Non-indentation adhesive welding connection method for metal plates

A connection method and a technology of metal plates, which are applied in metal processing, welding equipment, metal processing equipment, etc., can solve the problems of high glue welding process, accelerated electrode wear, and cavity formation, so as to achieve excellent corrosion resistance and improve joint performance , The effect of preventing the adhesive layer from burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

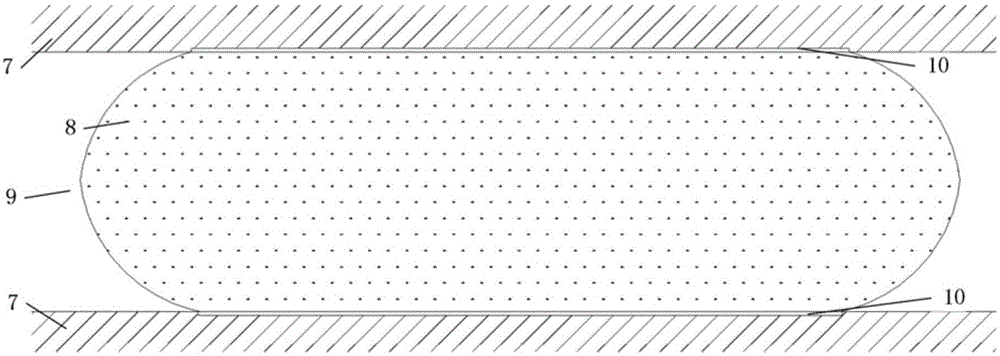

[0027] The upper metal plate 1 of this embodiment is a stamped galvanized steel sheet with a thickness of 2mm for automobiles produced by Baosteel, and the lower metal plate 1 is also a stamped and galvanized steel sheet with a thickness of 2mm for automobiles produced by Baosteel. The diameter is 0.35mm, and its material is a certain type of zinc-tin-copper solder. Adhesive 3 is Henkel 5016 epoxy-polyurethane structural adhesive, and the roller electrode has a smooth surface.

[0028] Process parameters: The welding current is 6000A, the electrification equipment is a certain type of intermediate frequency DC welding machine, and the welding speed is 0.2m / min.

