Cylinder head gasket

A technology of gaskets and cylinder heads, which is used in engine sealing, engine sealing devices, machines/engines, etc., can solve the problems of easy cracks and accelerated deformation of cylinder barrels, so as to reduce indentation, restrain deformation, and restrain surface The effect of rising pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

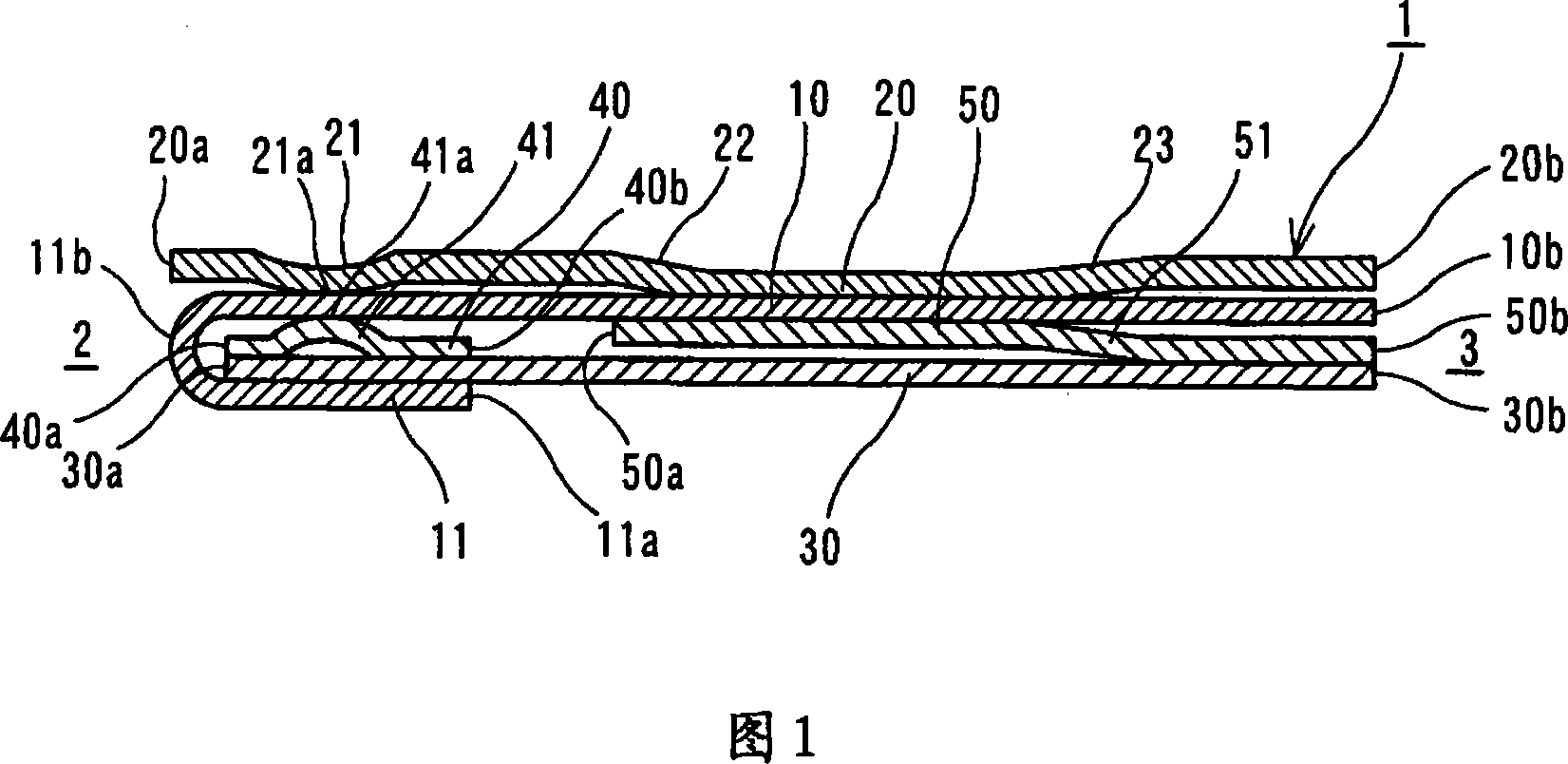

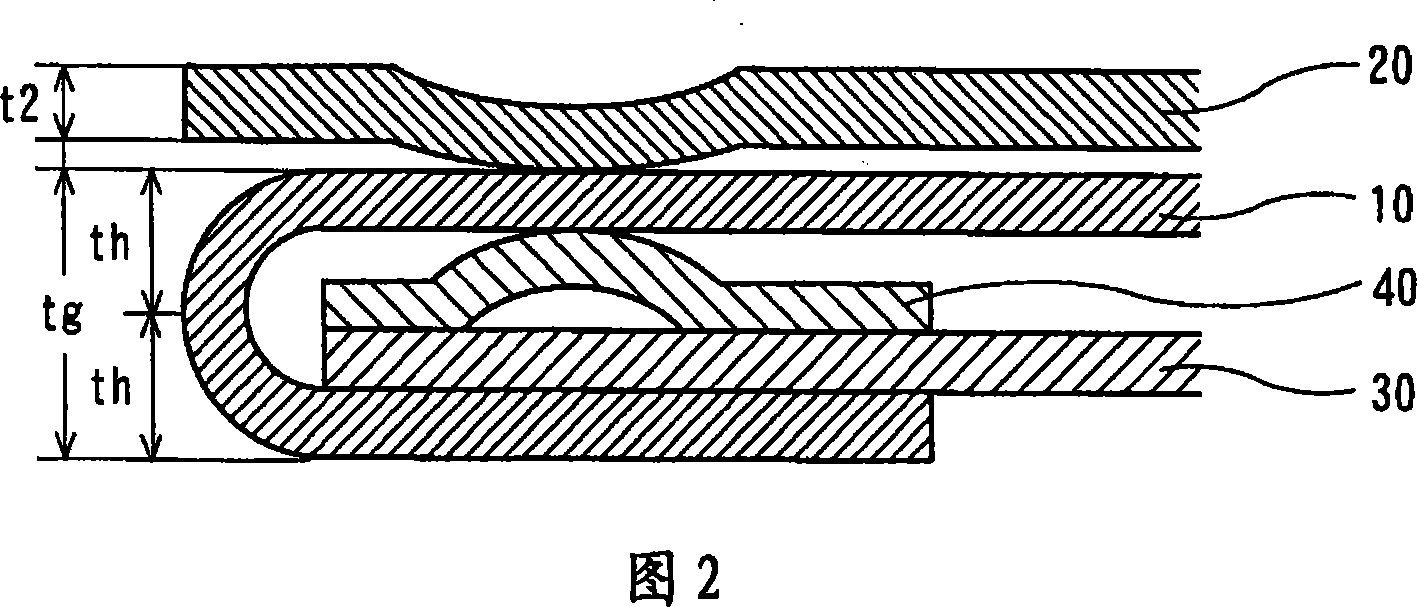

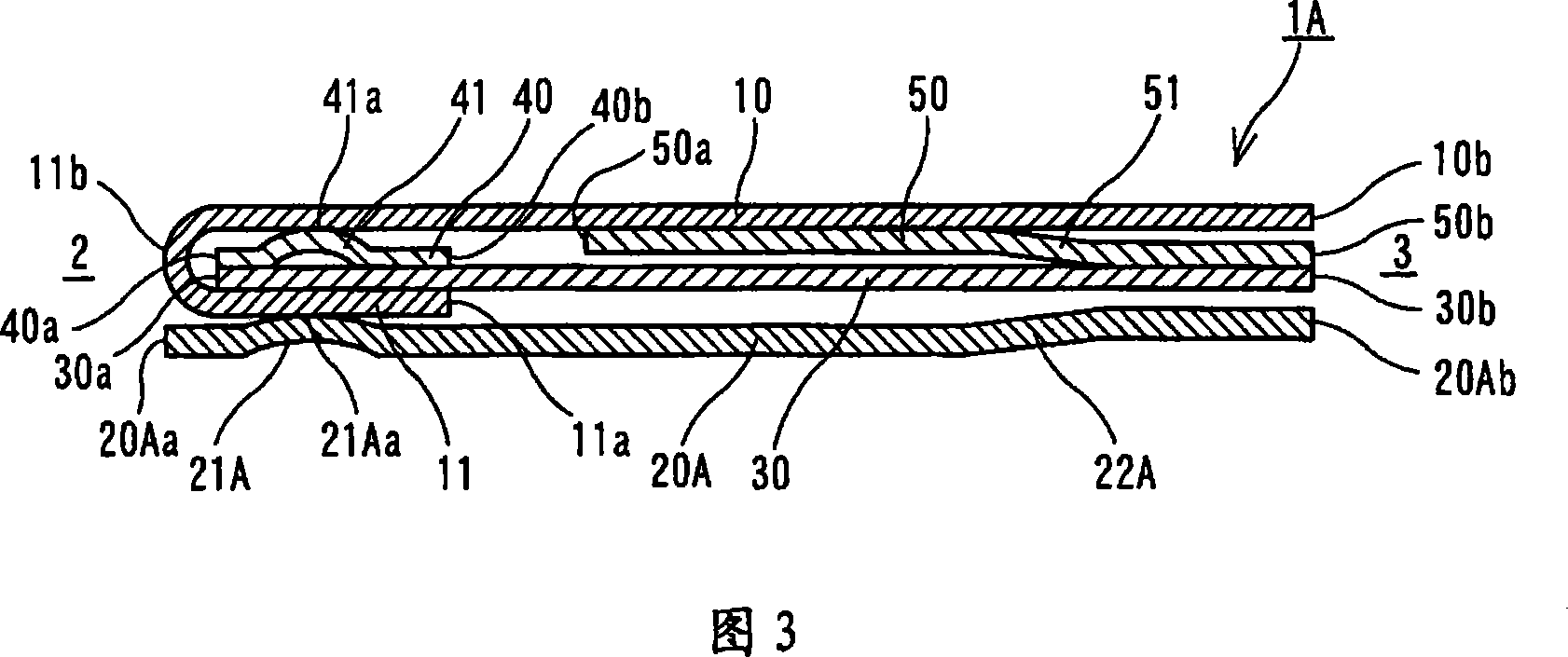

[0042] Next, embodiments of the cylinder head gasket of the present invention will be described with reference to the drawings. In addition, Fig. 1 to Fig. 6 are schematic explanatory diagrams, in order to make the structure easier to understand, the dimensions such as the plate thickness, the size of the hole for the cylinder bore, the size of the folded part, and the size of the flange are all different from the actual size. , exaggerated to express.

[0043] The cylinder head gasket of the present invention is a metal gasket sandwiched between engine components such as the cylinder head and the cylinder block of the engine, and is resistant to the high temperature and high pressure combustion gas of the cylinder bore, the cooling water passage, the cooling oil passage, etc. Cooling water, engine oil and other fluids are sealed.

[0044] The cylinder head gasket is composed of a single or a plurality of metal constituent plates (metal substrates) formed of mild steel plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com