Square pipe supporting steel plate bunker and manufacturing method

A technology of pipe support and steel silo, applied in building materials, building components, buildings, etc., can solve the problems of out-of-plane curvature, steel waste, and low out-of-plane stiffness, so as to increase out-of-plane stiffness, reduce construction costs, and ensure compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

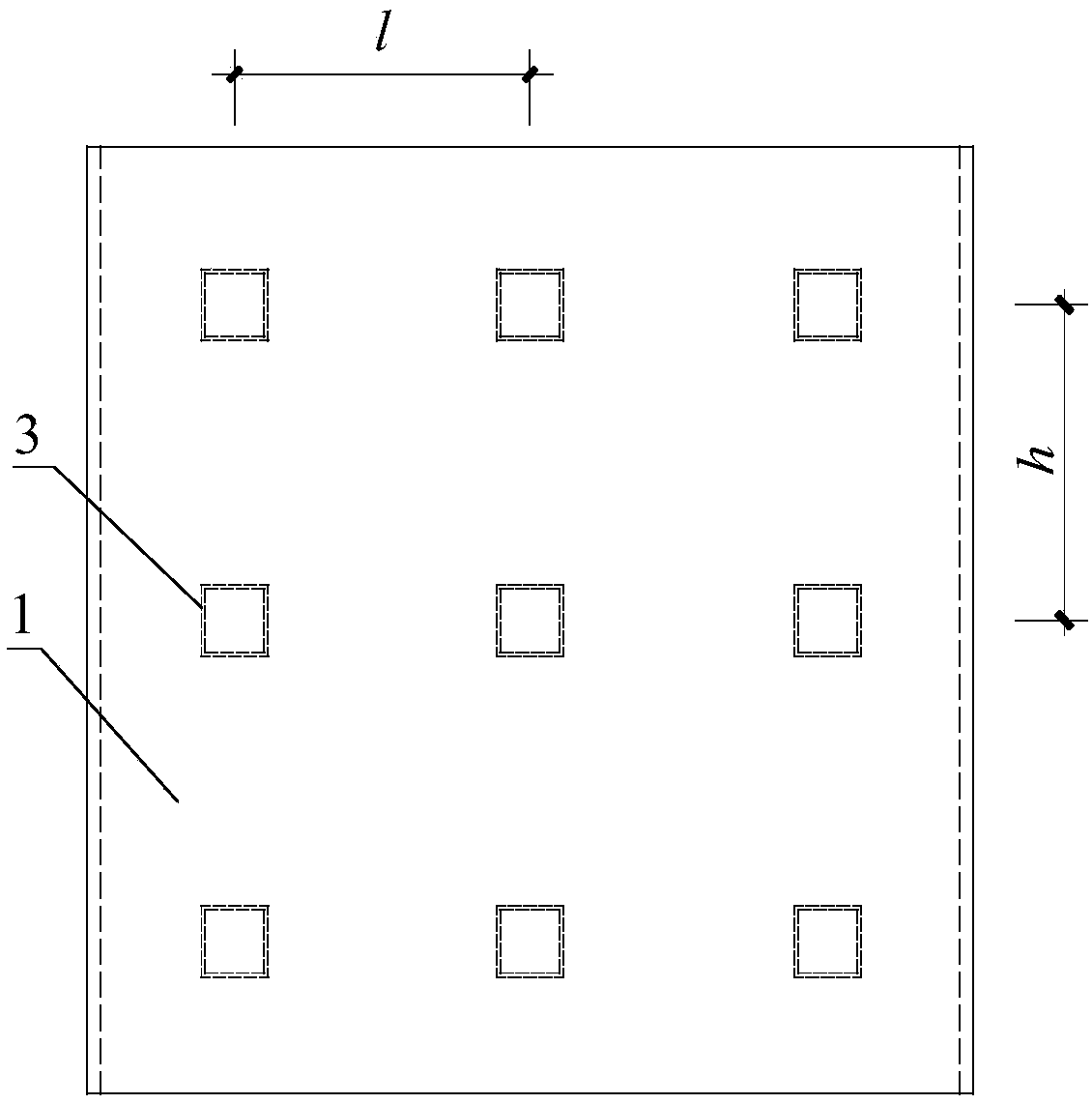

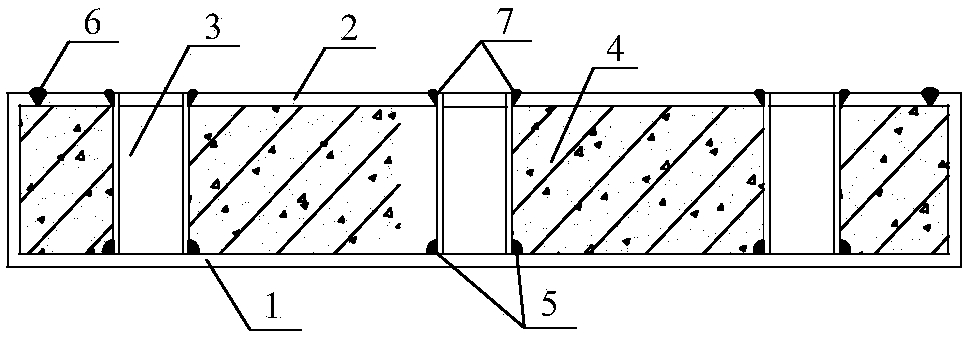

[0021] A steel silo supported by a square tube, which consists of a basic unit consisting of a steel plate 1, a steel plate 2, and a square tube support 3. The two sides of the basic unit are respectively a steel plate 1 and a steel plate 2. The thickness t of the steel plate is 2 mm to 3 