Circular tube support steel plate silo and manufacture method

A technology for supporting steel plates and steel silos, applied in building materials and other directions, can solve the problems of out-of-plane bulging, waste of steel, and low out-of-plane stiffness, and achieve the effects of increasing out-of-plane stiffness, reducing construction costs, and ensuring compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

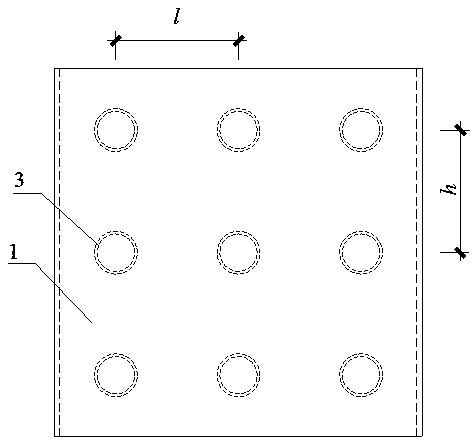

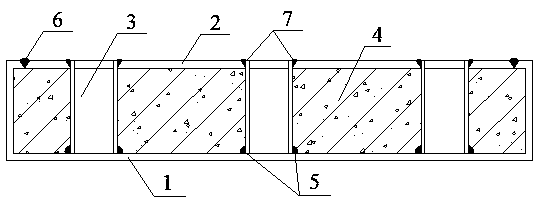

[0021] A circular tube support steel silo, consisting of a steel plate 1, a steel plate 2, and a circular tube support 3 as a basic unit, the two sides of the basic unit are respectively a steel plate 1 and a steel plate 2, wherein the cross section of the steel plate 1 is a curling groove shape, two pieces The thickness t of the steel plate is 2 mm to 3 mm, and the circular tube support 3 is connected to the steel plate 1 through the weld 5. The diameter of the circular tube support 3 is 30 mm to 50 mm, and the thickness is 3 mm. The horizontal and vertical distances between the adjacent circular tube supports 3 are equal. (200-300) t, a circular hole is left at the position corresponding to the steel plate 2 and the circular tube support 3; The steel plates 2 are connected by welds 7; concrete 4 is poured in the empty warehouse formed by the steel plates 1 and 2.

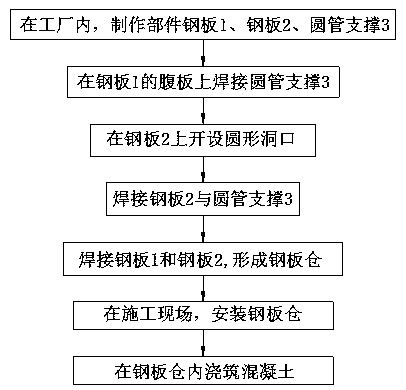

[0022] The manufacture of a steel silo supported by a circular tube includes the following steps:

[0023] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com