A double-gusset clamping type anti-buckling bracing bolted-welded hybrid joint

A technology of anti-buckling bracing and double-node plate, which is applied in the direction of earthquake resistance, building components, building structures, etc., can solve the problems of large steel consumption, long node connection length, difficult construction and installation positioning, etc., to achieve less steel consumption, Advantageous effect of short joint length, out-of-plane stability and seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

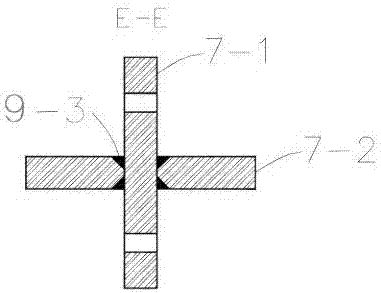

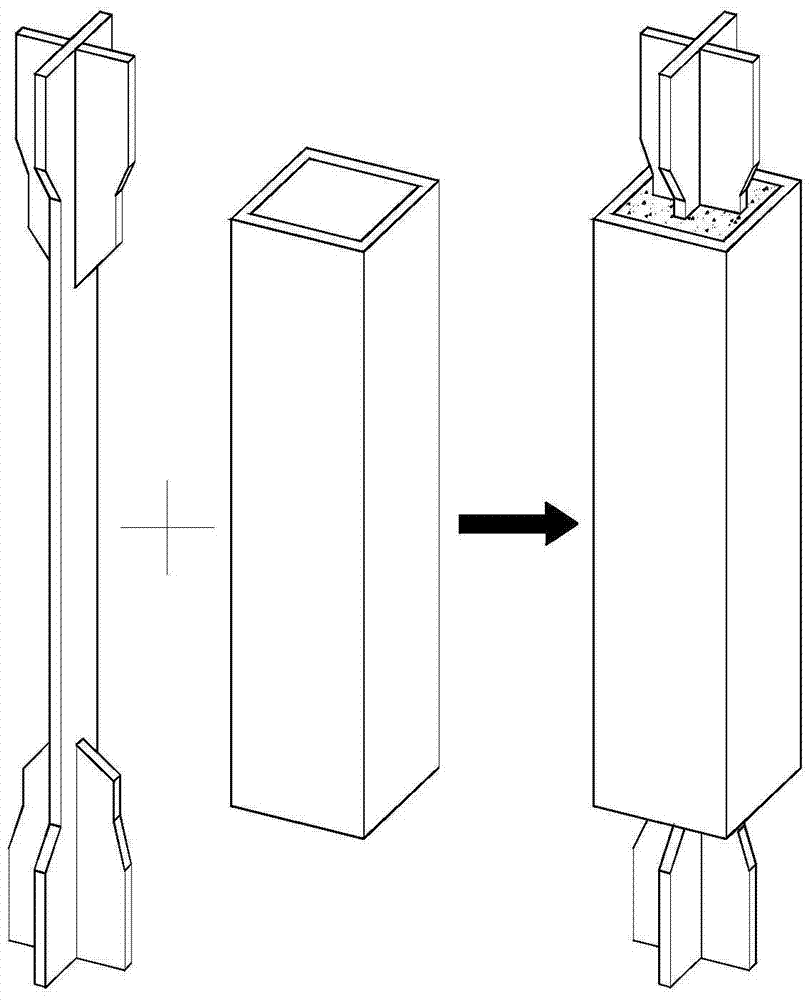

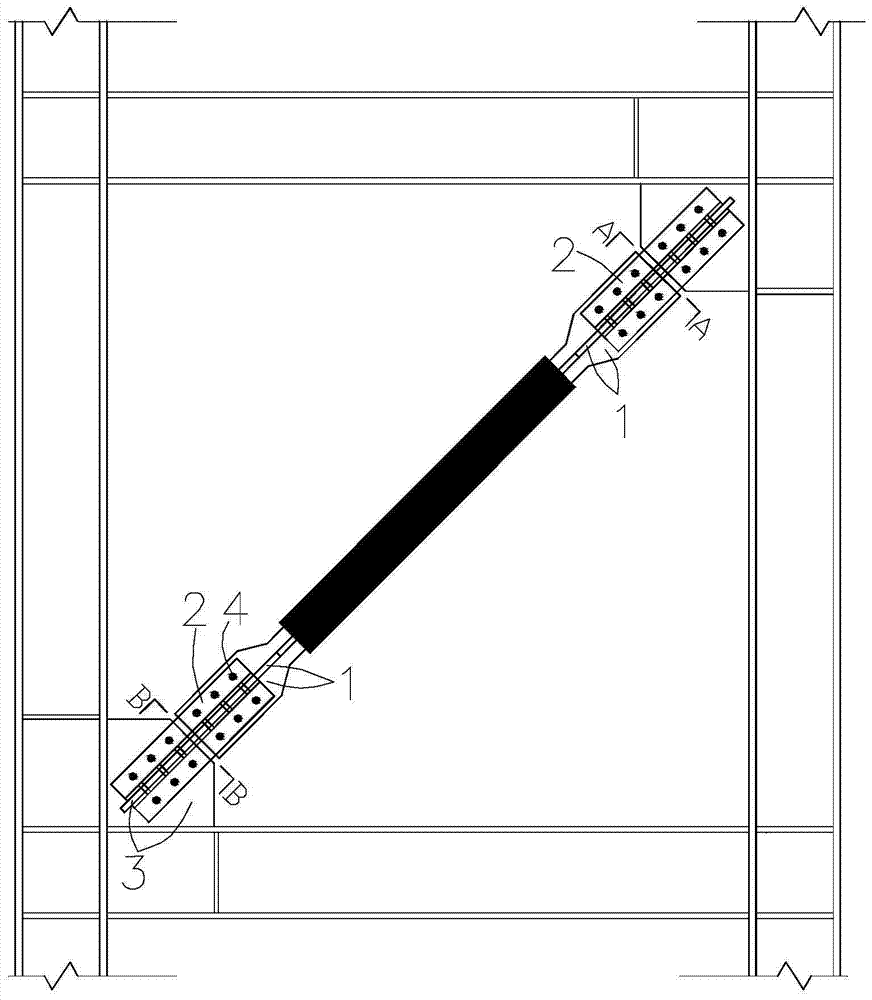

[0018] Specific implementation mode 1: Combination Figure 8~Figure 13 Explain that the double gusset plate clamping type anti-buckling support bolt-welded hybrid connection node of this embodiment includes a back gusset plate 6-1 and a front gusset plate 6-2, with a gap between them and arranged in parallel , And the flange surfaces of the beam and the column are perpendicular to each other and connected by welding seams; the connecting nodes also include anti-buckling support nodes 7, friction type high-strength bolts 4, and connecting welds 9-1 to 9-3.

[0019] The core plate 7-1 of the supporting node is inserted into the gap between the double gusset plates 6-1 and 6-2, and the two stiffening ribs 7-2 are inserted into the back gusset plate 6-1 and the front gusset plate 6-2 respectively. In the channel, and align the bolt holes of the dual gusset plate 6 and the core plate 7-1 in unison, friction type high-strength bolts 4 are passed between the back gusset plate 6-1 and the...

specific Embodiment approach 2

