Seawater sea-sand concrete structure with corrugated composite pipe

A technology of concrete structure and composite pipe, which is applied in the direction of basic structure engineering, columns, pier columns, etc., can solve the problems of poor corrosion resistance and easy buckling of steel pipes, achieve good corrosion resistance, reduce project cost, and reduce lateral expansion deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

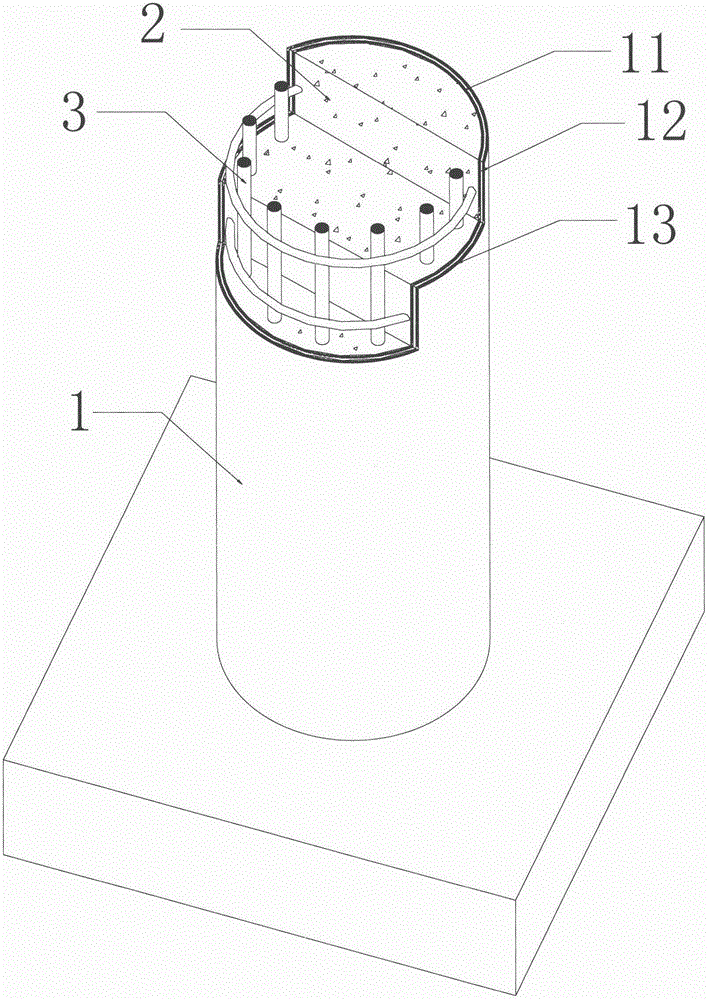

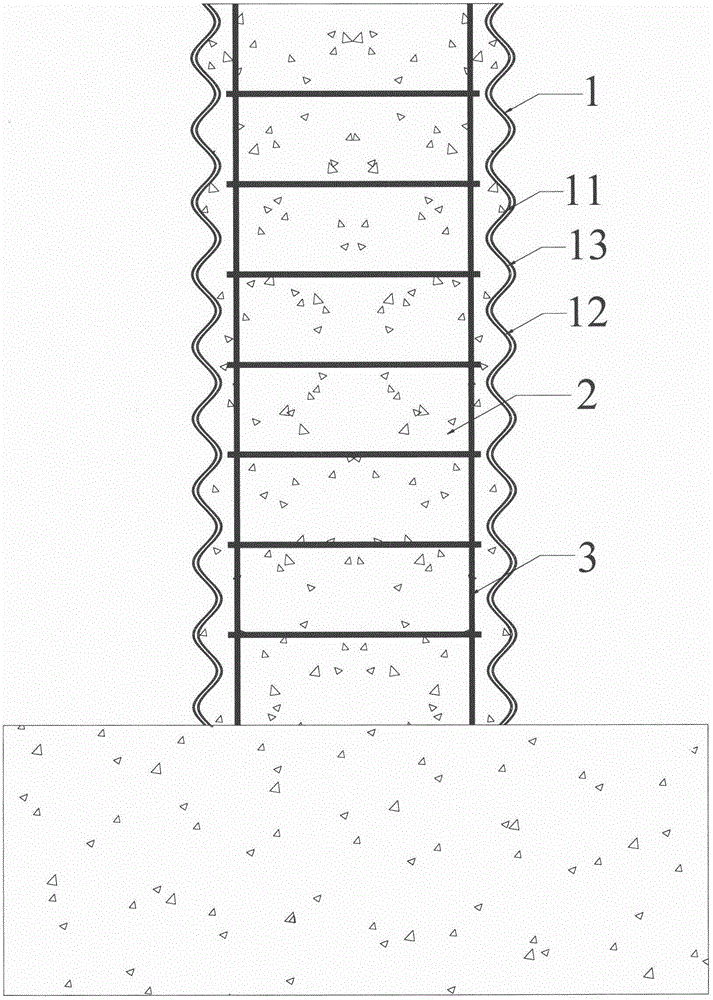

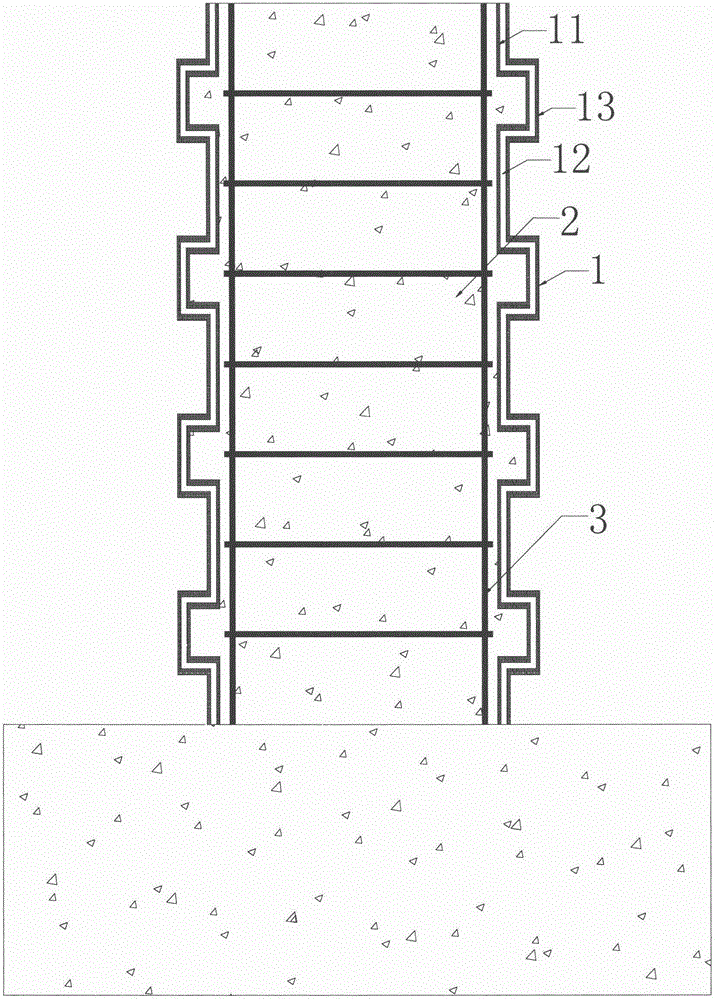

[0045] figure 1 It is a three-dimensional schematic diagram of a circular cross-section corrugated composite pipe seawater sea-sand concrete structure, Figure 2-7 Sine wave type, rectangular sawtooth type, trapezoidal sawtooth type, continuous-half-wave type, discontinuous-half-wave type, broken line corrugated composite pipe seawater sea sand concrete structure schematic diagram, Figure 8-13 The cross-sectional diagrams of corrugated composite pipe seawater and sea-sand concrete structures are circular cross-section, oval cross-section, rounded square cross-section, rounded rectangular cross-section, round-end cross-section, and rounded polygonal cross-section.

[0046] In the specific implementation, the corrugated composite pipe 1 and the composite rib 3 are first processed according to the predetermined cross-sectional shape and size, and the corrugated steel pipe 12 is manufactured and formed by a controlled welding process. Paste lamination process or winding process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com