Forming mold used for refrigerator door shell and forming method of refrigerator door shell

A technology for forming molds and refrigerator doors, which is applied in the directions of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting the surface quality of refrigerator door shells, complex production processes, low production efficiency, etc., and achieves efficient and reliable forming methods. The effect of cost reduction and product qualification rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

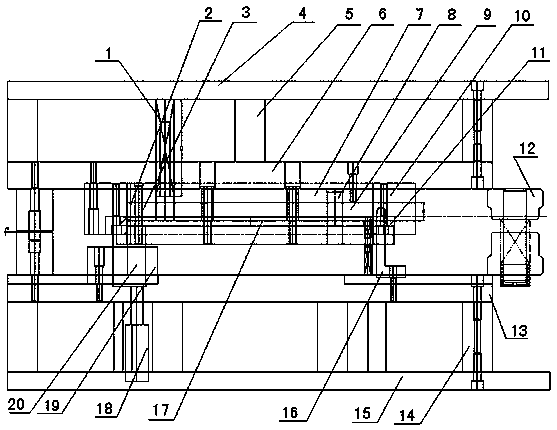

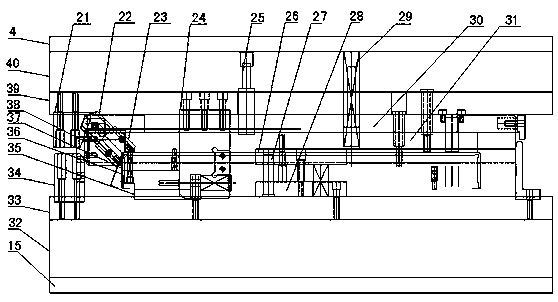

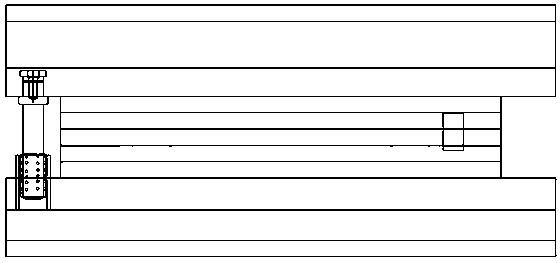

[0022] refer to Figure 1-Figure 2 , the forming mold for the refrigerator door shell of the present embodiment, it comprises upper supporting plate 4, lower supporting plate 15, the first sequence mold and the second sequence mold, the front and rear of the first sequence mold and the second sequence mold Installed side by side between the upper and lower pallets, the first sequence mold includes an upper pad leg 5, a spring 1, an upper mold base 6, a lower pad leg 14, a nitrogen spring 18, a nitrogen spring protection column, a lower mold base 13 and Molding lower mold 17, described upper pad leg 5, spring 1, upper mold base 6 are installed on the upper pallet 4, described lower pad leg 14, nitrogen spring 18 are installed on the lower pallet 15, described lower mold base 6 Connected to the lower supporting plate 15 through the lower pad, the second sequence mold includes an upper pad leg 40. Nitrogen gas spring 25. Spring 29. Upper mold seat 39. Lower legs 32. Low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com