[0020] Specific implementation manner two: combination Figure 8~Figure 10 Note that the dual gusset plate in this embodiment includes a back gusset plate 6-1 and a front gusset plate 6-2, with a gap between them and arranged in parallel; the back gusset plate 6-1 and the front gusset plate 6-2 The geometric dimensions are the same, including two vertical sides, two horizontal sides and one hypotenuse. The specific dimensions need to be determined comprehensively according to the bearing capacity of the connection weld between the gusset plate and the beam-column, the horizontal angle of the support, and the width of the support node , The back gusset plate 6-1 and the front gusset plate 6-2 are provided with a rectangular channel in the perpendicular direction of the hypotenuse, the width of which is 1-2mm larger than the width of the support stiffener 7-2, and its length is consistent with the support stiffening The length of the parallel section of the rib 7-2 is the same, th...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination Figure 11~Figure 13 It is explained that the anti-buckling support node 7 of this embodiment includes a core plate 7-1 and two stiffening ribs 7-2. The stiffening ribs 7-2 are symmetrically arranged on both sides of the center line of the core plate 7-1 and are connected to the core plate 7-1. 7-1 is vertical, the plane where the short side of the stiffener 7-2 is located has a 45-degree bilateral groove along the length direction, and the stiffener 7-2 is connected to the core plate 7-1 through a fillet weld 9-3 at the groove position For connection, the core plates 7-1 on both sides of the stiffening rib 7-2 are provided with bolt holes along the length direction, and the positions of the holes are symmetrically arranged with respect to the stiffening rib 7-2. Such a setting is easy to install and locate, convenient to weld and connect on site, and the connection is reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com