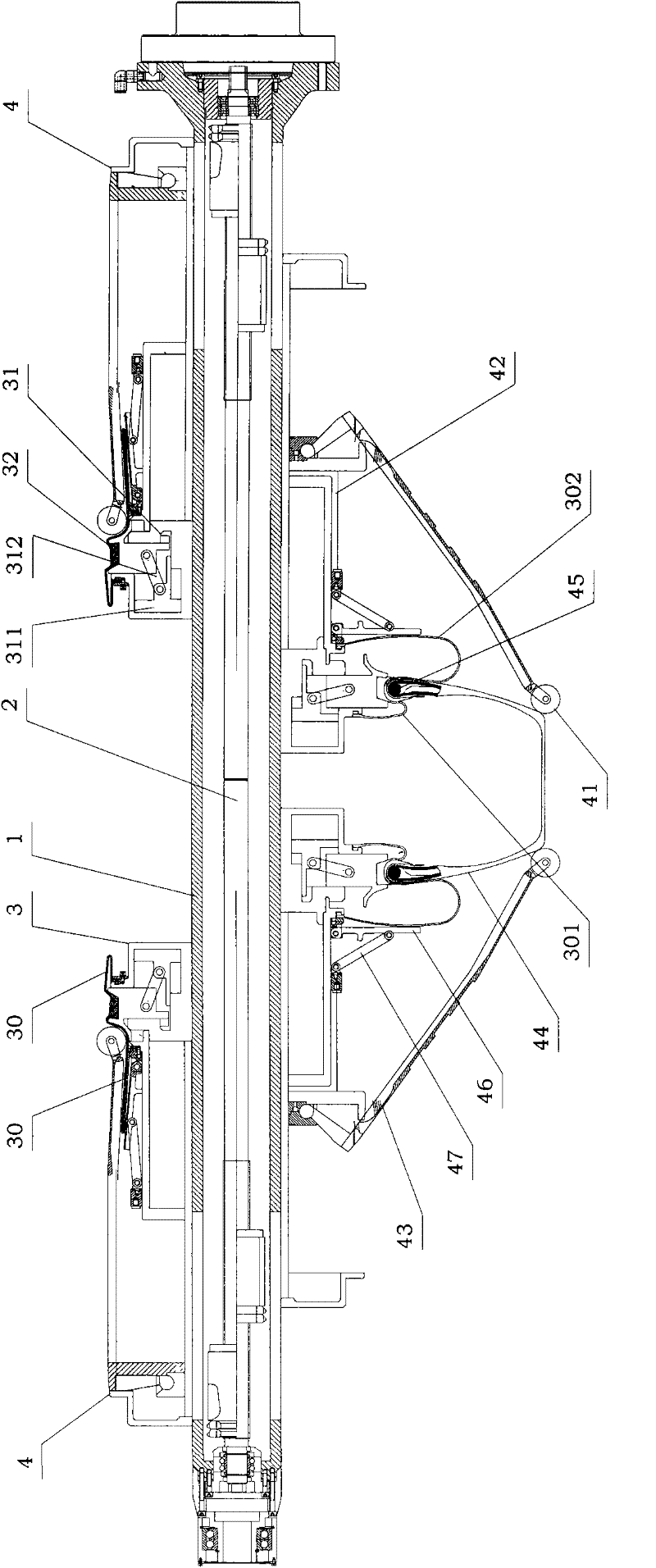

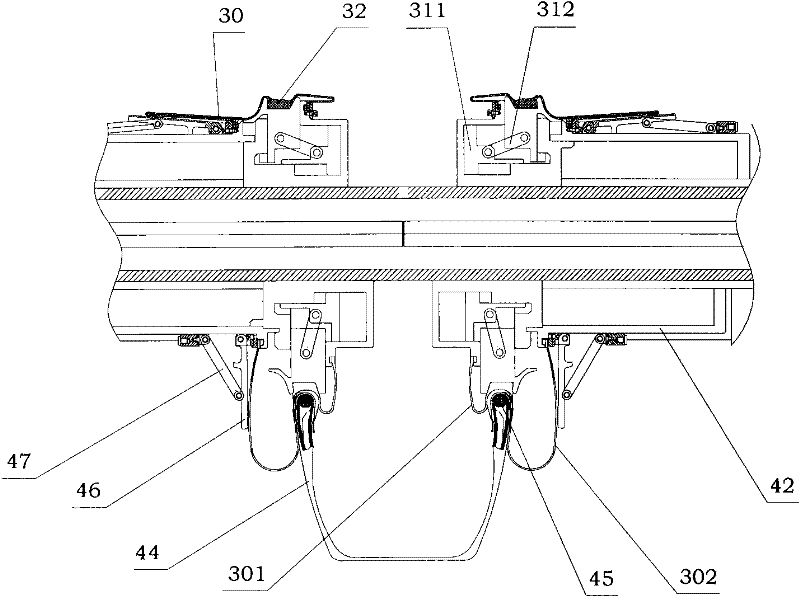

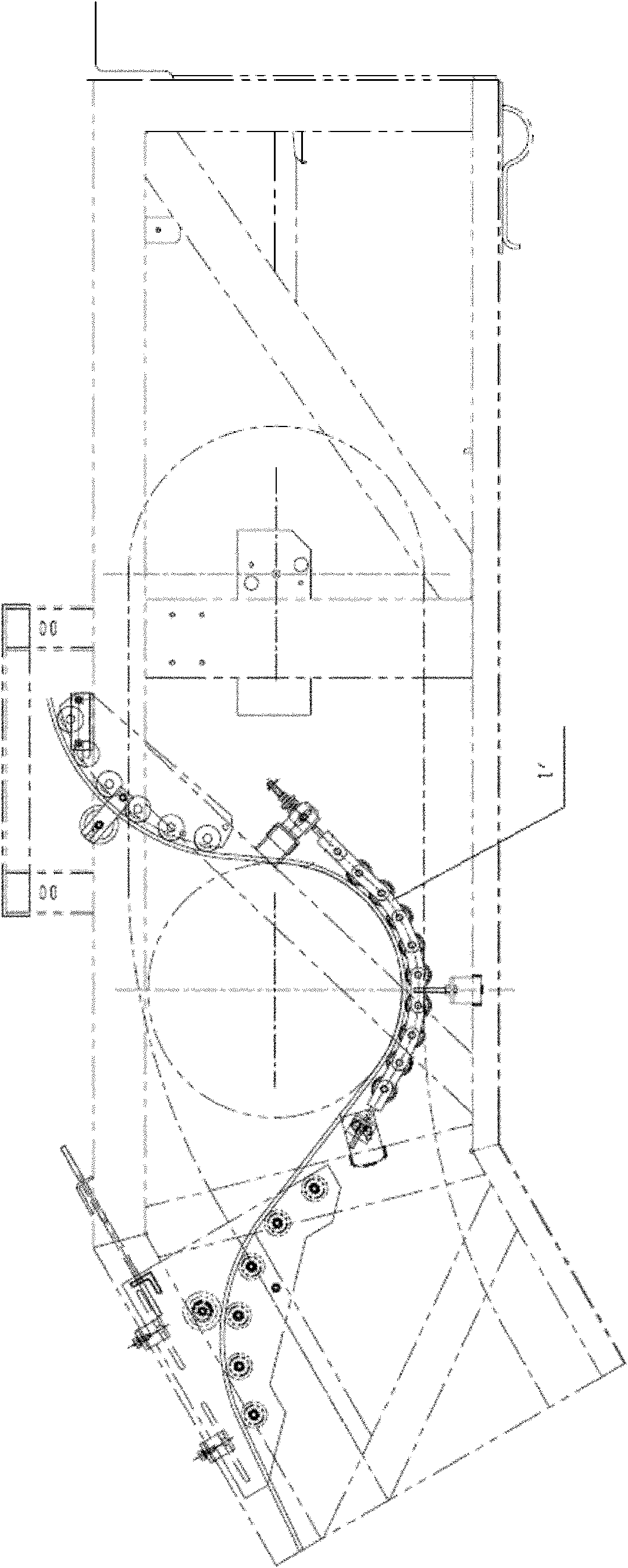

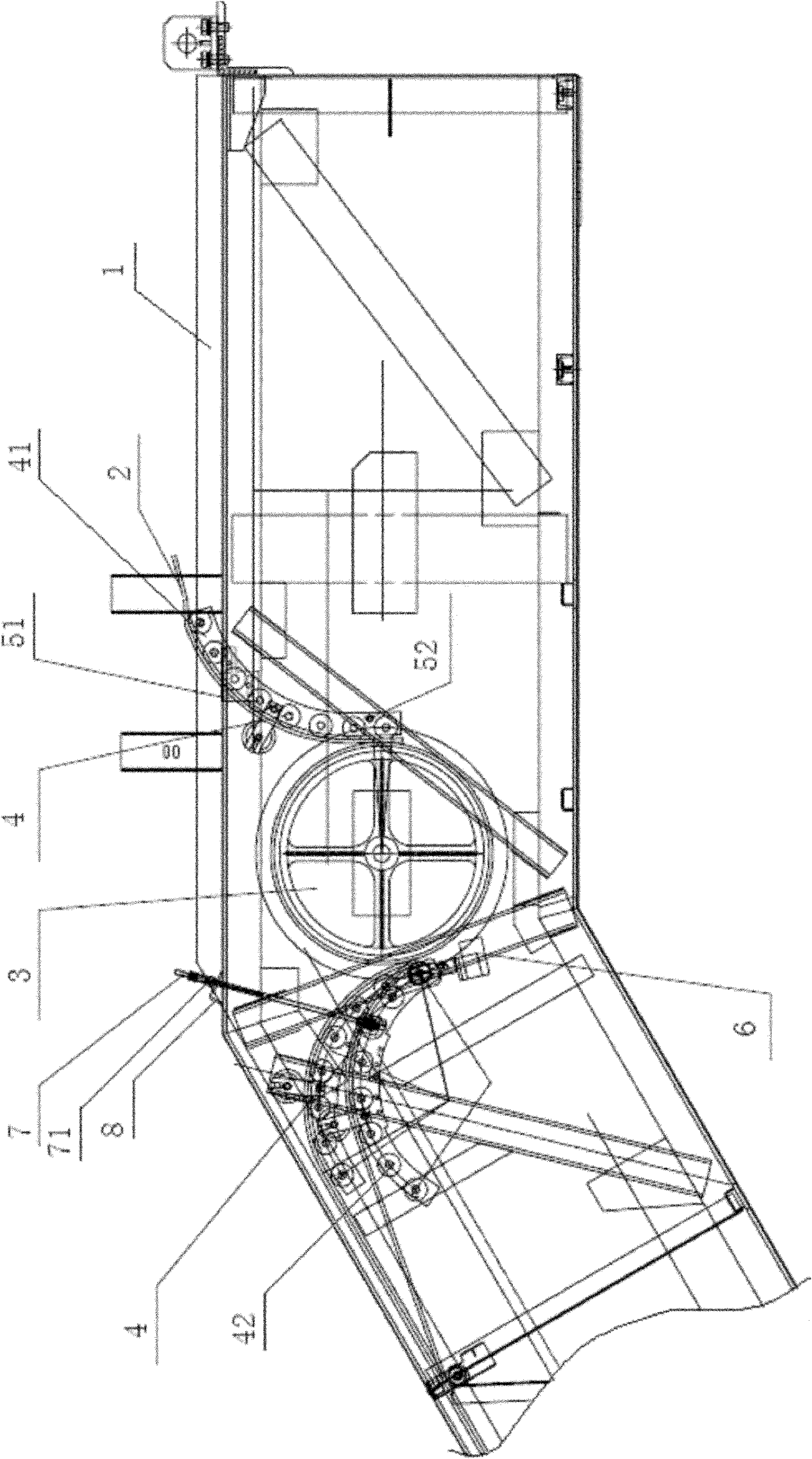

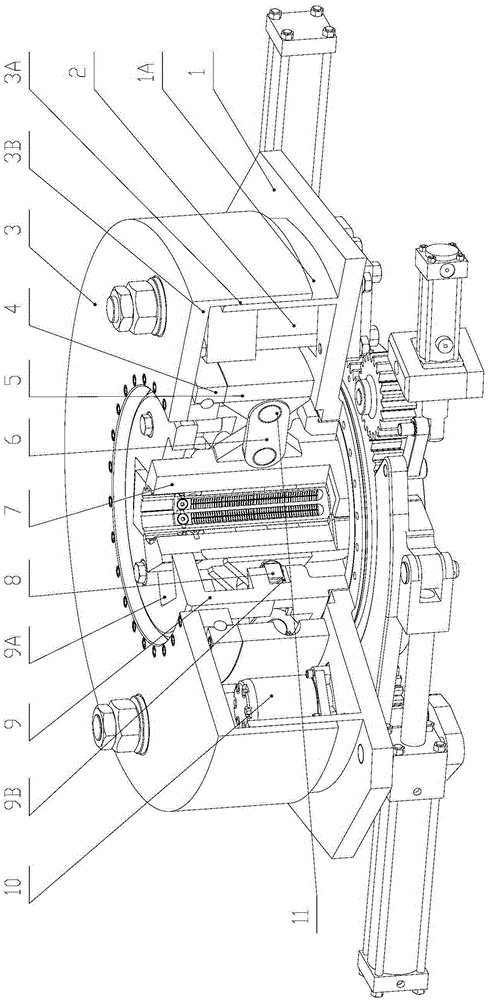

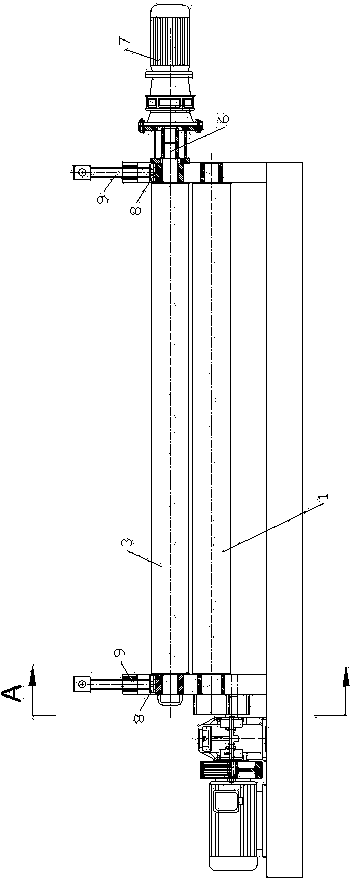

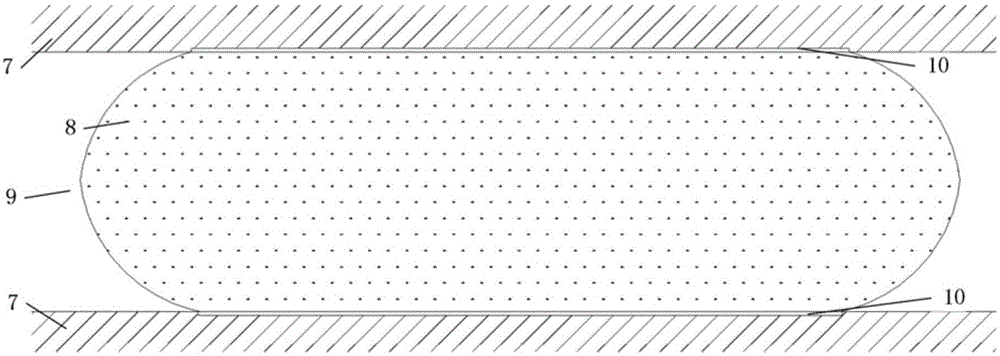

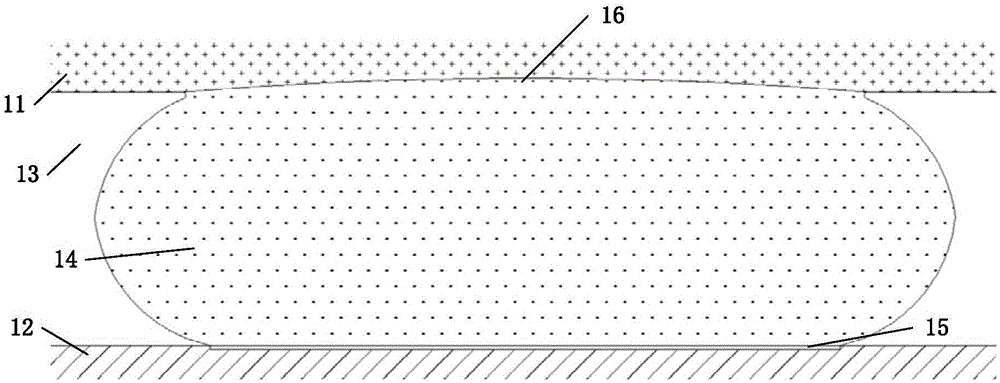

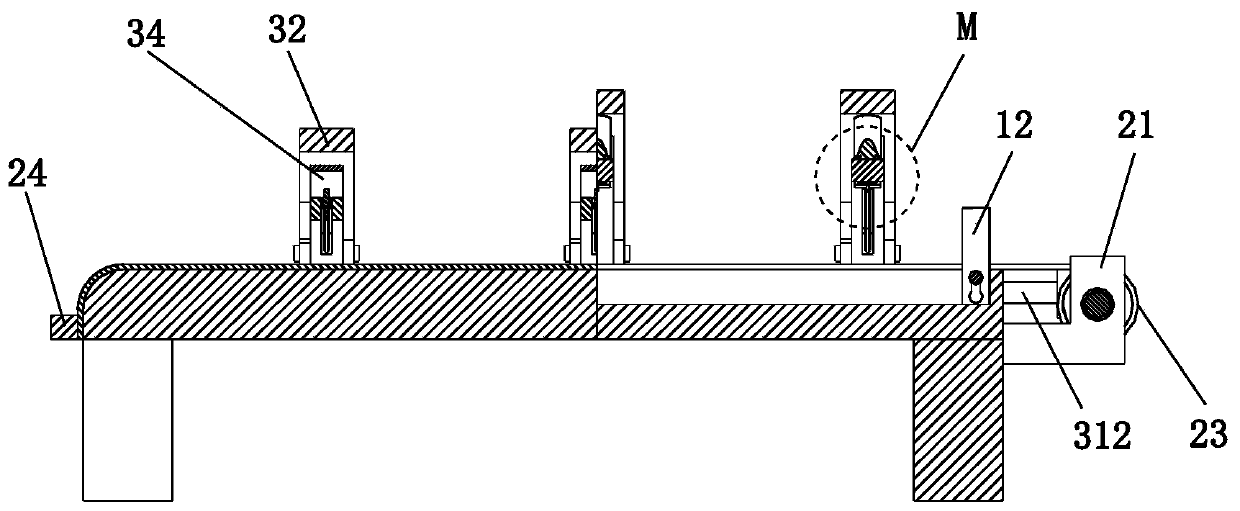

Mechanical forming drum and method thereof for realizing auxiliary turn-up of tire embryo slit

According to a mechanical assembly drum assisting turn-up of tire embryo seam allowance and a method for realizing assisted turn-up provided in the invention, rubber ring structures capable of swelling when inflated are arranged at the interior and exterior side of the tire embryo seam allowance and form into capsules after inflation to realize internal and external extrusion to the part of seam allowance, thereby improving quality of turn-up and compaction of the tire embryo seam allowance. The invention enables the operation of wrapping and compacting directed to the part of seam allowance to be realized and bubbles in the interior and exterior side of the tire embryo seam allowance to be completely eradicated, thereby substantially enhancing quality of turn-up of the part of the seam allowance. The mechanical assembly drum has a hollow cylindrical main shaft and a driving shaft which drives a locking piece assembly and a finger type turning up means for reciprocating motion; a rubber ring, which is connected with a locking piece unit and forms a closed ring structure around the periphery of the main shaft, is provided on the top of a locking piece cylinder body; two ends at the exterior side of the rubber ring are respectively fixed on the interior and exterior side of the locking piece cylinder body; a breather pipeline of the locking piece cylinder body communicates with the interior of the rubber ring. When the rubber ring is inflated, internal and external capsules are formed for direct wrapping, compacting and venting of the part of the seam allowance.

