Three-roller transmission veneer reeling machine

A plate rolling machine and auxiliary transmission technology, which is applied in the field of plate rolling machines, can solve the problems that the third pressure roller cannot be driven, and achieve the effects of saving labor costs, ensuring quality, and reducing wear and indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

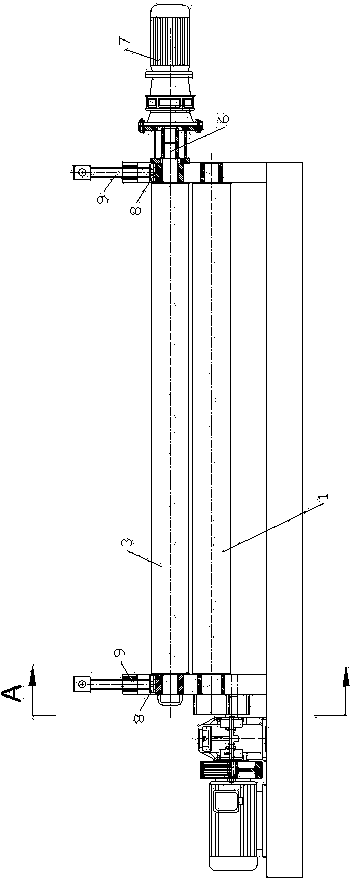

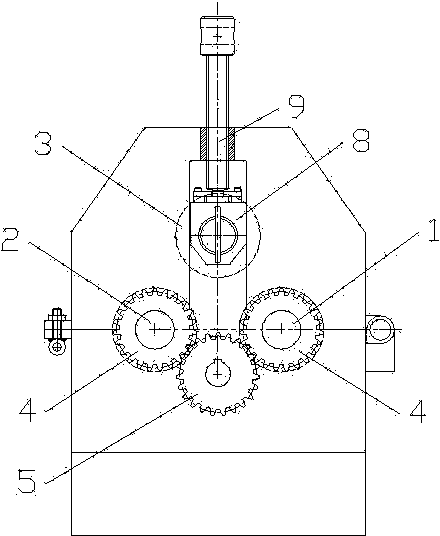

[0009] see figure 1 , 2 The three-roller transmission plate bending machine shown includes three parallel first rollers 1, second rollers 2, and third rollers 3 that are rotatably arranged on the frame. The third roller 3 is positioned on the first roller The upper part between the second pressure roller.

[0010] The gears 4 at one end of the first pressure roller and the second pressure roller are all meshed with the gear 5 on the output shaft of the belt main transmission mechanism. The third pressing roller 3 is connected with the motor 7 through the coupling sleeve 6 , the two ends of the third pressing roller 3 are rotatably arranged on the slider 8 , and the motor 7 is fixed on the slider 8 . The slide block 8 is arranged on the frame to slide up and down through the lead screw nut structure 9 .

[0011] This equipment uses a geared motor to drive the upper pressure roller to rotate. Realize the simultaneous rotation of the upper and lower pressure rollers. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com