Screwdriving tool and tool holder for such a screwdriving tool

A tool and tool head technology, applied in the direction of tool joints, tool holder accessories, tool workpiece connections, etc., can solve the problems of outer wall deformation, axial orientation influence, limited centering effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

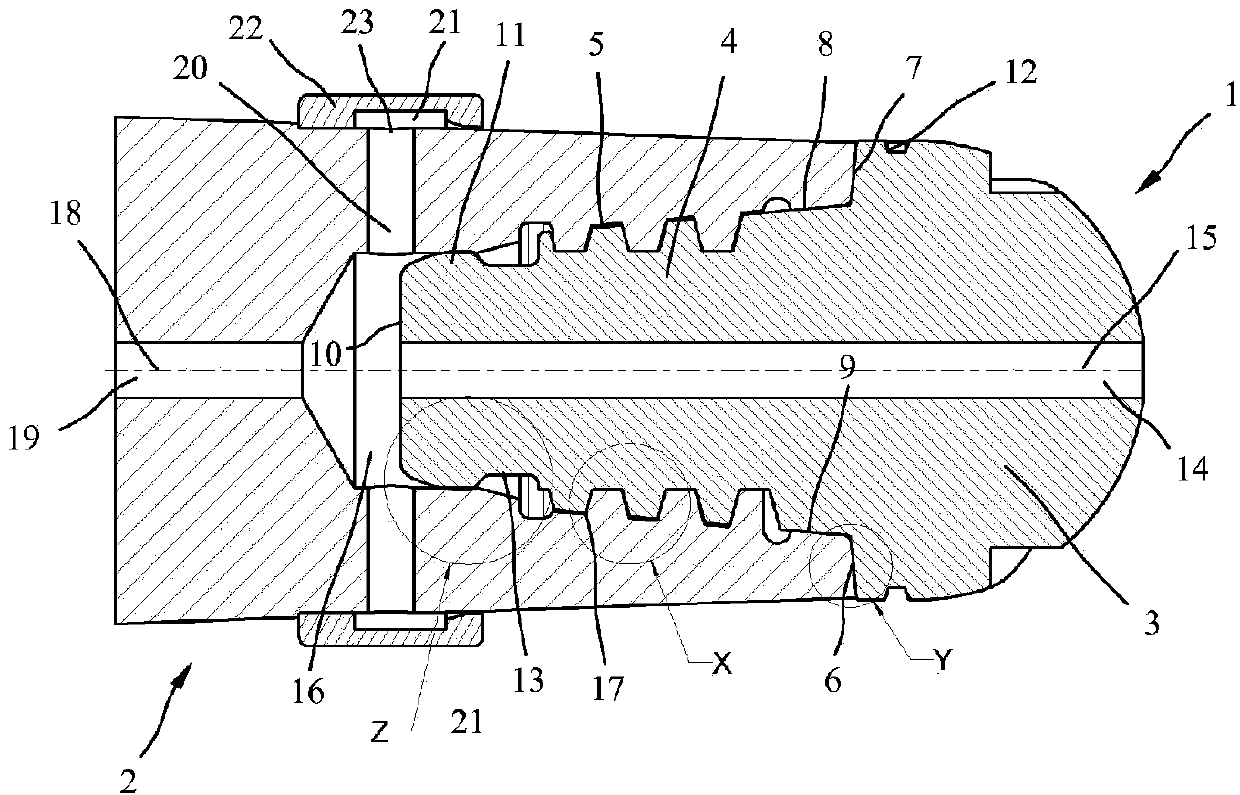

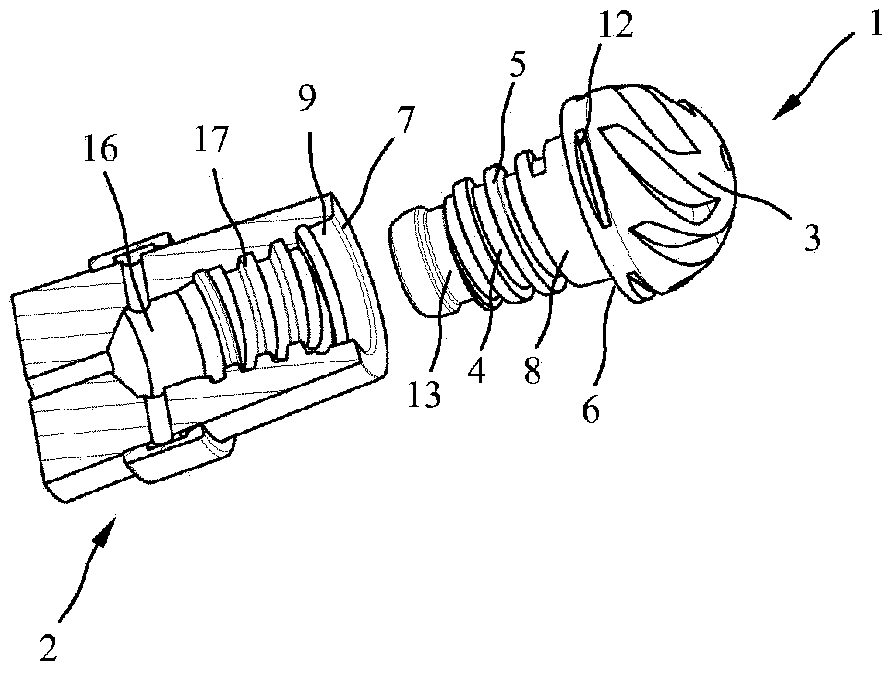

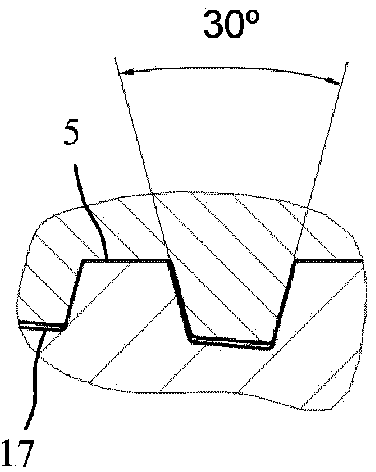

[0028] exist figure 1 and 2 The figure shows a tool assembly with a screw-in tool 1 and an associated tool receptacle 2 in longitudinal section and in perspective view. The screw-in tool 1 has a tool head 3 designed here as a ball-nose milling cutter and a conical, rearwardly tapering tool shank 4 with an external thread 5 . Provided between the tool head 3 and the external thread 5 is a first support region with a conical first contact surface 6 for bearing against a corresponding conical surface on the front side of the tool receptacle 2 . and a second conical contact surface 8 for abutting against a second conical bearing surface 9 inside the tool receiving device. This results in a double-cone structure at the transition between tool head 3 and external thread 5 , which double-cone structure serves for improved centering and increased support. A second support region 11 is provided on the free rear end 10 of the tool shank 4 .

[0029] as specified by figure 2 Conseq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com