Owner:MESNAC

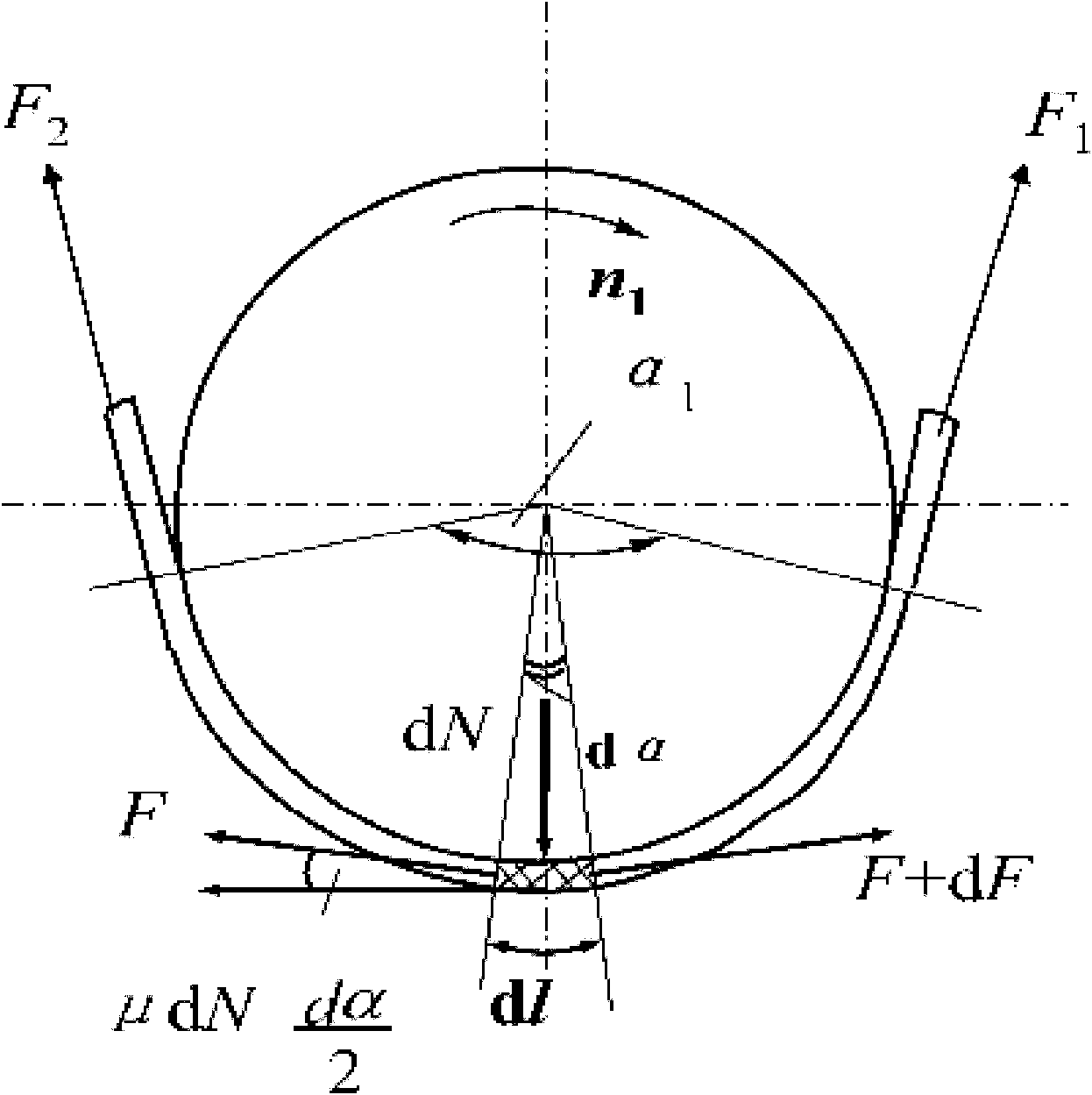

Escalator with Euler handrail driving system

Owner:上海爱登堡电梯集团股份有限公司

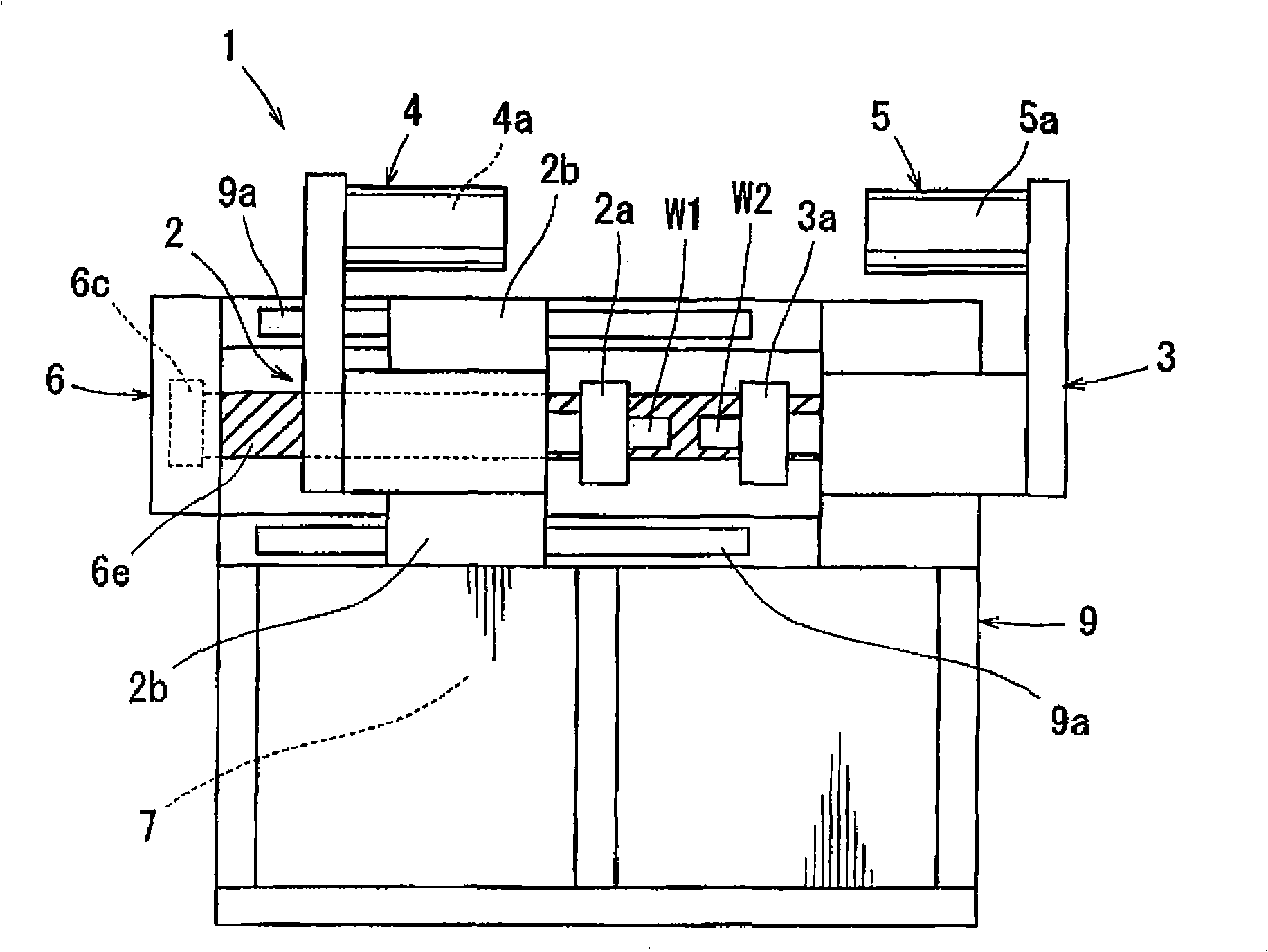

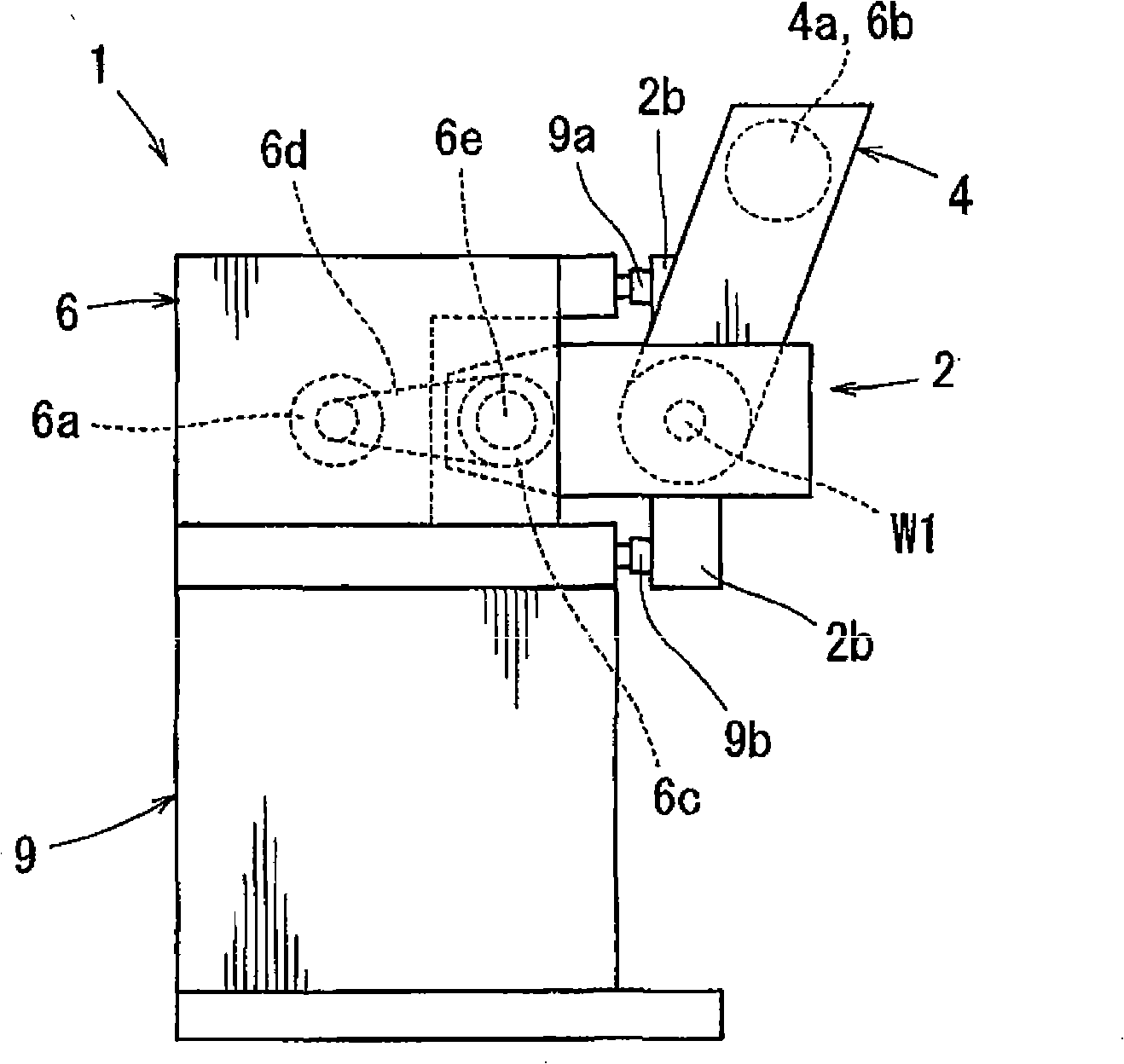

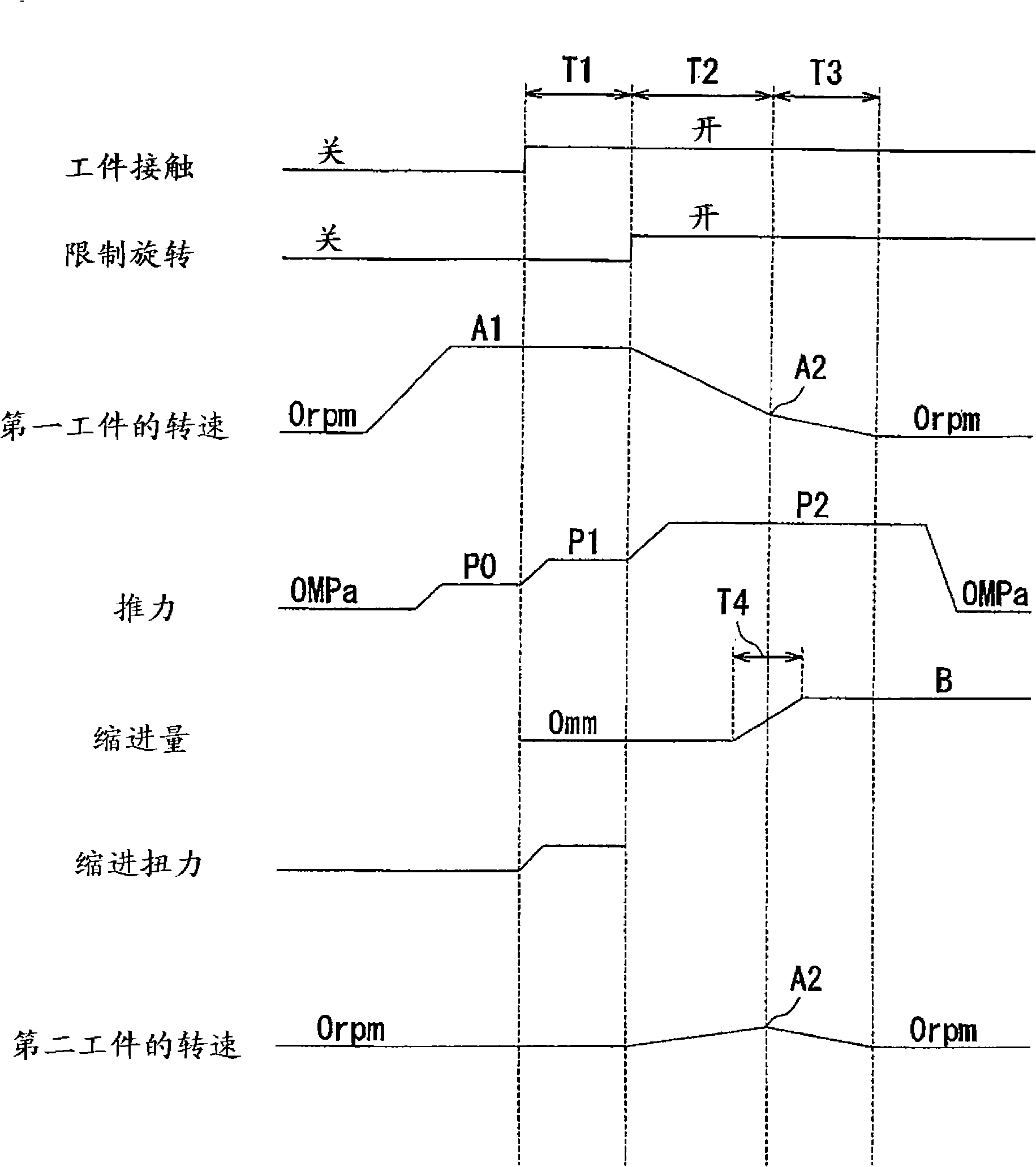

Friction welding methods and friction welding apparatuses

Owner:TOYOTA IND CORP +1

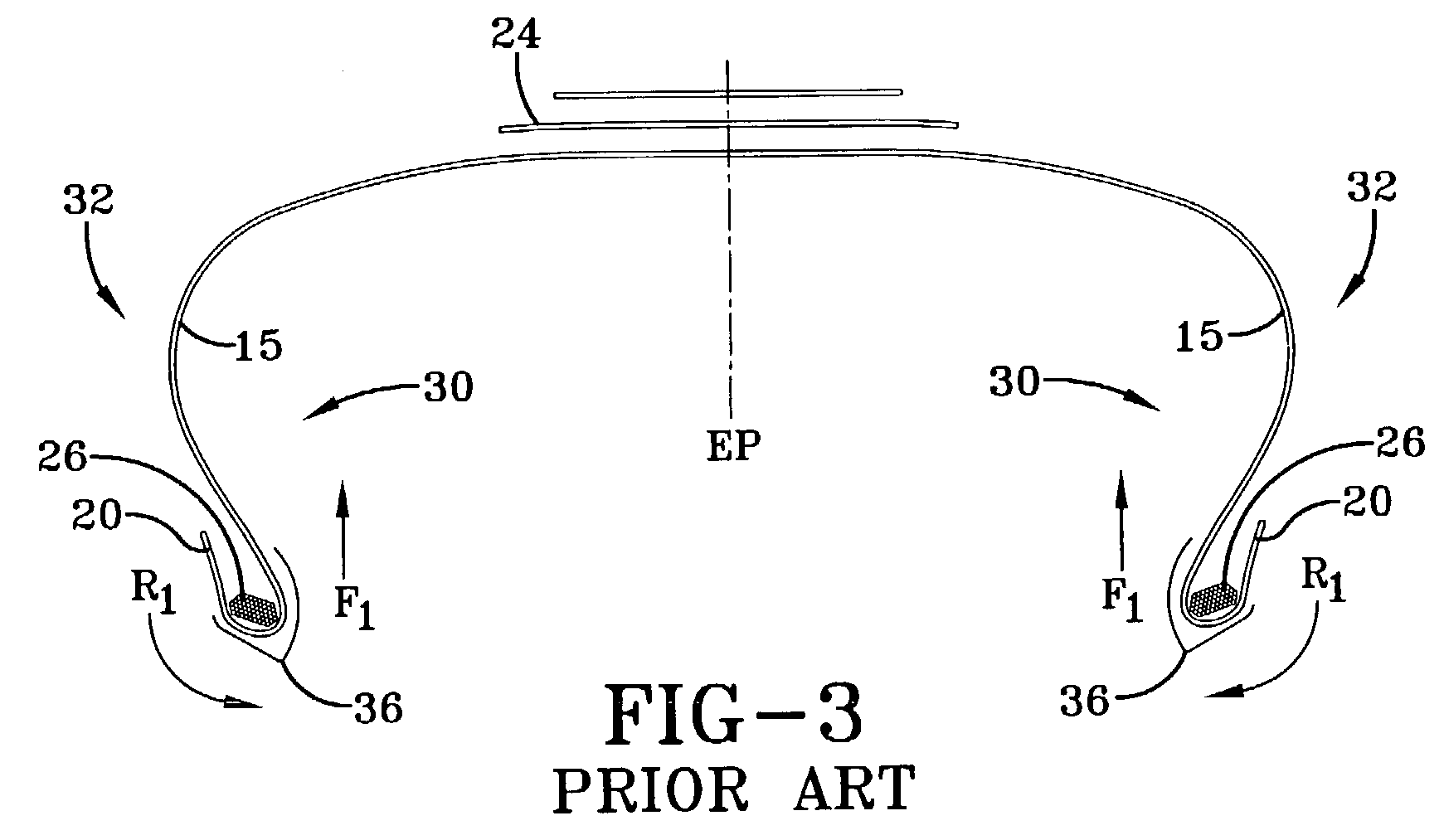

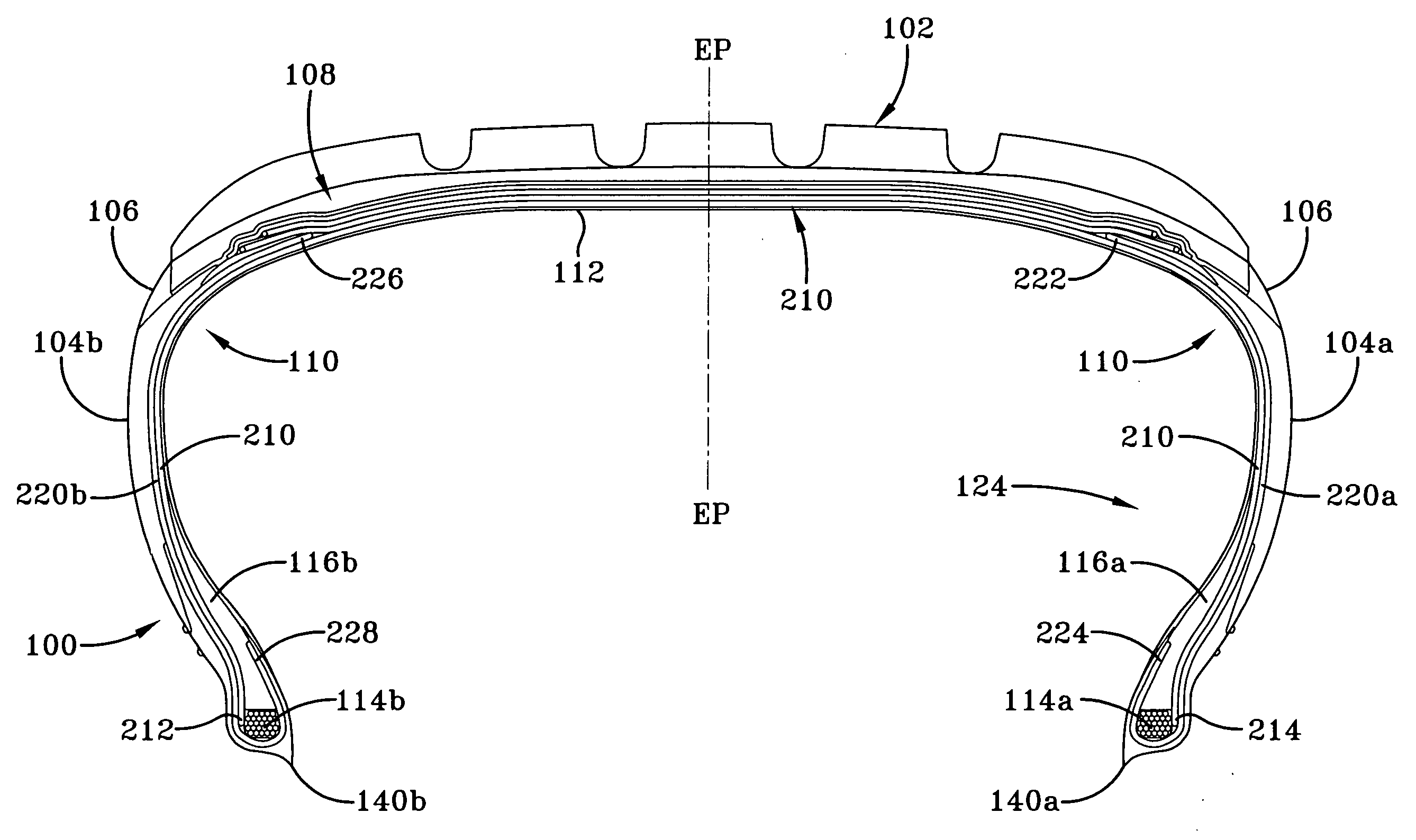

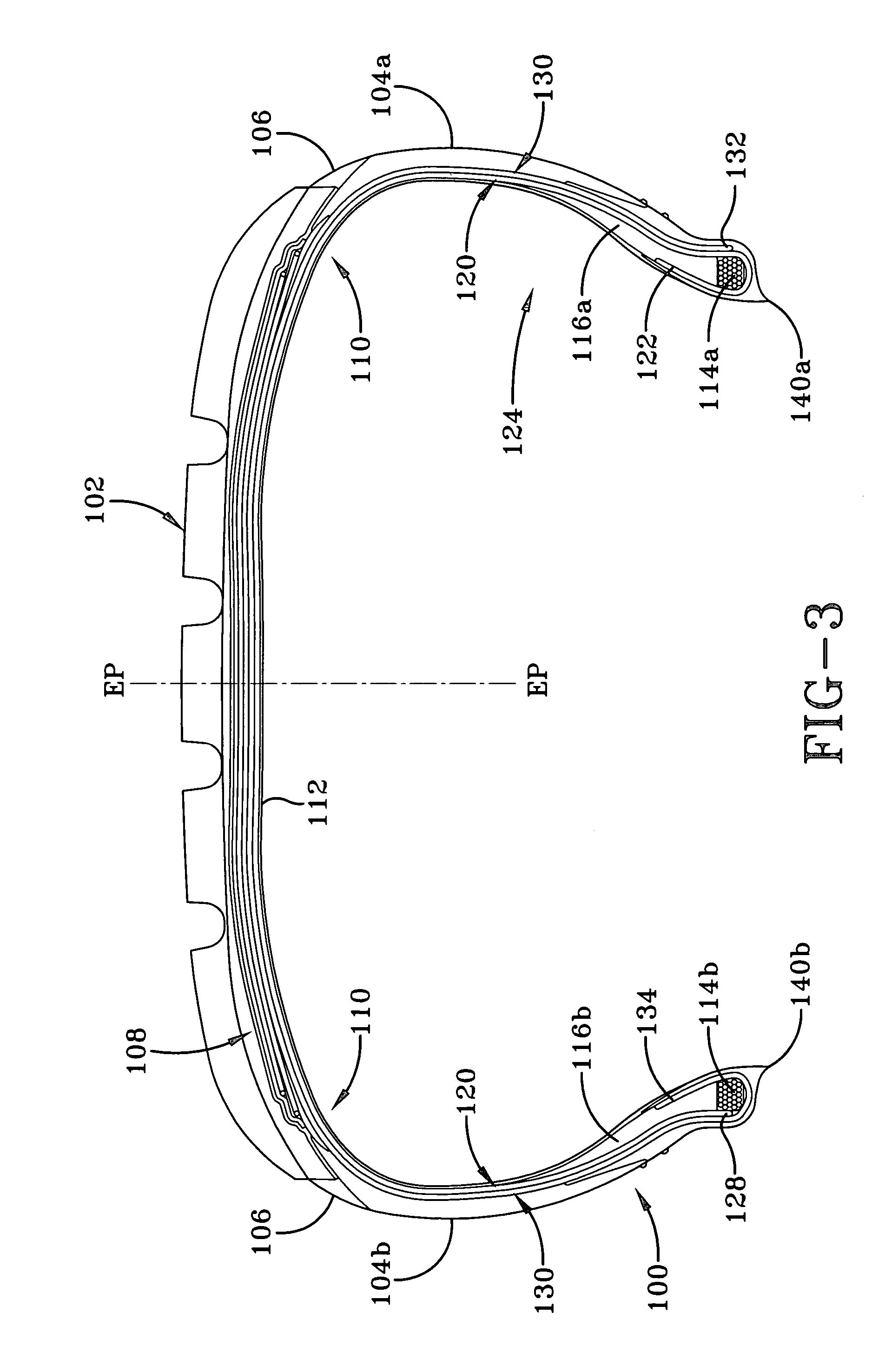

Tire with turned down ply construction

InactiveUS7509987B2Smooth connectionStable supportTyresPneumatic tyre reinforcementsTire beadEngineering

A tire having an outside-in ply construction is provided which torques the tire bead into the rim of the wheel to which it is mounted. The tire has first and second axially-spaced bead cores, a carcass having at least one belt extending under a tread, and a first ply layer having first and second ends. A first end is located axially outside and adjacent a first bead core, and a second end folds from a position axially outside a second bead core to a position axially inside and around the second bead core. The carcass further comprises a second ply layer having first and second ends, a first end is located axially outside and adjacent the second bead core, and a second end that folds from a position axially outside a first bead core to a position axially inside and around the first bead core. The tire may also comprise a first and second axially-spaced bead core, a carcass having at least one belt extending under a tread, and a first ply layer having first and second ends, a first end is located axially outside and adjacent a first bead core, and a second end that is