Precast modular buckling-restrained brace bolting and welding mixed connection joint

A technology of buckling constraint and mixed connection, which is applied in the directions of building components, earthquake resistance, building types, etc., can solve the problems of increasing the out-of-plane stiffness of nodes, achieve the effects of short connection length of nodes, reduced welding difficulty, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

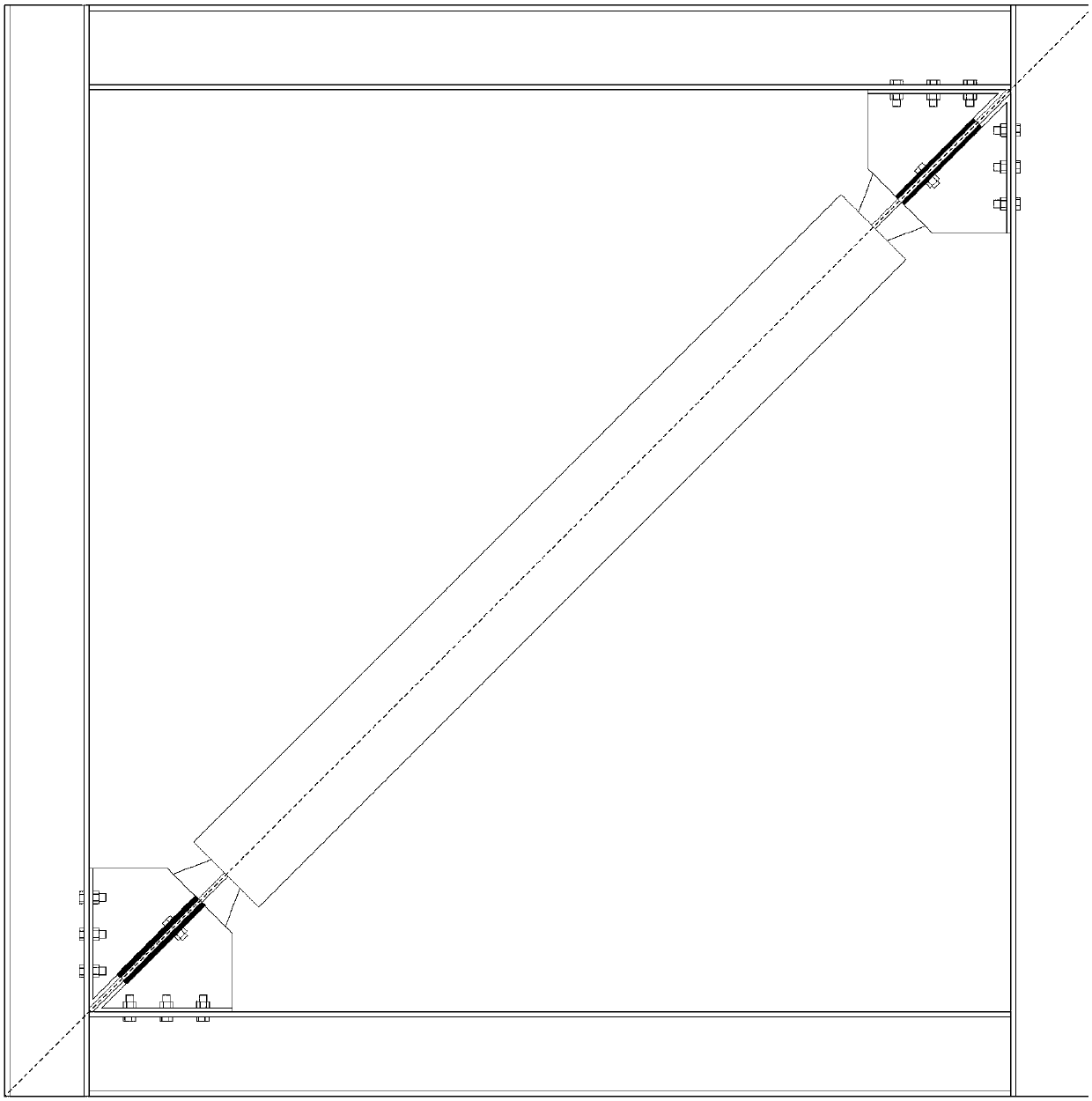

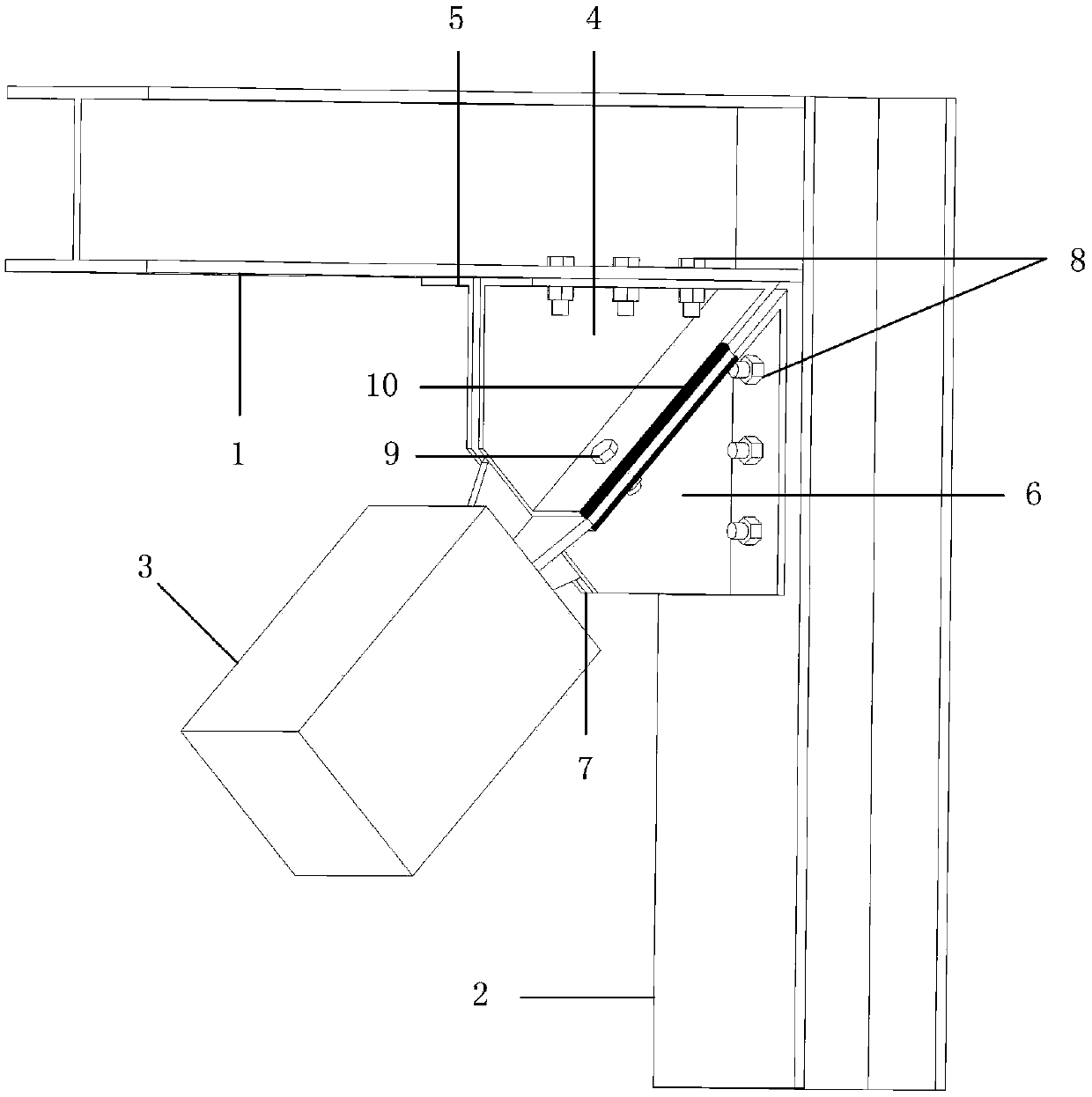

[0039] combine figure 2 Note that the prefabricated modular buckling-constrained brace bolt-welded hybrid connection node in this embodiment includes prefabricated steel node modules, buckling-constrained braces 3 , connecting high-strength bolts 8 , fixed high-strength bolts 9 and connecting welds 10 .