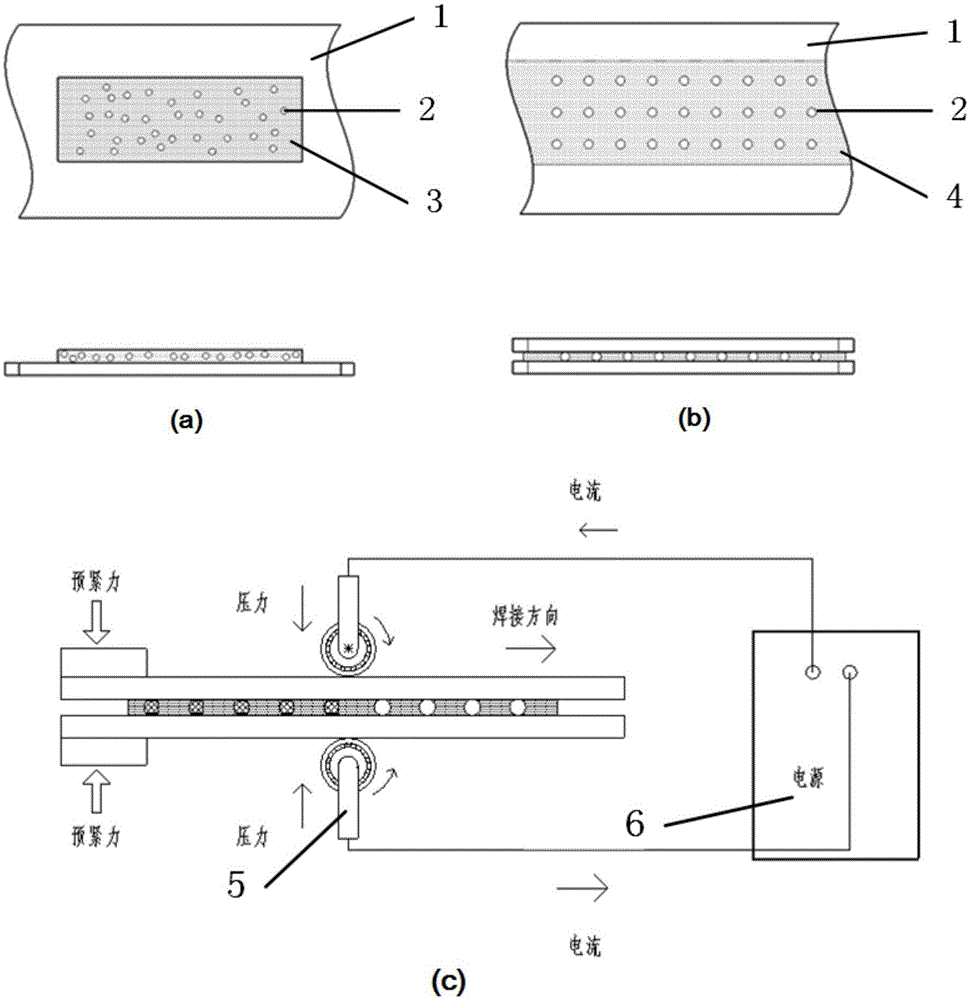

[0029] The process of this embodiment is as figure 1 a) ~ c) as shown:

[0030] 1) The glue injection gun moves to the top of the metal plate 1 to be glued, squeezes the glue injection gun so that a certain amount of structural glue 3 mixed with metal particles 2 falls on the metal plate, and the adhesive 3 is coated...

Embodiment 2

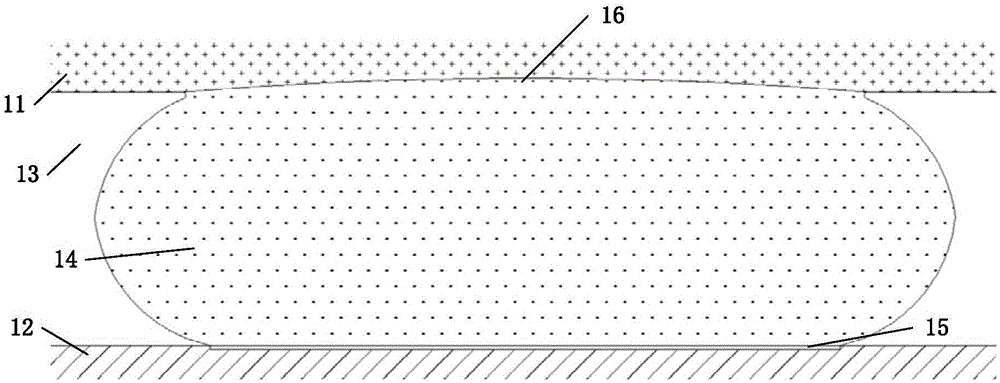

[0037] The upper metal plate 1 of this embodiment is a 1.6mm thick AA6061-T6 aluminum alloy plate, and the lower metal plate 1 is a stamped galvanized steel plate with a thickness of 2 mm for automobiles produced by Baosteel. The diameter is 0.76mm, the material is aluminum-silicon solder, the adhesive 3 is Dow 1486 epoxy structural adhesive, and the roller electrode has a smooth surface.

[0038] Process parameters: The welding current is 4000A, the electrification equipment is a certain type of intermediate frequency DC welding machine, and the welding speed is 0.1m / min.

[0039] The process of this embodiment is as figure 1 a) ~ c) as shown:

[0040] 1) The glue injection gun moves to the top of the metal plate 1 to be glued, squeezes the glue injection gun so that a certain amount of structural glue 3 mixed with metal particles 2 falls on the metal plate, and the adhesive 3 is coated by the continuous movement of the glue injection gun Cover the surface to be joined.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com