located axially outside and adjacent a second bead core. The carcass further comprises first and second shoulder ply layers each shoulder ply layer having first and second ends, a first end is located under the tread belt, the shoulder ply extending down the side wall region with the second end folding from a position axially outside a respective bead core to a position axially inside and around the bead core.

Owner:THE GOODYEAR TIRE & RUBBER CO

Method for manufacturing high-accuracy pure titanium rod

InactiveCN104493433ALow heating temperatureMetallographic structure has little influenceMicrometerTitanium

The invention discloses a method for manufacturing a high-accuracy pure titanium rod. The method includes the steps of blank preparation, blanking, cogging-down forging, deformation processing, annealing, thermal straightening, lathe machining, piece finishing and finished product packaging inspection. During lathe machining of a rod, diameter of the rod can be directly machined to be in the size of a finished product rod, and waste chips generated during turning of the rod can be recycled, so that economic value is increased; heating temperature is low during finishing, so that influence on metallographic structure of the rod is small, service life of the rod is prolonged, and mechanical strength of the rod is improved; due to low heating temperature, oxidation scale on the surface of the rod is extremely thin, total indentation of the rod is small during straightening, grinding is not needed after straightening, and requirements, on coarseness of 1.6 micrometers and size tolerance, of the finished product rod can be met by directly polishing for two times.