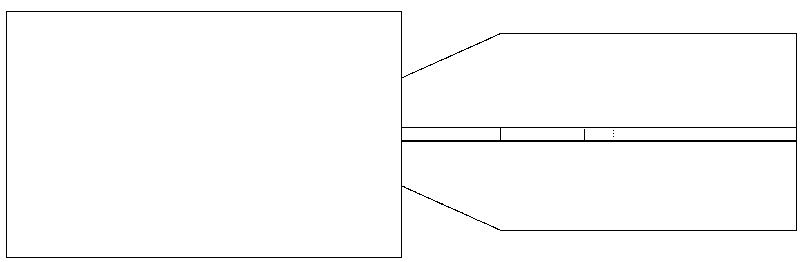

[0040] combine Figure 3 ~ Figure 6 It shows that the cross-shaped plate of the connecting section of the buckling-constrained support 3 is welded by steel plates, and a bolt hole is symmetrically arranged on two of the steel plates.

[0041] combine figure 2 and Figure 7 ~ Figure 10 Explain that the first prefabricated steel node module 4, the second prefabricated steel node module 5, the third prefabricated steel node module 6 and the fourth prefabricated steel node module 7 all include connecting steel plates 11, clamping steel plates 12 and clamping and fixing steel plates 13; A number of bolt holes are longitudinally arranged on the connecting steel plate 11, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com