mm, and the square tube support 3 is connected to the steel plate 1 through the weld 5. The side length of the square tube support 3 is 30 mm to 50 mm, and the thickness is 3 mm. The horizontal and vertical distances between adjacent square tube supports 3 Both are (200-300) t, and a square hole is left at the position corresponding to the steel plate 2 and the square tube support 3; The steel plates 2 are connected by welds 7; concrete 4 is poured in the empty warehouse formed by the steel plates 1 and 2.

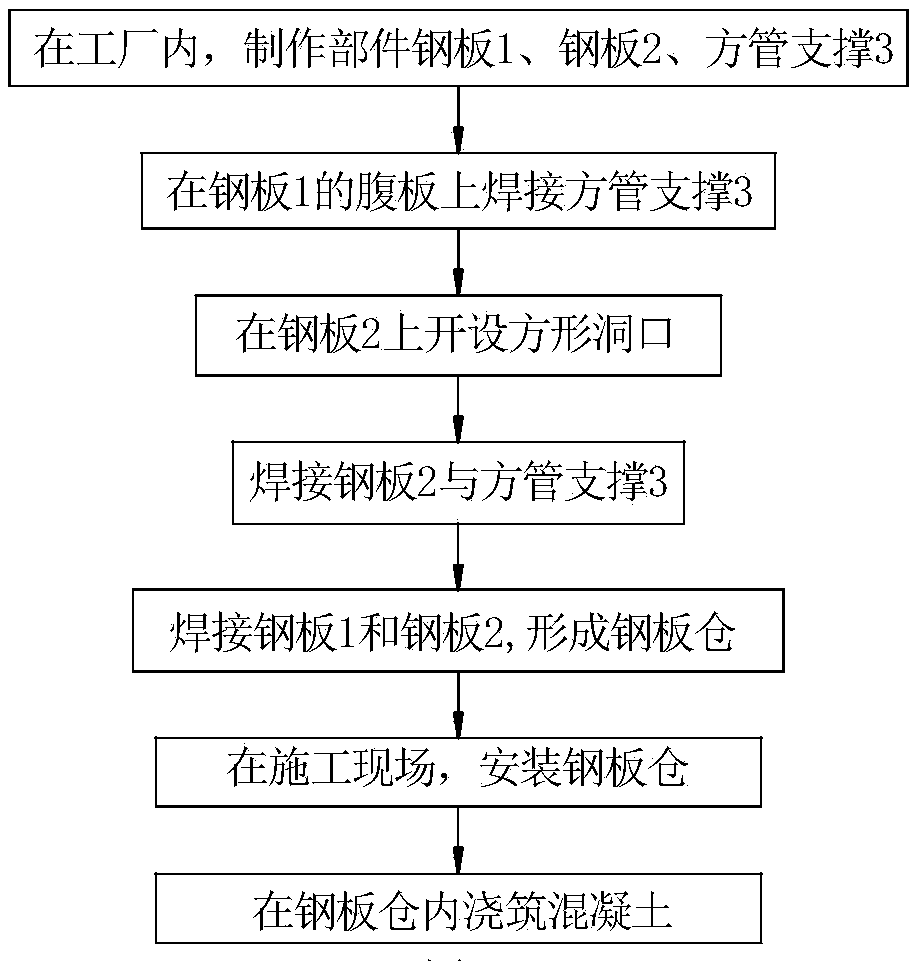

[0022] The manufacture of a steel silo supported by a square tube comprises the following steps:

[0023] (1) In the factory, make parts steel plate 1, steel plate 2, square tube support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com