Owner:QINGDAO MATE RUIOU NEW MATERIAL TECH CO LTD

Cylinder head gasket

Owner:ISHIKAWA GASKET CO LTD +1

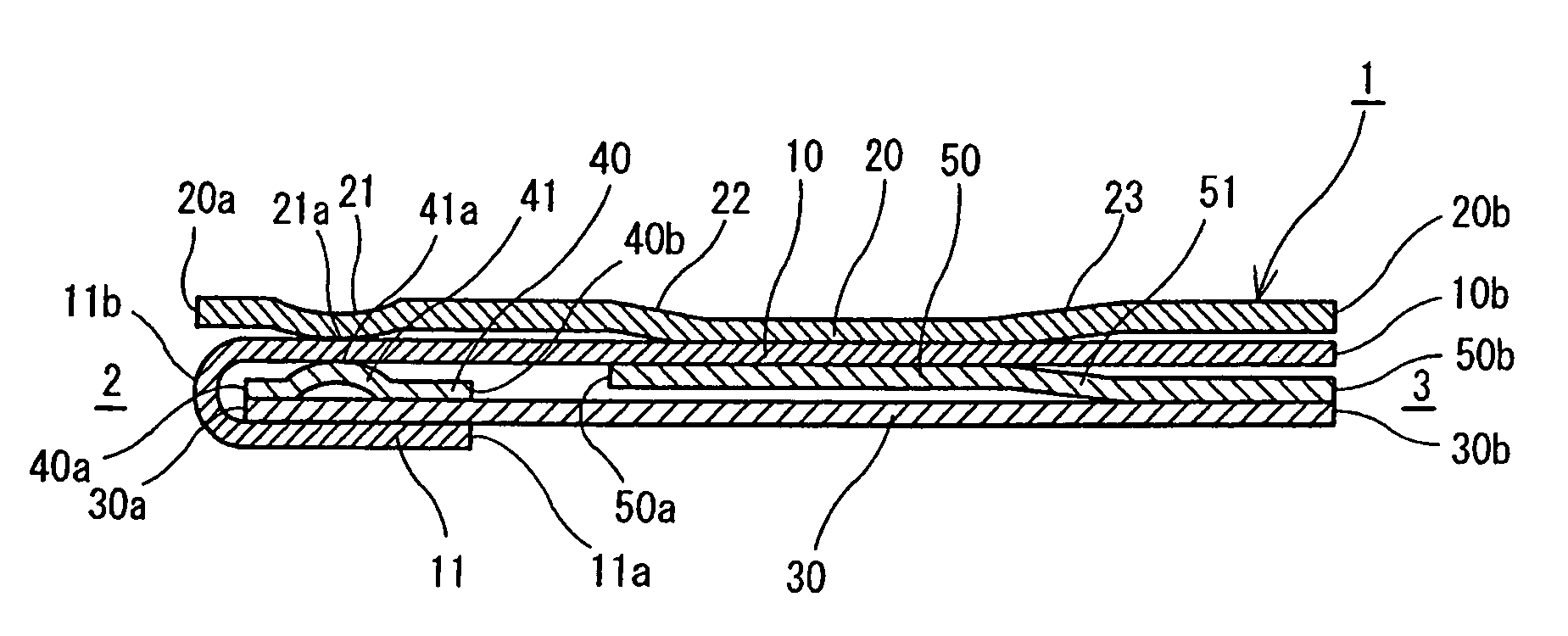

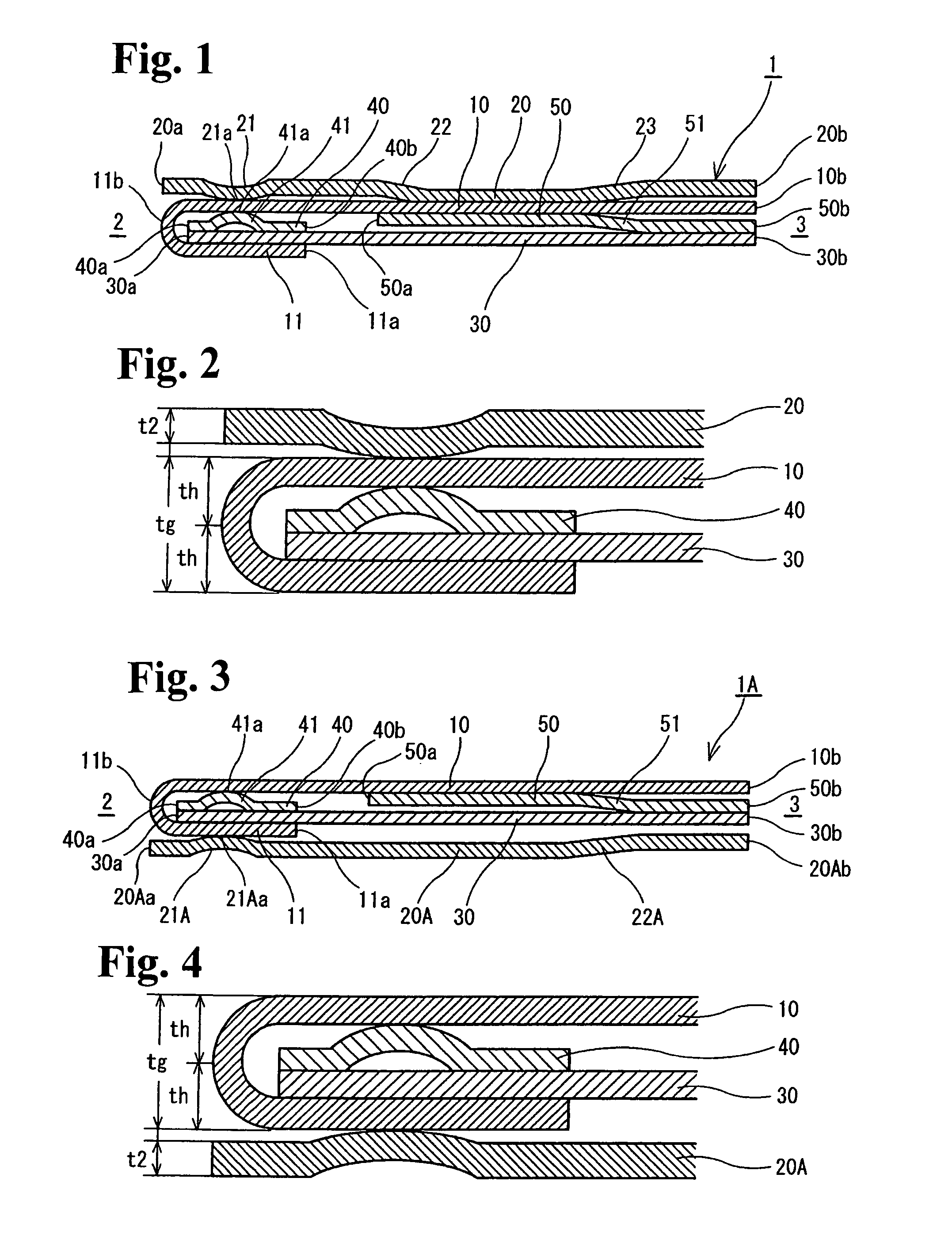

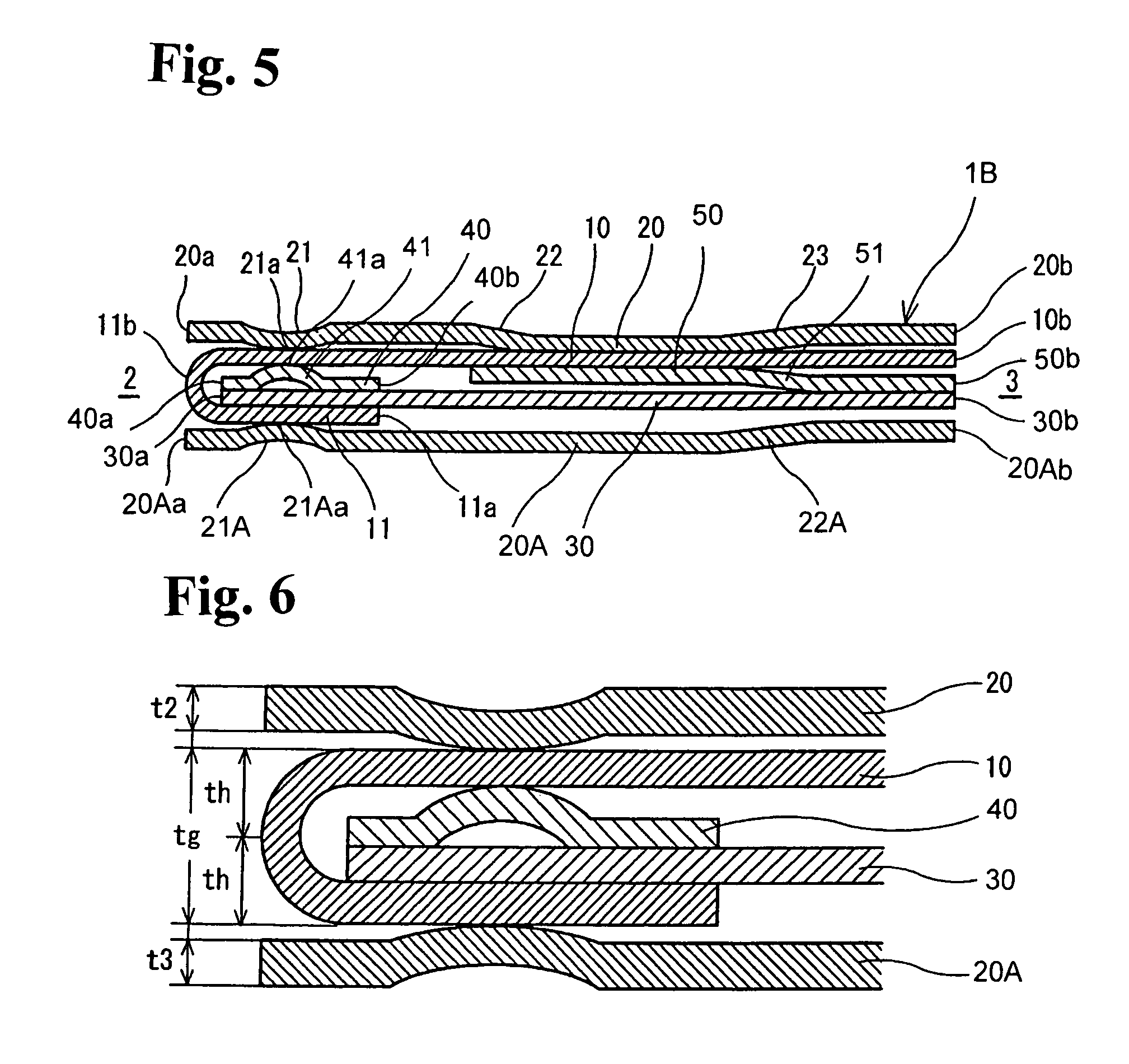

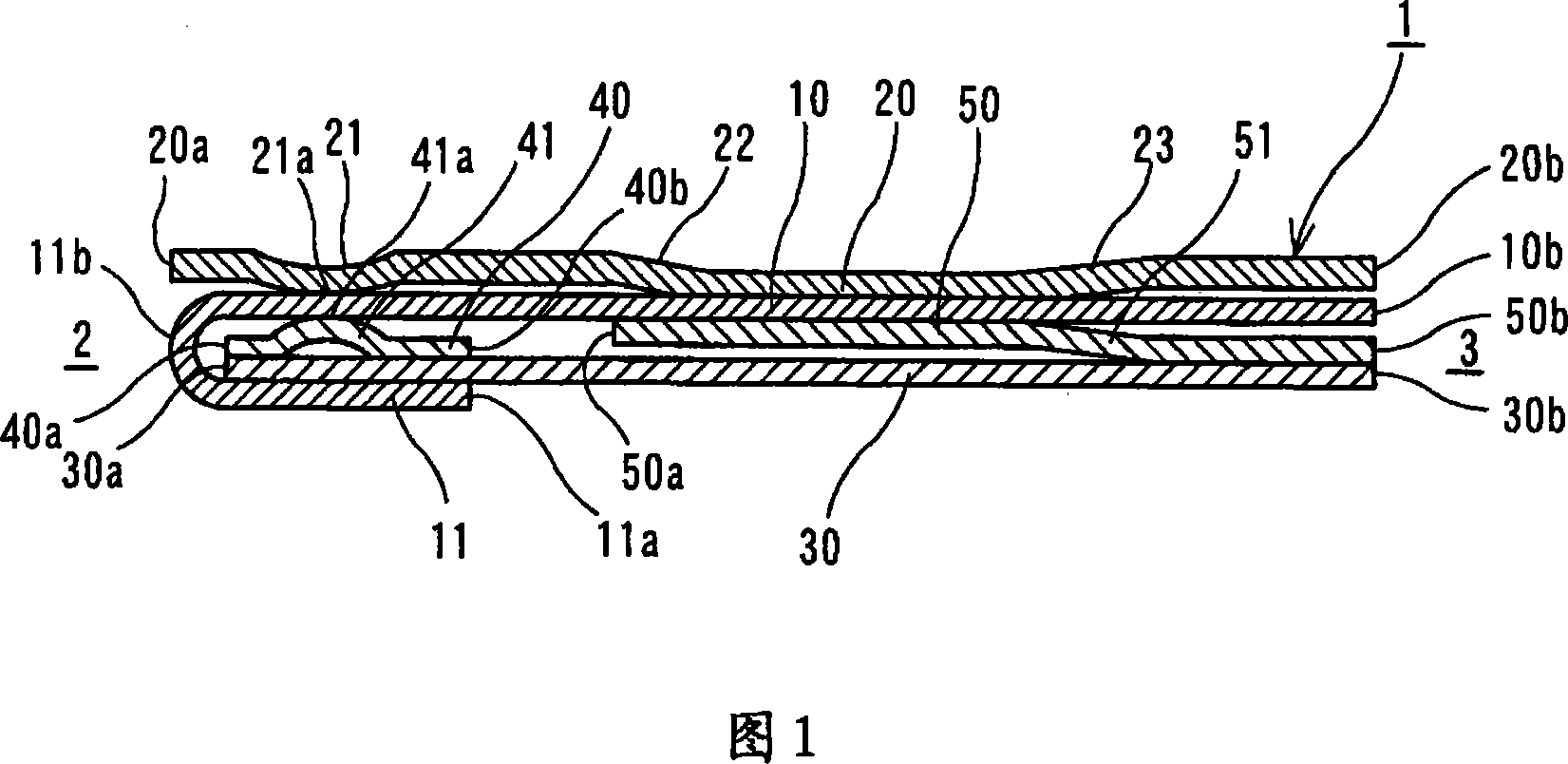

Cylinder head gasket

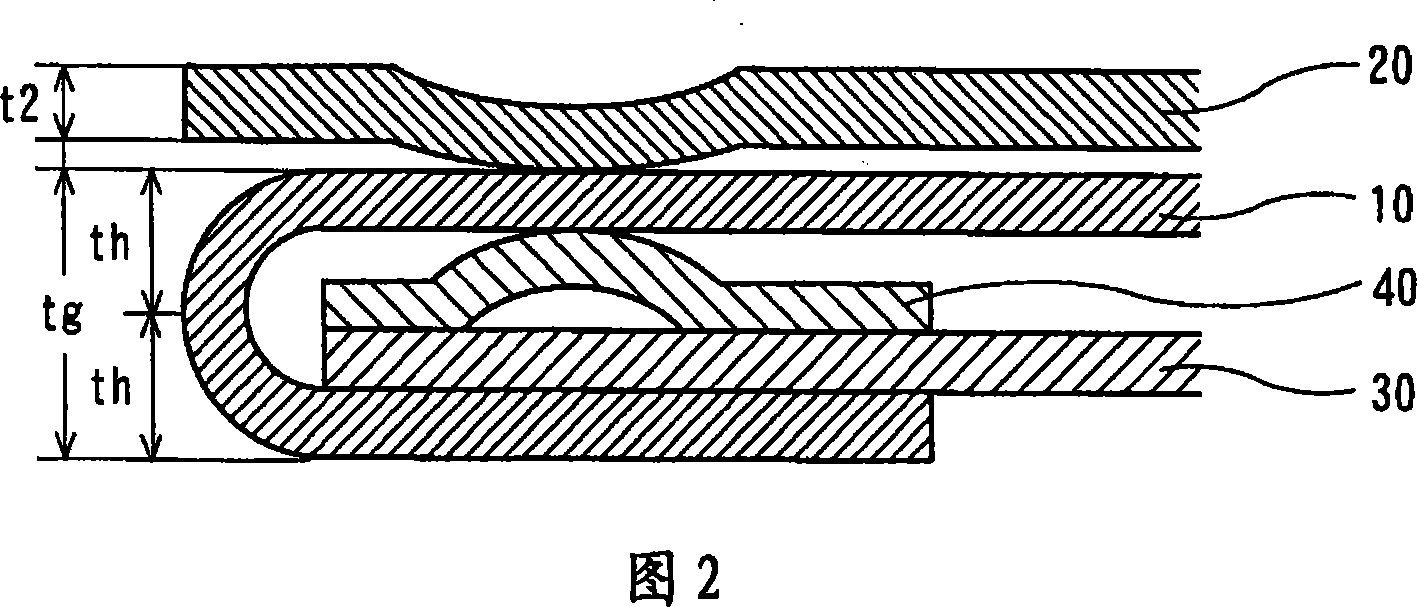

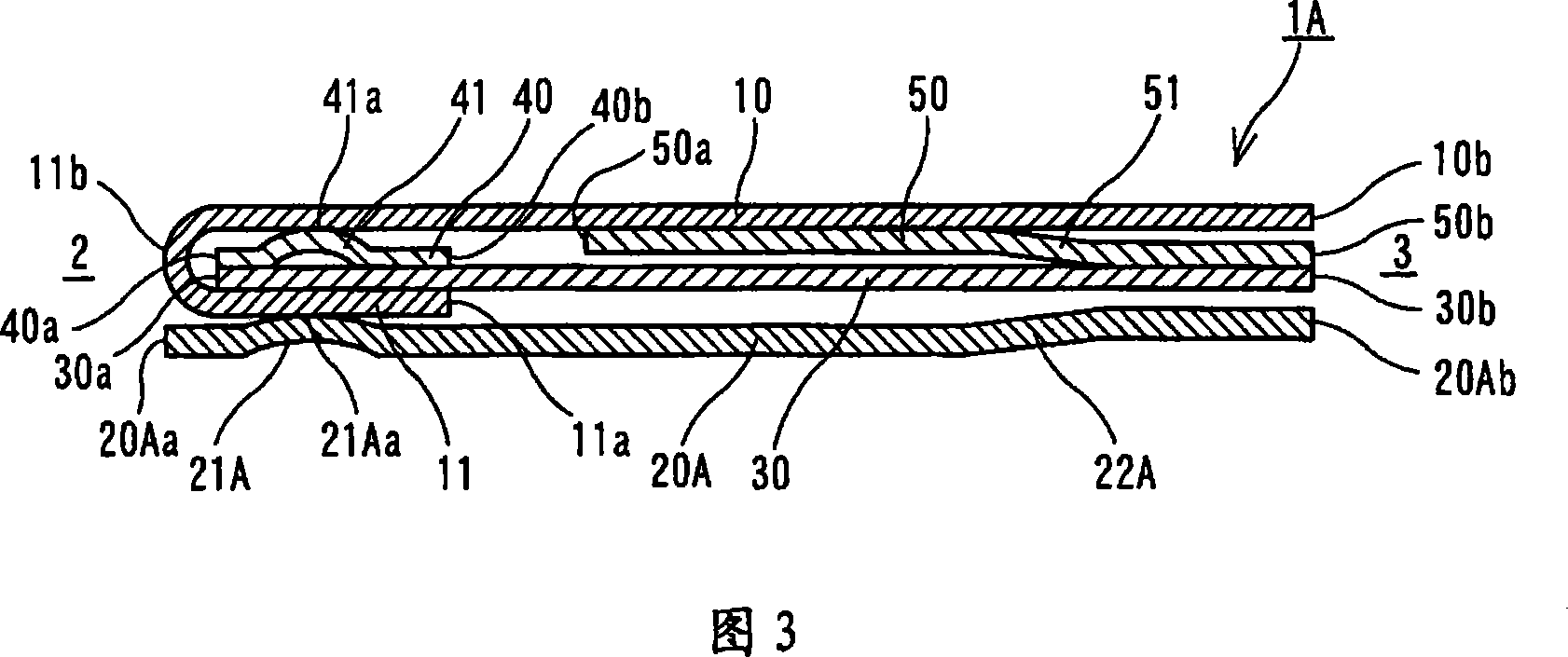

InactiveCN101074730AAvoid deformationAdequate airtightnessEngine sealsSealing arrangements for enginesCylinder headEngineering

The invention provide a cylinder head gasket having sufficient sealing performance around a cylinder bore hole while suppressing the deformation of a cylinder bore of an engine. The cylinder head gasket 1 comprises: a first metal structural plate 10 having a folded back portion 11 and formed around the cylinder bore hole 2; and full beads 21 formed opposite to each other on a second metal structural plate 20 and a third metal structural plate 30, respectively, holding the first metal structural plate 10 therebetween with their protrusions on the sides of the first metal structural plate 10, the full beads 21 which have protruded portions 21a arranged on the inner periphery side of an end 11a of the folded back portion 11. At least one or more sub plates 40, 50 are inserted and arranged inside the folded back portion 11. Thicknesses t2 of the second metal structural plate 20 and the third metal structural plate 30 around the cylinder bore hole 2 are respectively smaller than a half th of a thickness tg of the folded back portion 11.

