Assembled joint applicable to monolayer triangular space grid structure

A technology of grid structure and space grid, which is applied in the direction of building structure and construction, can solve the problems that the single-layer space grid structure cannot be applied, the welding quality cannot be guaranteed, and the construction speed is slow, so that the construction quality is easy to control, Fast construction speed and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

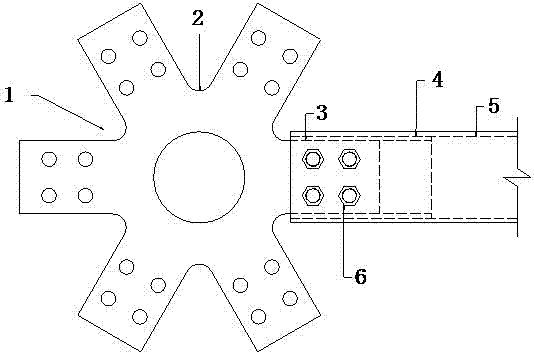

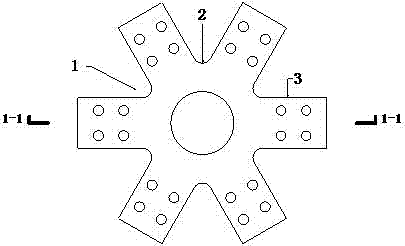

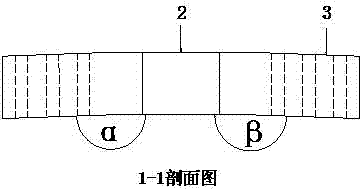

[0036] Figure 1 to Figure 6 It is a schematic diagram of nodes in Embodiment 1 of the present invention, and the nodes of the present invention include:

[0037] Central node 1, connecting arm 3, sleeve 4, rod 5, high-strength bolt 6. The central node 1 is connected by the central ring 2 and several connecting arms 3 at a certain angle, and there are four bolt holes on the connecting arms 3; the number of connecting arms 3 is determined by the specific spatial structure; the sleeve 4 is processed by steel pipe cutting, The sleeve 4 also has four bolt holes for connection; the sleeve 4 is sleeved on the connecting arm 3, and the length of the sleeve 4 is greater than the length of the connecting arm 3; the rod 5 is a square steel pipe or a rectangular steel pipe, and the sleeve 4 On the sleeve 4; after the node assembly of the present invention is completed, the length of the sleeve 4 extending into the rod 5 will be greater than the length of the connecting arm of the centra...

Embodiment 2

[0046] Such as Figure 9 to Figure 11It is a schematic diagram of Embodiment 2 of the present invention. When the structural span is large and the section of the rod 5 is increased, the length of the high-strength bolt 6 will be lengthened, and the size of the central node 1 will also be increased a lot, which will inevitably cause unnecessary waste. In order to adapt to the connection of large-section rods, the second embodiment is improved as follows: in the first embodiment, the high-strength bolt 6 is long, and in the second embodiment, the high-strength bolt 6 is divided into two upper and lower bolts, such as Figure 9 As shown, the upper bolt fixes the upper flange of the rod 5 and the sleeve 4 and the upper part of the connecting arm 3, and the lower bolt fixes the lower flange of the rod 5 and the sleeve 4 and the lower part of the connecting arm 3; in the embodiment In one, the connecting arm 3 is solid, in the second embodiment, as Figure 10 As shown, the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com