Reconfigurable die and forming device for same

A molding device and mold technology, applied in the field of reconfigurable molds and molding devices of reconfigurable molds, can solve the problems of slow deformation of formed parts, large volume of single point control unit, complex structure of reconfigurable molds, etc. Achieve the effect of reducing volume, reducing internal residual stress and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The reconfigurable mold and the molding device for the reconfigurable mold of the present invention will be further described in detail below with reference to the accompanying drawings.

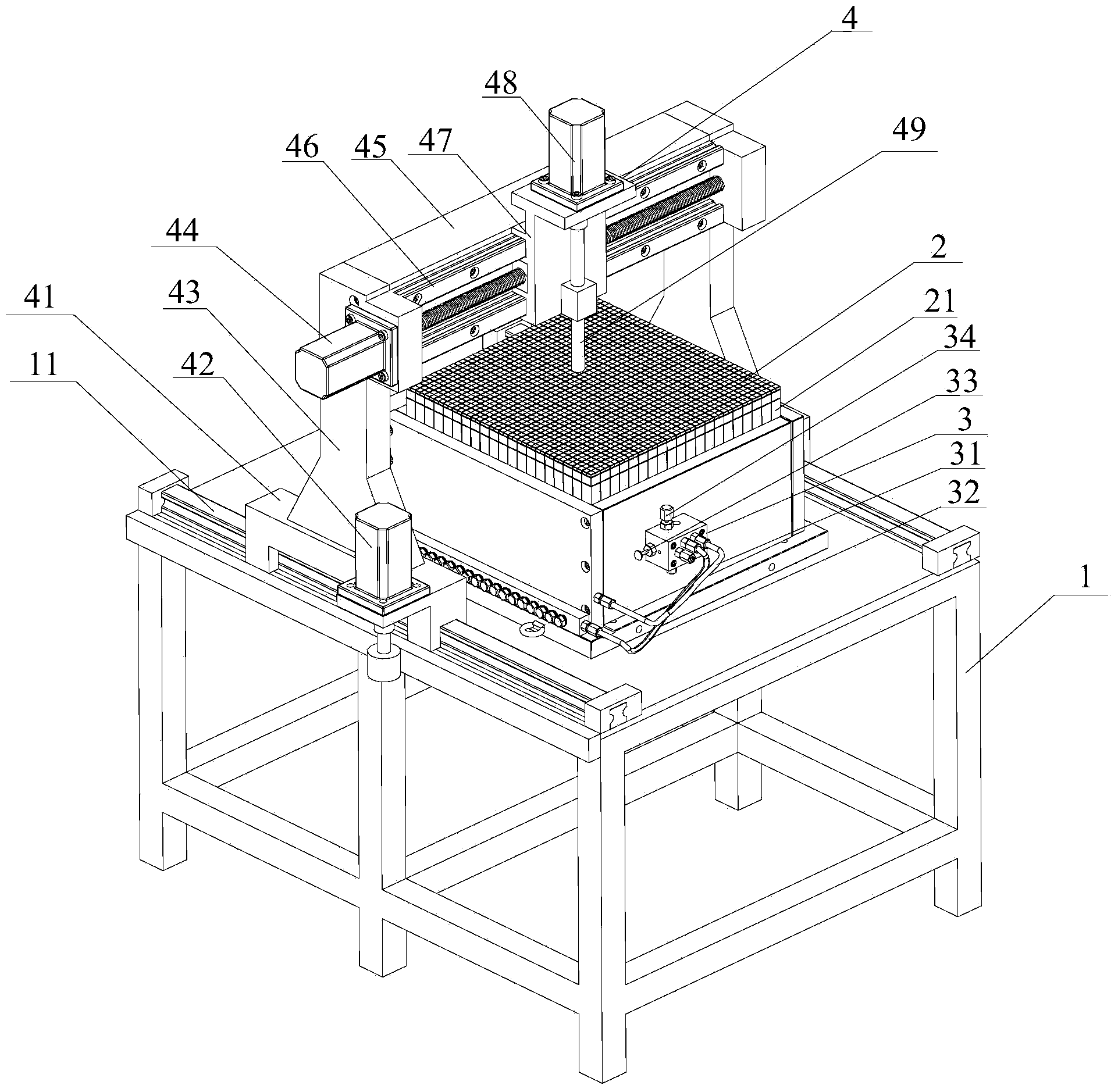

[0034] like figure 1 As shown, the molding device of the reconfigurable mold of the present invention includes: a frame 1, a reconfigurable mold 2 placed on the frame 1; The hydraulic telescopic unit 21 points-controls the mold point-control mechanism 4 that forms the required curved surface.