Owner:TOYOTA JIDOSHA KK +1

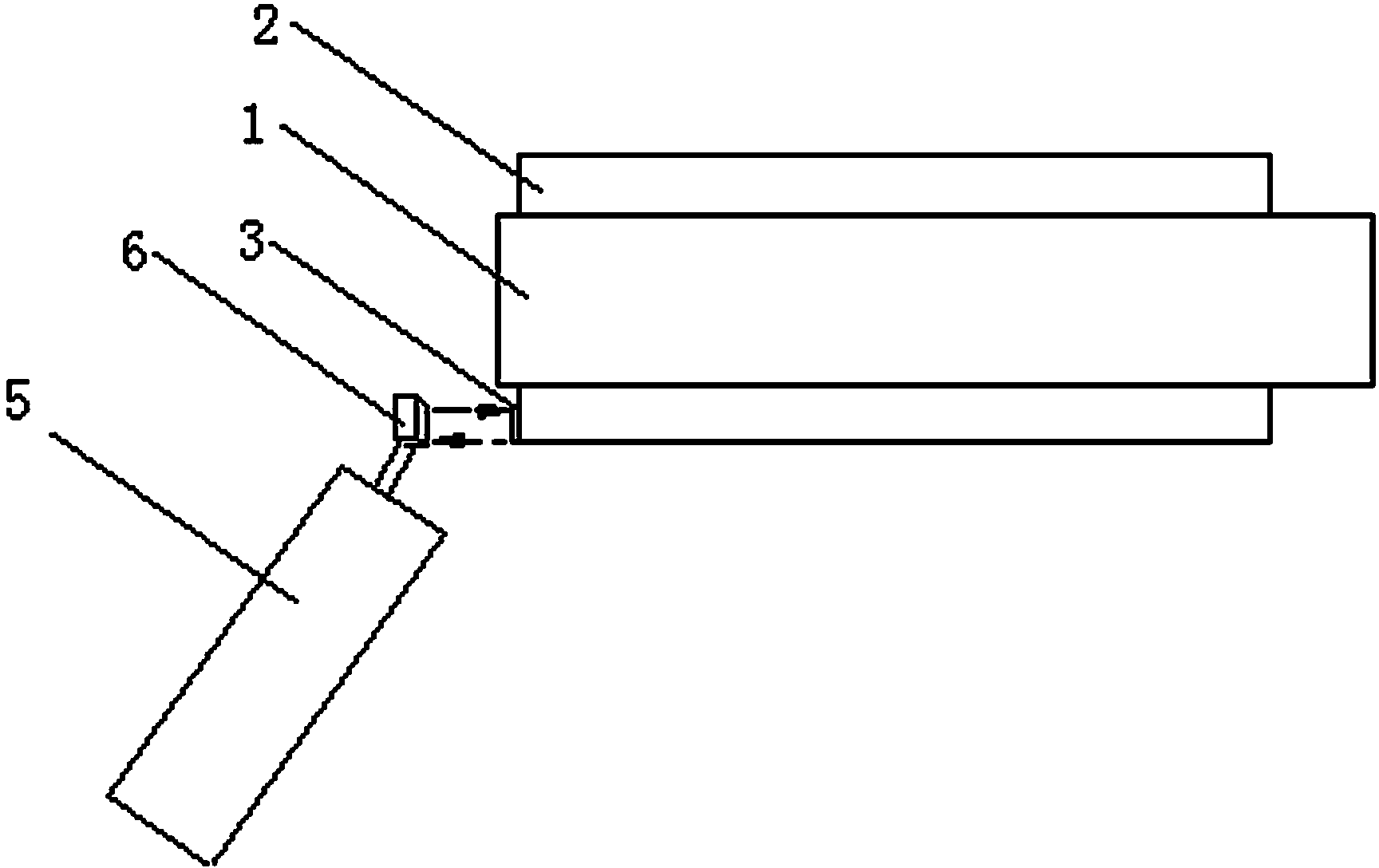

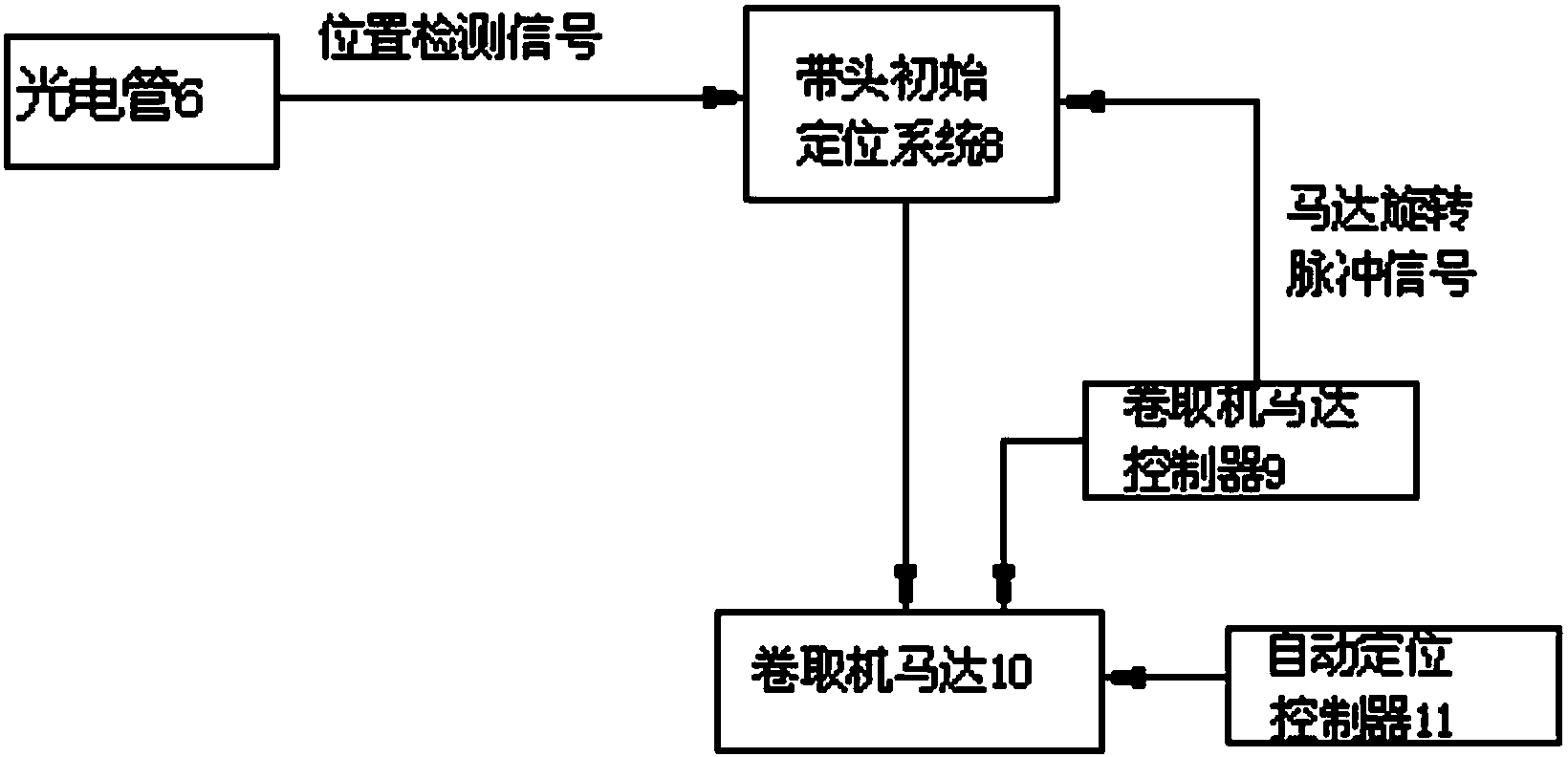

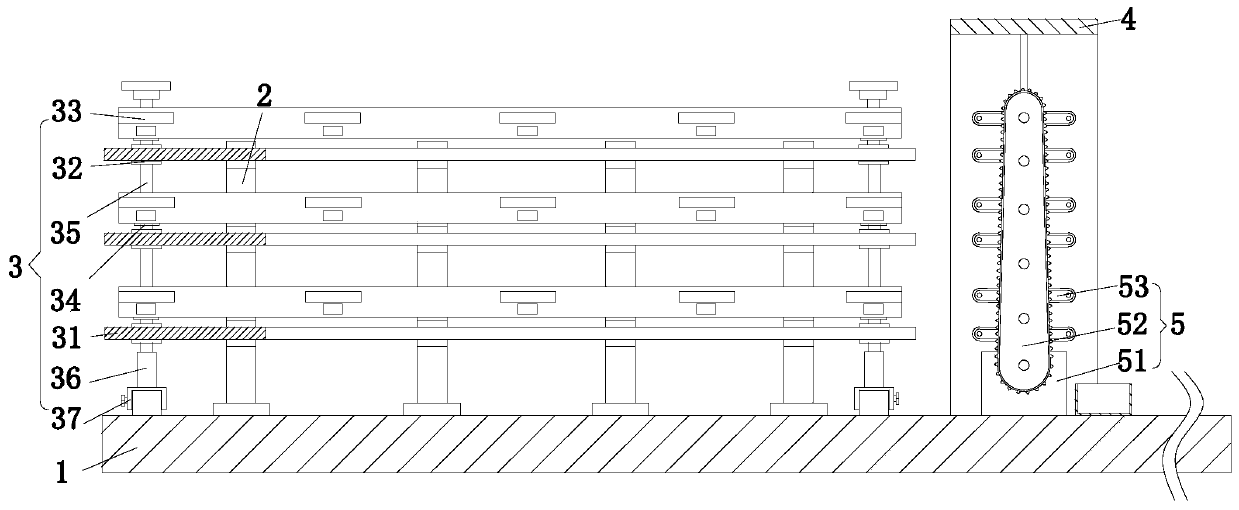

Self-threading tape positioning device of soft tape sleeve in outlet of cold rolling and continuous annealing unit and positioning method thereof

InactiveCN104028581ASimple structureReasonable designRoll mill control devicesMetal rolling arrangementsEngineeringStrip steel

The invention discloses a self-threading tape positioning device of a soft tape sleeve in an outlet of a cold rolling and continuous annealing unit and a positioning method thereof, and relates to the technical field of strip steel reeling machines. The device comprises a mandrel, the soft tape sleeve, a reflective sheeting, a soft area, an outer supporting arm and a phototube, wherein the soft tape sleeve is sleeved at the outer side of the mandrel; the soft area is penetrated through the soft tape sleeve from front to back; the reflective sheeting is arranged at the front end, opposite to the soft area, of the soft tape sleeve; and the phototube is mounted on the outer supporting arm at the operation side of the soft tape sleeve. The soft area is arranged on the sleeve; the automatic control from leading positioning to the soft area is realized through the program modification; and a simple and efficient self-threading tape method is realized, so that the generation of impressions in the strip steel reeling process is reduced, the material is saved, the cost is decreased, and the production efficiency is guaranteed.

Owner:SHANGHAI KEQI ELECTRICAL TECH CO LTD

Tire with turned down ply construction

InactiveUS20070113947A1Smooth connectionStable supportTyresPneumatic tyre reinforcementsTire beadEngineering

A tire having an outside-in ply construction is provided which torques the tire bead into the rim of the wheel to which it is mounted. The tire has first and second axially-spaced bead cores, a carcass having at least one belt extending under a tread, and a first ply layer having first and second ends. A first end is located axially outside and adjacent a first bead core, and a second end folds from a position axially outside a second bead core to a position axially inside and around the second bead core. The carcass further comprises a second ply layer having first and second ends, a first end is located axially outside and adjacent the second bead core, and a second end that folds from a position axially outside a first bead core to a position axially inside and around the first bead core. The tire may also comprise a first and second axially-spaced bead core, a carcass having at least one belt extending under a tread, and a first ply layer having first and second ends, a first end is located axially outside and adjacent a first bead core, and a second end that is located axially outside and adjacent a second bead core. The carcass further comprises first and second shoulder ply layers each shoulder ply layer having first and second ends, a first end is located under the tread belt, the shoulder ply extending down the side wall region with the second end folding from a position axially outside a respective bead core to a position axially inside and around the bead core.

