Mechanical forming drum and method thereof for realizing auxiliary turn-up of tire embryo slit

A technology for forming drums and embryos, which is applied in the field of rubber machinery, can solve problems such as discounting of sidewall parts, affecting the appearance of embryos, and poor quality of turn-up operations, and achieve the effect of reducing indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

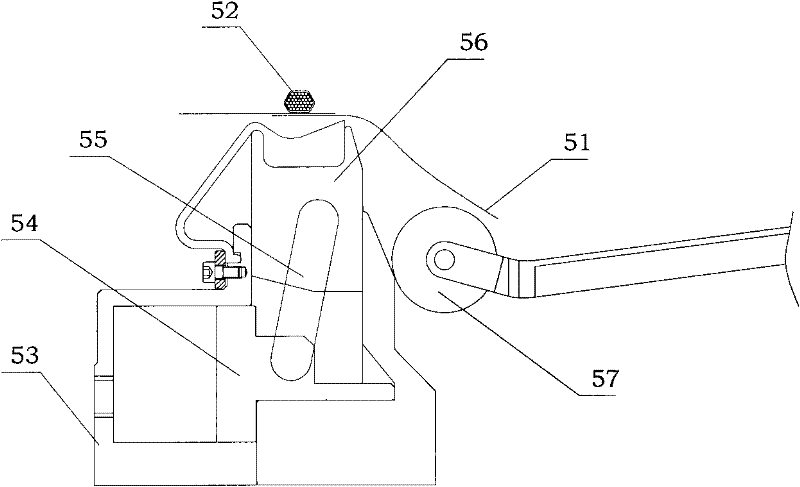

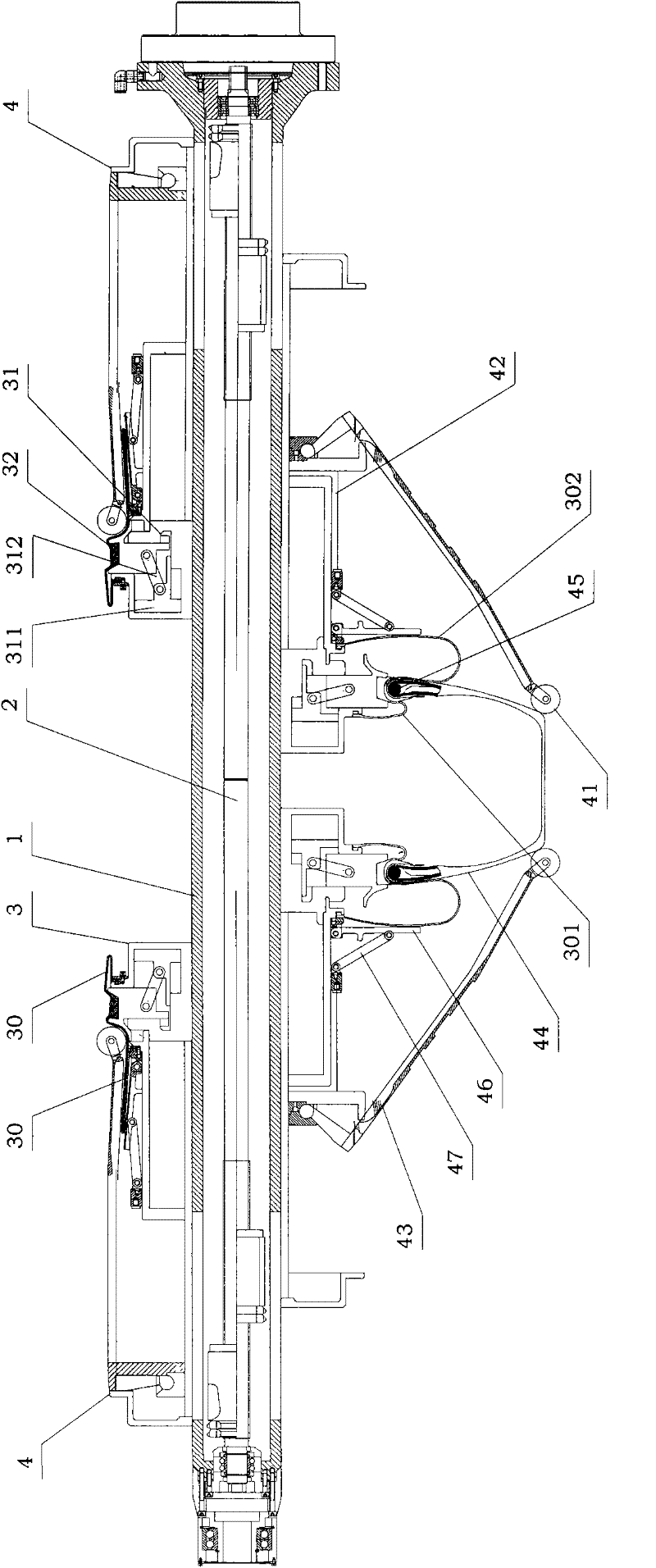

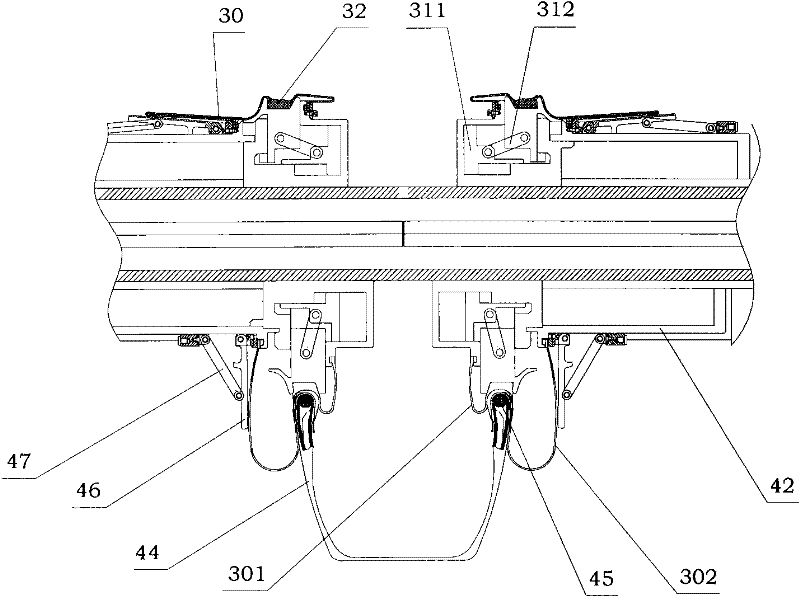

[0055] Example 1, such as figure 2 and image 3 The mechanical forming drum that realizes the auxiliary turn-up of the tire embryo slit mainly has,

[0056] a hollow cylindrical main shaft 1,

[0057] The lock block assembly 3 and the finger-shaped turn-up device 4 are symmetrically sleeved on the outer periphery of the main shaft 1 along the vertical center line,

[0058] Inside the main shaft 1, a drive shaft 2 for driving the lock block assembly 3 and the finger-shaped turn-up device 4 to reciprocate along the axial direction of the main shaft 1 is provided.

[0059] Specifically, the drive shaft 2 is a roller screw with left-hand and right-hand symmetrical threads.

[0060] Described finger-type turn-up device 4 has several finger-shaped turn-up bars 43, and several turn-up bars 43 are evenly arranged along the outer circumference of the main shaft 1, and turn-up rollers 41 are arranged on the top of the turn-up bar 43 to realize the The sidewall of the embryo is turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com