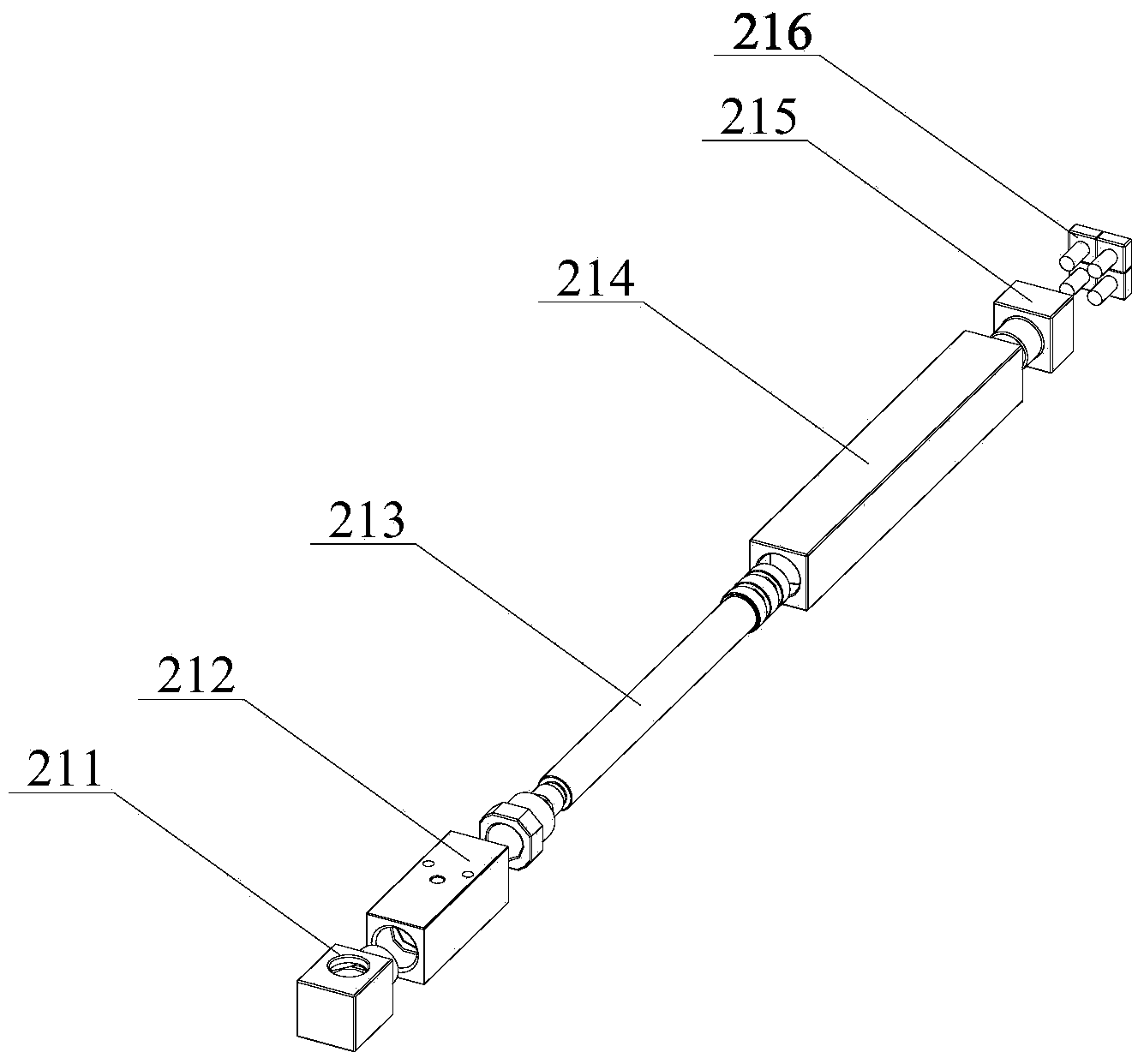

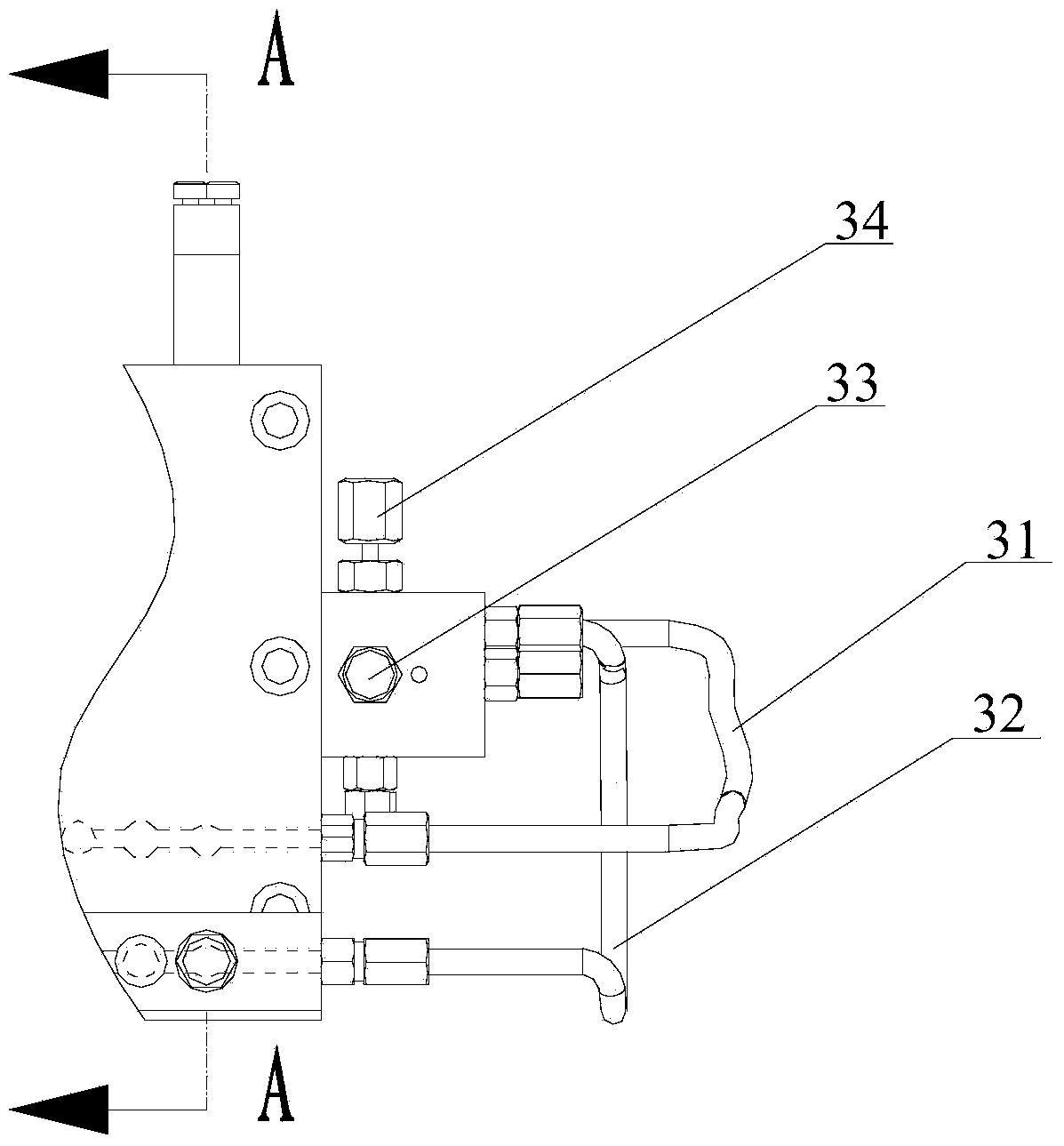

[0035] like figure 1 , 2As shown in , 3 and 4 , the reconfigurable mold 2 includes a plurality of closely arranged hydraulic expansion and contraction units 21 and a hydraulic system 3 connected with the hydraulic expansion and contraction units 21 . In order to be able to clearly understand the structure of the reconfigurable mold 2, figure 2 It is a schematic diagram of the parts assembly structure of the hydraulic expansion unit, image 3 It is a schematic diagram of the 2-part structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com