Owner:THE GOODYEAR TIRE & RUBBER CO

Method for preparing high-accuracy titanium and titanium alloy bars

InactiveCN103659280AMetallographic structure has little influenceExtended service lifeOther manufacturing equipments/toolsTitaniumTitanium alloy

The invention provides a method for preparing high-accuracy titanium and titanium alloy bars. The method comprises the steps of preparing a blank, blanking, cogging and forging, performing deformation processing, annealing, hot straightening, turning, finishing, and inspecting a finished product and packing. According to the method, the bars are turned before finishing treatment, the diameter of the bars can be directly processed into the size of finished bars, sweeps generated by turning the bars can be recycled, and the economic value is high; the heating temperature is low during finishing treatment, metallographic structures of the bars are influenced a little and nearly not changed, the service life of the bars is prolonged, and the mechanical strength of the bars is enhanced; meanwhile, because the heating temperature is low during finishing treatment, oxide skins on the surfaces of the bars are very thin, the indentations of the integral bars are small in the straightening process, the bars are not required to be ground after straightening, directly enters a polishing machine and are polished twice to meet the requirements of the finished bars on roughness 1.6[mu]m and size tolerance.

Owner:BAOJI MINGHAI TITANIUM IND

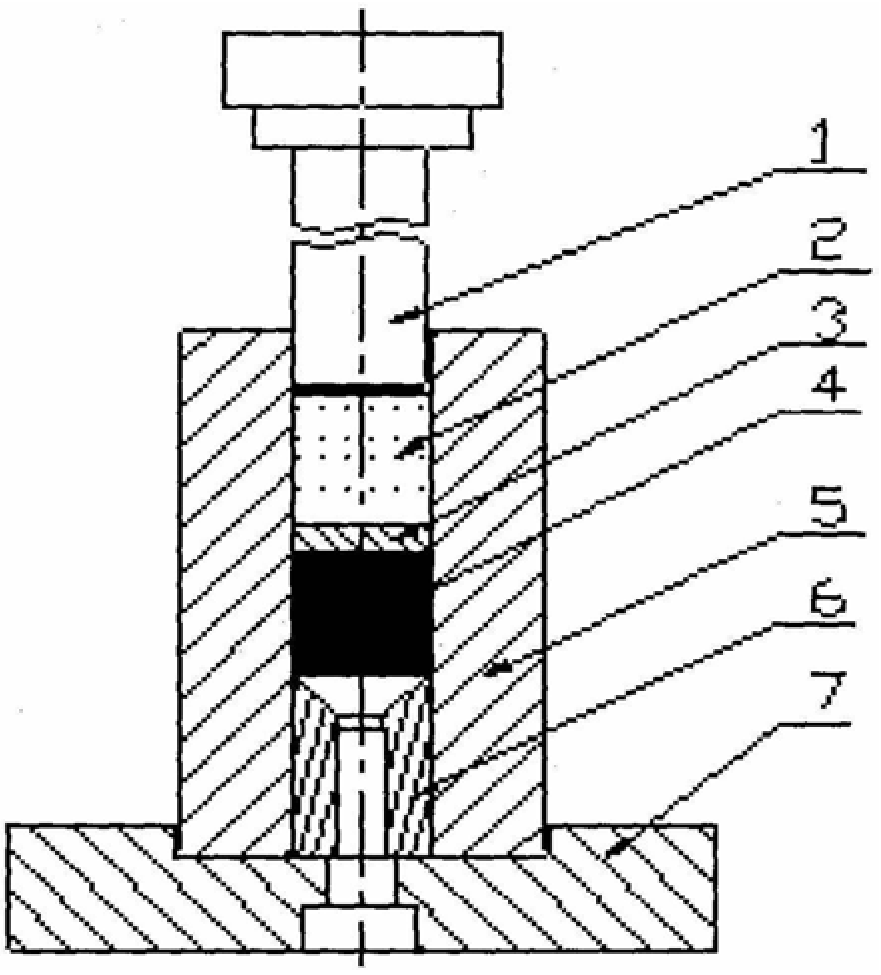

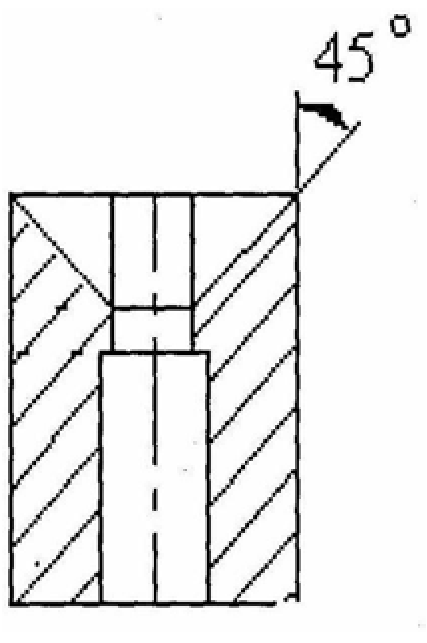

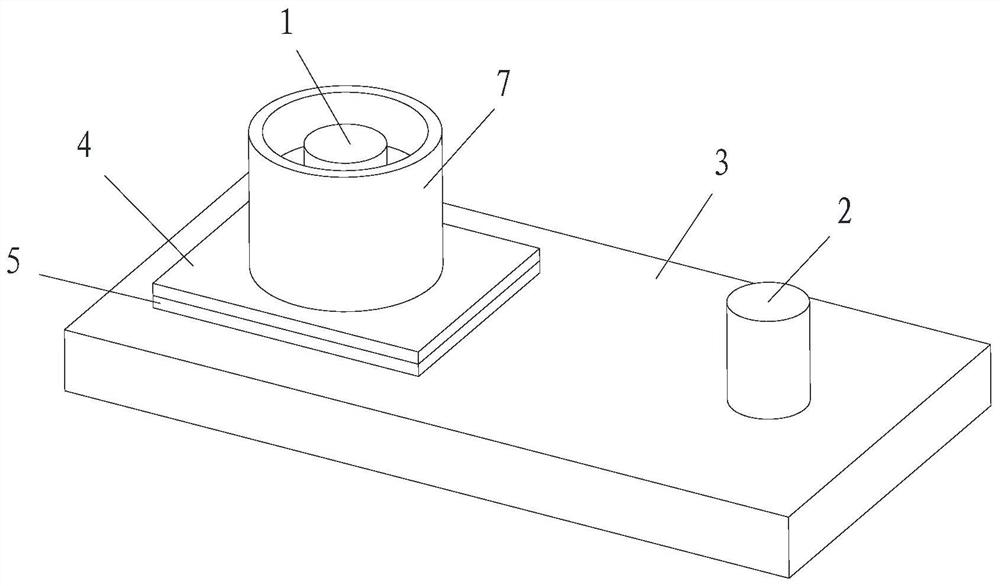

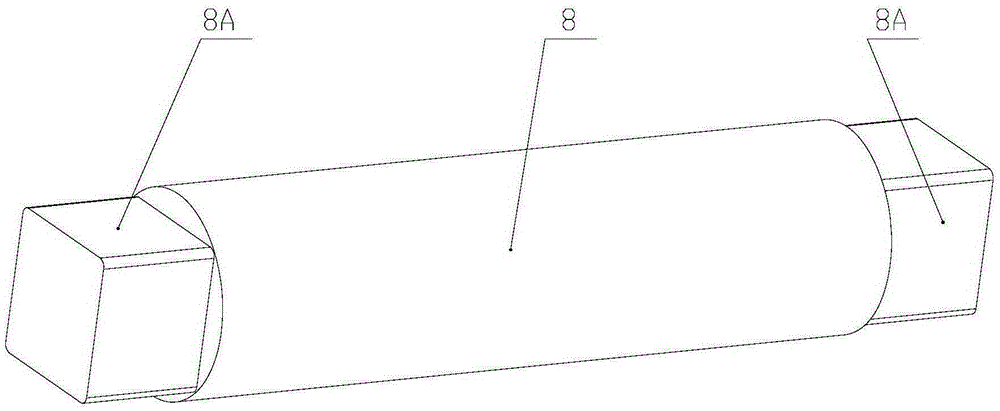

Cobalt Regulating Rod Component Pellet Extrusion Forming Technology and Its Die

The present invention provides a cobalt regulating rod assembly core block extrusion molding process, which is carried out as follows: (1) using powder metallurgy method to form a cobalt green body; (2) sintering and turning the cobalt green body to the extrusion required Size; (3) put the cobalt green body into the mold and extrude it into a cobalt rod; (4) cut the extruded cobalt rod to obtain a cobalt pellet of the required size; (5) anneal and dehydrogenate the cobalt pellet ; (6) finishing the cobalt pellets to the required size; (7) cleaning the cobalt pellets, and then performing nickel plating. Through the extrusion molding of the method of the present invention, the cobalt regulating rod core block with smooth surface and high and uniform density is prepared, which saves manpower and material resources, reduces mold manufacturing and maintenance costs, and at the same time, the density of the cobalt regulating rod core block is also improved The 8.6g / cm3 increased to 8.7g / cm3.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

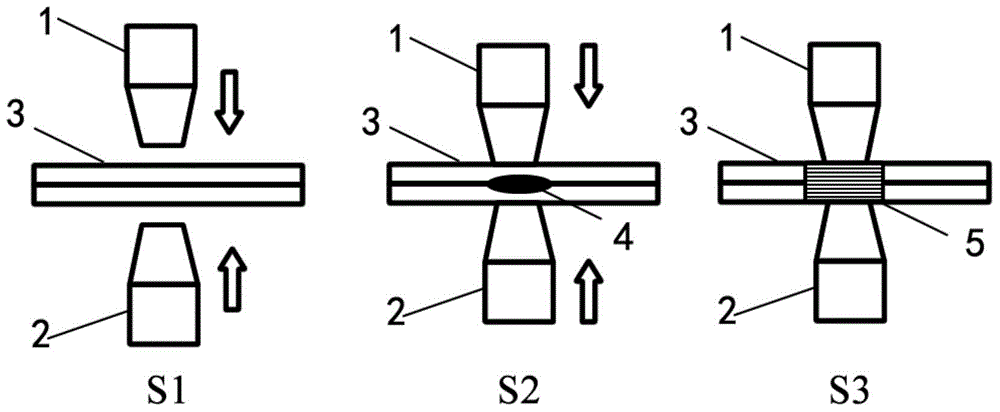

Magnetic auxiliary welding device and method

ActiveCN112077434AGuaranteed against oxidationAvoid electrolytic decolorizationNon-electric welding apparatusMetallurgyEngineering

Embodiments of the invention provide a magnetic auxiliary welding device and method. The welding device comprises a first electrode, a second electrode, a substrate, a first to-be-welded workpiece, asecond to-be-welded workpiece and magnetic units, wherein the first to-be-welded workpiece and the second to-be-welded workpiece are arranged between the first electrode and the substrate in an overlapped mode; the second electrode and the second to-be-welded workpiece abut against the substrate; the magnetic units are annularly arranged on the outer side of the first electrode; the first electrode abuts against the surface of the first to-be-welded workpiece, and nuggets are formed between the first to-be-welded workpiece and the second to-be-welded workpiece; and the magnetic units are usedfor stirring the nuggets. According to the embodiments of the invention, the magnetic units are arranged around the electrodes, the stirring magnetic field for stirring the nuggets is generated in theto-be-welded workpieces, and the three-dimensional coincidence real-time regulation and control is carried out on the welding area under the interaction of the stirring magnetic field and the weldingcurrent, so that the microhardness of the internal structures of the nuggets is increased in mechanism, the nugget form is improved, and the softening effect of a melting area in the axial directionis weakened to reduce indentations.

