Precast prestresed-concrete beam-type stair and making construction method

A concrete beam and prestressing technology, applied in the direction of manufacturing tools, stepped structures, molds, etc., can solve the problems of stair hoisting, transportation and installation difficulties, affecting normal use, and large own weight, etc., to eliminate the stress on the main structure and Effects of stiffness, damage reduction, and self-weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

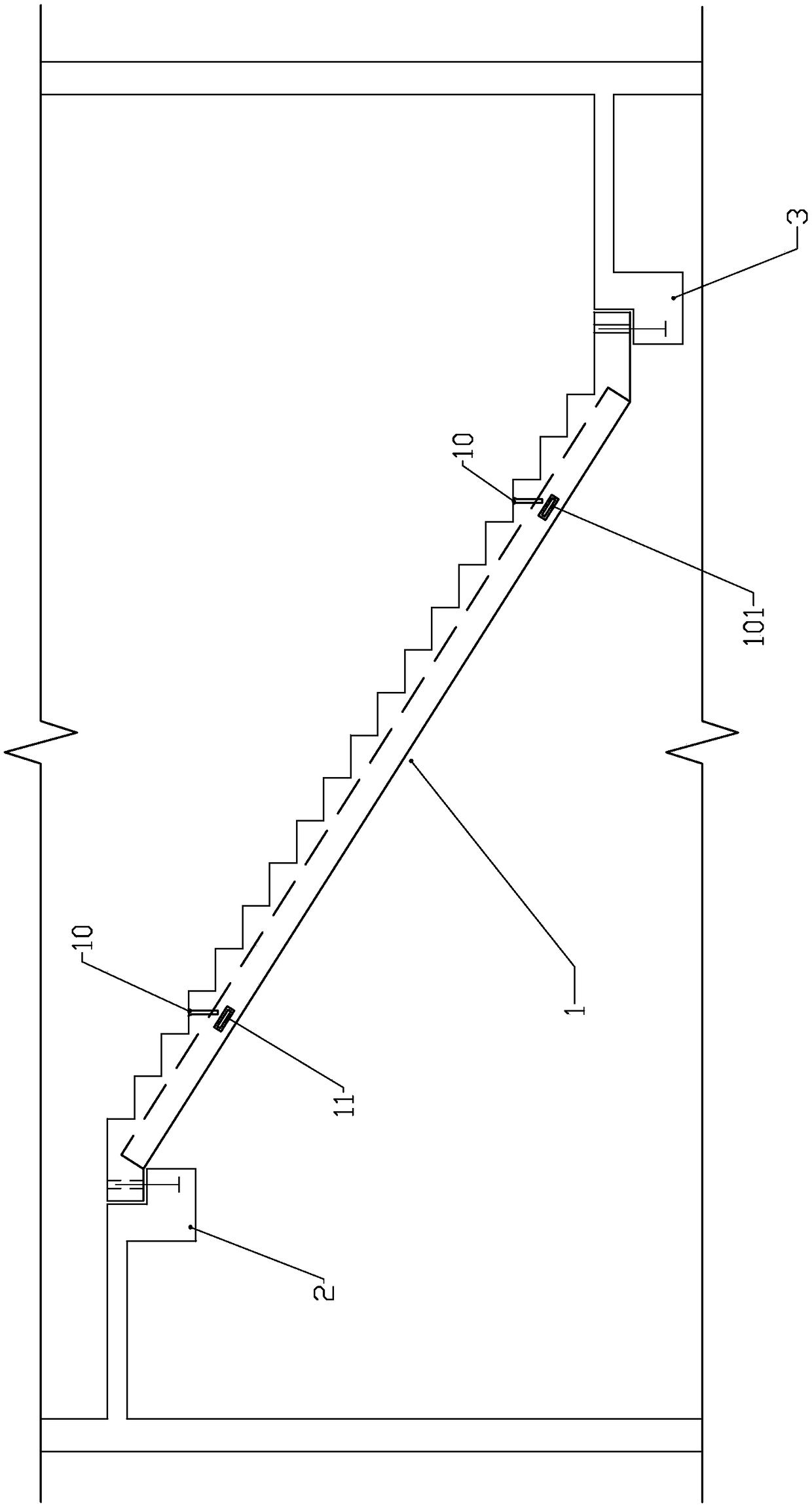

