Combined filling mold

A technology for filling molds and components, which is applied in the direction of formwork/formwork/work frame, building components, and on-site preparation of building components to achieve the effects of reducing production costs, reducing transportation losses, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

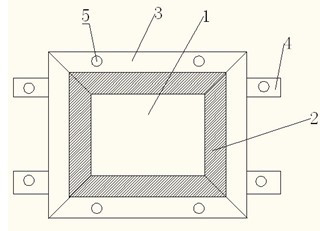

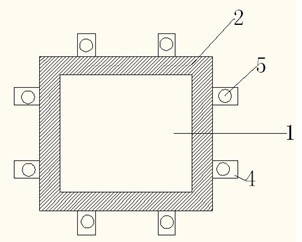

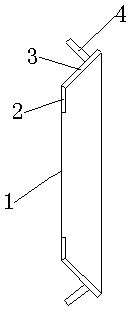

[0043] Embodiment 1:: the present invention adopts the thin-walled member of plastic material casting production standard in the factory, and thickness is 5mm, and panel 1 adopts concave-convex rectangular hemp panel, and size is two kinds of A:600x600mm and B:600x300mm, and panel 1 is connected around The stiffener, the width of the stiffener 2 is 50mm, the outer surface of the stiffener is also concave-convex, and the stiffener 2 is 45mm from the panel 1. o angle, the stiffening plate 2 is connected with the counter force plate 3 around, the width of the counter force plate 3 is 30mm, and the reaction force plate 3 is connected with the end of the stiffening plate 2, forming a 90 o Angle, two reaction force keys 4 are set on the reaction force plate in the left and right directions, the width of the reaction force keys 4 is 30mm, and a connection hole with a diameter of 10mm is set on the reaction force keys 4. After the standard components are transported to the constructio...

Embodiment 2

[0044] Embodiment 2:: the present invention adopts plastic material to cast and press the thin-walled member of production standard in factory, and thickness is 5mm, and panel 1 adopts concave-convex rectangular hemp panel, and size is two kinds of A: 600x600mm and B: 600x300mm, and panel is connected and stiffened around Plate 2, the width of the stiffener plate is 50mm, the outer surface of the stiffener plate 2 is also concave-convex, and the stiffener plate and the face plate are 60 o Included angle, two reaction keys are connected in each direction around the stiffening plate, the width of the reaction key is 30mm, and each reaction key is provided with a connecting hole with a diameter of 10mm. After the standard components are transported to the construction site, support the bottom formwork according to the design requirements, bind the bottom reinforcement and rib inner steel bars on the bottom formwork according to the design requirements, place the A-shaped component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com