Owner:CRRC QINGDAO SIFANG CO LTD

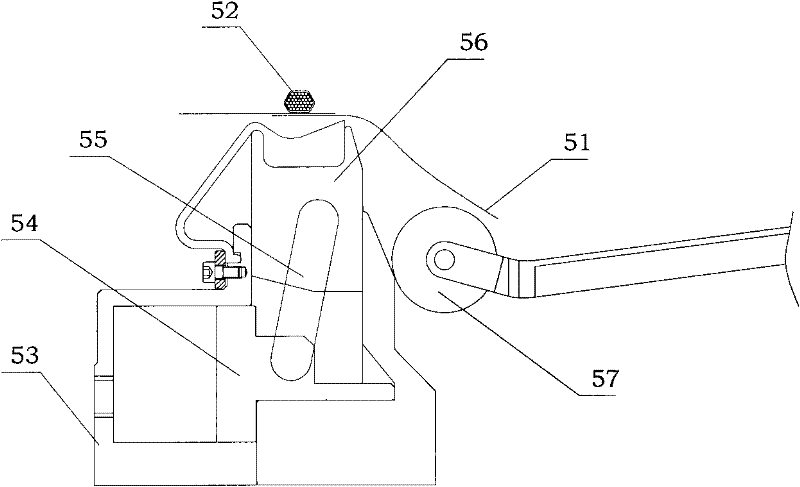

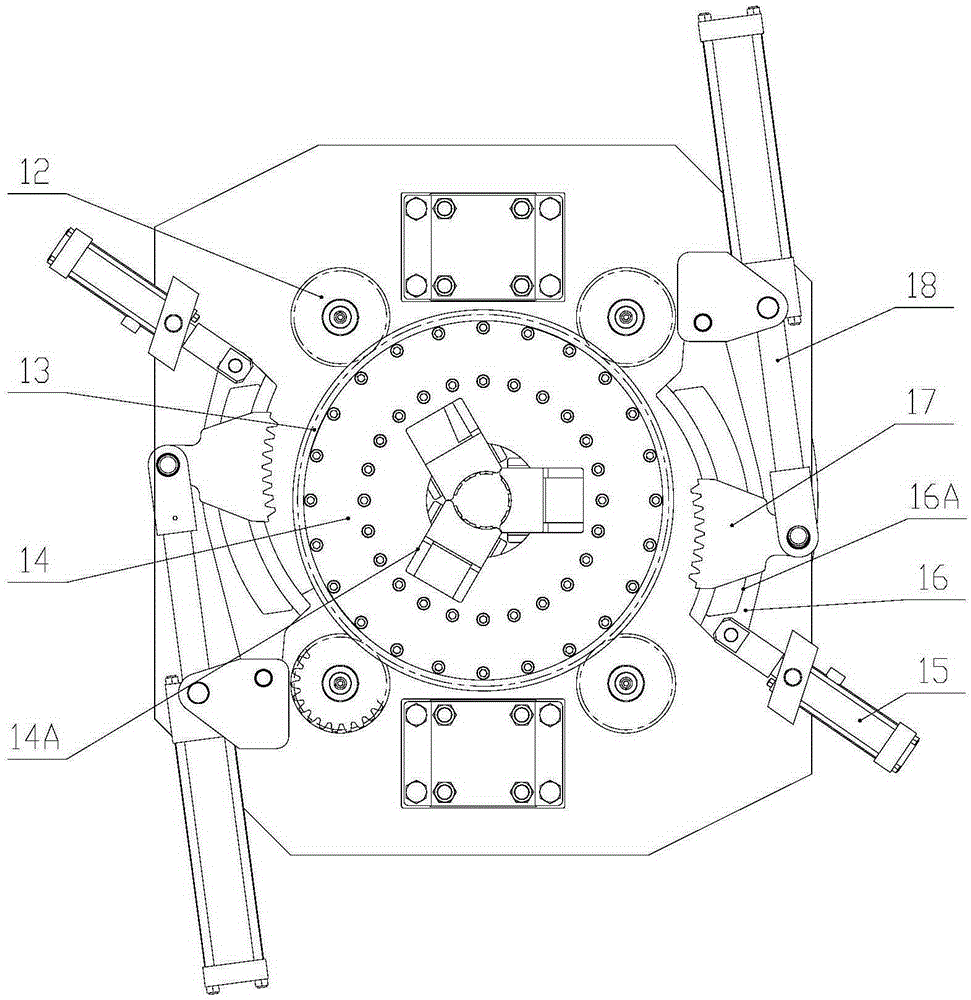

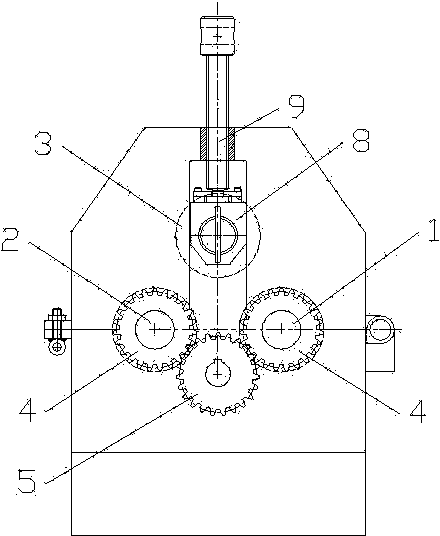

Annular drill pipe power tong

ActiveCN105239941AReduce indentationCompact structureDrilling rodsDrilling casingsEngineeringDrill pipe

The invention provides an annular drill pipe power tong. The annular drill pipe power tong comprises a base and a clamping mechanism; the base comprises a central through hole; the clamping mechanism comprises a driving assembly, a gland assembly that can be driven by the driving assembly to move in an axial direction of the central through hole, a plurality of power tong slips distributed in a circumferential direction of the central through hole, and a connecting rod, wherein one end of the connecting rod is hinged to the gland assembly, while the other end of the connecting rod is hinged to the power tong slips; when the driving assembly drives the gland assembly to move in the axial direction of the central through hole, the gland assembly is capable of driving the power tong slips to close in or expand in a radial direction of the central through hole through the connecting rod. The annular drill pipe power tong is capable of clamping a drill pipe in a continuously circular drilling process, and providing enough clamping force to the drill pipe to ensure no relative sliding between the annular drill pipe power tong, the drill pipe and the clamping mechanism after the drill pipe is clamped and to guarantee that an indentation of the drill pipe is as small as possible.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Three-roller transmission veneer reeling machine

The invention provides a three-roller transmission veneer reeling machine. The three-roller transmission veneer reeling machine can facilitate reeling and comprises a first press roller, a second roller and a three roller which are rotatably arranged in parallel on a machine frame, wherein the third press roller is arranged above and between the first press roller and the second press roller, the first press roller and the second press roller are connected with a main transmission mechanism which drives the first press roller and the second press roller to rotate, and the third press roller is connected with an auxiliary transmission mechanism which drives the three press roller to rotate.

Owner:LIYANG CITY ZHENGXIANG PRECISION MACHINERY

Forming mold used for refrigerator door shell and forming method of refrigerator door shell

PendingCN107442660ASimple and reasonable structureMolding method is efficient and reliableShaping toolsCushionEngineering

The invention discloses a forming mold used for a refrigerator door shell and a forming method of the refrigerator door shell. The forming mold comprises an upper supporting plate, a lower supporting plate, a first sequence mold body and a second sequence mold body; the first sequence mold body and the second sequence mold body are installed between the upper supporting plate and the lower supporting plate in a front-back side-by-side manner; the first sequence mold body comprises upper cushion legs, a spring, an upper mold base, lower cushion legs, a nitrogen spring, a lower mold base and a forming lower mold main body; and the second sequence mold body comprises an upper cushion leg II, a nitrogen spring II, a spring II, an upper mold base II, a lower cushion leg II and a lower mold base II. The structure is simple and reasonable. The forming method is efficient and reliable, original four procedures are changed into two procedures, the labor cost is reduced, the production cost is reduced by 70%, errors and pressing marks are reduced, and the percent of pass of products is increased by 50%.

Owner:青岛雄风实业有限公司

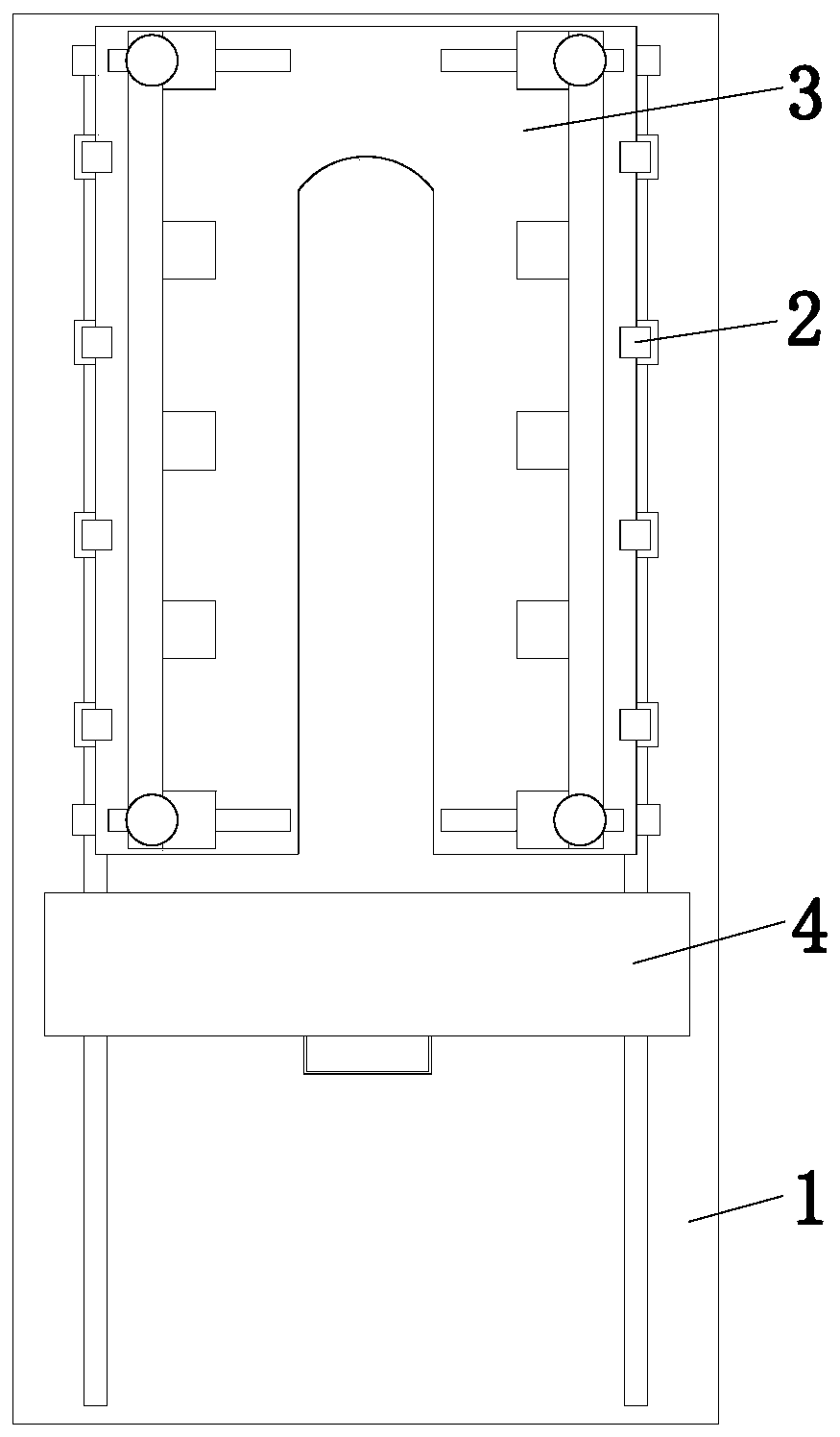

Integrated wallboard cutting device and cutting method thereof

ActiveCN110497530AClamp firmlyReduce indentationWorking accessoriesStone-like material working toolsFixed frameEngineering

The invention discloses an integrated wallboard cutting device and a cutting method thereof. The cutting device comprises a bottom plate, fixing frames, a clamping device, a protective plate and a cutting device body. The upper end of the bottom plate is symmetrically provided with the fixing frames. The fixing frames are connected to the bottom plate in a sliding fit mode. The cutting device andmethod can solve the problems that when integrated wallboards are cut at present, processing cannot be adjusted according to the change of the size of the integrated wallboards, when the integrated wallboards are clamped and fixed, the surfaces of the integrated wallboard are prone to being indented, consequently, the surface decorative layers of the integrated wallboard are damaged, the integrated wallboards cannot be supported internally, the integrated wallboards are damaged internally due to excessive clamping force, meanwhile, when existing equipment cuts the integrated wallboards, the surfaces of cuts cannot be protected, cracks or breaks are liable to occur to the cut surfaces, then materials are scrapped, cutting waste cannot be recycled during cutting, and the environment is impacted.

Owner:邵阳市环球工贸有限公司

Display panel, manufacturing method thereof and display device

ActiveCN109614961AAvoid surface contactAvoid contactAcquiring/reconising fingerprints/palmprintsDisplay deviceFingerprint recognition

The invention discloses a display panel, a manufacturing method thereof and a display device, relates to the technical field of display, and aims to solve the problem that an indentation is easy to appear on the surface of a display substrate attached with a fingerprint identification module after a reliability test. The display panel includes: a display substrate; the heat dissipation structure is arranged on the display substrate, the orthographic projection of the heat dissipation structure on the display substrate is located in the non-display area, and an opening corresponding to the display area is defined by the heat dissipation structure on the non-light-emitting side of the display substrate; the frame sealing glue layer is arranged on the surface, back on to the display substrate, of the heat dissipation structure, and the orthographic projection of the frame sealing glue layer on the display substrate surrounds the orthographic projection of the opening on the display substrate; the fingerprint recognition module is arranged on the surface, back on to the display substrate, of the frame sealing glue layer, and the orthographic projection of the fingerprint recognition module on the display substrate covers the display area; and the edge sealing adhesive layer is arranged at the periphery of the fingerprint identification module. The display panel provided by the invention is used for displaying.

Owner:BOE TECH GRP CO LTD +1

Method for cryogenic treatment of aluminium alloy resistance spot welding electrode

InactiveCN1435506AExtend working lifeReduce ablationElectrode featuresWelding/cutting media/materialsCold treatmentElectrical resistance and conductance

A process for deep cold treatment of spot-welding electrode for Al alloy includes putting the Cu alloy electrodes in a container full of deep cold treating medium in a deep cold treater layer by layer, setting up parameters, deep cold treating, and restoring their temp to ordinary temp naturally. Its advantages are long service life elongated by once or more, no splash on welding and high welding quality.

Owner:TIANJIN UNIV

Non-indentation adhesive welding connection method for metal plates

ActiveCN105149714AAvoid burnsImprove spot weld strengthNon-macromolecular adhesive additivesSoldering apparatusPower flowAdhesive

The invention discloses a non-indentation adhesive welding connection method for metal plates, and the method is implemented through the following steps that: an adhesive mixed with metal particles is coated between two layers of horizontally-placed metal plates; the two layers of metal plates gradually pass through a space between a roller electrode couple on which a welding current is exerted, so that a closed loop is defined by roller electrodes, the metal plates and the metal particles so as to achieve metallurgical interconnection; finally, after the adhesive is cured, an effect of non-indentation fixed connection is achieved. The method disclosed by the invention can be used for significantly improving the peel strength of joints and eliminate spot welding indentations, and also can be applied to the connection of heterogeneous metal sheets, and the normal tensile strength of processed metal plates can reach about 7000 N.

Owner:SHANGHAI JIAO TONG UNIV

Plastic film cutting device and cutting processing method

ActiveCN111203930AImprove the stabilityImprove cutting accuracyMetal working apparatusPlastic filmMaterials science

The invention relates to a plastic film cutting device. The plastic film cutting device comprises a working table, a clamping device and cutting devices, wherein the clamping device is arranged on theworking table; and the cutting devices are equidistantly arranged on the upper end surface of the working table from left to right. According to the plastic film cutting device and a cutting processing method, a plastic film is cut by adopting the design concept of multiple clamping, so that the stability of the entire plastic film is improved, the entire plastic film is in a non-relaxed state, and furthermore, the precision and efficiency of plastic film cutting are improved; and meanwhile, a pre-cutting structure and a cutting structure are combined for cutting the plastic film so as to improve the quality of plastic film cutting.

Owner:江门市蓬江区东洋机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com