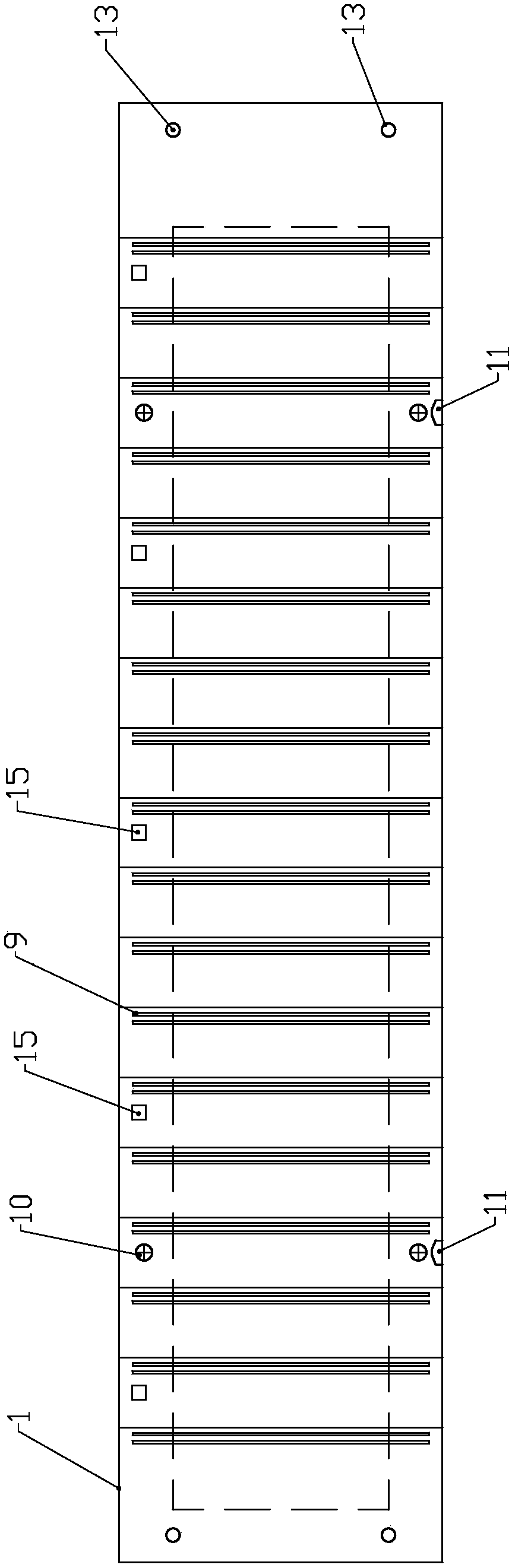

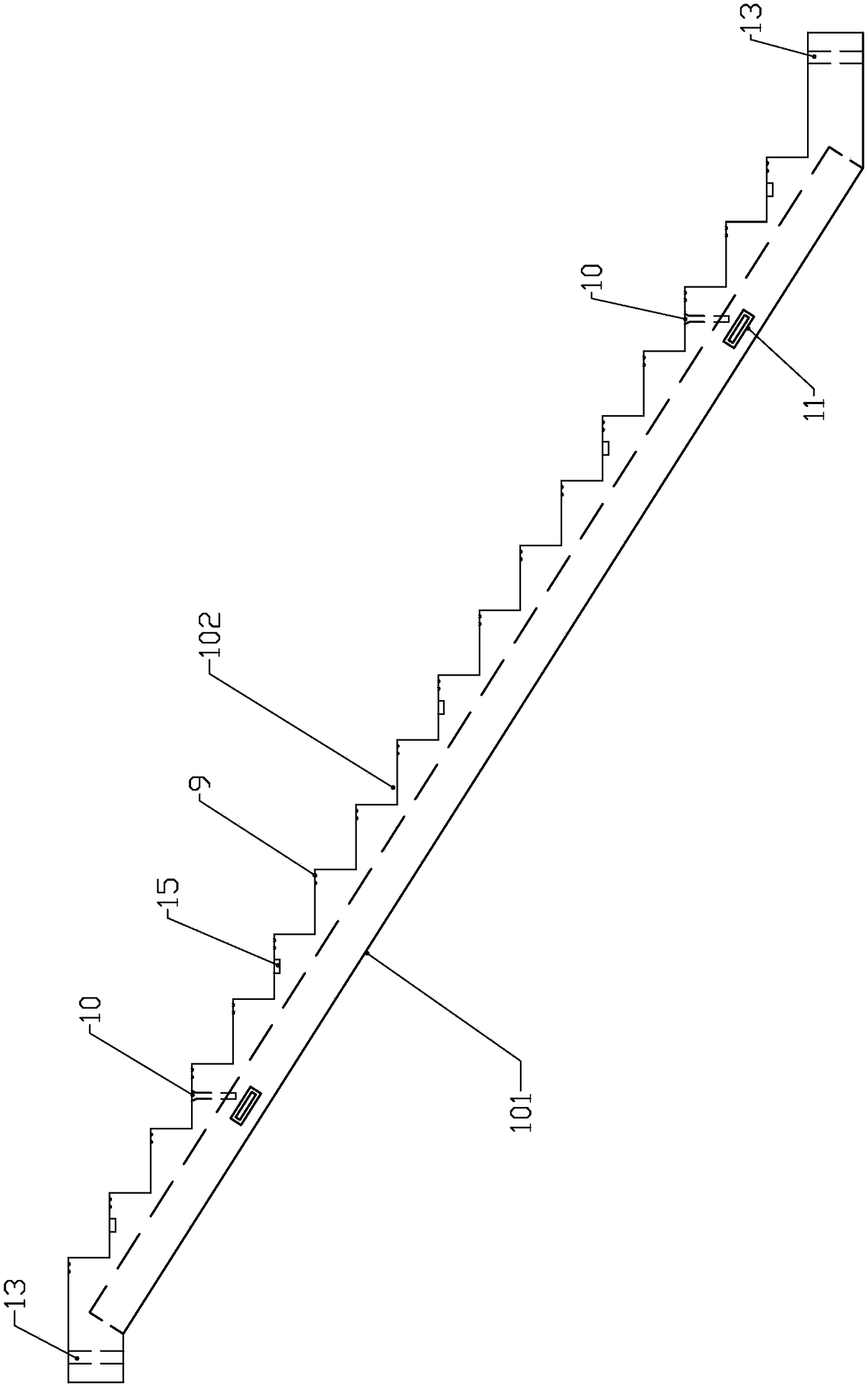

[0037] Refer to the attached figure 1 to attach Figure 7 A prefabricated prestressed concrete beam staircase of the present invention and its fabrication and construction method are described in detail below.

[0038] A prefabricated prestressed concrete beam staircase of the present invention comprises a beam staircase body 1 and an upper stair beam 2 and a lower stair beam 3 supporting the beam staircase body 1, and the beam staircase body 1 includes a stair beam 101 and stepped steps 102, the inclined beams 101 of the steps are arranged along the length direction of the beam staircase body 1, the two ends of the steps 12 are supported on the inclined beams 101 of the steps, the upper end surface of the steps 12 is a horizontally arranged step surface, and the step surface Anti-skid strip installation groove 9 is arranged on it, and the height and width of steps 12 should meet the requirements of national building codes, and the number of steps 12 should be determined acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com